Din 51818

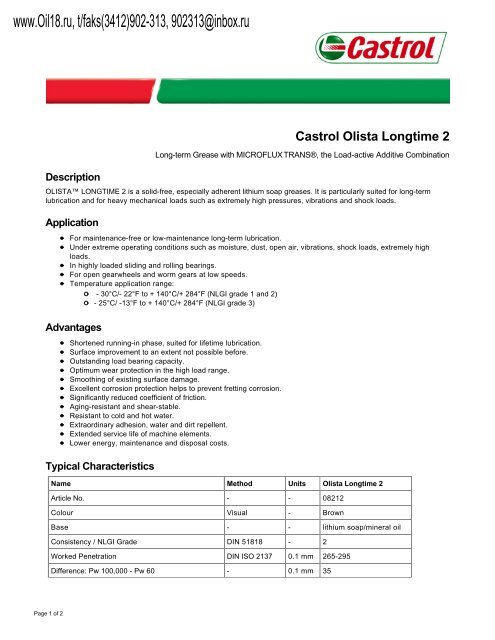

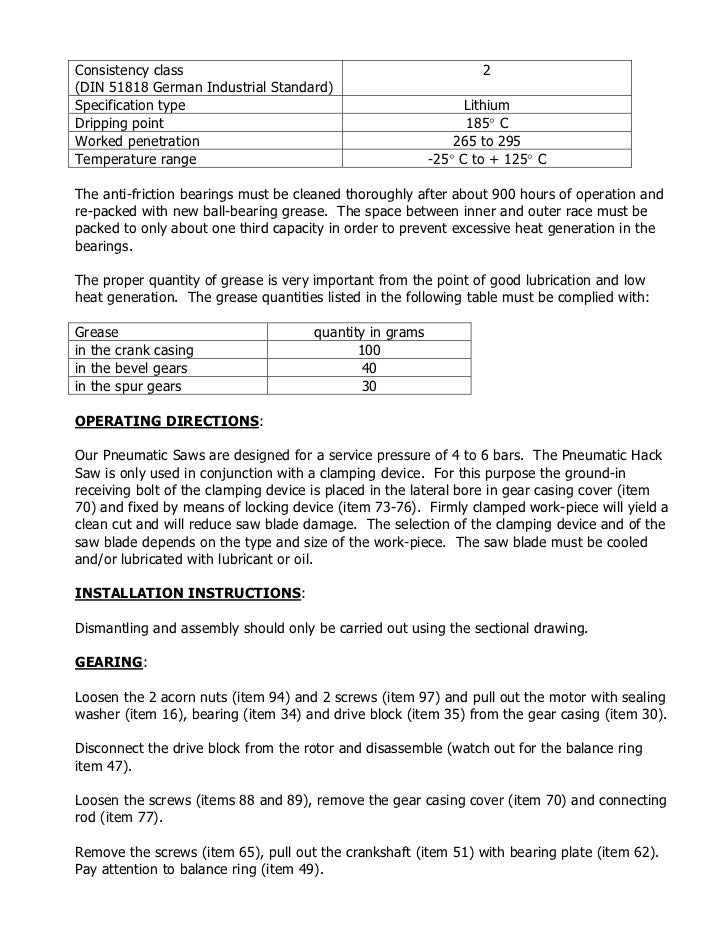

NLGI grade, DIN 2 Worked penetration, DIN ISO 2137, 25°C, lower limit value 265 x 01 mm Worked penetration, DIN ISO 2137, 25°C, upper limit value 295 x 01 mm Oil separation, based on ASTM D 6184 FTMS 791 C 321, after 30 h/0°C.

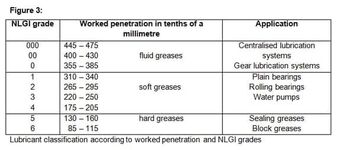

Din 51818. DIN (KP2K to DIN 515) – Good water resistance – Corrosion protection – Temperature range – to 80°C and on the runner block body at all four side lube ports 75 cm3 (3x) per port Initial lubrication for size 125 At one of the end face or side lube ports on either of the two end caps 25 cm3 (3x). NOTE Suitable greases are greases of NLGI classes 1 to 3 according to DIN 6 Suitable greases for lubrication of rolling bearings are especially greases according to ISO The test method according to this document delivers meaningful results for rolling bearings;. NLGI grade, DIN 2 Worked penetration, DIN ISO 2137, 25°C, lower limit value 265 x 01 mm Worked penetration, DIN ISO 2137, 25°C, upper limit value 295 x 01 mm Kinematic viscosity of the base oil, DIN pt 01/ASTM D445/ASTM D 7042, 40°C approx 4 mm 2 /s Kinematic viscosity, DIN pt 01/ASTM D445/ASTM D 7042, 100.

