Pull Test Procedure

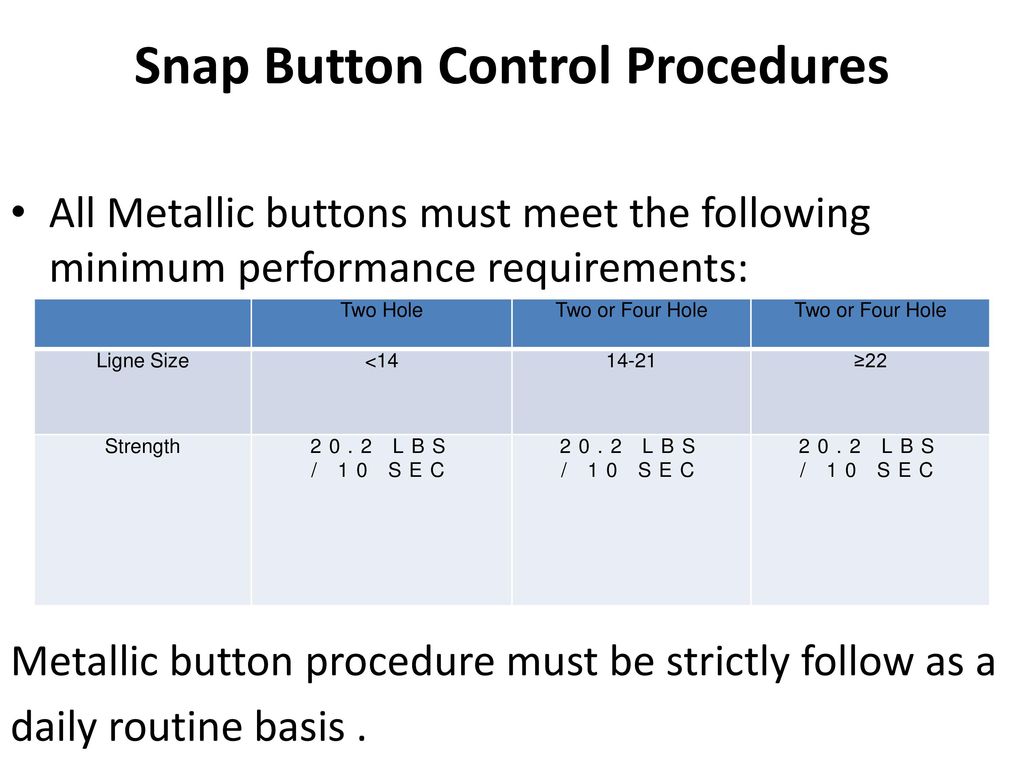

Button Pull Test Machine Sop We do the pull test of the button normal or snap according to the buyer requirementIf the requirement is not present we maintain our procedure.

