Aluminium Casting Design

There are aluminum alloys tailored for permanentmold casting including 319, 356, A356, 413, and 535 In general, silicon (Si) is the most important alloying element for any aluminum casting.

Aluminium casting design. Aluminium casting method comparison – Pros and cons of different casting methods for aluminium parts Aluminium is a great material for producing metal parts, whether you have an entirely new product or need to produce more of an existing product when its demand is rising It is inexpensive and has great thermal and electrical conductivity. A location where metal is melted 2 The complete setup of equipment to melt and cast metal, esp for a backyard hobbyist Iron casting and waste oil fuel The Machines Melting Iron Melting iron is no longer the domain of industial enterprises An individual can build a blast furnace and melt it in their backyard I've done it!. Reyazkhan1@yahoocom * Corresponding author Phone Abstract The main problems caused by improper gating are entrained aluminium oxide.

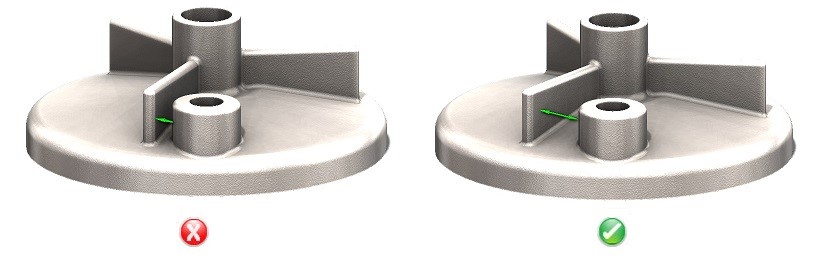

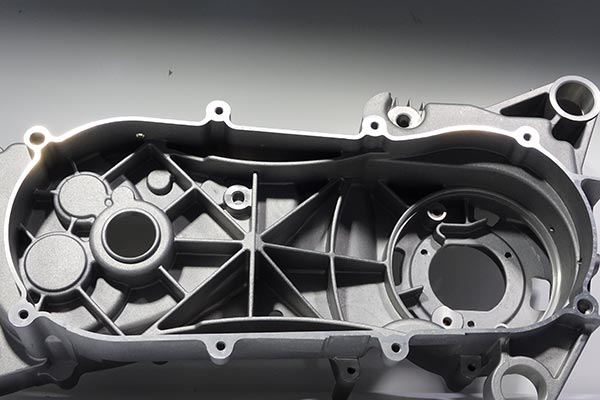

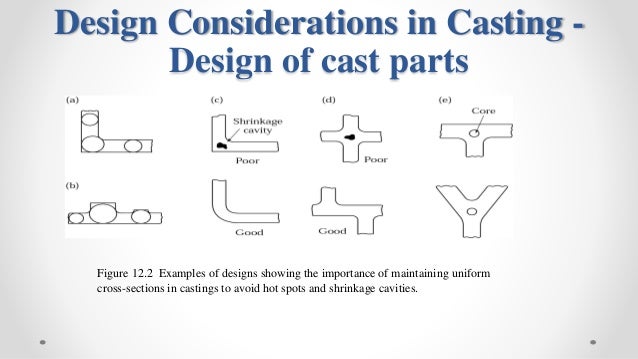

Improper rib, web and corner design can lead to sink spots In general web or wall thickness should as a minimum be 010" Aluminum, 13 Magnesium and 13 for SteelSee Casting Rib Design for additional information Sand Cast Tolerance Chart. Aluminum Design Die Casting Die Casting Design FAQ High pressure die casting is a fast, repeatable process that delivers quality metal components, every time—but only if your component is designed properly There are many factors that go into a successful design for highvolume manufacturing and our team of engineers helps thousands of. Design for Minimum Casting Stress Aluminum alloy castings contract approximately 3/325/32 in/ft during cooling to room temperature If the design configuration is such that the mold or core effectively restricts this normal contraction during cooling, the casting might crack or develop hot tears while in the mold.

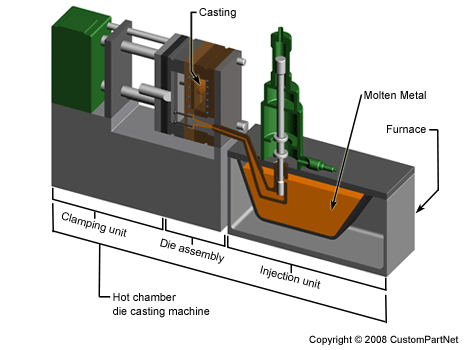

The element aluminum (Al) has a specific gravity of 27, placing it among the lightweight structural metals It is used as a base for die casting alloys with three primary constituents silicon, copper and magnesium Eight available aluminum die casting alloys give the designer the widest choice among the four primary alloy groups, and they. Casting defects and their remedies (14 classes) Metal forming processes Various metal forming techniques and their analysis, viz, forging, rolling, extrusion, wire drawing, sheet metal. As in most casting processes, draft, radius, and wall thickness are the main design elements critical to good castability Our engineering staff is available around the clock to help you get the most out of your investment.

