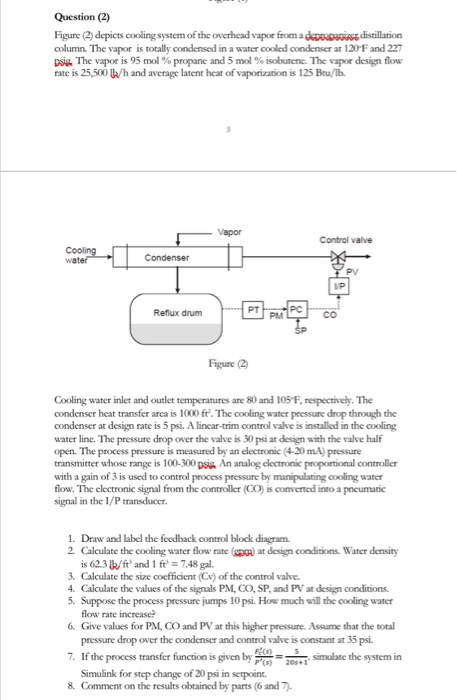

Reflux Condenser Water Flow

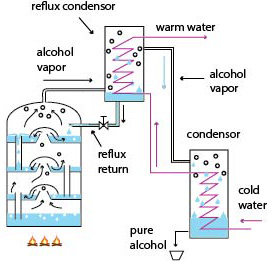

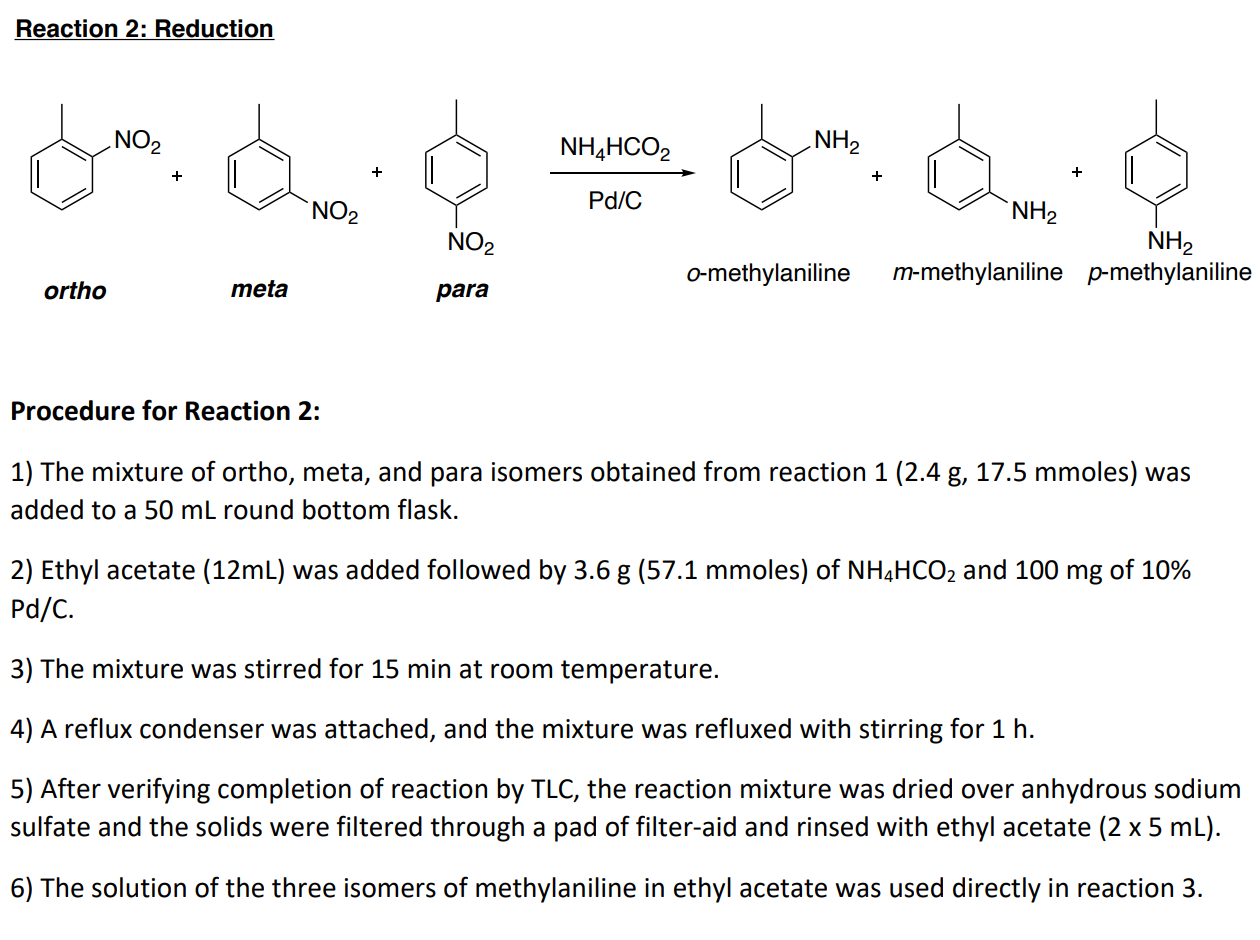

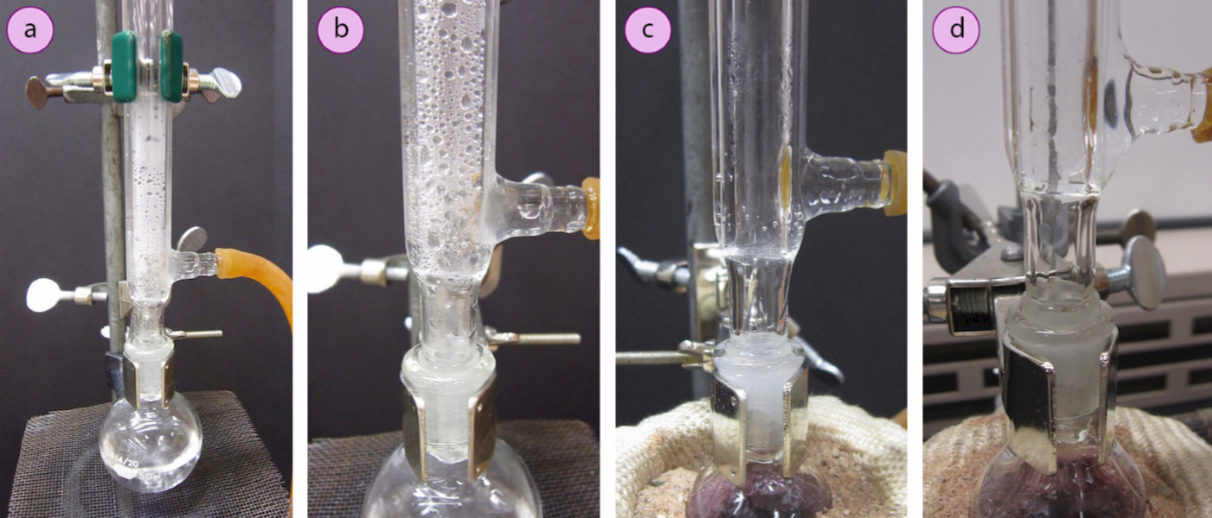

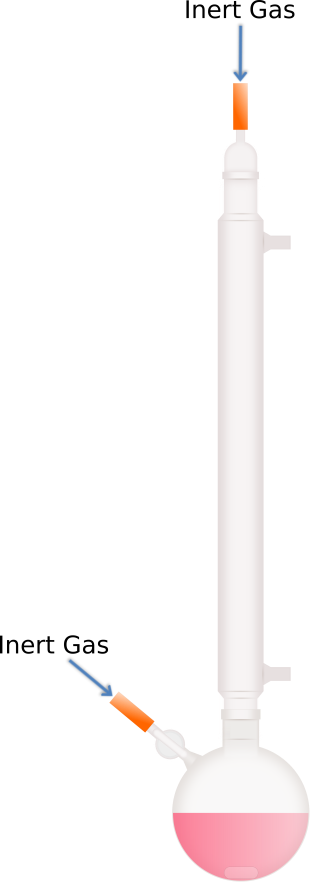

In a reflux apparatus the liquid starts boiling after heating and gets converted to vapors , these hot vapors gets cooled and condense while going up by a waterjacketed condenser Little liquid gets lost on account of evaporation and a persistent temperature is maintained which is equal to the boiling point of the liquid inside the reflux flask.