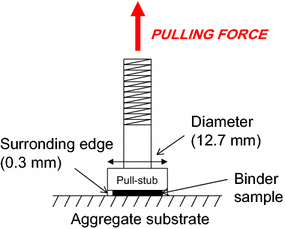

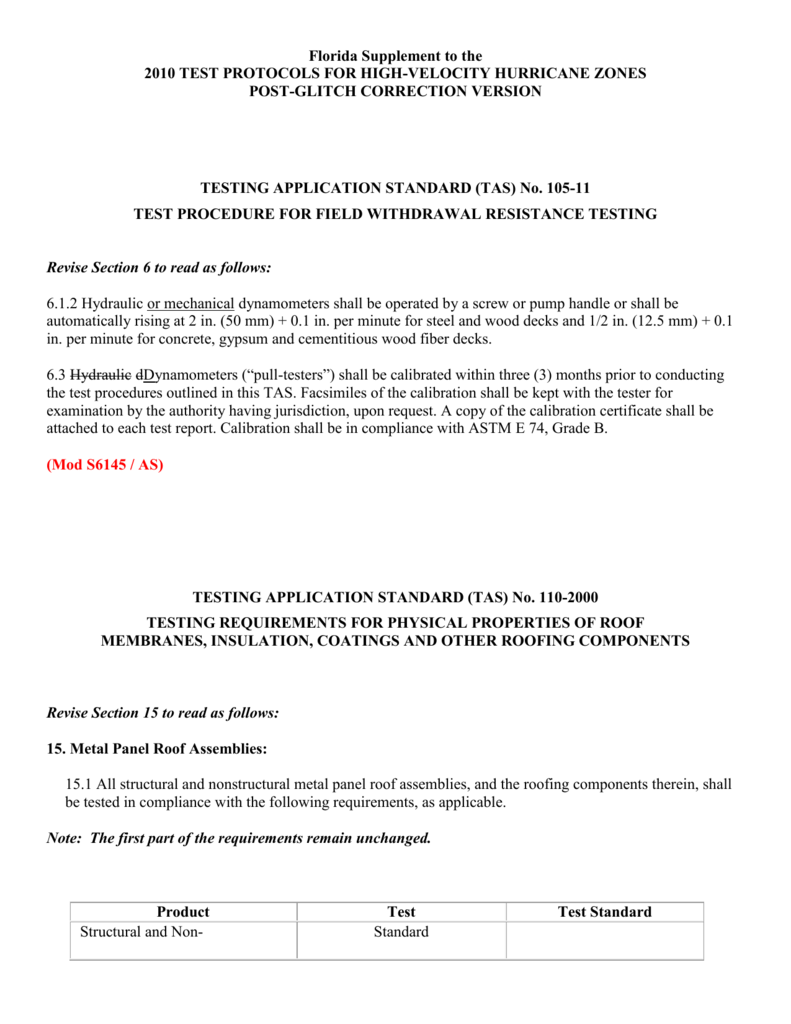

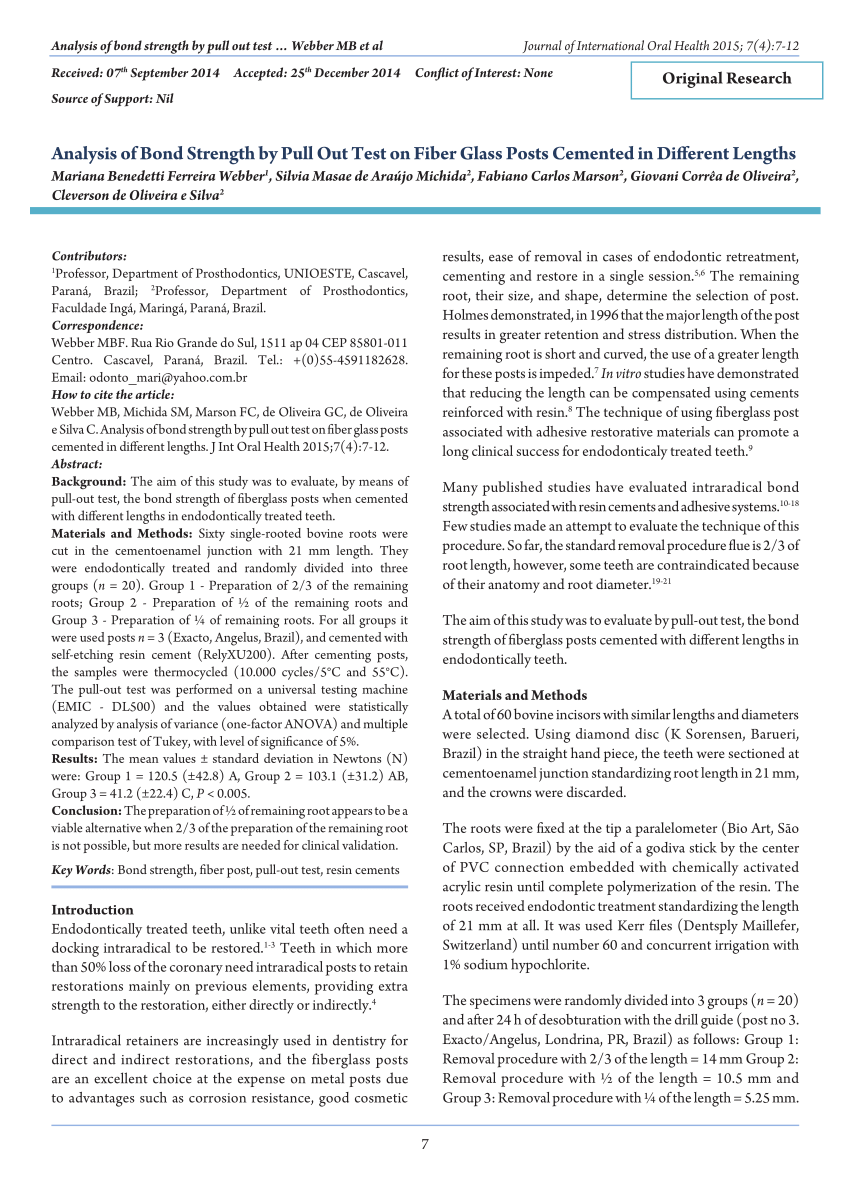

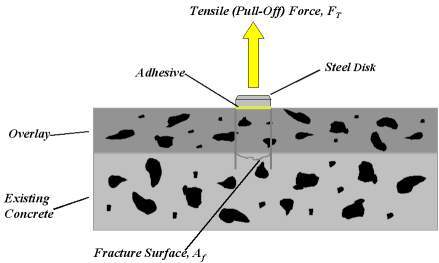

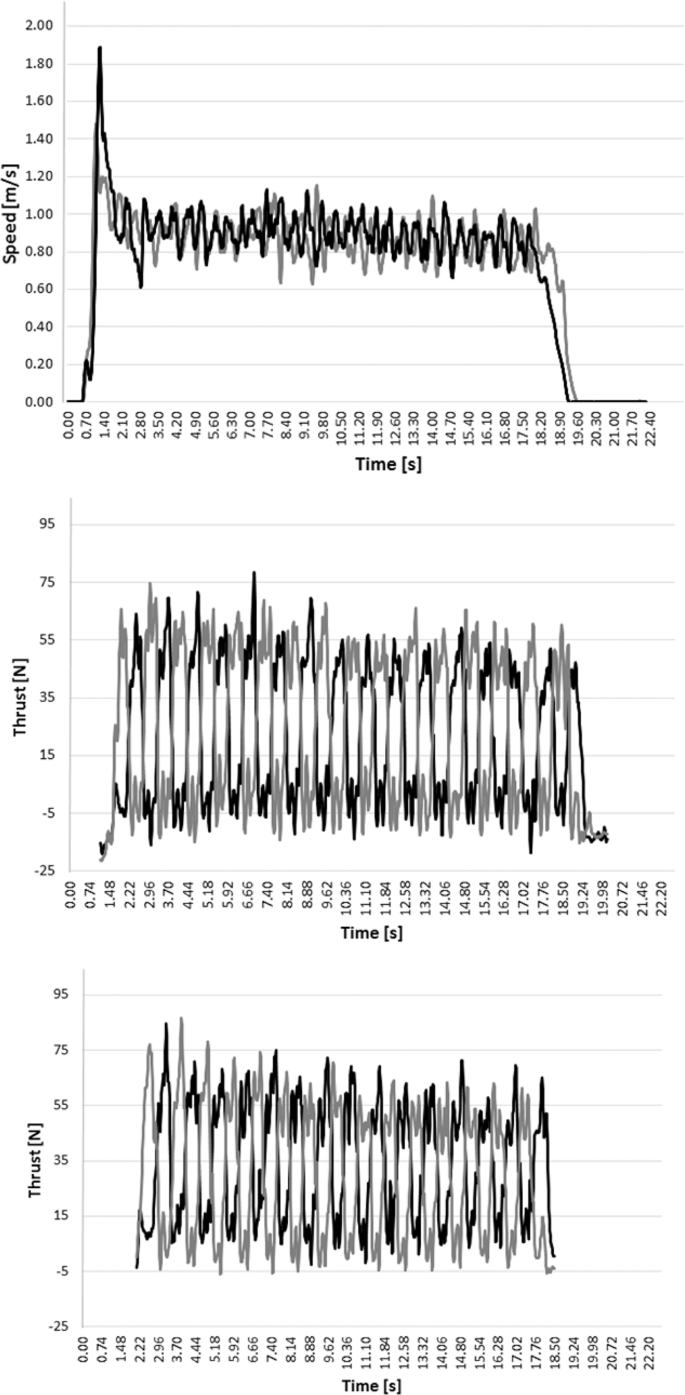

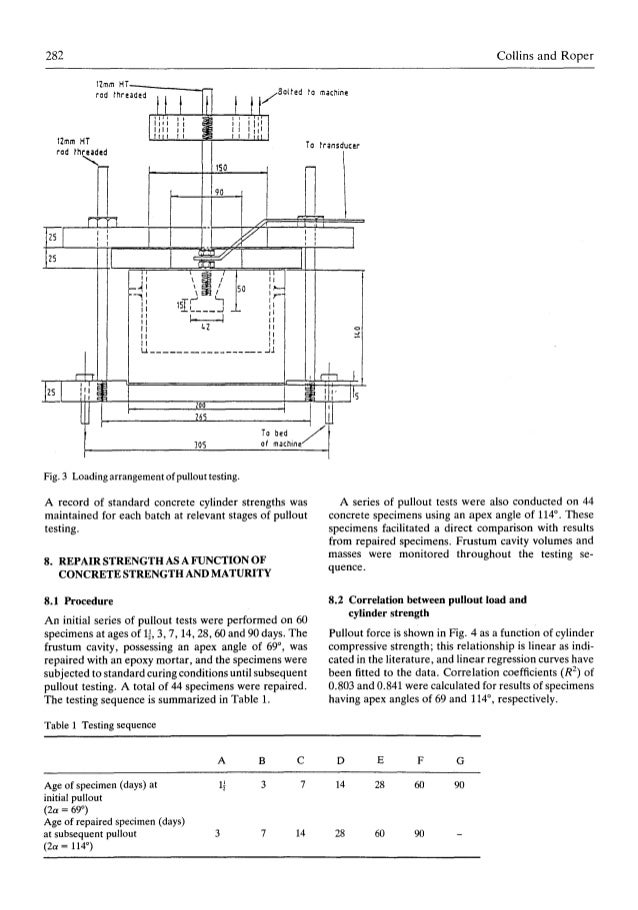

Pull test procedure. The tests were performed using a pullout bench that allows testing a wide range of parameters This paper provides an extensive database of laboratory pullout test results and confirms the influence of the confining pressure and the embedment length on the pullout response (rock bolts and cable bolts). A displacement controlled pull–out test was carried out to investigate behavior of progressive failure of reinforced soil structure (Fig 15) Figure 16 shows the outline of this test apparatus The pullout box is a rectangular parallelepiped 160 mm long, 150 mm wide and 0 mm height. 11 This test method describes the apparatus and procedure for evaluating the pulloff strength of wet layup or pultruded (shopfabricated) Fiber Reinforced