NLGI grade, DIN 2 Worked penetration, DIN ISO 2137, 25°C, lower limit value 265 x 01 mm Worked penetration, DIN ISO 2137, 25°C, upper limit value 295 x 01 mm Kinematic viscosity of the base oil, DIN pt 01/ASTM D445/ASTM D 7042, 40°C Approx 370 mm 3 /s Kinematic viscosity, DIN pt 01/ASTM D445/ASTM D 7042, 100. Color Cream color NLGI class 2 Din Temperature renge°C to 150°C Drop point > 0°C DIN ISO 2176 Olabscheidung 105% DIN. NOTE Suitable greases are greases of NLGI classes 1 to 3 according to DIN 6 Suitable greases for lubrication of rolling bearings are especially greases according to ISO The test method according to this document delivers meaningful results for rolling bearings;.

In order to help the layman understand them, we've included a chart here that compares NLGI Grades to something everyone can relate to food. DIN Lubricants;. Kin viscosity of the base oil at 100°C 48 mm²/s DIN EN ISO 3104 Worked penetration 265 – 295 mm/10 DIN ISO 2137 Consistency class (NLGI) 2 DIN Dropping point none °C DIN ISO 2176 Resistance to water 0 – 90 DIN Speed factor of grease (n x dm) 300 000 mm/min Fourball test OK load / welded load 8500 / 9000 N DIN.

DIN 51 807/1, 3 hrs at 90 °C 1 max Oil separation DIN 51 817, 7 days at 40 °C, static, % 1–6 Lubrication ability R2F, running test B at 1 °C Pass Copper corrosion DIN 51 811 2 max at 110 °C (230 °F) Shelf life 5 years * Typical value. NLGI Class (DIN ) 2 Temperature Range °C to 130 °C (4 °F to 266 °F) Basic oil viscosity at 40 °C 60 mm²/s Drop point (DIN ISO 2176) 190 °C Worked penetration (DIN ISO 2137) 280 Corrosion protection (SKF Emcor Test, DIN ) 0 VKA welding load () 2400 N. Highperformance grease NLGI grade 00 (as per DIN )water resistanceprotection against corrosionTem range from to 80 degree Celsius BoschRexroth product ID for Dynalub 5R3416 043 00 (400 g cartridge)R3416 042 00 (5 kg bucket) Alternative greases to Dynalub 5Castrol Longtime PD00Elkalub GLS 135/N00 OIL.

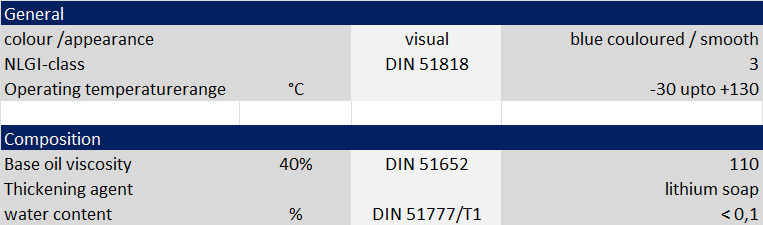

KP3K US Steel 370 y 375 2 Grasas Lubricantes de alto rendimiento Lítica especial EP 2/3 Para engrase general de maquinaria de agricultura, OP y automoción. Mobilux™ EP 0, 1, 2, 3, 004 and 023 products are a high performance family of four generalpurpose industrial greases and two specialduty semifluid greases. The depth to which a measuring cone penetrates at 25( C is measured in accordance with DIN In the USA , the NATIONAL LUBRICATING GREASE INSTITUTE (NLGI) introduced penetration grades that were adopted by DIN for the "consistency classification of lubricating greases".

NLGI grades Subscribe on standards with our subscription service When you use our service you can be assured the latest editions and easy access. Consistency classification of lubricating greases;. NLGI grade 12 DIN Dropping point 290 ° C DIN ISO 2176 Water resistance 190 rating DIN Copper strip test 1100 rating DIN EMCOR dist Water 0/0 rating DIN Four Ball Test welding load 30/3400 N DIN TIMKEN OKload 30 lbs ASTM D 2509 FAGFE 9 test A/1500/ F10= 1,F50= 152 h DIN 511 LLS = LUBRITECH.