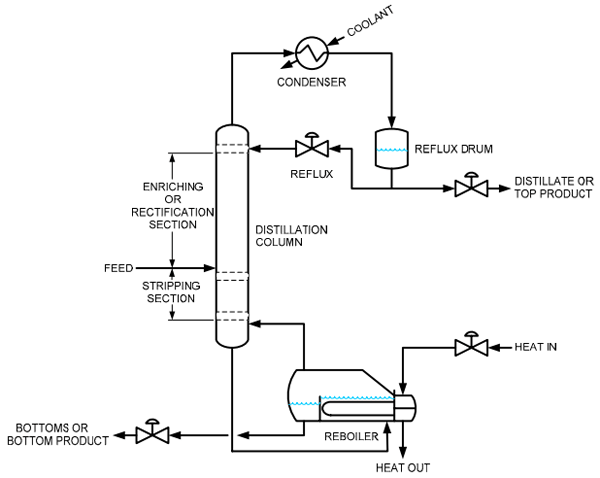

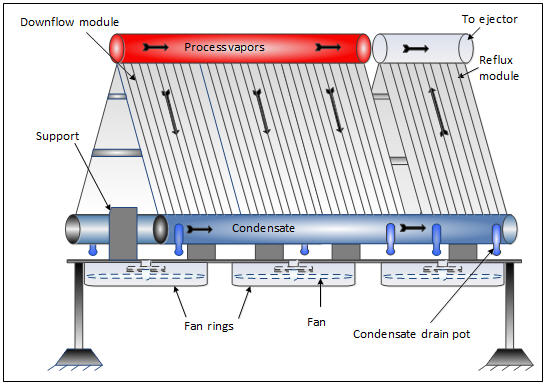

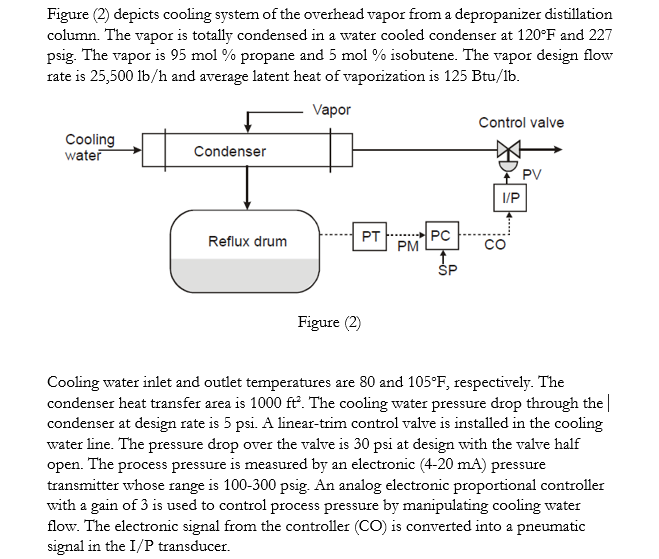

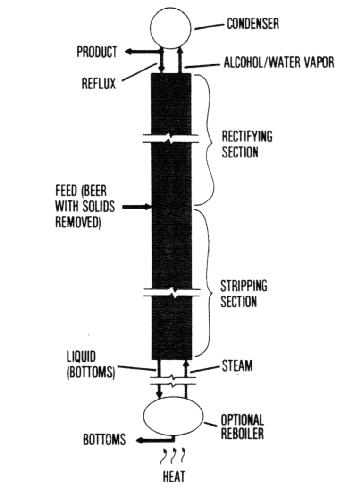

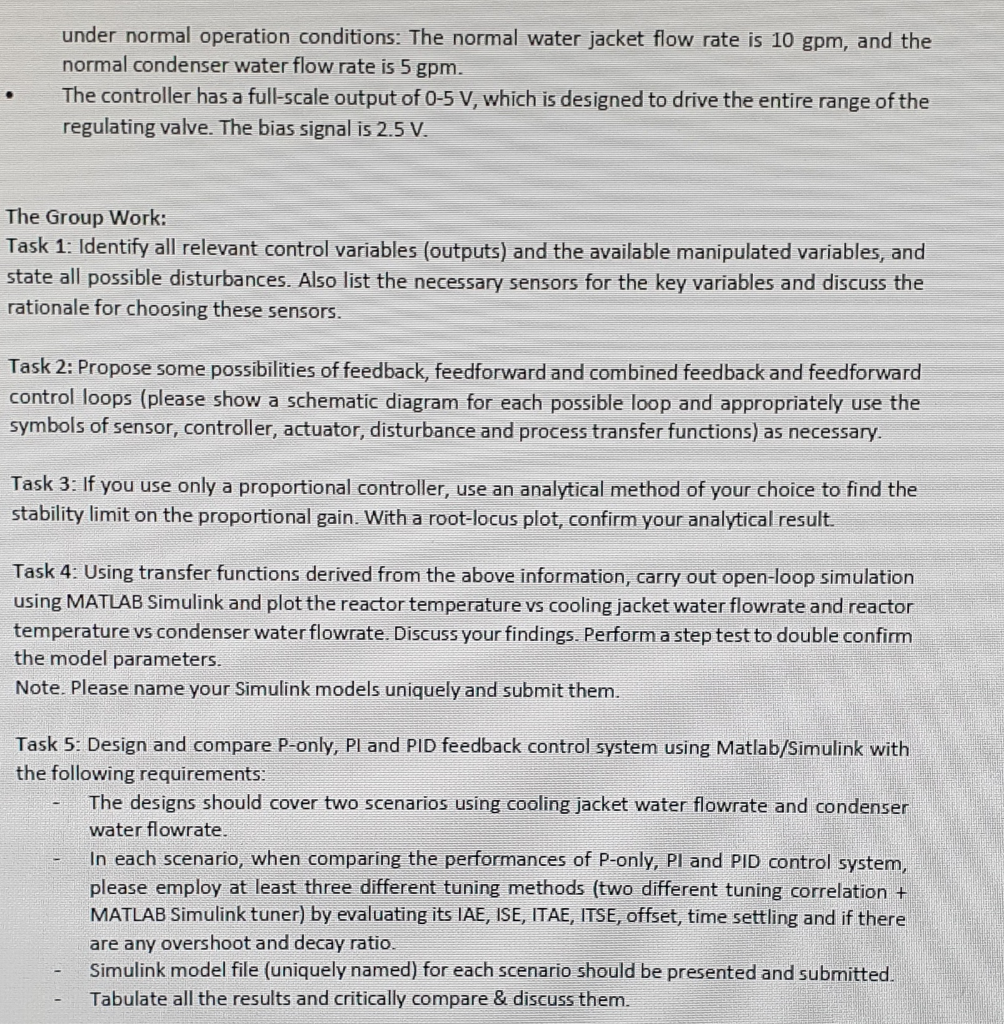

Reflux condenser water flow. The speed of distillation, and therefore the reflux ratio, is controlled by the speed and temperature of the cooling water being run through the lines In the past, most of these designs used two cooling lines, one in the middle to lower portion of the column and another directly above it near the top of the column. Water is contained the glass cylinder;. Since fundamentally at a fixed overhead product rate, condenser pressure and temperature the water vapor content is fixed Thus a greater total overhead flow is needed to transport water as vapor out of the column to be condensed into the reflux drum and removed Greater total overhead means larger condenser duty.