Polymer (FRP) laminate systems adhesively bonded to a flat concrete substrate The test determines the greatest perpendicular force (in tension) that an FRP system can bear before a plug of material is detached.

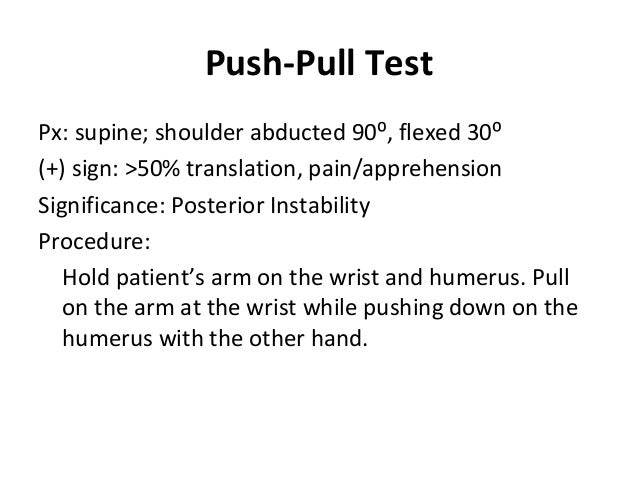

Pdf 02 MiB DateFebruary 6, 16 Downloads5364 VersionFX1 16. UPDRS 5) is a commonly used clinical test of postural stability for patients with PD This test evaluates the ability of patients to recover from a backward pull on the shoulders. PULL TEST KIT • OPERATION MANUAL PTK00, PTK3002 & PTKDGT02 TOLL FREE 8501 MAGNETIC PULL TEST Why test Magnetic Strength?.

Odessa, TX 3356 Kermit Hwy Odessa, TX Tollfree Phone Fax. Knitted covered buttons – plastic buttons to be lockstitched on and crochet around the button to give the effect Must pass a 90N button pull test;. A magnetic pull test is a reliable method of determining the magnetic strength of a magnet A magnetic pull test can be used in comparing two magnetic devices that look very similar on the outside.