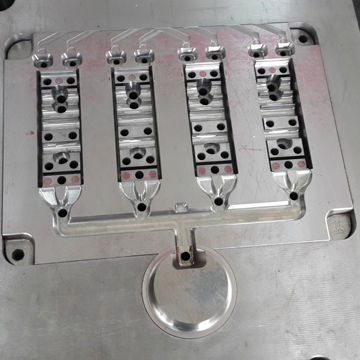

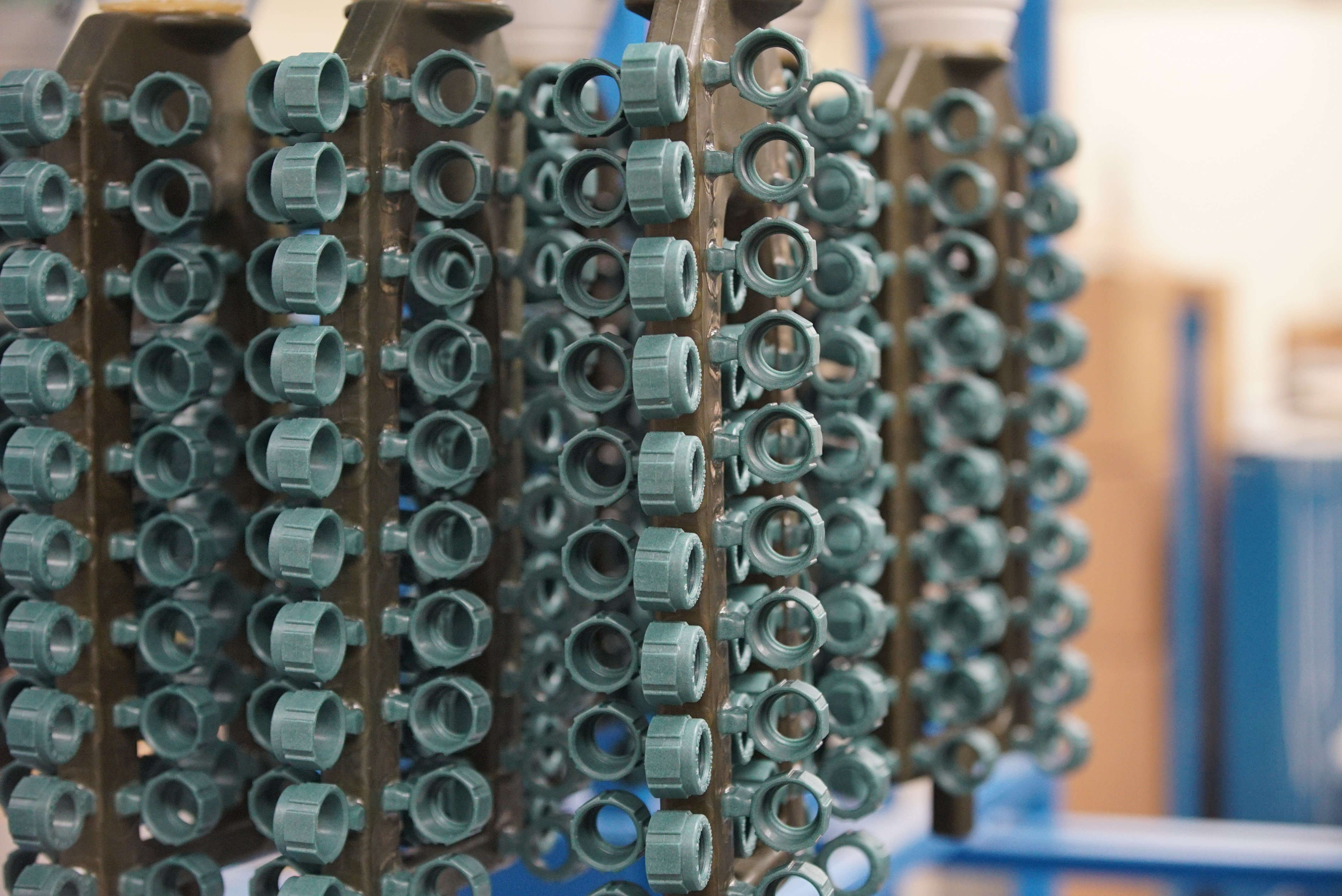

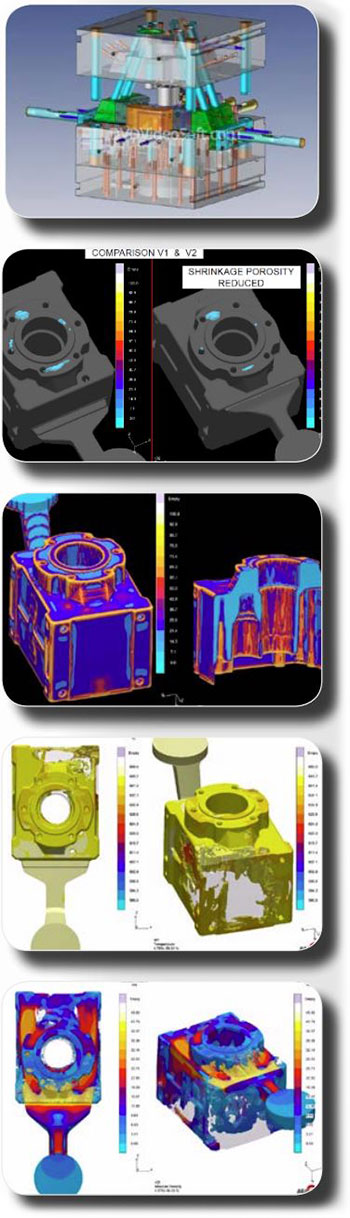

O eform technology co,ltd is one of the leading manufacturers of highquality Aluminium and zinc base die casting components across China Our product range includes high pressure die castings, gravity castings,Investment Casting and sand castings & hot chamber die castingAll our casting products are manufactured according to international quality and safety standards, using best grade raw. Permanent mold aluminum castings "A Better Way to Cast Aluminum" & "An Example of Mold Tolerances" as featured in Machine Design Magazine Written by Arun K Gupta, Gupta Permold Corp "Permanent Mold Castings Pathway to Quality" from Technology Tips reprinted from MetlFax Magazine. Riser design is very important in metal casting manufacture If the passage linking the riser to the metal casting solidifies before the casting, the flow of molten metal to the casting will be blocked and the riser will cease to serve its function If the connection has a larger cross sectional area it will decrease its time to freeze.