DIN Operating Temp Range40 to 140 o C Worked Penetration DIN ISO 2137 01 MM approx 265 to 295 Color Beige Texture homogeneous Container sizes 400g cartridge (grease gun size), 1 kg can. NLGI grade, DIN 2 Worked penetration, DIN ISO 2137, 25°C, lower limit value 265 x 01 mm Worked penetration, DIN ISO 2137, 25°C, upper limit value 295 x 01 mm Kinematic viscosity of the base oil, DIN pt 01/ASTM D445/ASTM D 7042, 40°C approx 4 mm 2 /s Kinematic viscosity, DIN pt 01/ASTM D445/ASTM D 7042, 100. DIN Lubricants Lubricating greases K Classification and requirements In this standard the classification of and specifications for lubricating greases, NGLIclasses 1 to 4 according to DIN , and test methods are established.

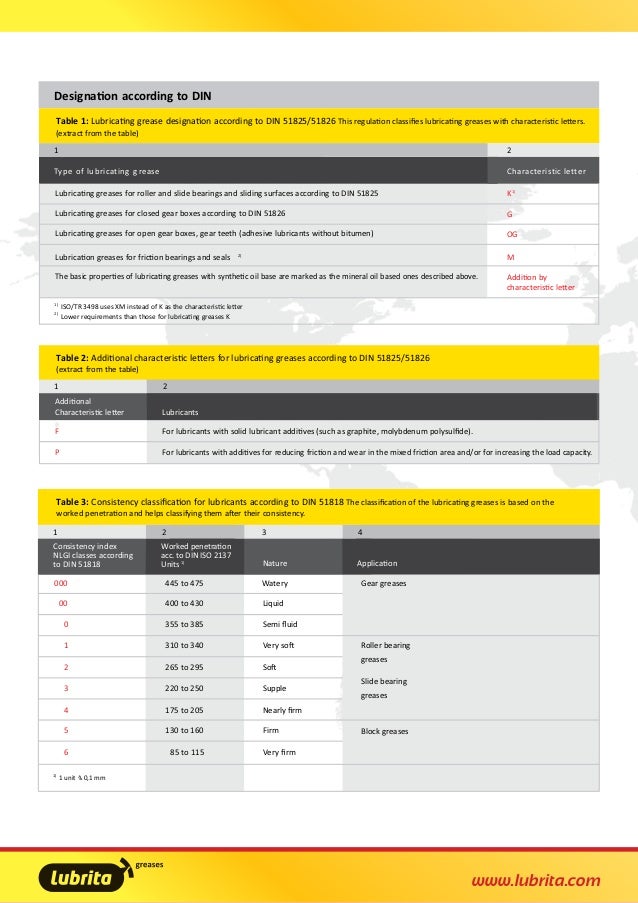

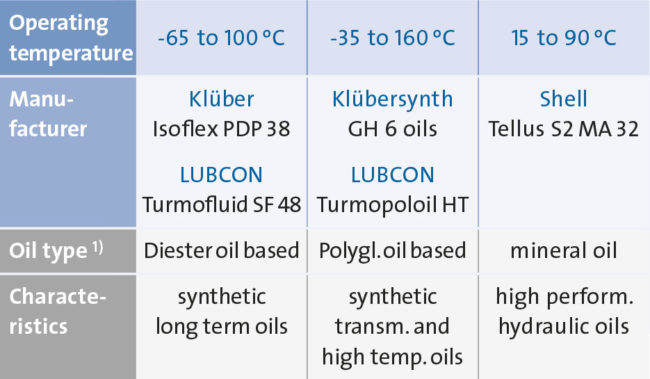

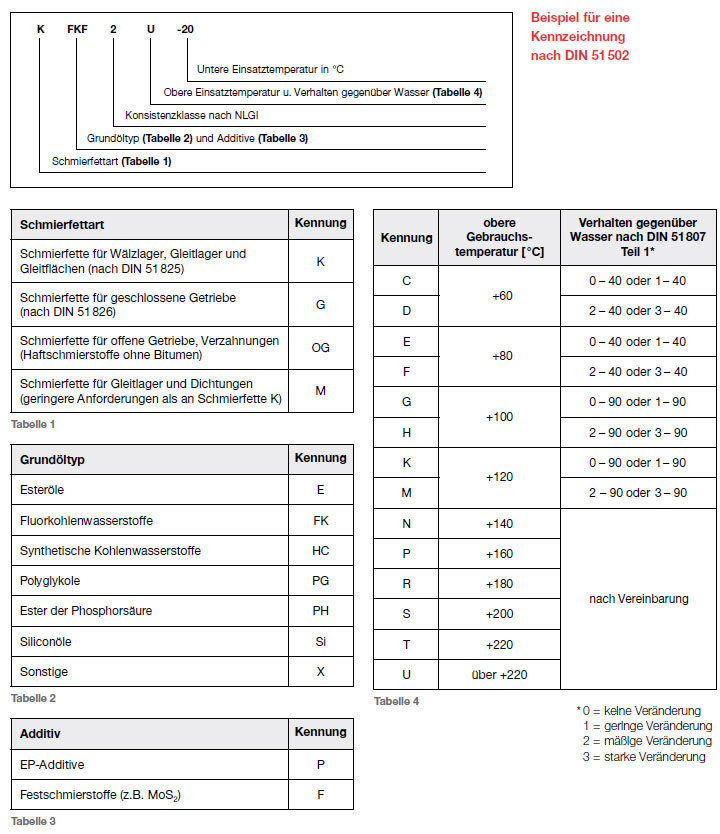

Table 3 Consistency classifica on for lubricants according to DIN The classifica on of the lubrica ng greases is based on worked penetra on and helps classifying them a‹er their consistency. DIN 515 designations of the SKF greases Grease LGMT 2 LGMT 3 LGEP 2 LGFP 2 LGEM 2 LGEV 2 LGLT 2 LGGB 2 LGWM 1 LGWM 2 LGWA 2 LGHB 2 LGHP 2 LGET 2 DIN 515 XXXXX K2K30 K3K30 KP2G K2N K2G KPF2K10 KP2G50 KPE2K40 KP1G30 KP2G40 K2N30 KP2N K2N40 KFK2U40 Related Interests. The classification according to NLGI (DIN 51 818) ranges from very soft (Class 000) to very firm (Class 6) Standard lubricating greases usually comply with NLGI Class 2 Designation and classification of lubricating greases to DIN 51 502.

DIN NLGI Consistency Class 1 Unworked penetration mm/10 290 340 ISO 2811 Density at °C g/ml 111 DIN Base oil viscosity at 40°C mm2/s 85 Temperature Service temperature range °C 30 to 300 Load carrying capacity, wear protection, speed DIN T4 Four ball tester, weld load N 30. Consistency classification of lubricating greases;. DIN ISO 2137 Consistency class NLGI 3 DIN Dropping point 190°C DIN ISO 2176 Temperature range 30°C up to 130°C, shortly up to 150°C Water resistance completely resistant DIN Copper corrosion Corrosive Grade 1 DIN Oxidation stability < 0,35 bar DIN MechanicDynamicTest pass B/1°C DIN Kinematic.