Fitness Testing > Tests > Strength > Pull Up > Horizontal Horizontal PullUp Test The Horizontal PullUp Fitness Test is a variation of the hanging pullup or chinup test, made easier as the whole body weight does not need to be pulled upThere is a similar Modified PullUp Test in which the legs are kept straight A test measuring a similar action and muscle groups is the Bench Pull Test. Postinstalled anchor testing The jobsite—where installer experience can vary dramatically—is no place to experiment with anchors That’s why we thoroughly test and document the performance parameters and application and installation guidelines for every Hilti anchor. Anchorage test for fully grouted bolts Standard pull tests have sometimes been employed, but they provide no information on the anchorage near the top of the bolt An alternative, first described more than 25 yrs ago in the US, is the shortencapsulation pull test (SEPT) With this test, the bolt is installed with only a short (1 ft or.

TestResources, Inc is a manufacturer of mechanical test solutions including universal test machines, static & dynamic test machines, grips, fixtures and testing accessories For over twenty years TestResources has utilized a modular design approach to create affordable and highly flexible systems to meet a wide range of applications. Test Procedure Load each end of the sample into opposing tensile grips;. Purpose This test measures upper body muscle strength and endurance equipment required Horizontal overhead bar, set at an adequate height so that the participants can hang from it with their arms fully extended and feet not touching the floor(see pullup bars) pretest Explain the test procedures to the subjectPerform screening of health risks and obtain informed consent.

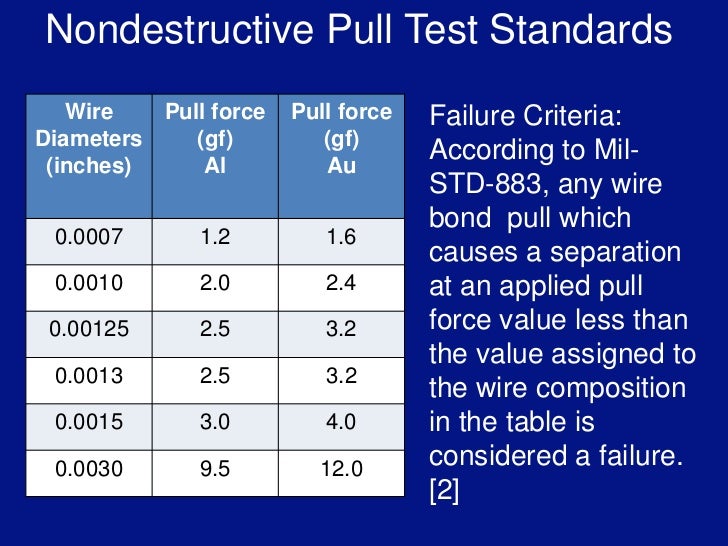

Wire pull testing is the most basic type of wire bond test, but testing procedures can vary based on thickness Typically, wires up to 3 mil in diameter are classified as thin Wires with larger diameters are described as thick. Test Procedure Bollard pull tests should be carried out under similar conditions to facilitate comparison with results obtained at different testing establishments These conditions arePage 1 Bollard Pull Certification Procedures – Guidance Information, 1992 41 Testing environment. Drilling the Test Hole 711 Drill the test hole using the same procedure that will be used during construction Wash or blow the borehole clean of all cuttings7 Procedure 71 This test method is under the jurisdiction of ASTM Committee D18 on Soil and Rock and is the direct responsibility of Subcommittee D1812 on Rock Mechanics.

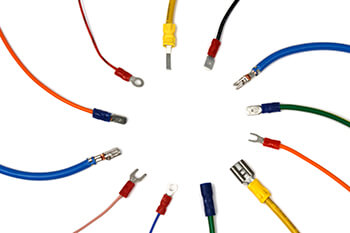

Pulloff / Pullout 'Pulloff' or 'pullout' testing generally involves the separation of two secured parts under tension This may be to test joints in assemblies of any kind ranging from the tensile strength of crimped or welded wire terminals, the seal integrity of adhesive joints, the mechanical strength of industrial fixings and fasteners, stoppers, lids and pushfit closures, through to. Cable pull pull, cut the c e a protectiv ape in place d splicing sla PN447B pecovered r the cable able jacket (Figure 10) w the mesh Y to the top how clearly ess the mesh are desired, ble jacket to shingles, so t ropriate ball ) The grip able 91 cm e cap over to prevent ck so that it. Button pull test procedure.

Test Procedure Load each end of the sample into opposing tensile grips;. Pool testing relies on the same polymerase chain reaction (PCR) technology as individual diagnostic tests, but the method by which people are tested is quite different than the standard testing. Separate grips at a constant rate of speed (see spec) throughout the length of the specimen (about 9 inches) Report peak load and average load per unit width of bond;.

The hand pull test procedure is as follows a Make a knife cut across the joint b Make cuts along each side of the joint approximately 3" (75 mm) long c Place a 1" (25 mm) mark on the sealant tab as shown in the illustration d Grasp a 2" (50 mm) piece of sealant firmly just beyond the 1" (25 mm) mark and pull at a 90° angle e. How to conduct a proper pull test The pull test procedure begins with cleaning the magnet surface Even a small gap between the pull test piece and magnet will adversely affect test results Then use the following steps Select the appropriate pull test piece and spacer for the separatorbased on guidelines found in your pull test kitand. The field adhesion test is simply a hand pull test of a cut area of joint sealant It is a very useful procedure for evaluating the effects of various cleaning methods and primers It is also a good indicator of the fundamental adhesive properties of a sealant on a particular substrate The field adhesion test procedure is as follows 1.

Test Procedure Bollard pull tests should be carried out under similar conditions to facilitate comparison with results obtained at different testing establishments These conditions arePage 1 Bollard Pull Certification Procedures – Guidance Information, 1992 41 Testing environment. Postinstalled anchor testing The jobsite—where installer experience can vary dramatically—is no place to experiment with anchors That’s why we thoroughly test and document the performance parameters and application and installation guidelines for every Hilti anchor. CAPO test (Cut and Pull out Test) LOK Test The LOKTEST system is used to obtain a reliable estimate of the inplace strength of concrete in newly cast structures in accordance with the pullout test method described in ASTM C900, BS 117, or EN.