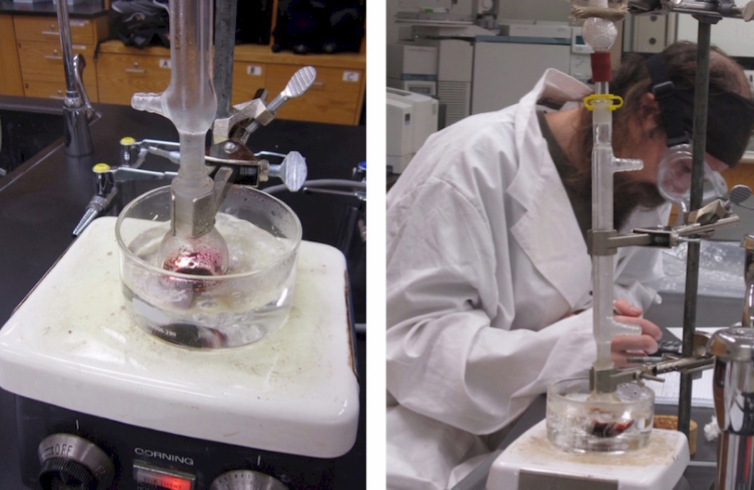

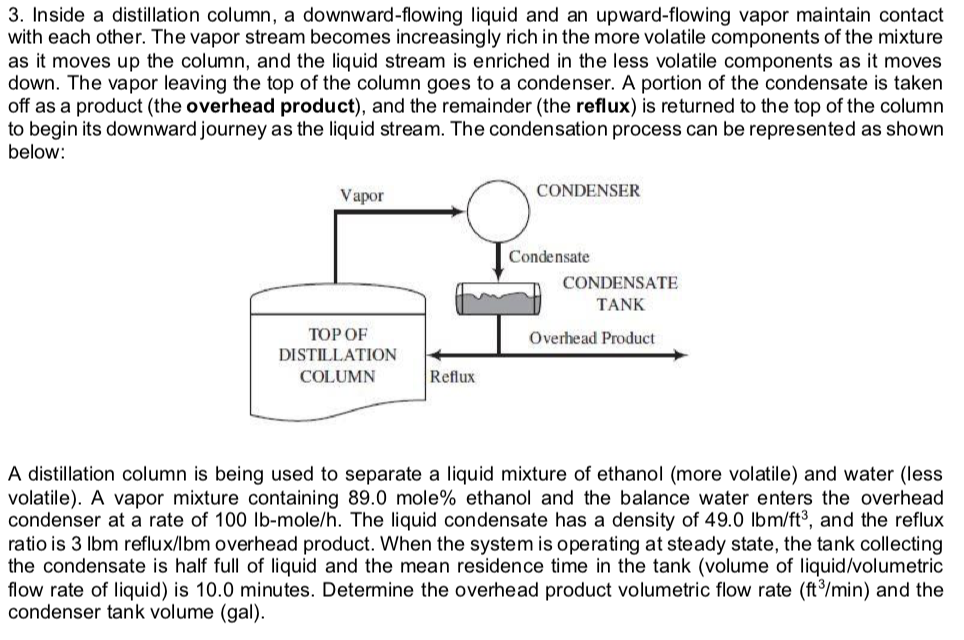

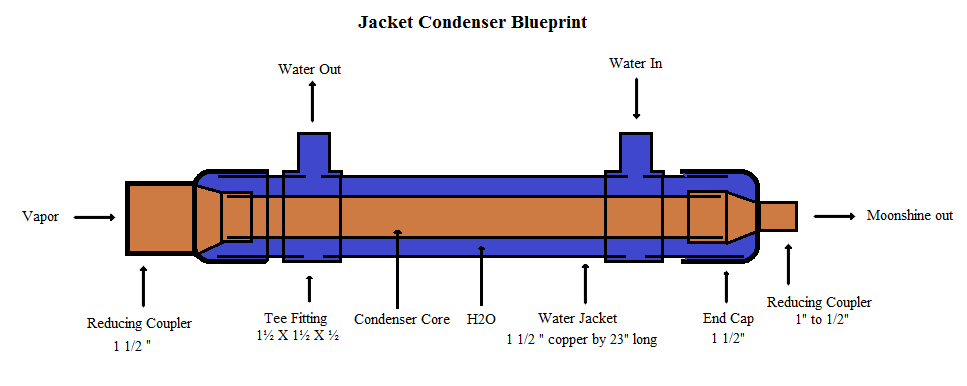

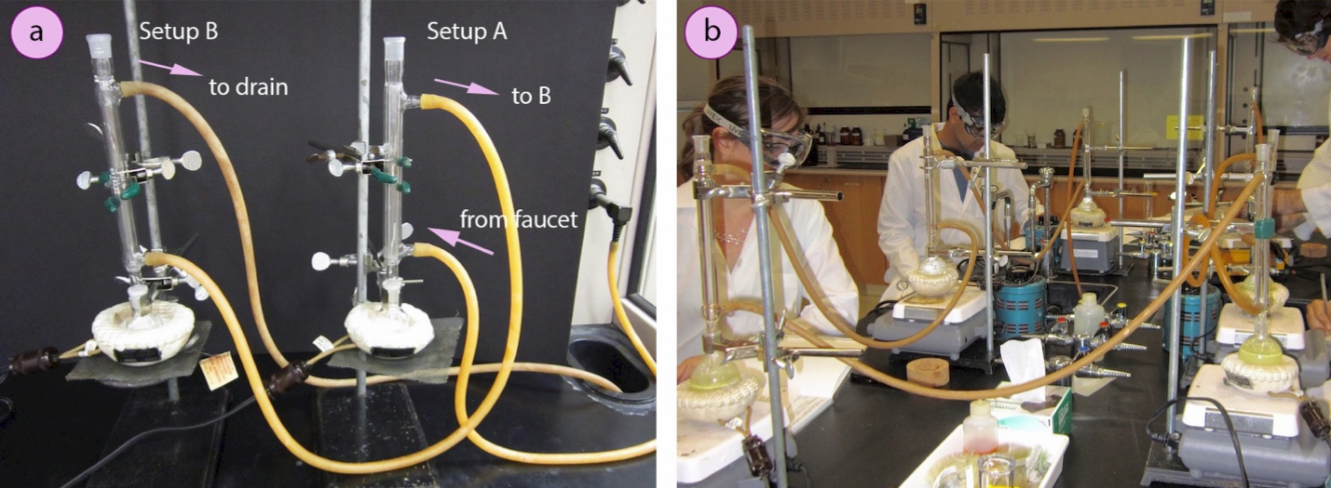

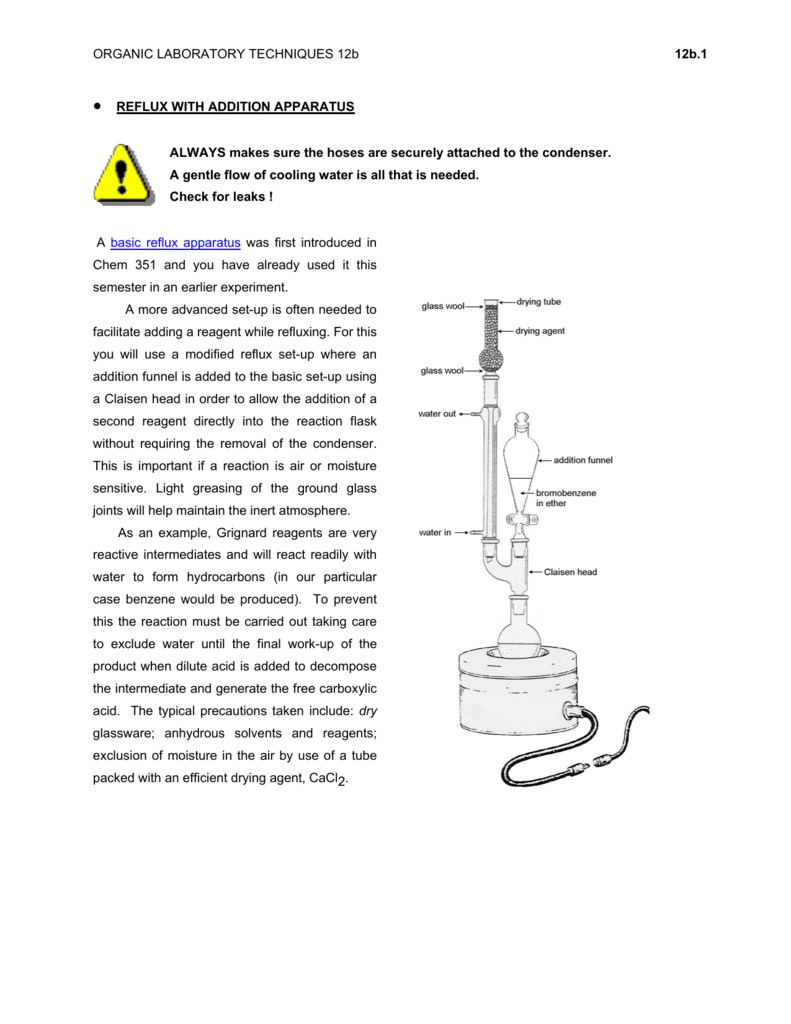

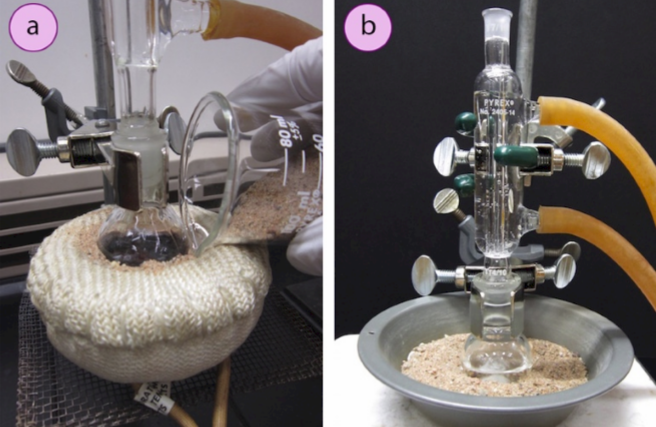

You need the water to be flowing, but you also need it to be present Filling the condenser from the top means that less water is present Try it You will quickly notice that a condenser fills more completely with water if you attach the inlet to the lower end of the condenser. The Internal Reflux Still To start the run, mount the boiler on top of the heat source, fill it with about a gallon of tap water, and attach the column to the boiler Then connect the cooling hoses on the column to the water supply and drain Do not allow the cooling water to circulate through the apparatus at this time. Connect a tube between the coldwater source and the bottom port of the condenser column Then, make another tube connection between the top of the condenser column and the lab sink Finally, turn on the water slowly and fill the condenser column with circulating cold water Adjust the water flow to prevent overpressurizing the tube connections.

Remove plastic cap on heat sink to fill with distilled water Water passes through to glass condenser Complete apparatus includes Airflux aluminum heat sink, removable glass condenser, and boiling flask Use with flasks up to 250 mL size and heating mantles with 60 W max output. Have rarely used a water condenser since, and when I did it was a superefficient condenser with jacket AND