DIN 516 Lubricants Lubricating greases G Classification and requirements Published by DIN on April 1, 15 Dieses Dokument gilt für Schmierfette G der NLGIKlassen 000 bis 2 nach DIN zur Schmierung von Elementen der Antriebstechnik, insbesondere von geschlossenen Getrieben. Conditions for NLGI grade with DIN Corrosion protection period conditions in accordance with DIN , SKF Emcor test Conditions for VKA welding load in accordance with DIN , VKA test (Institute for Internal Combustion Engines). NLGI grade, DIN 3 Worked penetration, DIN ISO 2137, 25°C, lower limit value 2 x 01 mm Worked penetration, DIN ISO 2137, 25°C, upper limit value 250 x 01 mm Oil separation, based on ASTM D 6184 FTMS 791 C 321, after 30 h/0 °C.

DIN Determining the moisture content of solid fuels This document specifies three different methods for the determination of the total water content of solid fuels depending on the type of sample and water content. N din part 2 hlp type meets the requirements of n iso (hm fluids) n gm ls/2 n afnor nfe n mannesman rexroth (re) 90 21 nswedish standard (ss) 15 54 34 am shell australia lubricants product data guide 13 industry hydraulic fluids industry hydraulic fluids shell tellus s2 m shell tellus s2 m industrial hydraulic fluid. Understanding NLGI Grades can be a bit daunting to the average person What does it mean when your grease has an NLGI Grade 00?.

NLGI grade, DIN 0 Worked penetration, DIN ISO 2137, 25 °C, lower limit value 355 x 01 mm Worked penetration, DIN ISO 2137, 25 °C, upper limit value 385 x 01 mm Kinematic viscosity of the base oil, DIN pt 01/ASTM D445/ASTM D 7042, 40 °C approx 100 mm²/s Kinematic viscosity, DIN pt 01/ASTM D445/ASTM D 7042, 100 °C. NLGI grades Subscribe on standards with our subscription service When you use our service you can be assured the latest editions and easy access. Rexroth DIN 515 DIN 516 under DIN (°C) R3416 037 00 Dynalub 510 KP2K 2 to 80 1 x 400 g Shaft d ≥ 8 mm R0419 090 01 Dynalub 5 GP00K 00 to 80 5 ml maintenance kit Shaft d < 8 mm.

