Iso 16232

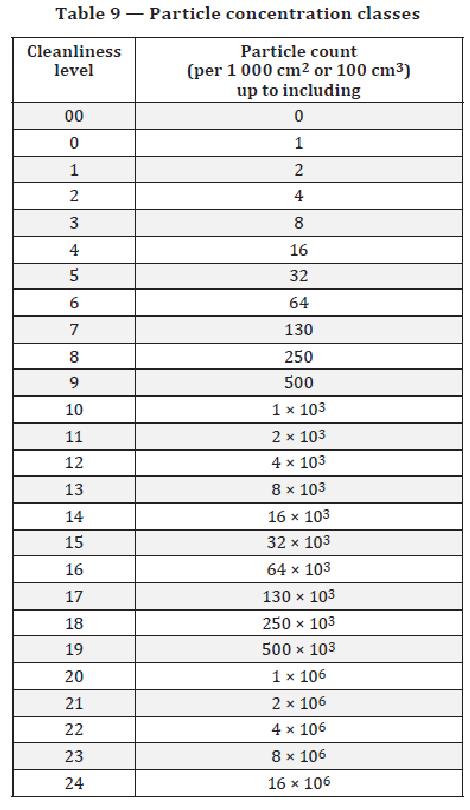

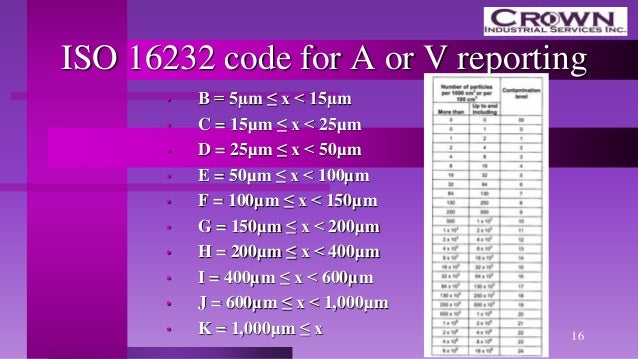

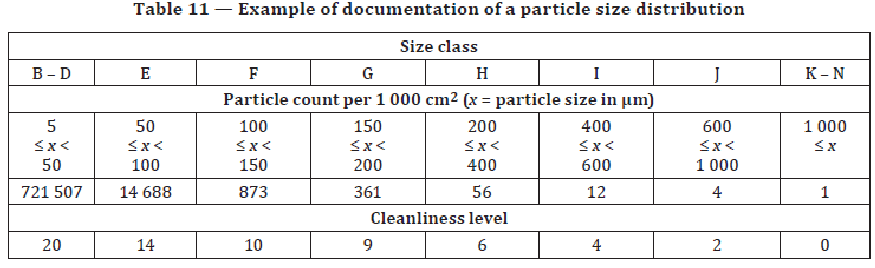

This is the coding from the 07 version of ISO – Size classes ended with K being 1000µm and greater (no L, M, or N) – Contamination Level or Cleanliness Level coding was the same as.

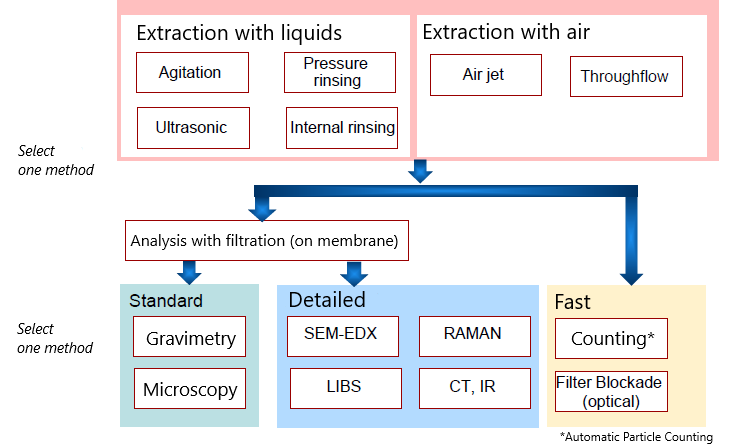

Iso 16232. Check out our FAQs Customer care 41 22 749 08 customerservice@isoorg Opening hours Monday to Friday , (UTC1) Keep up to date with ISO Sign up to our newsletter for the latest news, views and product information. ISO describes the principles of extraction of contaminants from a component by pressure rinsing It is preferably applied to components of which the surface to be examined is accessible by a jet of test liquid This method can be employed on its own or in association with other methods of extraction described in the ISO series. ISO defines the vocabulary used in the characterization and measurement of particulate contamination of parts, components, subassemblies and assemblies constituting the fluid circuits of internal combustion engines of road vehicles.

And in the international ISO "Road vehicles Cleanliness of components of fluid circuits" In our lab, we follow the directives laid down in VDA Vol 19 and the international ISO , and document the technical cleanliness of your components. The purpose of ISO is to determine the mass of particulate contamination by gravimetric analysis Contaminants are separated from the extraction liquid by filtration It applies to automotive components in contact with a fluid Unless otherwise specified, ISO deals with particulate cleanliness only. This is the coding from the 07 version of ISO – Size classes ended with K being 1000µm and greater (no L, M, or N) – Contamination Level or Cleanliness Level coding was the same as current revision.