coil that required only a gentle flow of cooling water With a job in academia now I’ve been trying to convince people to stop using water condensers, in view of the multithousand euro damage already done by flooding. Synthware ™ reflux condenser with large cooling capacity and removeable hose connection 1 Product Result Match Criteria Product Name.

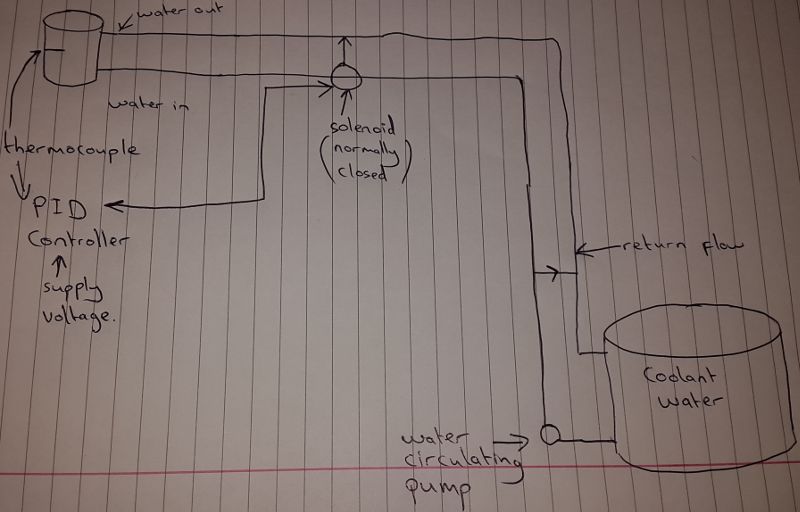

It is the subcooling of the condensate for which the flow regime becomes relevent, and in case of vertical reflux condenser, with water inlet at the bottom, it becomes countercurrent flow The measure of true countercurrent flow is a factor called LMTD Log Mean Temperature Difference. During most of the distillation process the cooling water flowing through the condenser should be flowing at about 500 mls (17 US fl oz) per minute To measure the flow, fill a calibrated jug from the outlet pipe for one minute Note 500mls per minute (17 US fl oz) is the ideal flow rate for cooling water that is under °C (68°F). During most of the distillation process the cooling water flowing through the condenser should be flowing at about 500 mls (17 US fl oz) per minute To measure the flow, fill a calibrated jug from the outlet pipe for one minute Note 500mls per minute (17 US fl oz) is the ideal flow rate for cooling water that is under °C (68°F).

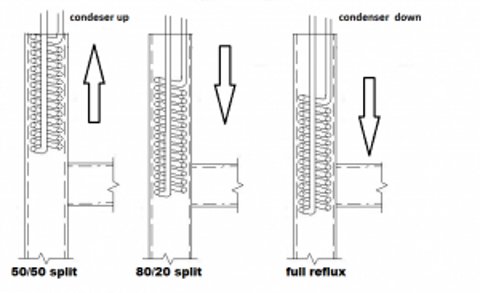