This standard is included in DIN Handbook 198 Provides requirements and methods of test for type K lubricating greases of NLGI grades 1 to 4 (see DIN ) for use in rolling bearings and plain bearings and on slide ways, establishes a system of designating such lubricants and provides information on their application. NLGI grade/conditions 2 / with DIN Base oil viscosity, kinematic/conditions 110 mm²/s / at 40°C Min dripping point/conditions 180 °C / in accordance with DIN ISO 2176. The depth to which a measuring cone penetrates at 25( C is measured in accordance with DIN In the USA , the NATIONAL LUBRICATING GREASE INSTITUTE (NLGI) introduced penetration grades that were adopted by DIN for the "consistency classification of lubricating greases".

NLGI Class (DIN ) 2 Temperature Range °C to 130 °C (4 °F to 266 °F) Basic oil viscosity at 40 °C 60 mm²/s Drop point (DIN ISO 2176) 190 °C Worked penetration (DIN ISO 2137) 280 Corrosion protection (SKF Emcor Test, DIN ) 0 VKA welding load () 2400 N. Es la temperatura a la cual una muestra de grasa comienza a fluir a través de un orificio cuando se calienta Se mide según la normativa DIN ISO 2176 Es importante entender que este punto se considera de relevancia limitada para el rendimiento de la grasa, ya que se encuentra siempre muy por encima del HTPL. Consistency classification of lubricating greases;.

NLGI Class (DIN ) 2 Temperature Range °C to 130 °C (4 °F to 266 °F) Basic oil viscosity at 40 °C 60 mm²/s Drop point (DIN ISO 2176) 190 °C Worked penetration (DIN ISO 2137) 280 Corrosion protection (SKF Emcor Test, DIN ) 0 VKA welding load () 2400 N. Standard Foreign standard public · DIN Lubricants;. DIN 515 Lubricants Lubricating greases K Classification and requirements standard by Deutsches Institut Fur Normung EV (German National Standard), 06/01/04 View all product details Most Recent.

DIN 51 807/1, 3 hrs at 90 °C 1 max Oil separation DIN 51 817, 7 days at 40 °C, static, % 1–6 Lubrication ability R2F, running test B at 1 °C Pass Copper corrosion DIN 51 811 2 max at 110 °C (230 °F) Shelf life 5 years * Typical value. We use cookies to make our website more userfriendly and to continually improve it Please agree to the use of cookies in order to proceed with using our websites More information can be found in our data protection. Greases in accordance with DIN 515 K2K and, for higher loads, KP2K of NLGI Class 2 in accordance with DIN are recommended for the longest possible lubrication intervals Tests have shown that greases of NLGI Class 00 achieve only about 50% of the running perfor mance of Class 2 at higher loads The relubrication interval depends on.

NLGI class according to DIN 2 Density 087 kg/dm³ Classifi cation according to DIN KHC2S60 Classifi cation according to IEN SO ISOLXEGH Temperature range (for AUMA products) Multiturn actuators, partturn actuators, Gearboxes, Output drive types A, Antibackdrive devices –60 °C to 140 °C. Highperformance grease NLGI grade 00 (as per DIN )water resistanceprotection against corrosionTem range from to 80 degree Celsius BoschRexroth product ID for Dynalub 5R3416 043 00 (400 g cartridge)R3416 042 00 (5 kg bucket) Alternative greases to Dynalub 5Castrol Longtime PD00Elkalub GLS 135/N00 OIL. ASTM D217, DIN (Cone Penetration of Lubricating Grease) This test determines grease consistency by measuring the depth in tenths of millimeters to which a standard cone will sink when allowed to fall into a sample The consistency after using a standard grease worker to apply a shear stress at 1 Hz for 60 strokes to the sample is.

Klasse DIN Thickening agent Dickungsmittel Lithium soap / Lithiumseife Lithium soap / Lithiumseife Lithium soap / Lithiumseife Mineral oil / Minerall Mineral oil / Minerall Base oil type Grundltyp Mineral oil / Minerall Lithium soap / Lithiumseife Lithium soap / Lithiumseife Aluminiumcomplex soap Aluminiumkomplexseife. NLGI grades There is no abstract currently available for this document Order online or call Americas 1 800 854 7179 Asia Pacific 852 2368 5733 Europe, Middle East, Africa 44 1344. DIN , 1981 Edition, December 1981 Lubricants;.