Campbell’s Complete Casting Handbook Metal Casting Processes, Techniques and Design, Second Edition provides an update to the first singlevolume guide to cover modern principles and processes in such breadth and depth, while also retaining a clear, practical focus The work has a unique viewpoint, interpreting the behavior of castings, and metals as a whole, in terms of their biofilm. Campbell’s Complete Casting Handbook Metal Casting Processes, Techniques and Design, Second Edition provides an update to the first singlevolume guide to cover modern principles and processes in such breadth and depth, while also retaining a clear, practical focus The work has a unique viewpoint, interpreting the behavior of castings, and metals as a whole, in terms of their biofilm. 113 Casting Terminology Pattern approximate duplicate of the part to be cast Molding material material that is packed around the pattern to provide the mold cavity Flask rigid frame that holds the molding aggregate Cope top half of the pattern Drag bottom half of the pattern Core sand or metal shape that is inserted into the.

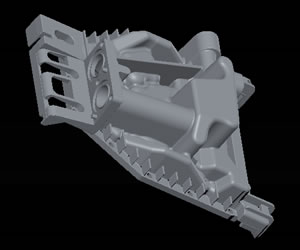

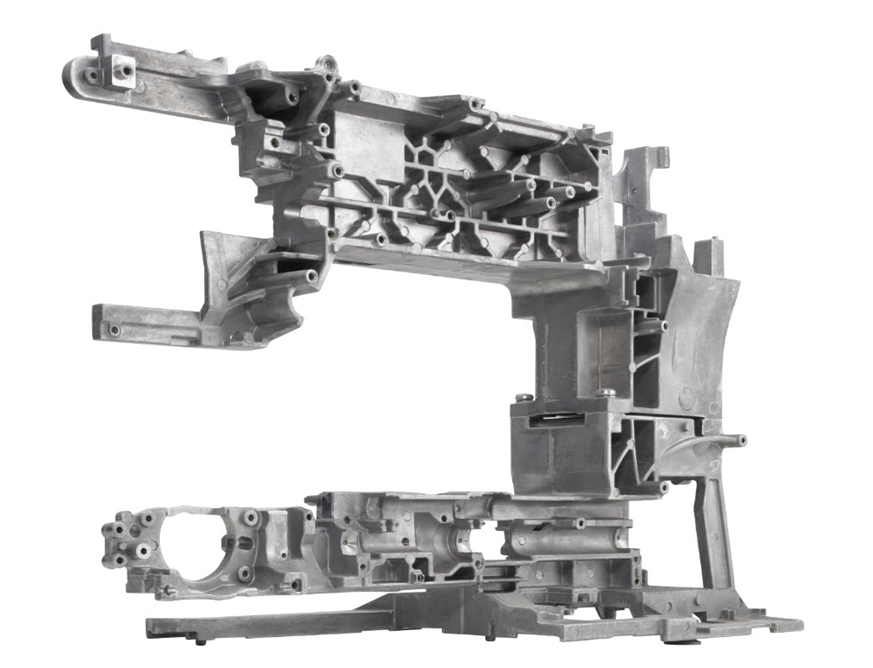

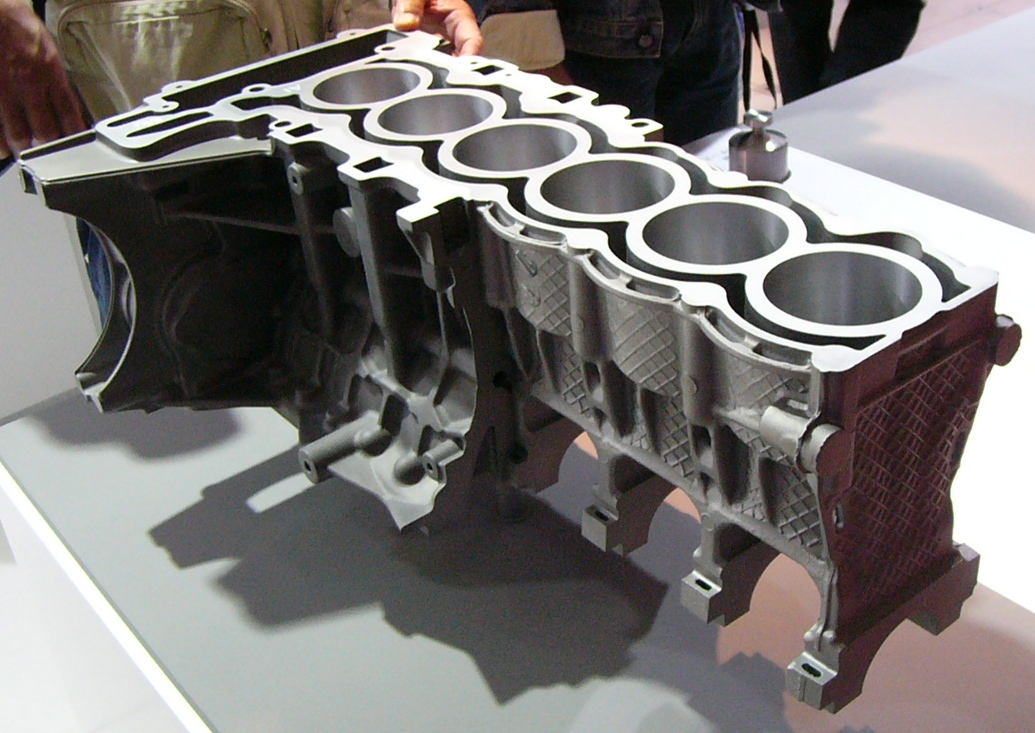

Very flexible process with high productivity for the manufacture of aluminium castings Automatic patternchange stations enable complete sets to be changed within the cycle time For automotive applications, the process is used to cast. Aluminum die casting alloys are lightweight and possess high dimensional stability for complex part geometries and thin walls Aluminum has good corrosion resistance and mechanical properties as well as high thermal and electrical conductivity, making it a good alloy for die casting. The die injection equipment is large and operates at pressures of 100 megapascals However, aluminum can be cast at relatively lower pressure A welldesigned metal diecasting can yield over 500, 000 workpieces in its production lifetime The high number of castings helps offset the high cost of the dies.