Basically when you get it up to temp with the coolant flowing through the column jacket After you let it reflux the amount of time you want 30 min to an hour Start turning the coolant flow down a little at a time until you get the output you want Slower drip product output higher ABV Faster drip or stream product output less ABV. Reflux is the process of boiling reactants while continually cooling the vapor returning it back to the flask as a liquid It is used to heat a mixture for extended periods and at certain temperaturesA condenser is attached to the boiling flask, and cooling water is circulated to condense escaping vapors. Condensers, Reflux, with Removable Hose Connections Coil stlye reflux condenser with a larger diameter jacket and coil, thereby providing maximum cooling capacity, while being shorter in length Hose connections are on the bottom of the condenser which makes it easier to connect hose/tubing Connections are GL14 polypropylene hose barbs and screw caps.

Automating Reflux Condenser Water Flow CothermanDistilling 14 December 14 0856PM edited December 14 in Accessories Automated Dephlegmator Coolant Flow Wiring a PID controlled mechanical ball valve for constant output temperature on a Reflux Condenser By Michael Cotherman Cotherman Distilling, LLC. Reflux is the process of boiling reactants while continually cooling the vapor returning it back to the flask as a liquid It is used to heat a mixture for extended periods and at certain temperaturesA condenser is attached to the boiling flask, and cooling water is circulated to condense escaping vapors. With a downhill flow of water, only the lower portion of the condenser fills with the circulating water, leading to inefficient cooling of gas traveling through the inner tube.