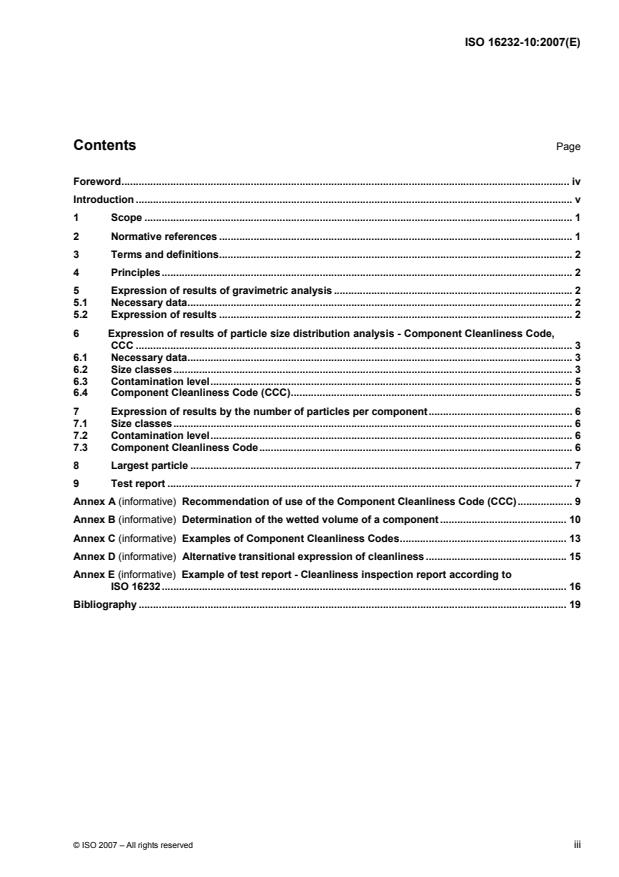

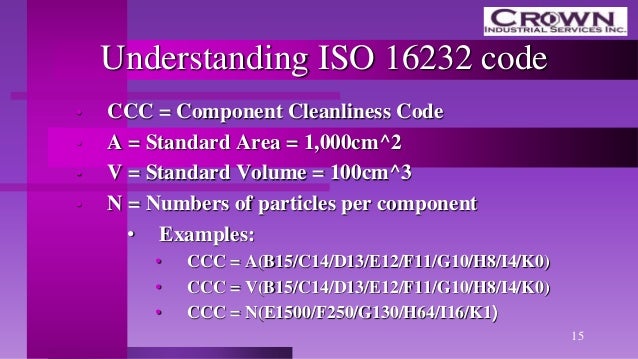

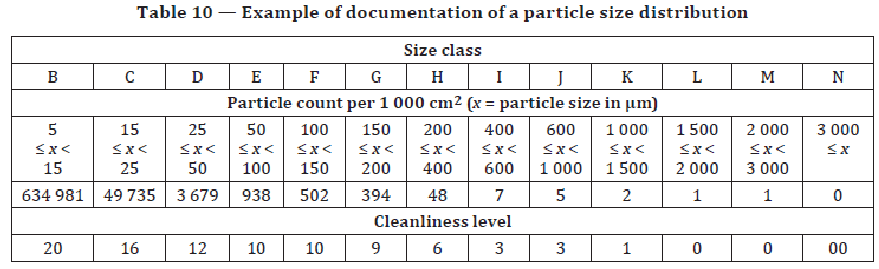

This part of ISO defines rules for expressing these cleanliness levels when measured by the methods defined in ISO , ISO , ISO and ISO Users of the ISO series introducing this coding system are encouraged to inform the ISO/TC 22/SC 5. Iso 07(r10) road vehicles cleanliness of components of fluid circuits part 6 particle mass determination by gravimetric analysis iso 07(r10) road vehicles cleanliness of components of fluid circuits part 9 particle sizing and counting by automatic light extinction particle counter iso 07(r10). ISO Cleanliness Operational procedures inline with ISO and VDA19 to establish a Component Cleanliness Code (CCC) for the item being assessed and can be reported per surface area (A), volume (V) or component (n).