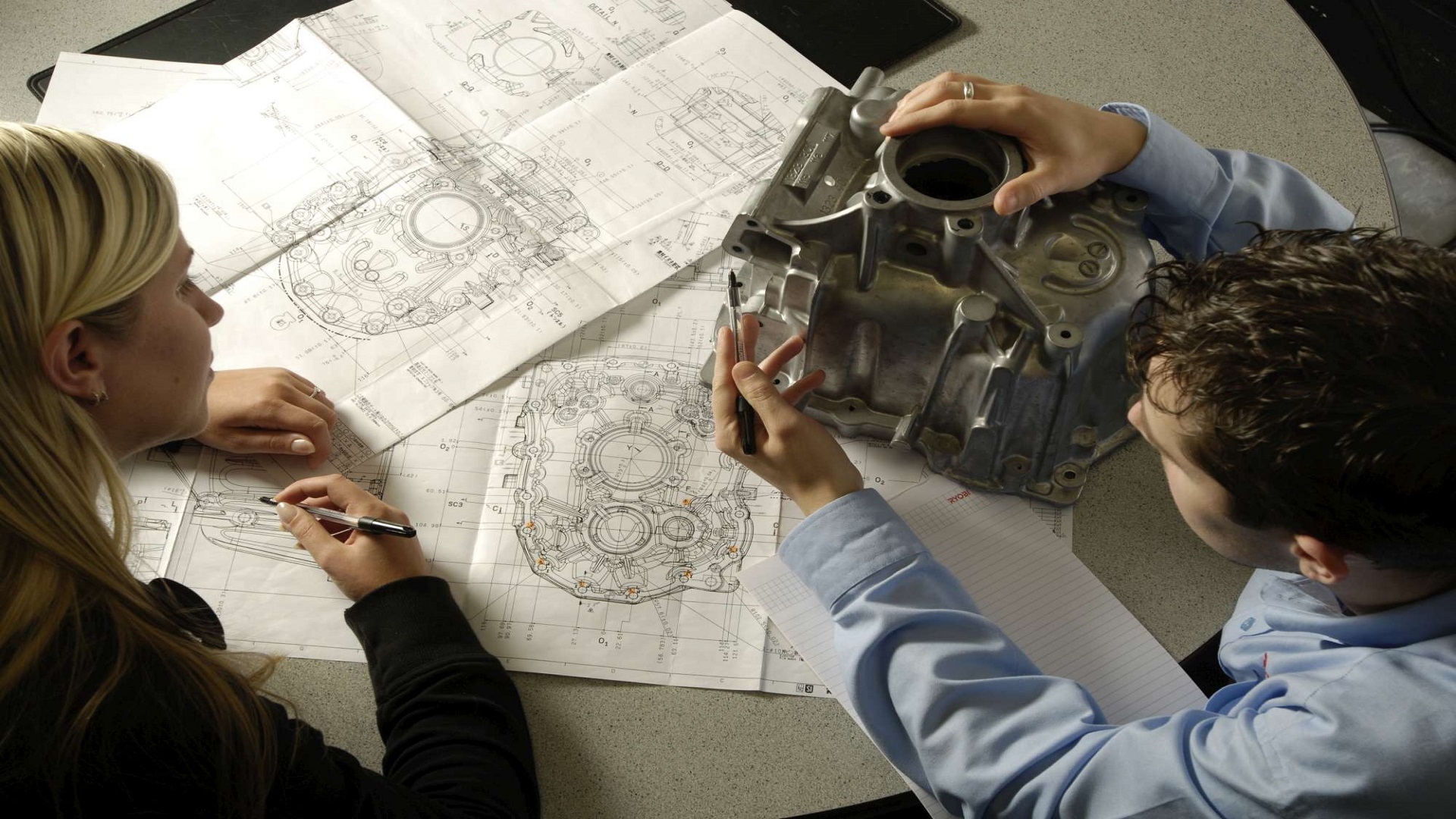

Design Considerations in Casting Design of cast parts • Corners, angles and section thickness avoid using sharp corners and angles (act as stress raisers) and may cause cracking and tearing during solidification Use fillets with radii ranging from 3 to 25 mm 6. View 4 Metal Casting Designpdf from ENGIEERING 211 at Cairo University Metal Casting Design, Materials, & Economics Design Considerations • Developed over many. Aluminum die casting has its own video here, where we explore what this metal provides as a die casting material, and look in detail at the cold chamber cast.

CWM created these comprehensive guidelines to aid you when designing for die casting, whether it is for aluminum, magnesium, or zinc alloys Each design guide incorporates over 75 years of CWM’s die casting knowledge into a condensed guide for the OEM product design engineer. Looking for Cast Aluminum and Iron Part or Casting Tooling Foundry Design Solution?. Welcome to contact us We supply Street Lighting Base, Street Sign Base, Fence, Table, Chair, Bench Furniture Part, Mailbox Post, Garden Decoration, Gate, Fireplace Casting.

The traditional green sand casting process, combined with highspeed moulding lines, is a very flexible process with high productivity for the manufacture of aluminium castings Automatic patternchange stations enable complete sets to be changed within the cycle time For automotive applications, the process is used to cast. Diecasting is our forte and hence we do not outsource any of our high pressure diecasting production Our experienced diecasting team operates industry standard cold chamber German and Japanese machines ranging from 135 tonnes to 840 tonnes We have the capability to cast various aluminium specifications such as A360 ADC12, A380 and N14. There are aluminum alloys tailored for permanentmold casting including 319, 356, A356, 413, and 535 In general, silicon (Si) is the most important alloying element for any aluminum casting.