Button Pull Test Procedure Button Pull Test SOP Button Pull Test SOP for Apparel Industry Button pulls test is used to determine the pulling strength of any type of button and snaps used in garments It is also used to determine the holding or breaking strength of prong ring attached snap fasteners onto garments to ensure the button fixed on. Button Pull Test Procedure Button Pull Test SOP Button Pull Test SOP for Apparel Industry Button pulls test is used to determine the pulling strength of any type of button and snaps used in garments It is also used to determine the holding or breaking strength of prong ring attached snap fasteners onto garments to ensure the button fixed on. Understanding the Pull Test Procedure iCONN performs pull testing inhouse to determine if the tension and breaking strength specifications have been met per regulation or contract Temperature rise validation testing is done to ensure UL over 30 degrees Celsius is met over ambient temperature requirements.

Starting the Pull Test Procedure Clean the magnet surface Even a small gap between the pull test piece and the magnet will adversely effect the test results Select the appropriate pull test piece and spacer for your separator based on the guidelines set forth, and attach it to the scale (if you are using the Graduated Scale). The concrete pull out test is done by LOK test method and CAPO Test method The fundamental principle behind the pull out testing with “Lok Test” and “CAPO Test” is that the test equipment generates pull force on the concrete and produce results that closely correlate to the compressive strength of concrete. Wire pull testing is the most basic type of wire bond test, but testing procedures can vary based on thickness Typically, wires up to 3 mil in diameter are classified as thin Wires with larger diameters are described as thick SHINE can perform pull testing with thin wire or thin wire accordingly to your project requirements.

For reference to ASTM F2256 blog post on TPeel adhesive bond testing. A test procedure to evaluate the adhesive strength of the epoxy coating was developed and is recommended for quality control The test is simple, quick, and reliable, and can be performed at the Figure 12 Schematic of pulloff adhesion testing system used in the NCHRP 1037 study2. The concrete pull out test is done by LOK test method and CAPO Test method The fundamental principle behind the pull out testing with “Lok Test” and “CAPO Test” is that the test equipment generates pull force on the concrete and produce results that closely correlate to the compressive strength of concrete.

The field adhesion test is simply a hand pull test of a cut area of joint sealant It is a very useful procedure for evaluating the effects of various cleaning methods and primers It is also a good indicator of the fundamental adhesive properties of a sealant on a particular substrate The field adhesion test procedure is as follows 1. Button Snap Pull Testing Button Snap Pull Tester i2 ™Button Snap Pull Tester i2 ™To determine the pulling strength of any type of button and snaps used in garments with maximum capacity 30 kg & least count 250 gm 4 different types of jaws with calibration weight & all accessories as per American (GAP) & European (H&M) standards. Vehicle manufacturers test procedures Number Details 101 Passenger Car Controls and Displays Standard regulation on passenger car controls and displays visual inspection Engineer Neil Dold 102 Transmission Shift Lever Sequence, etc Standard regulation on transmission shift lever sequence, etc visual inspection Engineer Ahmad Barnes 103.

Test Procedure Bollard pull tests should be carried out under similar conditions to facilitate comparison with results obtained at different testing establishments These conditions arePage 1 Bollard Pull Certification Procedures – Guidance Information, 1992 41 Testing environment. Onsite testing checks the structural strength of an anchoring system or base material Our tests are carried out with regularly calibrated test equipment and by expert Hilti engineering staff We give you a written report of the test including test data For more information contact you local Hilti team and we’ll be happy to help. It provides a robust, economical and reproducible method of measuring the page pull strength of perfectbound books By enabling an efficient binding endurance test, the Page Pull Tester is a proven reliable quality control and assessment tool, identifying many binding adhesion problems as they occur.

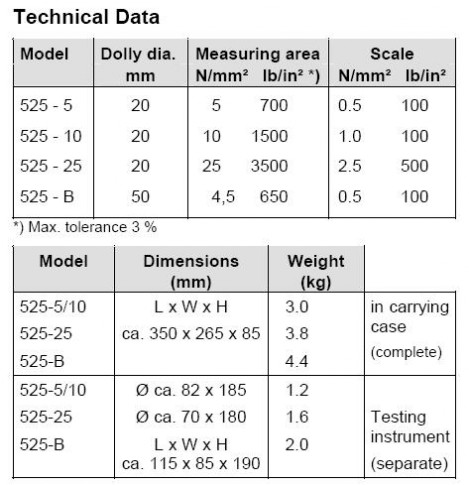

Vehicle manufacturers test procedures Number Details 101 Passenger Car Controls and Displays Standard regulation on passenger car controls and displays visual inspection Engineer Neil Dold 102 Transmission Shift Lever Sequence, etc Standard regulation on transmission shift lever sequence, etc visual inspection Engineer Ahmad Barnes 103. A "pull test" is a test for excessive shedding To perform the pull test, the clinician gently wraps his or her thumb and index finger around approximately 60 hairs and pulls gently upwards If more than 3 hairs are removed, one should consider it a positive pull test. A standard method for the application and performance of these tests is available in ASTM D3359 PullOff Tests A more quantitative test for adhesion is the pulloff test where a loading fixture, commonly called a dolly or stub, is affixed by an adhesive to a coating.

Understanding the Pull Test Procedure iCONN performs pull testing inhouse to determine if the tension and breaking strength specifications have been met per regulation or contract Temperature rise validation testing is done to ensure UL over 30 degrees Celsius is met over ambient temperature requirements. The tensile pulloff method for adhesion testing, as outlined in ASTM D 4541 and similarly in BS EN ISO 4624, involves gluing a test dolly to the coated surface and then pulling the dolly by exerting a force perpendicular to the surface in an effort to remove the dolly with the coating from the substrate. Purpose This test measures upper body muscle strength and endurance equipment required Horizontal overhead bar, set at an adequate height so that the participants can hang from it with their arms fully extended and feet not touching the floor(see pullup bars) pretest Explain the test procedures to the subjectPerform screening of health risks and obtain informed consent.