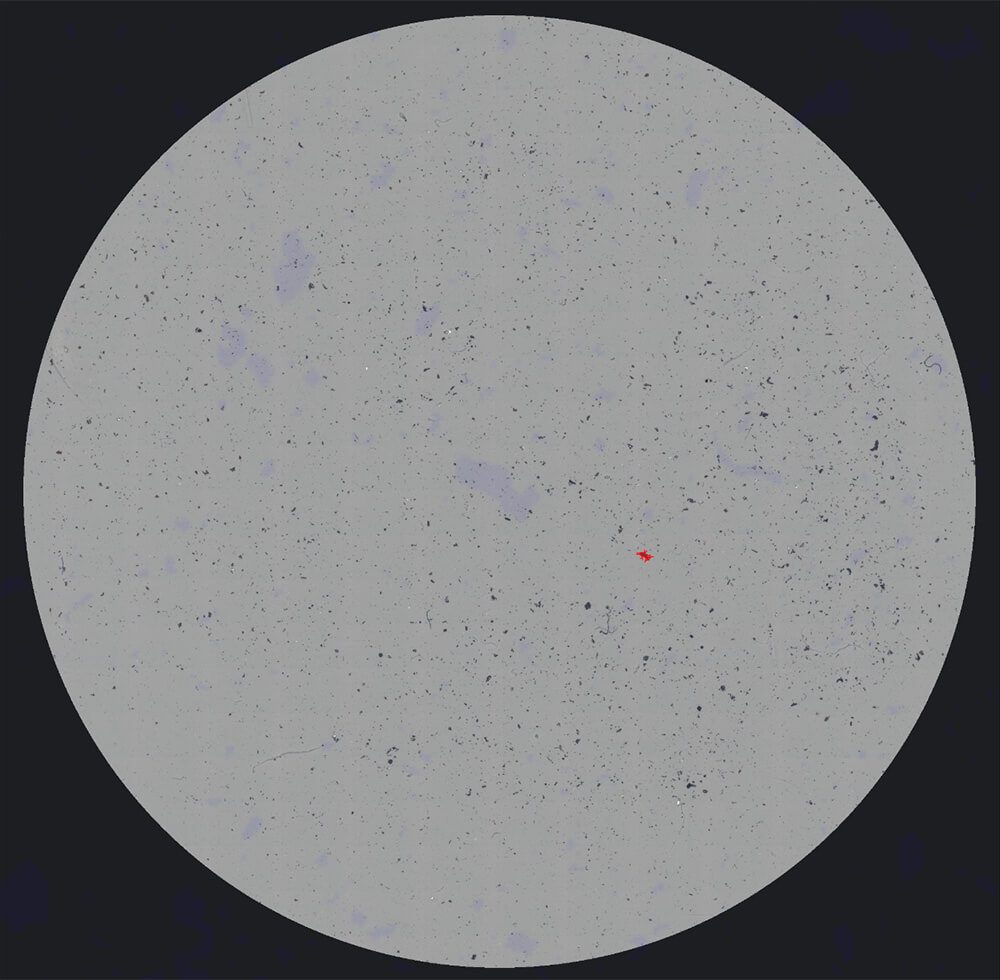

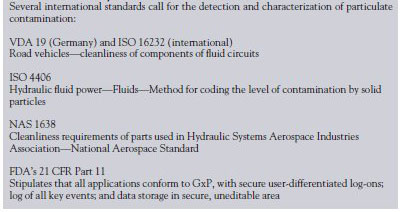

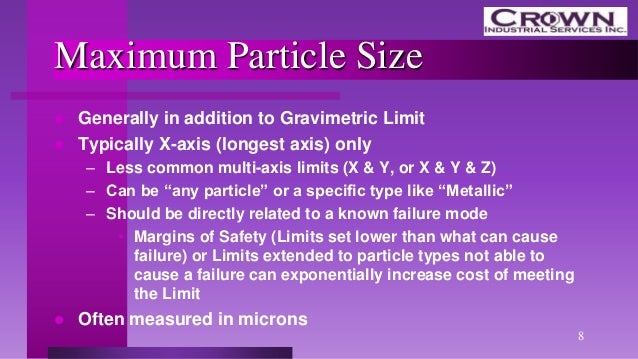

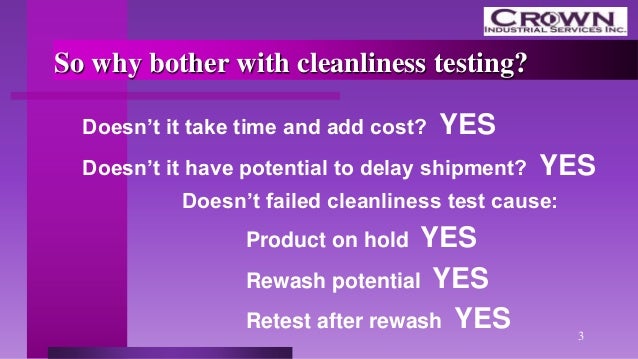

Measurement of particles down to 5 µm size Conformity to ISO and VDA 19 Length, breadth and height measurements of particles to evaluate overall risk potential Reproducible illumination settings for comparable measurements No user interaction Automatic differentiation between reflective (metallic) and nonreflective (plastic) particles. Contamination removal and analysis is carried out in accordance with International Standards ISO / VDA 19 These standards specify the methods to be used for evaluating (extracting, analysing and expressing results) the cleanliness of component parts. Crown Industrial Services, Inc is a stalwart in automotive cleanliness spec technology ISO driven and compliant Our lab has tested products, parts and fluids to over 300 cleanliness specifications, spanning 6 different industries, for customers who traverse the globe.

Buy iso 07(r10) road vehicles cleanliness of components of fluid circuits part 7 particle sizing and counting by microscopic analysis from sai global. Complete Iso Pdf Download online with US Legal Forms Easily fill out PDF blank, edit, and sign them Save or instantly send your ready documents. ISO , “Road Vehicles – Cleanliness of Components of Fluid Circuits,” is the international counterpart to VDA Vol 191 The directive on VDA Vol 191 contains the application and documentation conditions for determining the particle contamination of functionally relevant components in the automobile industry.

The requirements of Technical cleanliness and Cleanliness of environment are specified in the Standards ISO , ISO 13 485, ISO , in Standards VDA 191 and VDA 192, and possibly in branch specifications (automotive industry – VW , QV 11 111, STD ). ISO_18 Free ebook download as PDF File (pdf), Text File (txt) or read book online for free ISO_18. ISO – Particle sizing and counting by automatic light extinction particle counter;.

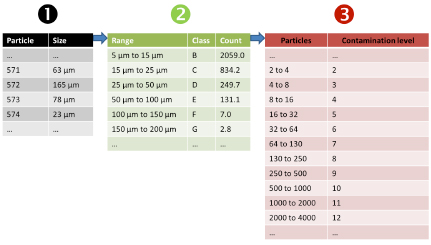

This part of ISO defines methods for determining the size and number of contaminant particles, which have been extracted from components and deposited on the surface of a membrane filter, as determined by using either a light optical microscope (LM) or a scanning electron microscope (SEM) The result of this measurement is the particle. This part of ISO defines rules for expressing these cleanliness levels when measured by the methods defined in ISO , ISO , ISO and ISO Users of the ISO series introducing this coding system are encouraged to inform the ISO/TC 22/SC 5. All freight traffic must contact go@iinspectioncom for dock appointment.