Innovative mould designs can deliver a host of productivity and value benefits, streamlining casting and expediting subsequent production processes As the mould life had come to an end, Aluminium Die Casting SRL carried out a total mould redesign for Bauer Gear Motor, delivering compound benefits of increased longevity, ease of production, lean maintenance, reduced wastage and improved cost. Methods/Casting Design Eng Casting Process • Pattern • Mold • Molten Metal / Pouring • Cooling / Shakeout • Cleaning / HT • QC • Machining – Added value Pattern Making 1 Casting Design –PL, draft, shrink, mach stock, tolerances, machine locators 2 Rigging risers, gating system, chills, vents. Amazing Cast Aluminum Process Using Sand Mold, Fast Melting Metal Casting Technology Working.

Casting Design Handbook INTRODUCTION The casting industry is one filled with mystery, science and art Founding is the second oldest profession Castings dating back to at least 4000 BC were made in ancient China In spite of that fact, it is a business that can be mysterious and intimidating to an outsider. Background Aluminium casting processes are classified as Ingot casting or Mould casting During the first process, primary or secondary aluminium is cast into rolling ingot (slab), extrusion ingot (billet) and wire bar ingot which are subsequently transformed in semi and finished products. Metal castability There are four main metal characteristics that affect the outcome of a casting design Fluidity is the ease with which various metals flow in a molten stateThe more fluid a metal is when liquid, the better it can capture small details within a mold.

What is Casting Shrinkage Casting shrinkage is the percentage reduction in the dimensions of the casting compared to the dimensions of the pattern Shrinkage occurs when the liquid aluminium in the mould cools and continues cooling after solidification Casting shrinkage is a source of stresses and cracking. Never Mind even if you don’t have any experience in Aluminium Alloy Casting Area, we offer design and Material suggestion to you we are your partner, as well as your guidance Design You have the detail 2D and 3D mold design drawing and Mold flow analyze report from die cast mold maker. Good aluminum die casting design is the first step in your die casting project,17 years experince china syx diecasting company help you success.

ALUMINUM CASTINGS US Aluminum Castings is a precision aluminum casting supplier located in Central Washington State As a full service foundry, we offer multiple casting processes as well as inhouse heat treat, machining, powder coating, and NDT Our castings are used in defense, aerospace, heavy truck, marine, and commercial applications. Aluminum Prototype Casting Tips for Design Engineers Electronic Enclosure Prototype The prototyping information in these pages was assembled for design engineers involved in the design of an aluminum part destined to be die cast It is our hope that you will find something of value, or be reminded of things learned long ago. Manufacturer of Aluminium Casting Aluminium Design Casting offered by K M Enterprises, Jaipur, Rajasthan K M Enterprises Krishna Vihar, Jaipur, Rajasthan GST No 08DGFPS9577G1ZL TrustSEAL Verified Call 76% Response Rate SEND EMAIL.

Carve or sculpt the wax into the shape you want to cast in aluminum The process used for casting aluminum with plaster molds is called lost wax casting In this process, a model of the desired object is made of wax and coated in plaster After the plaster has dried, the wax is melted out of the mold and replaced with aluminum. SJ Die Casting & Machining offers a one stop shop capability from design, to prototype and production for CNC machined parts of many different materials including Aluminum and Zinc Die Casting from all over the world SJ Die Casting & Machining delivers top quality castings, prototype and production machining of any material needed, in any. The concept paper "Aluminum casting Success story part 2" created by Johannes Messer Consulting describes the past, comments on the present and motivates for the future of the aluminum casting industry We spoke to business owner Johannes Messer about the contents, findings and recommendations of the paper.

We began as pattern makers and today offer complete design assistance for wood and metal patterns, including close tolerance aluminum castings Our specialized knowledge enables us to meet customer needs for aluminum sand castings requiring up to seven cores. Parting Line The parting line is where the two halves of the die casting die meet on the part geometry CAD draft analysis is a quick and powerful way to help design and view the parting line of a die cast part model. Aluminum can be cast into nearly any shape resulting in castings of sculptures, art pieces or even tools Although casting aluminum involves very high heat and molten metal, it can be done at home with relatively little equipment Many people around the world cast aluminum, and many useful items have been produced by.

Metal casting can truly be a great solution for producing small metal parts with precious metals From jewelry and decorative elements to watches, you can experience new design freedom for metal casting thanks to 3D printing. The oldest types of molds for aluminum casting are the molds that have been used since the time of the Egyptians These types of molds are made when a cavity is created in sand that is held in a box or “flask” Usually the original “pattern” is made out of wood, metal or other solid material. Casting investment casting, pressure die casting, centrifugal casting, continuous casting, thin roll casting;.

Riser design 1 Risers help to feed liquid metal into the last portion of the casting Proper placement of the risers on castings changes the way in which both the casting and riser(s) solidify such that the riser is the last to solidify 2 When designed correctly, a casting that’s free of shrinkage will be. "I find it (Aluminum Castings Engineering Guide) to be an excellent book on aluminum castings covering the entire gambit from casting design, application in various fields, engineering aspects, alloy selection, and the limitations and advantages of different casting processes This book is strongly recommended as a standard guide for practical. Manufacturer of Aluminium Casting Aluminium Design Casting offered by K M Enterprises, Jaipur, Rajasthan K M Enterprises Krishna Vihar, Jaipur, Rajasthan GST No 08DGFPS9577G1ZL TrustSEAL Verified Call 76% Response Rate SEND EMAIL.

Looking for Cast Aluminum and Iron Part or Casting Tooling Foundry Design Solution?. Standards For Aluminum Sand and Permanent Mold Castings ENGINEERING SERIES (E) AACSE1966 METAL THICKNESS Many conditions and affect the ability of foundries to cast to a desired metal wall thickness ie fluidity of alloy (2) metallurgical quality (3) design (4) surface finish or mold The figures in the graph show desired minimum metal thickness that should be s*cified for aluminum castings Of minimum complexity. Aluminum Prototype Casting Tips for Design Engineers Electronic Enclosure Prototype The prototyping information in these pages was assembled for design engineers involved in the design of an aluminum part destined to be die cast It is our hope that you will find something of value, or be reminded of things learned long ago.