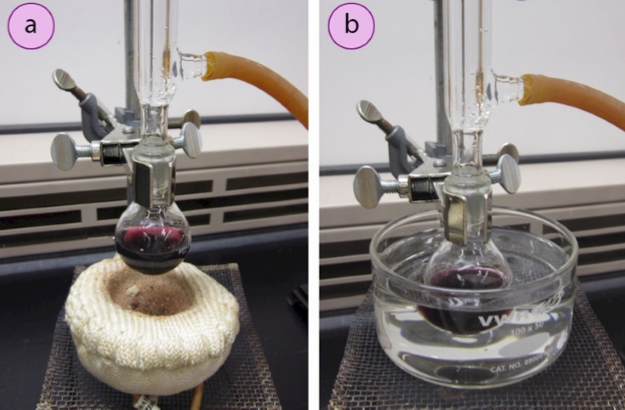

Water should enter the condenser at the bottom and leave from the top NOTE In the equipment set up shown here, a heating mantle with a heating controller is being used to. As the increased reflux flow slowly makes its way down the rectifying section, L/V increases, causing a decrease in the impurity level in the overhead product Therefore, for this scenario, an increase in V results in an inverse response in the concentration of the overhead product due to the difference in vapor and liquid dynamic in the column. Connect the hose on the lower arm of the condenser to the water faucet and allow the hose on the upper arm to drain to the sink (Figure 160b) It is important that water goes in the bottom of the condenser and out the top (so water flows against gravity) or else the condenser will be ineffective as it will not fill completely.

To increase the amount of Reflux within the column of the still I’ve run the 1/2 ” supply and return lines to the condenser through the column For the still to operate correctly the direction of water flow is important The water should enter the bottom of the condenser and exit out the top. Remove plastic cap on heat sink to fill with distilled water Water passes through to glass condenser Complete apparatus includes Airflux aluminum heat sink, removable glass condenser, and boiling flask Use with flasks up to 250 mL size and heating mantles with 60 W max output. Condensers, reflux, removable hose connections Coil style reflux condenser with a large diameter jacket and coil, similar to CG1213L but with detachable hose connections Connections are made of polypropylene and provide a safe and easy way of connecting and disconnecting flexible tubing to the condenser.

This reflux flow is required to produce a downward flowing liquid stream in the top section of the column Without the reflux stream, there can be no liquid in the rectifying section of the column, which means no separation would then occur in the rectifying section. With the top interface of the reflux condenser Make sure that the other end leads to a water sink • Use tape to attach the tubing to the edge of the sink in case the water leaks • Make sure tubes are securely attached to the condenser • Use hose clips in case the water leaks Figure 3 Round bottom flask Figure 4 The direction of water flow. The internal reflux, that is, the actual flow of liquid from tray 1 to tray 2, can be calculated as follows IR = R * (1C p * (T O – T R) / Λ) Where R = External reflux flow C p = Heat capacity of the reflux (eg, BTU/lb°F) T O = Overhead vapor temperature (entering the condenser) T R = Reflux temperature.

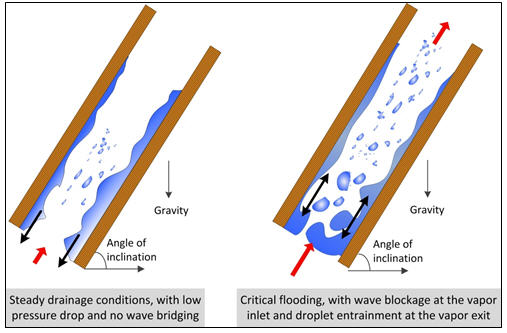

This is commonly known as the reflux condenser It is not advisable to attempt cocurrent upward vapor and liquid flow unless there is a high vapor velocity at the outlet of the tubes The reflux condenser must be designed such that vapor velocity is less than the flooding velocity. A major limiting factor in the design and operation of reflux condensers occurs when vapor velocity at the condenser’s inlet inhibits condensate downflow from the condenser Flooding, a complex twophase flow phenomenon, can occur at different places within a tube, depending upon vapor and condensate liquid rates. When this vapor condenses, it adds to the total liquid flowing from tray 1 down the column In other words, a subcooled reflux introduces a greater volume (or mass or molar) flow of reflux than is delivered to the column by the external reflux flow controller.

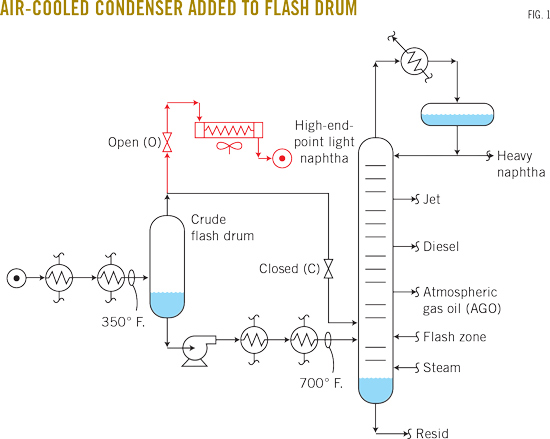

Connect a tube between the coldwater source and the bottom port of the condenser column Then, make another tube connection between the top of the condenser column and the lab sink Finally, turn on the water slowly and fill the condenser column with circulating cold water Adjust the water flow to prevent overpressurizing the tube connections. The reflux system consists of reflux condenser, accumulator and pump Overhead vapor from the stripper mainly consisting of water vapor and acid gases passed through the reflux condenser which condenses most of the water vapor and small amount of amine solution which may vaporize in the stripper This two phase stream flows to the reflux accumulator where the acid gases are separated from the condensed liquid. The reflux condenser has two small openings on the sides, one for water to flow in from a faucet and one for water to flow out into a sink of some sort, and rubber hoses are used to attach to each.

If the flow come from the bottom, any flow will fill the condenser;. When water is allowed to flow into the condenser, it surrounds the inner tube and creates a cooling effect That way when the vapors from the boiling liquid hit the cool area of the Liebig. A typical condenser consists of a glass tube nested within another Water flows between these two tubes A chemist attaches the condenser to the top of a flask so that as refluxing solvent evaporates and travels up through the center tube, the flowing water cools the solvent It then condenses on the glass surface and drips back into the flask.

Reflux ratio is L0/D = 3 A liquid side stream is withdrawn above the feed stage Side stream is 70 wt % ethanol, and side stream flow rate is 10 kg/min Find D, B, Qc, and QR Data are in Figure 24 32. Basically reflux condensers fall into two categories, namely, Graham type and coil type In Graham type of condenser vapour flows through the central tube and condenses along its walls to flow back into the reaction flask In the coil condenser water as a coolant is passed through the central coil and the vapour moves along the larger outside jacket. Assuming a lossofcoolant accident, steam flows into the condensers together with nitrogen, which fills the containment drywell Then steam is condensed in the tubes, and the decay heat is released to the atmosphere by vaporization of the pool water, suppressing and pressure of the PCV below the design pressure.