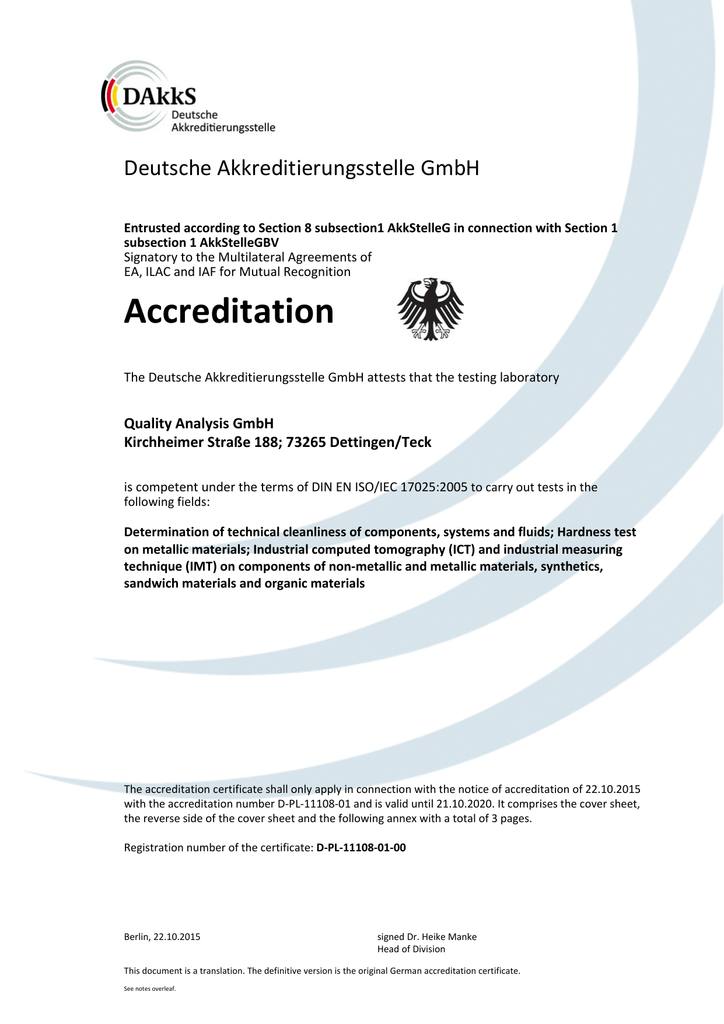

During our forum, specialists from the manufacturing industry, process engineers, department managers and production directors will meet with suppliers of machines, services and technologies to ensure technical cleanliness in accordance with the requirements of VDA 19 and ISO in the production and assembly process. Complete Iso Pdf Download online with US Legal Forms Easily fill out PDF blank, edit, and sign them Save or instantly send your ready documents. We are an accredited laboratory for testing technical cleanliness of components according to ISO and VDA 191 Besides the accredited norms, we naturally also analyse your components according to requirements of other norms or factory regulations (for instance BMW, Bosch, Continental, Daimler, TRW, VW, and ZF).

ISO describes the principles of extraction of contaminants by test on a laboratory functional test bench with the test liquid flowing under pressure or under vacuum It is applicable to both active and passive components through which the fluid can easily flow. Iso 07(r10) road vehicles cleanliness of components of fluid circuits part 7 particle sizing and counting by microscopic analysis iso 15 hydraulic fluid power cleanliness of components inspection document and principles related to contaminant extraction and analysis, and data reporting. The ISO series has been drafted to fulfil the requirements of the automotive industry, since the function and performance of modern automotive fluid components and systems are sensitive to the presence of a single or a few critically sized particles Consequently, ISO requires the analysis of the total volume of extraction liquid.

ISO_18 Free ebook download as PDF File (pdf), Text File (txt) or read book online for free ISO_18. ISO Cleanliness Operational procedures inline with ISO and VDA19 to establish a Component Cleanliness Code (CCC) for the item being assessed and can be reported per surface area (A), volume (V) or component (n) The facility has a range of extraction techniques at its disposal to suit individual requirements from flushing. Iso 07(r10) International Equivalents – Equivalent Standard(s) & Relationship (Show below) (Hide below) Equivalent Standard(s).

Complete Iso Pdf Download online with US Legal Forms Easily fill out PDF blank, edit, and sign them Save or instantly send your ready documents. BS ISO is based on existing International Standards such as those developed by ISO/TC 131/SC6 They have been extended, modified and new ones have been developed to produce a comprehensive suite of International Standards to measure and report the cleanliness levels of components and systems fitted to road vehicles. ISO ISO / VDA19 ( SOFTWARE RELEASE) IESTSTDCC1246 (21 SOFTWARE RELEASE) Samples Mesh filters Membrane filters Paper filters Wafers Tape lifts KEY FEATURES STREAMLINED WORKFLOW From inserting a sample to exporting results, we have reduced the number of steps needed for a user Increase your lab’s sample handling.

BS ISO ,Road vehicles – Cleanliness of components and systemsBS ISO pdf free download In order to achieve reliable performance of components and systems, control over the amount of particles introduced during the build phase is necessary, and measurement of particulate contaminants is the basis of control. ISO – Particle sizing and counting by automatic light extinction particle counter;. ISO – Expression of results (CCC coding) Surface Residues Isolation The first step to any cleanliness assessment is to isolate the surface residues from the particular component (or area of the component).