Welcome to contact us We supply Street Lighting Base, Street Sign Base, Fence, Table, Chair, Bench Furniture Part, Mailbox Post, Garden Decoration, Gate, Fireplace Casting. Gating System Design for Casting thin Aluminium Alloy (AlSi) Plates Victor ANJO 1* and Reyaz KHAN 1 1 Department of Mechanical Engineering, Federal University of Technology Minna Niger, State Nigeria Emails victoranjo08@livecom *;. The oldest types of molds for aluminum casting are the molds that have been used since the time of the Egyptians These types of molds are made when a cavity is created in sand that is held in a box or "flask" Usually the original "pattern" is made out of wood, metal or other solid material.

Backyard Metal Casting and Homemade Forges For thousands of years, man has worked metals Although some of the technology to work metals is relatively recent, the initial human drive to create is still with us. Aluminium casting industry in India Since 19, VJP Aluminium Foundry At VJP we have over 38 year's experience in producing high quality precision aluminium castings in IndiaWe provide highprecision Defense Castings, aerospace castings, gravity die casting, sand casting aluminum and Greensand casting for a broad range of performancecritical industries. Aluminum die casting has its own video here, where we explore what this metal provides as a die casting material, and look in detail at the cold chamber cast.

Aluminum casting at home is so fun and amazing A simple process can let you create a lot of things only limited by your skill and imagination Right from designing and pattern creation to mold making, all the processes can be performed easily at home. Learn More About Quality Die Casting Design For more than 70 years, Premier Die Casting has provided highquality metal forming services to a wide range of industries Our aluminum casting expertise is unmatched and we can design just the die casting you need for highquality parts for all your applications every time To find out more about. Casting is the original and most widely used method of forming aluminum into products Technical advances have been made, but the principle remains the same Molten aluminum is poured into a mold to duplicate a desired pattern The three most important methods are die casting, permanent mold casting and sand casting.

Die Casting Design Tips Dfm Tips For Die Cast Parts

Gf Casting Solutions Georg Fischer Ltd

Die Cast Design Aluminum Die Casting Design Guide

Aluminium Casting Design のギャラリー

Casting Design Guidelines By Dfmpro

Die Casting Design Guide And Tips With China Aluminum Die Casting Company Experience

Castech Uk Ltd Casting The Unexpected Precision Castings From Castech Uk

Aluminum Casting Design Gate At Rs 230 Kilogram Aluminium Gate Id

Electric Modern Design Louver Aluminium Casting Gates Buy Aluminium Casting Gates Louver Aluminum Gates Casting Gates Product On Alibaba Com

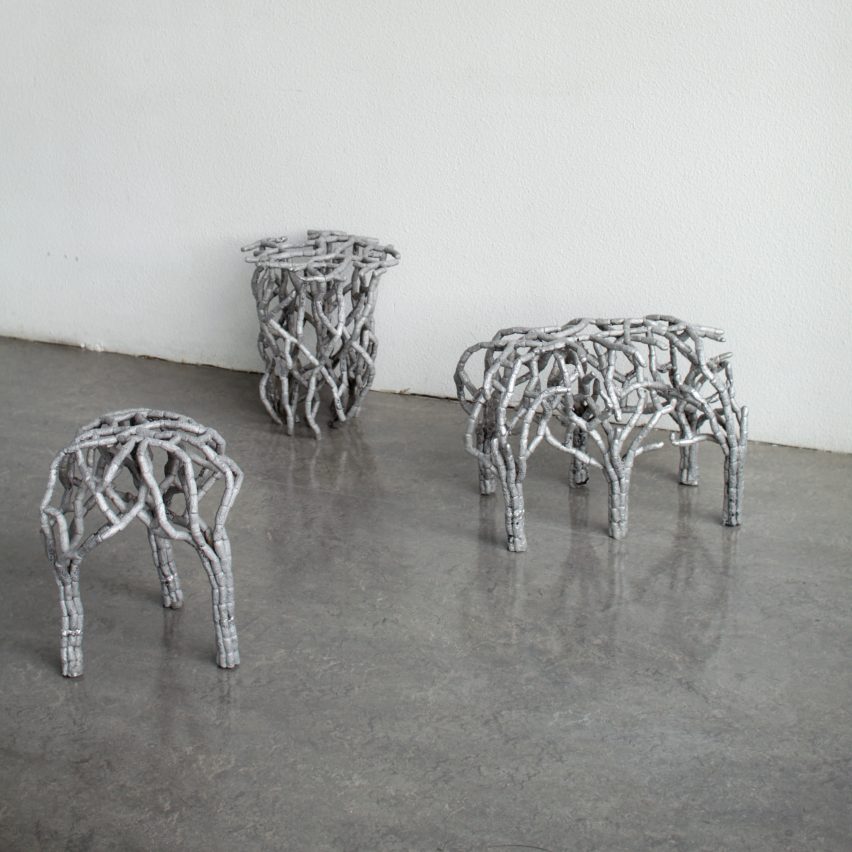

Hilla Shamia Casts Tree Trunks In Aluminium To Create Dramatic Furniture

What S The Difference Between Investment Casting And Sand Casting Machine Design

Aluminium Casting Fancy Door Flower Design Steel Mold Flowers For Steel Door Casting Mold Casting Youtube