The NLGIclass as per DIN indicates the consistency of the lubricant, and gives information on the stiffness of the grease It does not give any indication of the general ability to supply in lubrication systems, since lubricating greases with the same NLGI class can have different fl ow characteristics. NLGI grade/conditions 2 / with DIN Base oil viscosity, kinematic/conditions 110 mm²/s / at 40°C Min dripping point/conditions 180 °C / in accordance with DIN ISO 2176. Consistency classification of lubricating greases;.

NLGI grade/conditions 2 / with DIN Base oil viscosity, kinematic/conditions 110 mm²/s / at 40°C Min dripping point/conditions 180 °C / in accordance with DIN ISO 2176. This standard is included in DIN Handbook 198 Provides requirements and methods of test for type K lubricating greases of NLGI grades 1 to 4 (see DIN ) for use in rolling bearings and plain bearings and on slide ways, establishes a system of designating such lubricants and provides information on their application. DIN 1 DIN ISO 2176 DIN 515 DIN DIN ISO 2137 DIN DIN 1 DIN DIN DIN DIN 4 DIN 5 mm²/s mm²/s 0,1 mm NLGICl °C kPa Range hPa CorrGrad CorrGrad N mm FE8 tests (rolling element wear) FE9 tests (grease service lifetime) DIN 1 °C Flow pressure at.

DIN (KP2K to DIN 515) – Good water resistance – Corrosion protection – Temperature range – to 80°C and on the runner block body at all four side lube ports 75 cm3 (3x) per port Initial lubrication for size 125 At one of the end face or side lube ports on either of the two end caps 25 cm3 (3x). NLGI grade, DIN 0 Worked penetration, DIN ISO 2137, 25 °C, lower limit value 355 x 01 mm Worked penetration, DIN ISO 2137, 25 °C, upper limit value 385 x 01 mm Kinematic viscosity of the base oil, DIN pt 01/ASTM D445/ASTM D 7042, 40 °C approx 100 mm²/s Kinematic viscosity, DIN pt 01/ASTM D445/ASTM D 7042, 100 °C. NLGI grade/conditions 2 / with DIN Base oil viscosity, kinematic/conditions 110 mm²/s / at 40°C Min dripping point/conditions 180 °C / in accordance with DIN ISO 2176.

The accumulator grease gun generates a substantial delivery rate through the reduction gear and an eccentric This makes it possible to pump greases with NLGI grades 000 to 2 (according to DIN ) up to an operating pressure of approx 400 bar Screw in the SR cartridge, ready Considerable relubrication quantities can be applied easily and without effort. NLGI grades Inform now!. Lubrication Guide Applicable DIN Standards Codes for Lubricants According to DIN Code letters K P 2 K 30 Type of grease lubricant Lubricating materials Consistency index (NLGI Class) Additional code letter (reaction to water) Additional code number for lower service temperature Code letter Example K P 2 K30 Lubricating materials Example K P 2 K30 Type of grease lubricant.

Understanding NLGI Grades can be a bit daunting to the average person What does it mean when your grease has an NLGI Grade 00?. Lubrication Guide Applicable DIN Standards Codes for Lubricants According to DIN Code letters K P 2 K 30 Type of grease lubricant Lubricating materials Consistency index (NLGI Class) Additional code letter (reaction to water) Additional code number for lower service temperature Code letter Example K P 2 K30 Lubricating materials Example K P 2 K30 Type of grease lubricant. DIN Determination of the shear viscosity of lubricating greases using a rotational viscometer, with a coneandplate measuring system, 1999, draft 05 DIN Testing lubricants The consistency classification of lubricating greases (NLGI grades), 1981/19 DIN.

Bosch Rexroth doesn't sell grease or oil, but we recommend that customers purchase a grease that complies with the specification given in our catalogs, typically NLGI 00 or 2, DIN or DIN 515, KP2K Dynalub 510 is the standard grease supplied with the majority of our bearing products from Germany. Din e 1999 TESTING OF LUBRICANTS MECHANICALDYNAMIC TESTING IN THE ROLLER BEARING TEST APPARATUS FE8 PART 2 TEST METHOD FOR LUBRICATING GREASES, OBLIQUE BALL BEARING OR TAPERED ROLLER BEARING. DIN Determining the moisture content of solid fuels This document specifies three different methods for the determination of the total water content of solid fuels depending on the type of sample and water content.

Standard Foreign standard public · DIN Lubricants;.