This is the coding from the 07 version of ISO – Size classes ended with K being 1000µm and greater (no L, M, or N) – Contamination Level or Cleanliness Level coding was the same as. Iso June 07 Road vehicles Cleanliness of components of fluid circuits Part 9 Particle sizing and counting by automatic light extinction particle counter. ISO – Expression of results (CCC coding) Surface Residues Isolation The first step to any cleanliness assessment is to isolate the surface residues from the particular component (or area of the component).

ISO –Extraction method by pressure rinse (example) Main parameters impacting the effectiveness of the pressure rinse method Pressure Distance Geometry of the nozzle Flow rate Volume of solvent Solvent properties Often particles adhere to a surface helped by moisture, grease, oil, etc Particle. ISO describes the principles of extraction of contaminants from a component either by immersion in an ultrasonic bath or by applying ultrasonic vibrations directly via sonotrodes. Most recent ISO Road vehicles Cleanliness of components and systems This document specifies requirements for applying and documenting methods for determining particulate contamination on functionallyrelevant components and systems (cleanliness inspection) of road vehicles.

The first thing to understand is that the ISO specification is a guideline for performing and validating cleanliness test procedures The 10 volumes total about 100 pages of reading Each section discusses a specific area. ISO Part 5 Method of extraction of contaminants on functional test bench ISO Part 6 Particle mass determination by gravimetric analysis ISO Part 7 Particle sizing and counting by microscopic analysis. ISO Cleanliness Operational procedures inline with ISO and VDA19 to establish a Component Cleanliness Code (CCC) for the item being assessed and can be reported per surface area (A), volume (V) or component (n) The facility has a range of extraction techniques at its disposal to suit individual requirements from flushing.

ISO (E) Foreword ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO member bodies) The work of preparing International Standards is normally carried out through ISO technical committees Each member body interested in a subject for which a technical. BS ISO The extraction conditions should be agreed upon between parties and included in the inspection document A synopsis of the operations to perform is given in Annex A The detailed description of operating conditions and equipment used in application of this standard to rinse and empty the component constitutes the iao procedure. ISO ISO ;.

Please feel free to contact us when you need help understanding ISO and/or VDA 19 In an effort to reach out further with needful education we have started a series of articles to help increase understanding regarding ISO and VDA 19 We have five articles in the series completed currently. The most common ISO cleanliness codes display Standard Area based spec Limits designated by the “A” in front of the parentheses “CE” means that size classes C (15µm25µm), D (25µm50µm), and E (50µm100µm) are combined so that particles from 15µm100µm essentially make up a size class named “CE”. Now ISO Got a question?.

The purpose of ISO is to determine the mass of particulate contamination by gravimetric analysis Contaminants are separated from the extraction liquid by filtration It applies to automotive components in contact with a fluid Unless otherwise specified, ISO deals with particulate cleanliness only. Consultation and conducting cleanliness audits according to ISO and VDA 191 Cleanliness and residual dirt analyses in an accredited testing laboratory according to ISO IEC VDA License Training TopQMSystems is a licensed training provider of VDA QMC. ISO , 1st Edition, June 1, 07 Road vehicles Cleanliness of components of fluid circuits Part 5 Method of extraction of contaminants on functional test bench This part of ISO describes the principles of extraction of contaminants by test on a laboratory functional test bench with the test liquid flowing under pressure or under vacuum.