Die Casting Design Die Casting Mold Design Parison Die Casting

What S The Difference Between Investment Casting And Sand Casting Machine Design

Aluminum Casting Rose Design Double Faced 10 W 25 3 8 H 5 Lbs

Aluminium Die Casting Innovation Pro Active Mould Re Design

Michigan Based Aluminium Die Caster Acquires Accuride Corp S Brillion Iron Works

House Number Cast Aluminium Lion Design Rectangular Door Etsy

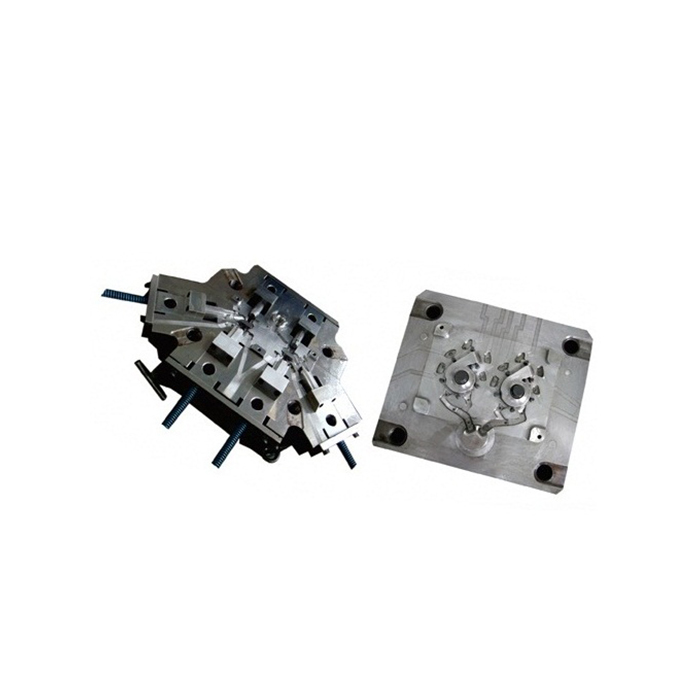

Die Casting Mold Design

Aluminium Casting Mold Design And Manufacturer Global Sources

Die Casting Design Tips Dfm Tips For Die Cast Parts

Aluminium Casting Method Comparison Pros And Cons Of Different Casting Methods For Aluminium Parts Alteams Aluminium Casting Method Comparison Production Volume Matters

Die Casting Design Wall Thickness Tolerances

Die Casting Design Wall Thickness Tolerances

Top Ten Aluminium Casting Manufacturers In The World

Die Casting Wikipedia

Designer Aluminum Casting Aluminium Castings Aluminium Casting Machining एल य म न यम क स ट ग Balaji Metal Casting Jaipur Id

3d Design Drawings Car Die Casting Tool Design Aluminium Mold Making

Die Casting Design Guide Materials Advantages And Disadvantages Engineeringclicks

Chinese Exporting Professional Design Sophisiticated Techonology Aluminum Automotive Die Casting China Aluminium Die Casting Big Mould

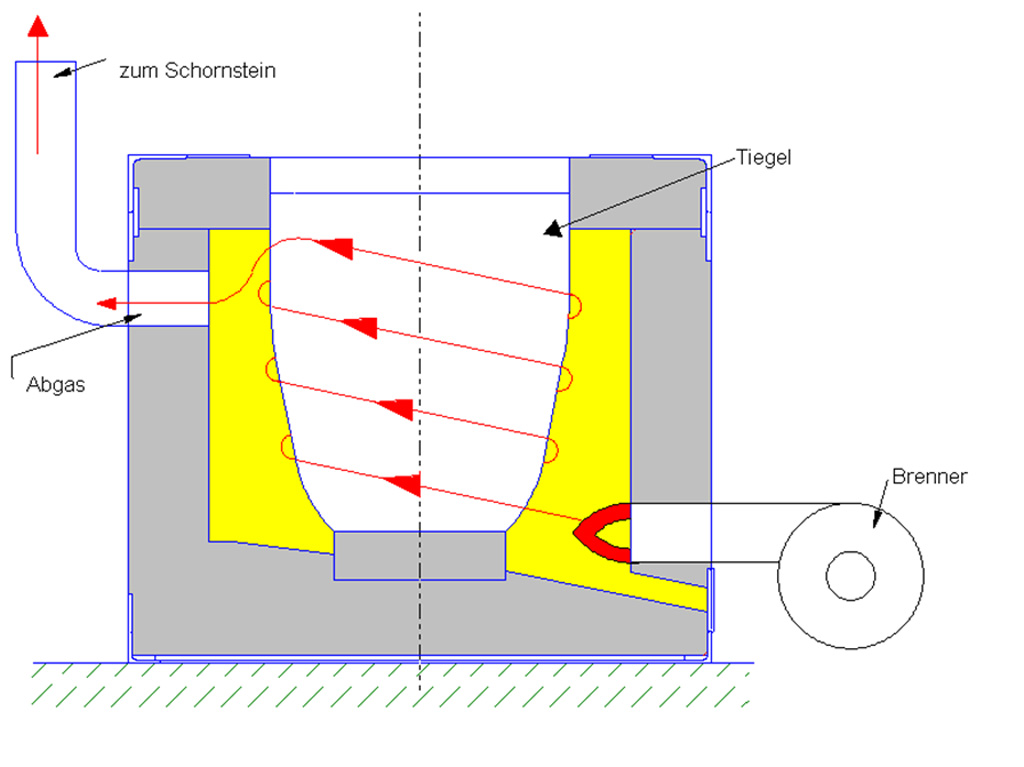

Aluminium Melting Furnaces For Die Casting Foundry Planet Com B2b Portal

Product Design Optimization For Good Casting Quality

Young Designers Make Aluminium Furniture Desirable For Design Collectors

Die Casting Tolerances Tolerance For Metal Parts Dynacast

Aluminum Die Casting Design Drawer Door Furniture Aluminium Kitchen Square Pull Handle Buy Cabinet Cupboard Drawer Bedroom Fitting Furniture Handle Aluminium Die Casting Handle 96mm 128mm 160mm 192mm 224mm 256mm Pull Accessory

Custom Design Adc 12 Aluminium Die Casting Led Cup Oem Die Casting Factory Buy Customized Die Casting Led Housing Oem Die Cast Aluminum Light Parts High Quality Aluminium Housing Product On Alibaba Com