Fag Rolling Bearing Grease Arcanol Multitop Diy Rolling Bearing Grease Arcanol Multitop Properties Applications Bearing Grease For High Loads Din Iso 2176 Din 515 Din

Din Lubricants Consistency Classification Of Lubricating Greases Nlgi Grades

Ad Glit

Din 51818 のギャラリー

Technical Comparison Of Fuchs Hd Skf Lgev 2 Greases 2

E Coll Das Original Kennzeichnung Von Schmierfetten Nach Din Kennzeichnung Von Schmierfetten Nach Din

Www Kic Krones Com Sdb Pdf Td L7007 En Pdf

Www Boschrexroth Com Ics Cat Content Assets Online Do Lt Lbs Lubrication En Pdf

2

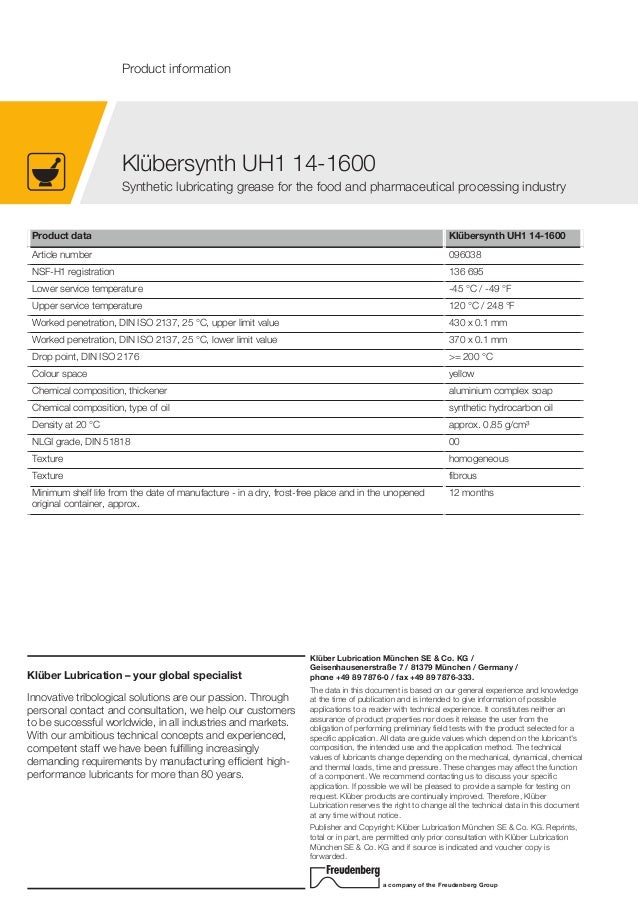

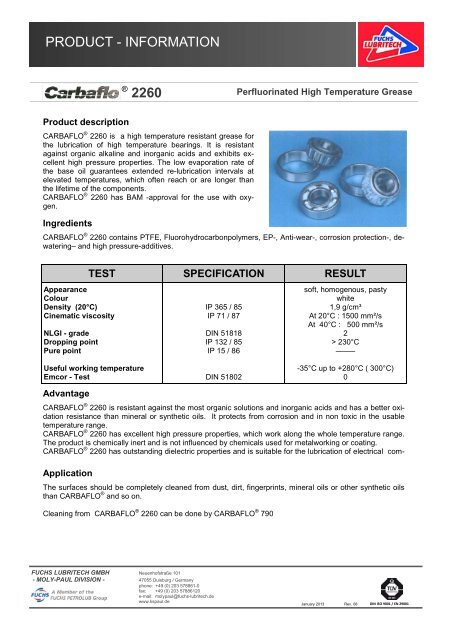

Manufacturing In Accordance With Gmp Standards Speciality Lubricants For The Pharmaceutical Industry Pdf Free Download

Klubersynth Uh1 14 1600 Mr Tung 0987 9 407 Www Khodaumo Com

Http Www4 Total Fr Asia Oceania Australia Technical data sheets Total Total industrial 10 grease Statermic nr tds Pdf

Lubrita Lubricating Greases Brochure

2

Allround Lubricant High Performance Greases High Performance Greases 250 Catalogue Weicon Al F 254 Al H 254 Al M 255 Al T 256 Al W Pdf Free Download

2

2

2

Www Kic Krones Com Sdb Pdf Td Sp7401 En Pdf

2

2

Oks Greases Oks 403 Marine Grease Distributor Channel Partner From Mohali

2

2

Pngn Tech Masters Com Media 1 N Nlgi3 Web Web Techmasters En Nlgi3 Pds Pdf

Cassida Grease Hts 2 Grease Hts 2 Nlgi Number Din 2 Kin Visc Classification Din Din Kp Hc 2 S 30 Classification Iso Iso 6743 9 L Xcgea 2 Pdf Document