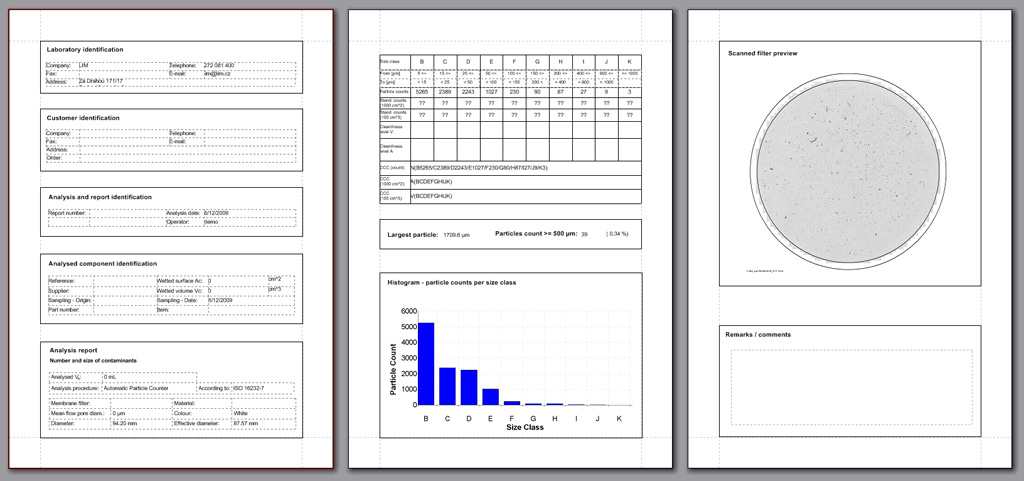

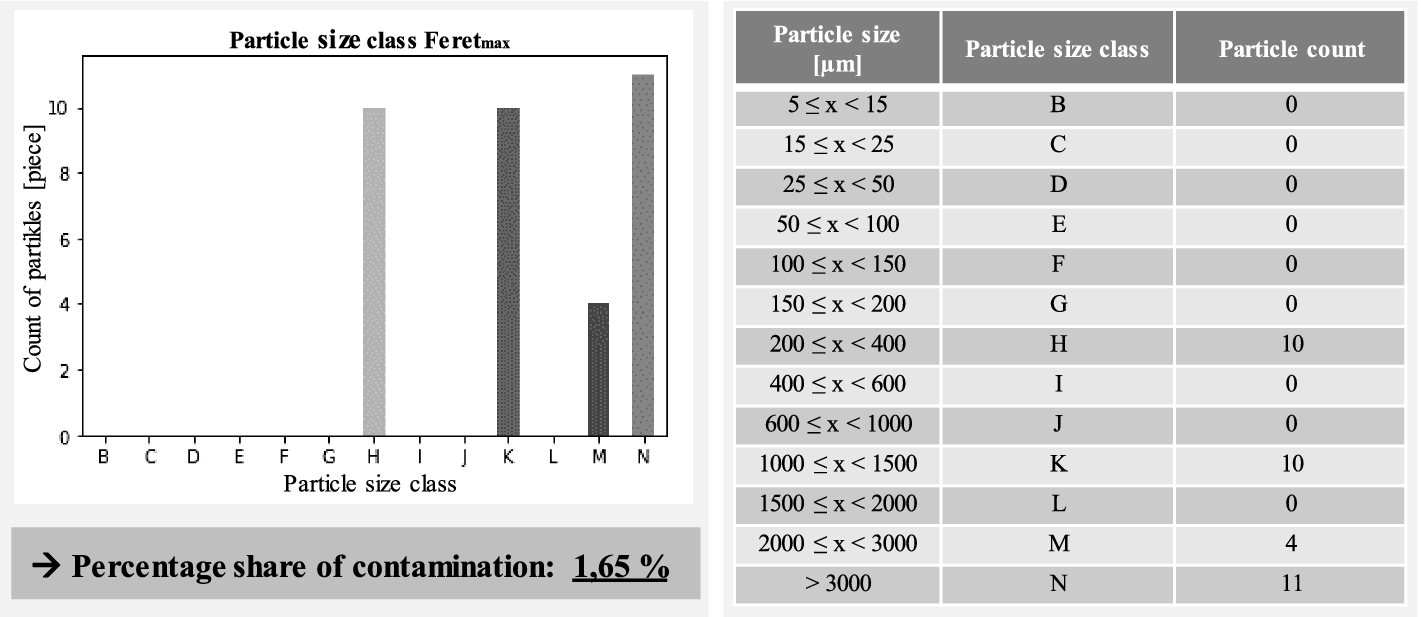

ISO "Road vehicles Cleanliness of components and systems" is the latest version and thus now the international equivalent of VDA191 Both guidelines were developed in cooperation with numerous companies within and around the automotive industry. ISO and VDA 19 define the standards to ensure quality and reliability of the components for automotive sector and its suppliers In this example, one membrane filter sample was submitted for particulate contamination determination and identification according to ISO. We are proud to exhibit the ISO certification at each of our inhouse labs With our cleaning equipment and certified labs, we are able to support our customer cleaning specifications at PPAP submissions, production shipments and annual certification throughout the life of the program Get in Touch.

This part of ISO defines methods for determining the size and number of contaminant particles, which have been extracted from components and deposited on the surface of a membrane filter, as determined by using either a light optical microscope (LM) or a scanning electron microscope (SEM) The result of this measurement is the particle. Complete Iso Pdf Download online with US Legal Forms Easily fill out PDF blank, edit, and sign them Save or instantly send your ready documents. Contamination removal and analysis is carried out in accordance with International Standards ISO / VDA 19 These standards specify the methods to be used for evaluating (extracting, analysing and expressing results) the cleanliness of component parts.

And in the international ISO "Road vehicles Cleanliness of components of fluid circuits" In our lab, we follow the directives laid down in VDA Vol 19 and the international ISO , and document the technical cleanliness of your components. ISO , VDA 19, internal company standards or customer specifications can be carried out in the airconditioned vehicle, on samples taken directly onsite HYDAC's own laboratories offer an analysis service to determine the technical cleanliness of components Experienced laboratory staff guarantee expert analysis of component cleanliness based. ISO ISO defines the rules and the forms of expression and presentation of the results of measurements of particulate cleanliness of components for the fluid circuits of motor vehicles It also defines a cleanliness coding system for simplifying the reporting and communication of particulate contamination data ISO also defines the rules to be used.

During our forum, specialists from the manufacturing industry, process engineers, department managers and production directors will meet with suppliers of machines, services and technologies to ensure technical cleanliness in accordance with the requirements of VDA 19 and ISO in the production and assembly process. Thispart of ISO defines the rules and the forms of expression and presentation of the results of measurements of particulate cleanliness of components for the fluid circuits of motor vehicles It also defines a cleanliness coding system for simplifying the reporting and communication of particulate contamination data.