Casting Metalworking Wikipedia

Hong Kong Awards For Industry Die Casting Unit Wins

Die Casting An Overview Sciencedirect Topics

Asian Steel Fabrications

Aluminium Casting Design Designed By Whistle Design Group

Die Casting Runner Gate Design Study Case References Upmold

Functions Of Aluminium And Zinc Casting By Lishinmech Issuu

Novel Sprue Designs In Metal Casting Via 3d Sand Printing Sciencedirect

Pdf Complete Simulation Of High Pressure Die Casting Process

Max Weld Inc Aluminum Casting Designs

Aluminium Casting A Relief Wall Kikukawa

Quot Back To The Future Quot Using Generative Design Amp Investment Casting

China 17 China New Design Aluminium Die Casting Housing Die Cast Aluminium Radiator Matech Manufacturers And Suppliers Matech

Light Building Exhibitors Products Hangzhou Hpwinner Opto Corporation Customized High Quality Outdoor Lamp Holders Aluminium Die Casting Part Led Street Light Housing Lampshade

Bauer Gear Motor Adds Aluminium Die Casting To Its Capabilities 18 07 13 Packaging Strategies

Latest Design Joran Pancing Aluminium Casting Scrap Buy Joran Casting Joran Pancing Casting Aluminium Casting Scrap Product On Alibaba Com

Design And Manufacture Of Die Casting Moulds For Aluminium And Magnesium Areas Agmma

Environmental Benefits Of Non Ferrous Casting Light Alloy Engineering

Die Casting Design Guide And Tips With China Aluminum Die Casting Company Experience

Pin On China Furniture Cast Design Manufacturer

Die Casting Runner Gate Design Study Case References Upmold

Aluminum Mailbox Product Name Mailbox Made By Aluminium Casting Materials Aluminum Alloy A356 T 6 Design Solutions Mailbox Installation Casting Materials

Powder Coating Aluminium Casting Design Rs 230 Kg Suman Casting Id

Aluminium Hindustan Casting Works

Key Sand Casting Design Considerations

Die Casting Design And Spec Guide Pdf Casting Metalworking Engineering Tolerance

Moulding Design And Manufacturer Aluminium Die Casting China Aluminium Die Casting Die Casting Made In China Com

Kastking Cadet Spincast Fishing Reel 3 1 1 Gear Ratio Trouble Free Push Button Bait Casting Design With 100m 10lb Nylon Line Lazada Singapore

Bay Metals Products Aluminium Casting Designs

1

Investment Casting Vs Die Casting 7 Considerations When Choosing A Process

Porosity In Pressure Die Casting

Aluminium Casting Fancy Door Flower Design Steel Mold Flowers For Steel Door Casting Mold Casting Youtube

Q Tbn And9gcsxui9t0lu0v Dcgvrxnhzcxz2muh9 A0hddnimhcf5fk0ee1vyygkzcdckmbhvqpmtcos65jwj5s1jqwfpzzu67ek45ql Hw Usqp Cau Ec

Recycling Aluminium Die Casting With Smooth Textured Surface Custom Design Supported

Aluminium Die Casting Innovation Pro Active Mould Re Design

Aluminium Die Casting Runner Gate Design From China Manufacturer Sunrise Metal Technology Co Ltd

Die Casting In Aluminium And Magnesium Prototypes And Small Series

Gf Casting Solutions Georg Fischer Ltd

Aluminium Casting Techniques Sand Casting And Die Casting Processes

Knowledge Of Aluminium Casting And Flowers Table

China Cheap Aluminium Keychain Bottle Opener Die Casting Design China Bottle Opener And Keychain Bottle Opener Price

Design Of Castings And Selection Of The Parting Line

Few Design Tips For Die Casting Any Part Design Either Made Through By China Casting Medium

China Customized New Design Aluminium Cast Metal Gravity Die Casting Parts China Motorcycle Spare Parts Aluminum Casting

Die Casting Design Guide Materials Advantages And Disadvantages Engineeringclicks

Die Casting An Overview Sciencedirect Topics

Aluminium Casting China Aluminium Die Casting Manufacturer

Cast Aluminium Stair Case Elegant Desigen Dunia Ul Abwab Aluminium Casting Doors Facebook

Young Designers Make Aluminium Furniture Desirable For Design Collectors

Die Cast Mould Designer With 3d Solidworks

Die Casting Design Tips Dfm Tips For Die Cast Parts

Structural Design Requirements For Aluminum Alloy Die Castings Emp Tech Co Ltd

Aluminium Die Casting Boqiao Machinery

Aluminium Design Die Casting Aluminium Pressure Die Castings Aluminum Die Casting एल य म न यम ड ई क स ट ग In Nangal Jaisabohra Jaipur Suman Casting Id

1

China Popular Design For Aluminium Casting Company Adc12 Motor Bearing Cover Diecasting With Sand Blasting Hexin Manufacturer And Supplier Hexin

Die Casting Process Defects Design

China 19 China New Design Aluminum High Pressure Die Casting Part Aluminium Hign Pressure Die Cast Junhua Factory And Manufacturers Junhua

Die Casting Wikipedia

Molten Aluminium And Wood Combine To Create Beautiful Furniture Designs Contented

Aluminum Casting At Rs 230 Kilogram Vki Area Jaipur Id

Mdk Machine Design Die Aluminium High Pressure Die Casting Dies

Defects In The Aluminium Die Casting Design By Dynacast Technologies Issuu

China Oem Factory For Mould Tool Design Aluminium Die Casting Mold And Custom Castings Mould And Chinese Aluminum And Tooling Mould Mold Haihong Factory And Manufacturers Haihong

3d Cad Design Die Casting Products With Aluminium Die Casting Process For Sale Precision Casting Parts Manufacturer From China

Typical Ingot Wheel Design For Casting Aluminium Ingots Showing The Download Scientific Diagram

Die Casting Runner Gate Design Study Case References Upmold