Button Pull Test Procedure For the pull test, you will always need to follow the buyer requirement pulling strength If a buyer does not give any requirement, then you can follow your company’s own procedure The Standard procedure is continued pulling 15 (second) in 934 /no weight for all attaching components like button, rivet, eyelet, snap, etc. PULL TEST KIT • OPERATION MANUAL PTK00, PTK3002 & PTKDGT02 TOLL FREE 8501 MAGNETIC PULL TEST Why test Magnetic Strength?. The Retropulsion Test’ or Pull Test’ (Postural Stability Item #30 of the Unified Parkinson’s Disease Rating Scale;.

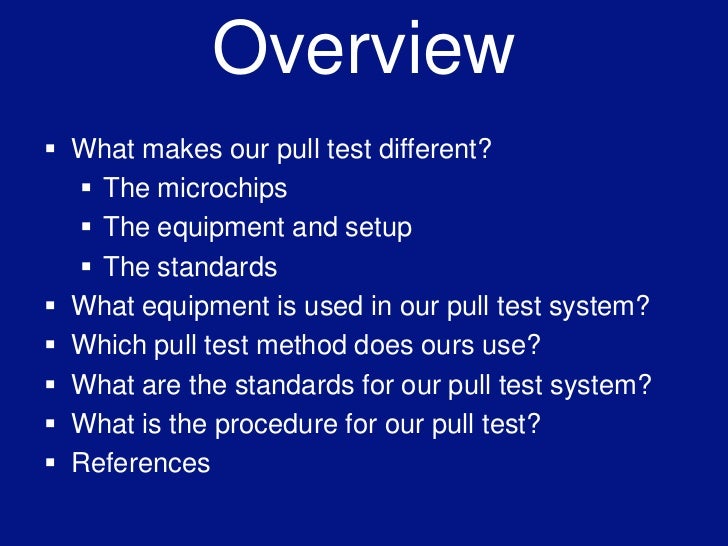

Odessa, TX 3356 Kermit Hwy Odessa, TX Tollfree Phone Fax. A pull test isAccording to IEEE member George Harman, the pull test is an accepted method used to test the quality of wire bond interconnections used in microchips 1A pull tester is a machine used to perform the pull test on microchipsThe pull test was first used by Bell Laboratories to test the strength of wire bonds. CBI chose two regularly available epoxy anchors, and hired an outside testing firm to perform pulltests on epoxy threaded rods in the rubble substrate The test was performed on four (4) pairs of two (2) anchor types – here called anchors #1 and #2 The following table gives the testing procedure Table 1 Anchor pull test profile.

BS8539 Standard We adhere to one of the most important codes of practice to affect the pull out testing industry, BS8539 Standard Designed to provide recommendations for the safe and effective selection and installation of anchors for use in masonry and concrete, this code of practice improves the level of safety and eliminates the potential for fixing failure. Pulloff strength of coatings from concrete is described in Test Method D7234 This test offers two test protocols This test offers two test protocols Protocol 1 (test to fracture) determines the greatest perpendicular force (in tension) that a surface area can bear before a plug of material is detached. Separate grips at a constant rate of speed (see spec) throughout the length of the specimen (about 9 inches) Report peak load and average load per unit width of bond;.

Pressuresensitive tape is applied over the cut Tape is smoothed into place by using a pencil eraser over the area of the incisions Tape is removed by pulling it off rapidly back over itself as close to an angle of 180° Adhesion is assessed on a 0 to 5 scale. 11 This test method covers determination of the pullout strength of hardened concrete by measuring the force required to pull an embedded metal insert and the attached concrete fragment from a concrete test specimen or structure The insert is either cast into fresh concrete or installed in hardened concrete. Drilling the Test Hole 711 Drill the test hole using the same procedure that will be used during construction Wash or blow the borehole clean of all cuttings7 Procedure 71 This test method is under the jurisdiction of ASTM Committee D18 on Soil and Rock and is the direct responsibility of Subcommittee D1812 on Rock Mechanics.

Motorized pull force test devices for forces from 100 N (225 lbf) up to 10,000 N (2,250 lbf) Capabilities such as multiple force ranges and pulling rates, job memory and networking capabilities vary between models Wire and terminal holders can be configured or customized to suit specific application requirements. To test the anchors or to perform an anchor pull test, the bolt is pulled with a hydraulic manifold and the displacement of the head of the bolt is measured concurrently Tensile load is applied to the bolt via a hydraulic lift up to the specified design load to verify that neither the joint, the substrate material nor the anchor bolt fails. The standard test method covered in ASTM D – Standard Test Method for PullOff Strength of Coatings Using Portable Adhesion Testers is used for evaluating the pulloff strength (otherwise known as adhesion) of a coating system from metal substrates The Pulloff strength determined by this procedure is a performance property, and it may be referenced in specifications.

A Positive Pull Test Many Diagnoses A "pull test" is a test for excessive shedding To perform the pull test, the clinician gently wraps his or her thumb and index finger around approximately 60 hairs and pulls gently upwards. A magnetic pull test is a reliable method of determining the magnetic strength of a magnet A magnetic pull test can be used in comparing two magnetic devices that look very similar on the outside.