Instituto Nacional De Normalizacion Iso 18

Http Instrumat Ch Wp Content Uploads 16 08 Microvision Filtrex Particle Counting Lrll Pdf

Extraction Method According To Iso 5 Cleancontrolling Youtube

Iso 16232 のギャラリー

Iso 10 07 Road Vehicles Cleanliness Of Components Of Fluid Circuits

Iso Vda 19

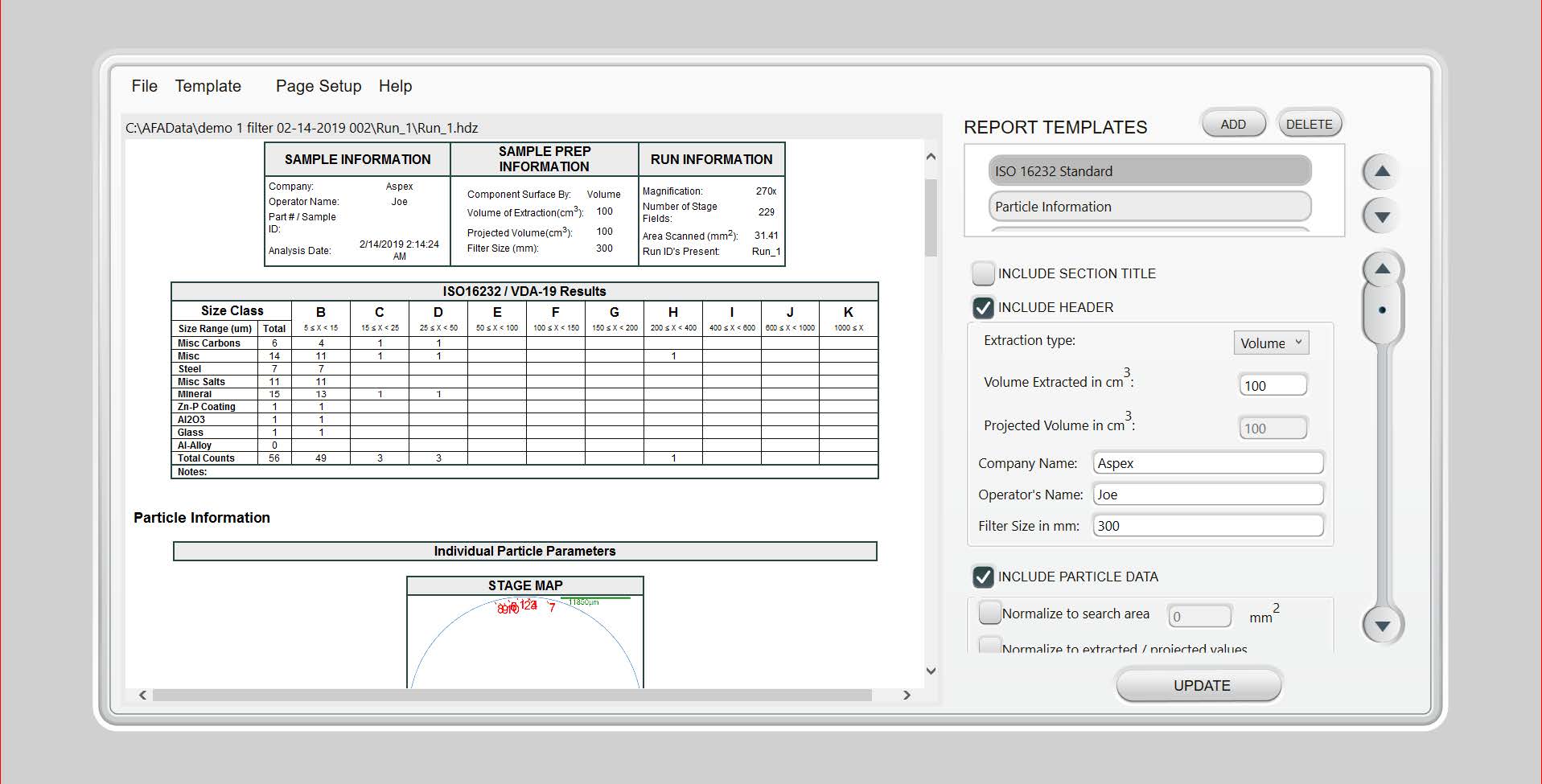

Cleanliness Analysis As Per Iso Clemex

Fillable Online Iso 4 Free Search Pdf Doc Live Fax Email Print Pdffiller

Breaking Down The Technical Cleanliness Workflow Part 4 Contamination Level Calculation Blog Post Olympus Ims

2

Info Tc Cleanliness Audits Excellence Cleanliness Audits Excellence

Vda 19 Iso Sem Edx Partikelanalyse Rjl Micro Analytic

Bs Iso 7下载 在线阅读 爱问共享资料

Fluid Contamination Systems Aone

Asset Downloads Zeiss Com Catalogs Download Mic E8b43e4f Cc05 4e0f 9061 Cf9bcdba6f En Product Info Correlative Particle Analysis Rel 1 1 Pdf

Www Atecorp Com Atecorp Media Pdfs Data Sheets Olympus Cix100 Cleanliness Inspection System Pdf Ext Pdf

Iso 18 Road Vehicles Cleanliness Of Components And Systems

Jack Griffes Cleanliness Testing To Iso And Oem Specification

Nis Elements Cz Laboratory Imaging

Component Cleanliness Code Or Ccc Of Iso Vda 10

/Chemistry/ReporterScreenShot.jpg?n=8592)

Automotive Parts Cleanliness The Cleanchk Analyzer Monitors Automotive Part Cleanliness Right On The Production Floor Thermo Fisher Scientific

Cleanliness Test On Motor Vehicle According To Iso Ilac Full Members Standard In The Laboratory Analytice

Training Iso Vda 19 1 Enge Solutions

Http Www Partscleaningevent Com Uploads 1 1 9 3 Krause Pdf

St Iso 2 07 In English Download Pdf Gostperevod Com

International Iso This Is A Preview Of Iso 18 Pdf Free Download

Bs Iso 10 07 Road Vehicles Cleanliness Of Components Of Fluid Circuits Word文档免费下载 文档大全