Din

Www Kic Krones Com Sdb Pdf 242 1910 Td Krones Celerol Sp 7409 Gb En Pdf

Http Www Highchem Co Kr Tds Long Life Pdf

2

2

Http Www Lubrita Com Uploads Brosiuros Lubrita Greases Broshure Pdf

2

Lubrication Of Freewheel Clutches Gmn

Fully Synthetic High Performance Grease Usable Up To 180 C Lubricating Greases Vgs 180 Meusburger

2

2

2

Www Kic Krones Com Sdb Pdf Td L7101 En Pdf

Grease Kettles

Www Kic Krones Com Sdb Pdf Td L7001 En Pdf

Lubrication Of Freewheel Clutches Gmn

Mp Carbaflo 2260 Engl Kspaul De

Buy Multi Purpose Grease I Online

Fette Oks Spezialschmierstoffe Gmbh

Bahr Modultechnik Din 515 K2k Kp2k Din Nlgi2 Ebay

2

Http Www Powersync Co Th Files Name2 Content5bdfbbb5cd6d8bb Pdf

2

Castrol Olista Longtime 2

Al H High Performance Grease

2

Grease Etg Meyer Glitza

Www Kic Krones Com Sdb Pdf 227 1910 Td Krones Celerol L 7102 Gb En Pdf

Mineral Oil White High Performance Grease Size 0 5kg Grade Din Rs 00 Kilogram Id

2

Www Boschrexroth Com Ics Cat Content Assets Online Do Lt Lms Ckx Lubricant Maintanance En Pdf

Www Techniekwebshop Nl Media Indexed S F Sf08 Tech Pdf

Din

Clasificacion Din Para Grasas Mantenimiento De Sistemas De Lubricacion Wiki Fandom

Grease Lubrication Using Grease Guns Or Progressive Kp2k To Din 515 At One Of The End Face Or Side Lube Ports On Either Of The Two End Caps 25 Cm3 3x Grease Lubrication

Class Din Lakshya International In Indore India

2

Http Www Lubrita Com Uploads Brosiuros Lubrita Greases Broshure Pdf

Www Totallubmarine Com Products Ceran Ad Plus Tds

Www Indi Nl Pdf Nl Nl Sf03 Tech Pdf

2

Greases Oks Spezialschmierstoffe Gmbh

2

2

Http Www Lubrita Com Uploads Brosiuros Lubrita Greases Broshure Pdf

.jpg)

Lithium Mehrzweck Schmierfett Nlgi2 Din 400g

2

Mnogofunkcionalnaya Smazka Wurth Tehnicheskie Harakteristiki Omylyayushaya Osnova 12 Gidroksistearat Litiya Cvet Zheltyj Klass Po Nlgi Din 2 Termostojkost Ot 30 C Do Katalog Wurth 15 Produkciya Str 00 Lab2u

2

2

Gzhls At Blob Ldb E 7 C 4 B4ec4356de9459b56e55e675aae9f3e31c Pdf

Products For Construction And Mining Equipment By Liqui Moly Gmbh Issuu

2

2

Binder 1 Screw Insulator Electricity

2

Www Ahrinternational Com Pdf Catalogues Grease specifications Kluber Grafloscon A G 1 Ultra En Msds Pdf

Cs Unitec Pneumatic Hack Saw 5 1212 5 1213 Operating Manual

2

.jpg)

Multi Purpose Grease Ii Automotive Grease Industrial Grease

2

Standard Din 1981 12 1 12 1981

2

Http Www Flytechgroup Com Catalog New folder Molykote 7325 tds Pdf

2

Manufacturing In Accordance With Gmp Standards Speciality Lubricants For The Pharmaceutical Industry Pdf Free Download

Www Ahrinternational Com Pdf Catalogues Grease specifications Temp0 E Komplett Pdf

Din 515 04 Lubricants Lubricating Greases K Classification And Requirements

Msdspds Castrol Com Bpglis Fusionpds Nsf Files 9d4fda6df45cd21 File Xi En Pdf

E Coll Das Original Kennzeichnung Von Schmierfetten Nach Din Kennzeichnung Von Schmierfetten Nach Din

Www Kic Krones Com Sdb Pdf Td Ic4005 En Pdf

Greases Oks Spezialschmierstoffe Gmbh

Grey Primer Bardahl

2

Codes For Lubricants Acc Din Pdf Lubricant Friction