Snap Button Control Procedures Ppt Download

Pullout Test An Overview Sciencedirect Topics

A Brief Guide To Button Pull Test Decorative Zips And Fashion Trend

Pull Test Procedure のギャラリー

Bs 3900 Pull Off Test Pdf Document

In Situ Concrete Pull Out Test For Compressive Strength

Determination Of Hardness Strength Of Materials By Brinell Testing Methods Labmonk

Doc Button Pull Test Sop Docx Mazedul Islam Academia Edu

Www Freedmanseating Com Wp Content Uploads 17 02 Fstl Sample Test Report Pdf

2

逆行测试 对帕金森氏病姿势不稳定性的良好评价 帕金森氏病杂志

Bollard Pull Test Procedure

How To Button Pull Test In Garments Production Of Goods A Garments Informative Article Site

Testing The Bond Strength Between Cold Bitumen Emulsion Composites And Aggregate Substrate Springerlink

Finish Coatings System Adhesion And Test Methods Resources Defelsko

Testing Protocols Florida Building Code

Pdf Analysis Of Bond Strength By Pull Out Test On Fiber Glass Posts Cemented In Different Lengths

About The Test Processing For Pull Off Strength Of Car Coating

Sd Tensile Bond Strength Of A High Performance Concrete Bridge Deck Overlay 9904 Mcl Project Reports Resources Mctc Concrete Materials Construction Technology Pavements Federal Highway Administration

Process Controls

Pullout Tests On Hardened Concrete

Pullout Test An Overview Sciencedirect Topics

Q Tech Com Wp Content Uploads Std 2 211 Pdf

Eriez Pull Test Kits

Www Brookes Ac Uk Uploadedfiles Faculty Of Technology Design And Environment School Of Engineering Computing And Mathematics Pagebuilder Pages Ecm Research Engineering Consultancy For Industry Pull Off Pdf

Single Channel Mode Parts List Tune Up Info Tkr 750 Tuning Procedure Kenwood Usa

Www Topline Tv Drawings Pdf Ccga Reference Ccga Solder Column Pull Test Mil Std 8k Tm38 Pdf

Http Www Hms Civil Uminho Pt Ibmac 00 67 Pdf

Q Tbn And9gcsoicyobj72utb3lwlektp Txgjsxa6c3rf9f6rf1ekp6pmcrj1 Usqp Cau

Www Engineersdaily Com 11 05 Pull Out Test Of Concrete Html

Pdf Evaluating Methods Of Underground Short Encapsulation Pull Testing In Australian Coal Mines

Recommended Test Methods Info Center Stonebtb Com

1100 Series Vwd Holmium Oxide Test Procedure Using Agilent

2

Apps Dtic Mil Dtic Tr Fulltext U2 A Pdf

Pull Test Presentation

Table 2 From How I Examine My Patient The Retropulsion Test A Good Evaluation Of Postural Instability In Parkinson S Disease Semantic Scholar

Www Engineersdaily Com 11 05 Pull Out Test Of Concrete Html

Pullout Test An Overview Sciencedirect Topics

Pull Test Standards And Methods Mecmesin

Stacks Cdc Gov View Cdc Cdc Ds1 Pdf

2

Eia 364 38 C Final

Pull Out Test Setup And Procedure Download Scientific Diagram

Bollard Pull Test Procedure Qvnd09kmdr4x

Variables Influencing The Pull Test 70 004 Fogra

Ms For Hydraulic Pull Out Test Hilti

Hot Pin Pull Method New Test Procedure For The Adhesion Measurement For 3d Mid Scientific Net

Q Tbn And9gcrsz6vvzdj6a3uaxsded5l K35vvy Pkouaxchzhbcbj5dfowuh Usqp Cau

Adhesive Pull Test Procedure Video

Http Onlinepubs Trb Org Onlinepubs Trr 19 11 11 004 Pdf

Reliability Of Pull Off Test For Steel Fiber Reinforced Self Compacting Concrete Sciencedirect

Ordnur Com Garments 2 Button Pull Test Sop Attachment Button Pull Test Sop For Apparel Industry

Www Ravenlining Com Wp Content Uploads 14 09 Adhesion Testing Coatings Pdf

Eia 364 38b Cable Pull Out International Electrotechnical Commission Electrical Connector

Construction Board Of Engineers Contractors Why Pull Out Test Is Necessary After Rebaring Work What Is Standard Procedure Of Pull Out Test

Marine Survey Practice Surveyor Guide Notes For Bollard Pull Tests

Www Ideadigitalcontent Com Files 155 Id Ins V2 Is 0810 Pdf

Special Tests

Www Codot Gov Business Designsupport Materials And Geotechnical Manuals 18 Fmm Cps Cp 60s 14 Cp 67 18

2

Pdf Pull Out Testing Of Geosynthetics Some Numerical Studies David A B Pereira Academia Edu

Bollard Pull Test Procedure Youtube

Nondestructive Testing Procedure To Evaluate The Load Carrying Capacity Of Concrete Anchors Journal Of Construction Engineering And Management Vol 142 No 5

Nondestructive Testing Procedure To Evaluate The Load Carrying Capacity Of Concrete Anchors Journal Of Construction Engineering And Management Vol 142 No 5

Main Factors Affecting Pullout Test Results Download Table

Pullout Test An Overview Sciencedirect Topics

Field Adhesion Testing Manualzz

Pull Test Presentation

Pig Signalling Switches Functional Testing Instrumentation Tools

Major Revision To Semi F104 Semi

Adhesives Design Toolkit

Astm D4541 And Iso 4624 Dfd Instruments

How To Conduct A Magnet Pull Test Pdf Free Download

Pull Off Test

Ocean Safety Rescueme Monthly Beacon Test Procedure 1 Datrex

2 Shows The Test Procedure Adopted In This Study For The Pull Out Test Download Scientific Diagram

Pull Out Test Setup And Procedure Download Scientific Diagram

Button Pull Test Procedure Archives Ordnur

Laticrete Com Media Support And Downloads Technical Datasheets Tds104 Ashx La En

Q Tbn And9gctagebk3cyo4kzy4vd3p Y463awgjpi6mcqk12si5z0orki15zi Usqp Cau

A Modified Laboratory Short Encapsulation Pull Test Thomas 12 Download Scientific Diagram