Basically when you get it up to temp with the coolant flowing through the column jacket After you let it reflux the amount of time you want 30 min to an hour Start turning the coolant flow down a little at a time until you get the output you want Slower drip product output higher ABV. As a result of its unique flow characteristics, the reflux condenser is ideal for eliminating condensable organic components from plant offgas streams Restrictions on these volatile organic compounds (VOC) will continue to become more rigorous, making reflux condensers even more important in the future. In chemistry, a condenser is laboratory apparatus used to condense vapors — that is, turn them into liquids — by cooling them down Condensers are routinely used in laboratory operations such as distillation, reflux, and extraction In distillation, a mixture is heated until the more volatile components boil off, the vapors are condensed, and collected in a separate container In reflux, a reaction involving volatile liquids is carried out at their boiling point, to speed it up;.

Once the feed settings are set, put the reflux flow rate controller in auto and set the starting point of the reflux flow to a set point of approximately 80% Start withdrawing the distillate product to maintain the reflux drum level between 25 and 75% Put the distillate flow controller in auto and adjust it's set point above zero flow. In other words, the vapors will not fully condense in the shorter condenser section But again, dwell time due to the increase in vapor tube quantity and resulting slower vapor speed will improve the condensing power of the condenser But due to the shorter water jacket path, you’ll need to keep the water flow rate higher for knockdown. The purpose of a lab condenser is to expose hot vapor to water, which has a high heat capacity and so cools the vapor efficiently You need the water to be flowing, but you also need it to be present Filling the condenser from the top means that less water is present.

The water is pumped in and out of the cylinder through its side arms The water cools the vapor within the tube and condenses it The are two kinds of reflux condensers Some reflux condensers use a dry ice and acetone mixture As the vapor condenses, it flows back into the reaction flask. Laboy Glass Allihn Condenser for Reflux & Distillation Apparatus with 24/40 Joints 300mm in Length Organic Chemistry Lab Glassware with Glass Hose Connections 42 out of 5 stars 8 Misc $3567 $ 35 67 Get it as soon as Wed, Jan 27 FREE Shipping by Amazon More Buying Choices $3102 (5 new offers). Water in the vapor exiting the top of the still is condensed in the Reflux Condenser and collects in the Reflux Accumulator The water is returned to the top of the tower using the Still Reflux Pumps, where it is comingled with the still feed liquid (rich amine) Vapor not condensed in the Reflux Condenser consists primarily of water vapor, hydrogen sulfide and carbon dioxide These.

Laboy Glass Allihn Condenser for Reflux & Distillation Apparatus with 24/40 Joints 300mm in Length Organic Chemistry Lab Glassware with Glass Hose Connections 42 out of 5 stars 8 Misc $3567 $ 35 67 Get it as soon as Wed, Jan 27 FREE Shipping by Amazon More Buying Choices $3102 (5 new offers). Reflux condenser mode is a cooling mechanism that could occur in a PWR usually in defined phases of smallbreak LOCA (SBLOCA) (Pretel, 1997 ) At a reduced inventory vapor is produced in the core and flows through the hot leg to SG Utubes where it can condense, fall back to the vessel, and help cool the core. Chemical Industry Reflux Condensers, sometimes called vent or knockback condensers, are commonly used when separating light elements from a vapor mixture Heavier components in the mixture condense and flow to the bottom along the tube walls while the lighter elements remain a vapor and exit through an upper vent.

See GBHEPEGHEA516 for a discussion of reflux condensers (dephlegmators) in which the condensate and vapors flow countercurrent For single pass down flow, the cheapest designs are generally obtained by using the maximum allowable tube length, subject to pressure drop constraints. The more cool water that flows through the condenser, the lower the temperature will be in the reflux column This will show on the thermometer The temperature of your tap water influences the amount you need. The water is returned to the top of the tower using the Still Reflux Pumps, where it is comingled with the still feed liquid (rich amine) Vapor not condensed in the Reflux Condenser consists primarily of water vapor, hydrogen sulfide and carbon dioxide These acid gases flow through the system back pressure valve and are sent to disposal.

To cause to flow back or return especially to heat (as under a reflux condenser) so that the vapors formed condense to a liquid that flows back to be heated again intransitive verb to flow back damage to the esophageal mucous membrane when gastric acid refluxed into the esophagus. Reflux Condensers, sometimes called vent or knockback condensers, are commonly used when separating light elements from a vapor mixture Heavier components in the mixture condense and flow to the bottom along the tube walls while the lighter elements remain a vapor and exit through an upper vent. Condenser can often be seen as a reflux line The direction of flow of the water should be such that the condenser will fill with the cooling water;.

If it flows from the top, the water will tend to flow under gravity to the bottom and low flow will mean the coils/free space isn't full as the flow will be determined by the rate water flows out under gravity not the inherent flow rate of the water $\endgroup$ – matt_black Sep 24 '16 at 1041. Feed flow rate is 2,500 lbmol/hr and feed temperature is 30oC The column is at 1 atm A distillate that is 97 mole % npentane is desired A total condenser is used.

G U N T Equipment For Engineering Education

Reflux Still Designs Explained Part 1 Brewhaus America

Organic Lab Equipment Distillation Reflux Separating Funnel Ppt Download

Reflux Condenser Water Flow のギャラリー

Pumparounds And Tower Heat Flows Mcgraw Hill Education Access Engineering

Distillation

Www Sciencedirect Com Science Article Pii S Pdf Md5 8ad7d1c91de6c809f4dd5ca3e24d8db5 Pid 1 S2 0 S Main Pdf Valck 1

What Is The Purpose Of Distillation And Reflux Condenser

Choosing The Right Condenser Chemistry Stack Exchange

Q Tbn And9gcqivlhrwca33w6t3eywiq Nsdmz4hezhakesjt3ytz6px8boano Usqp Cau

Refluxing With Tilted Condenser Chemistry Stack Exchange

Distillation

Schematic Diagram Of Assembly For Water Distillation The Boiler Download Scientific Diagram

Distillation Reflux Principle

Reflux Still Designs Explained Part 1 Brewhaus America

Oneclass Distillation With Reflux When Operation Of A Distillation Column Begins Vapor Is Generated

Choosing The Right Condenser Chemistry Stack Exchange

Schematic Diagram Of The Pyrolysis Reactor With A Reflux Condenser Download Scientific Diagram

All About Connecting Your Cooling Water Supply To Your Condensers Stilldragon Community Forum