Iso Dis 6en Filtration International Organization For Standardization

Rtilab Com Wp Content Uploads 17 08 Understanding Your Cleanliness Report Blog Post Pdf

Iso 1 07 En Road Vehicles Cleanliness Of Components Of Fluid Circuits Part 1 Vocabulary

Advanced Ptfe Coating Process In Gmors

Iso中文版下载 Iso 标准中文版pdf下载免费电子版 绿色资源网

Automotive Component Cleanliness Industrial Manufacturing Pall Corporation

Bs Iso 18

Iso 18 Enge Solutionsenge Solutions

Bs Iso 10 Bs Iso 10 Standards Pdf 60 Off Discount

Optic Measurement Cleanliness Detection Device Is Built To Find Your Products Iso Standards Powerful Measurements With Our High Performance Tresholding Algortihm Even Smallest Particles Are De Opticmeasure

Iso 18 Buy Officially Gost Stb Tch Tr Cu Price Internet Shop Standards For Sale Existing Technical Regulations And Information Publications

Iso Vda 19

Professional Filter Cleanliness Tester Vda Vol 19 Iso 4406 Iso 4407 Iso

Jack Griffes Cleanliness Testing To Iso And Oem Specification

Confidence Up Close American Laboratory

Iso 10 07 Road Vehicles Cleanliness Of Components Of Fluid Circuits

Http Www Hydac Com Uploads Media Ctm E Pdf

Rti Laboratories

Sample Report Cleanliness Analysis According Iso

Iso Vda 19

Clean Components Decrease Unexpected Maintenance Work R D Maintworld

Http Www Thomas Magnete Com Fileadmin User Upload Struktur Service Downloadbereich Vorgabedokumente Fuer Qsv Cs 0135 Technical Cleanliness 01 Pdf

Vda 19 Iso Partikelextraktion Rjl Micro Analytic

Www Irjet Net Archives V6 I12 Irjet V6i1216 Pdf

Iso 6 07 Road Vehicles Cleanliness Of Components Of Fluid Circuits

Cleanliness Inspection And Analysis Of Automotive Components Automotive And Aerospace Industries 4k Digital Microscope Application Examples And Solutions Keyence America

Iso 18

Gmw Test Method To Quantify Cleanliness Of Engine And Transmission Components

.jpg)

Validating The Technical Cleanliness Of Ball Bearings

Jack Griffes Cleanliness Testing To Iso And Oem Specification

Bs Iso 18

Bs Iso 4 07 Pdf Document

Iso 6 07 Road Vehicles Cleanliness Of Components Of Fluid Circuits

Iso Cleancontrolling Technical

Iso 1 07 En Road Vehicles Cleanliness Of Components Of Fluid Circuits Part 1 Vocabulary

2

Breaking Down The Technical Cleanliness Workflow Part 4 Contamination Level Calculation Blog Post Olympus Ims

Clean Components Decrease Unexpected Maintenance Work R D Maintworld

Automotive Component Cleanliness Industrial Manufacturing Pall Corporation

Http Www Partscleaningevent Com Uploads 1 1 9 3 Rossler Pdf

Iso 8 07 道路车辆 液压管路部件清洁度 第8部分 显微分析测定颗粒性质标准

Iso 05 Enge Solutionsenge Solutions

Quality Management Audits Seminars According To Vda 19 Vda 19 1 Vda 19 2 Technical Cleanliness Assembly Cleanliness Cleanliness Analyse Residual Contamination Analyses Iso Iec Iso Vda Licensee

Www Crownindservices Com Precision Cleaning Cleanliness Testing Understanding Iso Calibration Factor Or Scale Or Pixel Resolution

Vda 19 Iso Sauberkeitsbericht Rjl Micro Analytic

Www Technical Cleanliness Support Com Technical Cleanliness Audits Iso Vda 19 1

Optical Inspection For The Characterization And Classification Of Component Surfaces In The Field Of Remanufacturing Springerlink

Cleanliness Code Or Ccc Understanding Iso

Pulikom Iso 10 Espressione Dei Risultati

Microcopic Solutions For Oil Analysis

Cleanliness Analysis As Per Iso Clemex

Iso 6 07 Buy Officially Gost Stb Tch Tr Cu Price Internet Shop Standards For Sale Existing Technical Regulations And Information Publications

Bs Iso 7 07 Amazon Co Uk Bsi Books

Jack Griffes Cleanliness Testing To Iso And Oem Specification

Cleanliness Iso Artem

Rtilab Com Wp Content Uploads 17 08 Understanding Your Cleanliness Report Blog Post Pdf

The Best Technical Cleanliness Practices For Iso Production Machining

Iso 10 How To Break Down And Use Iso 10 Approaches In Real World Examples Iot Architecture

Iso Vda 19

Http Www Sambosc Com Adm s Down Php Code Library01 Idx 5678 No 1

Phenom Xl For Technical Cleanliness Nanoscience Instruments

Dss1 Clean Partner

Sample Report Cleanliness Analysis According Iso

Jack Griffes Cleanliness Testing To Iso And Oem Specification

Cleanliness Evaluation Iso

Cleanliness Code Or Ccc Understanding Iso

Rtilab Com Wp Content Uploads 17 08 Understanding Your Cleanliness Report Blog Post Pdf

Cleanliness Analysis In Relation To Particulate Contamination Learn Share Leica Microsystems

Standard Iso 3 07 8 5 07

Jack Griffes Cleanliness Testing To Iso And Oem Specification

Accreditation

Www Sis Se Api Document Preview

Cleanliness Analysis As Per Iso Clemex

Iso 18 International Organization For Standardization Technology Engineering