Arm Pull Thrust In Human Swimming And The Effect Of Post Activation Potentiation Scientific Reports

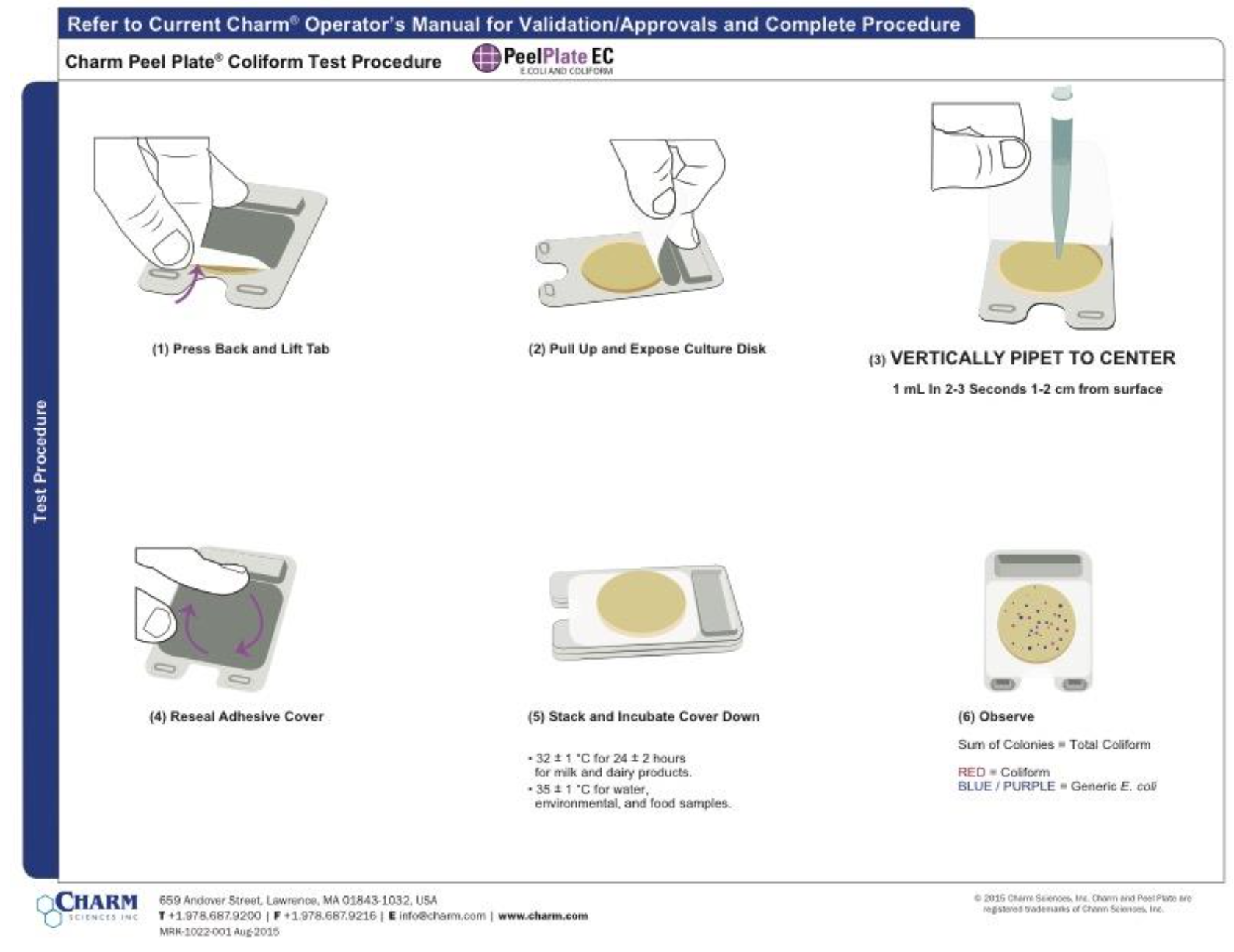

D Peel Plate Test Procedure Eesa01 Laboratory Manual Introduction To Environmental Science

Evaluation Of Concrete Spall Repairs By Pullout Test

Hot Pin Pull Method New Test Procedure For The Adhesion Measurement For 3d Mid Scientific Net

Pull Off Adhesion Of The Mortar Depending On The Test Procedure Download Scientific Diagram

Bollard Pull Test Procedure Ships Telemetry

Experimental Investigation On The Use Of Steel Concrete Bond Tests For Estimating Axial Compressive Strength Of Concrete Part 1

How To Perform Pull Tests On Crimped Wire Terminals Youtube

Field Adhesion Test For Use With Dow Corning R Brand Silicone

Safq Button Pull Test Machine Htp 005 Tony International Hk Co Ltd

Www Vbgov Com Government Departments Police Profstanddiv Documents Brieftestinstructionsandpreparationforcandidates Pdf

Bollard Pull Test Procedure Ships Telemetry

Www Statnett No Contentassets 511db4ed9affdedd14aadabf8 19 Guidelines For Quality Control Of Composite Insulators Pdf

Pull Off Adhesion Gauge Senze Instruments Benelux

Q Tbn And9gctaukolfb69ashmkd73vgnrrdszmlwmhmdpjrd Hw374akiuq4s Usqp Cau

Spill Box Test Procedure

Winch Test Procedure Pdf Document

2 Shows The Test Procedure Adopted In This Study For The Pull Out Test Download Scientific Diagram

Test Report For Acceptance Test Procedure For Pumping And Instrumentation Control Skid K Page 14 Of 129 Unt Digital Library

Citeseerx Ist Psu Edu Viewdoc Download Doi 10 1 1 4 8432 Rep Rep1 Type Pdf

Shank Button 100n Pull Test Youtube

Na Eventscloud Com File Uploads c0fbdb18cadbfec17de1ce3a3da403 1 Cbridges23 11 15 Pdf

2