Water Cooled Condenser An Overview Sciencedirect Topics

Controling Elements And Reflux Condensor Stilldragon Community Forum

Liebig Condenser Function Uses Study Com

Distillation Column Control Basics Part 1

Why Must The Water Enter From The Bottom In A Condenser Quora

1 4k Reflux Chemistry Libretexts

Question 2 Figure 2 Depicts Cooling System Of Chegg Com

Solved A When Setting Up The Reflux Condenser Does It M Chegg Com

Typical Pfd For Sour Water Stripper Column Enggcyclopedia

Developments In Heat Transfer Technology Can Improve Exchanger Efficiency And Reduce Water Demand

Q Tbn And9gcrobgfvwscphyd0dyry1ujsmoqy0xxzmj2ii1ljngmn7a7nue1b Usqp Cau

Http Www Chem Ucalgary Ca Courses 351 Laboratory Reflux Pdf

Still Spirits T 500 Essential Oil Extractor With Stainless Steel Reflux Condenser Column

Building The Condenser Home Distillation Buffalo Brewing Blog

Reflux Still Water Flow Setup 800mm Column 2 5 Inches Youtube

Optimization Pressure Control Optimization

Mdea Loss In The Lpg Treating Process Campbell Tip Of The Month

1 4k Reflux Chemistry Libretexts

Copper Turbo 500 Condenser Home Distilling

Answered 3 Inside A Distillation Column A Bartleby

Optimize Batch Distillation

All About Connecting Your Cooling Water Supply To Your Condensers Page 2 Stilldragon Community Forum

Why Must The Water Enter From The Bottom In A Condenser Quora

What Is Heating Under Reflux Chemistry Stack Exchange

Condenser Laboratory Wikipedia

Module 3 1 Control Of Distillation Columns

Column Processdesign

Clamp 2 Od64mm Direct Flow Dephlegmator Reflux Distiller Condenser Length 0mm Sanitary Steel 304 Distillers Aliexpress

Stainless Steel Turbo 500 Condenser Home Distilling

1 4k Reflux Chemistry Libretexts

Condenser Controlled Columns Page 8 Home Distiller

Vapor Path Flow And The Effects Of Product Condenser Stilldragon Community Forum

Eo Distillation Column Scheme Chemical And Biomolecular Engineering

Straight Shape Standard Ground Mouth Lab Glass Condenser Borosilicate Glass 3 3 Scientific Graham Condenser Buy Distillation Condenser Water Flow Use Of Condenser In Laboratory Condenser Laboratory Apparatus Uses Reflux Condenser Water Flow Air Condenser

Organic Lab Equipment Distillation Reflux Separating Funnel Ppt Download

How To Make A Reflux Still Complete Plans To Build A Homemade Still Learn To Moonshine

Reflux Wikipedia

Counter Current Flow Limitation In The Hot Leg Of A Pwr Nuclear Reactor Helmholtz Zentrum Dresden Rossendorf Hzdr

Schematic Diagram Of The Pyrolysis Reactor With A Reflux Condenser Download Scientific Diagram

Distillique How To Connect Coolant Water To A Column Still Column Still Still Spirits Column

Draw And Label The Feedback Control Block Diagram Chegg Com

Condensers An Overview Sciencedirect Topics

Solved Introduction The Purpose Of This Experiment Is To Chegg Com

What Is The Purpose Of Running Water Through A Liebig Condenser Quora

Reflux Wikipedia

1 4k Reflux Chemistry Libretexts

Www Utdallas Edu Scortes Ochem Ochem Lab1 Recit Notes Recit Exp13 Bananaoil Pdf

Reflux Problems In Distillation

Solved A When Setting Up The Reflux Condenser Does It M Chegg Com

Sciencemadness Discussion Board Condenser Pumps Powered By Xmb 1 9 11

Http Www Chem Ucalgary Ca Courses 351 Laboratory Reflux Pdf

Reflux With Addition Apparatus

Developments In Heat Transfer Technology Can Improve Exchanger Efficiency And Reduce Water Demand

Q Tbn And9gcsxrj9ppe9gfduyytogmctfd1ogxtjykxc H Ccprc Usqp Cau

Beyond Back To Basics Process Principles And Concepts 2 Understanding Reflux In Distillation Towers Oil Gas Journal

Refluxing Under An Inert Atmosphere The Schlenk Line Survival Guide

Water Flow In Condenser Chemistry Stack Exchange

Organic Chemistry Laboratory Techniques For Standard And Micro Scale Experiments Setting Up A Reflux Reaction Top Hat

Ae 117

Refluxing Under An Inert Atmosphere The Schlenk Line Survival Guide

Optimization Pressure Control Optimization

1 4k Reflux Chemistry Libretexts

Water Flow In Condenser Chemistry Stack Exchange

All About Connecting Your Cooling Water Supply To Your Condensers Page 2 Stilldragon Community Forum

Reflux Condenser An Overview Sciencedirect Topics

1 Scheme Of The Primary Loop During Reflux Condenser Mode Download Scientific Diagram

Process Descriptions Your Engineering Firm Won A T Chegg Com

Q Tbn And9gcridumgmyzk Ordsict6yis37ddzmtdlltbxrlgodh5ditt0il2 Usqp Cau

Organic Chemistry Laboratory Techniques For Standard And Micro Scale Experiments Setting Up A Reflux Reaction Top Hat

Dibosh Cm Reflux Still From China Home Distiller

It S The Rheo Thing A Poorly Engineered Condenser That Works Quite Well

Reflux Condenser An Overview Sciencedirect Topics

Campbell Tip Of The Month

1 4k Reflux Chemistry Libretexts

Solved 4 9 Inside A Distillation Column See Problem 4 8 Chegg Com

Water Production Through Co2 Capture In Coal Fired Power Plants Feron 17 Energy Science Amp Engineering Wiley Online Library

Condenser Laboratory Wikipedia

Sciencemadness Discussion Board Using Reflux Condenser In A Distillation Column Powered By Xmb 1 9 11

New Condensers Cool Solvent Without Flowing Water

Optimization Pressure Control Optimization

China Reflux Water And Air Cooled Condenser China Reflux Condenser Water Cooled Condenser

Still Spirits Turbo 500 T 500 Still Copper Reflux Condenser Column Toronto Brewing

Www Revamps Com S Main Fractionator Water Wash Systems Pdf

Reflux Condenser An Overview Sciencedirect Topics

Liebig Condenser Function Uses Study Com

Reflux Wikipedia