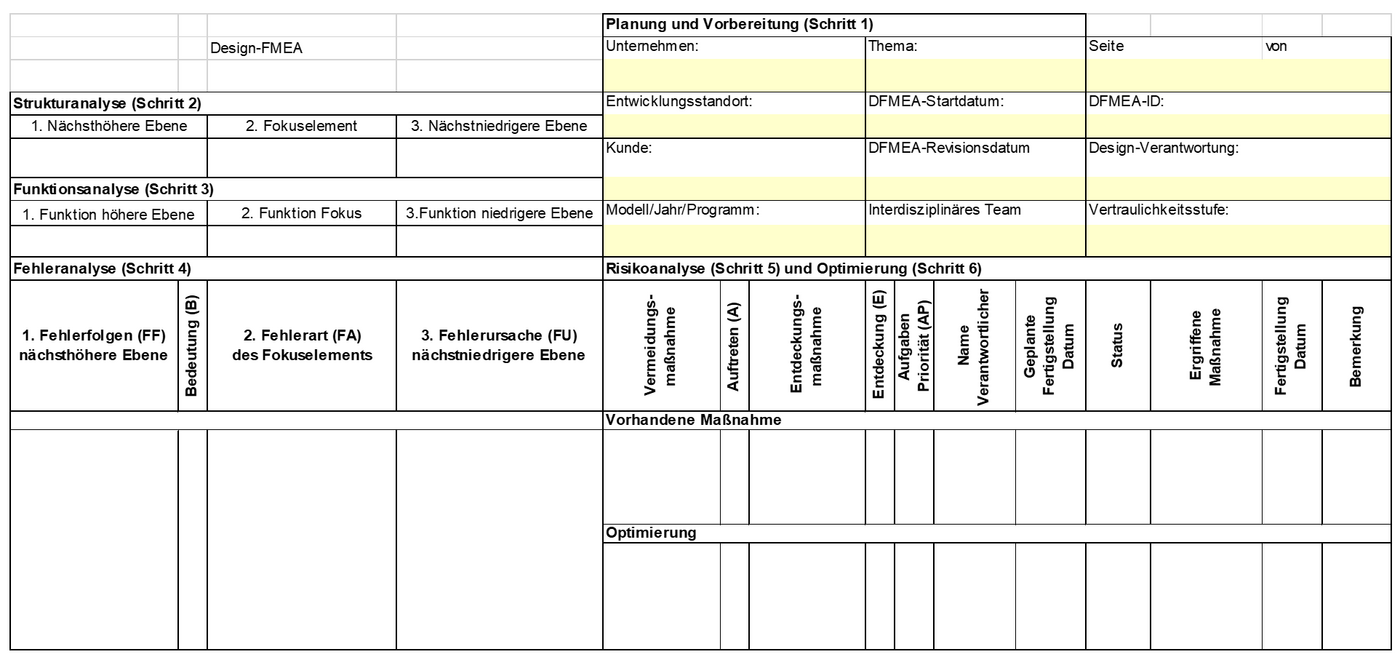

Fmea Tabelle

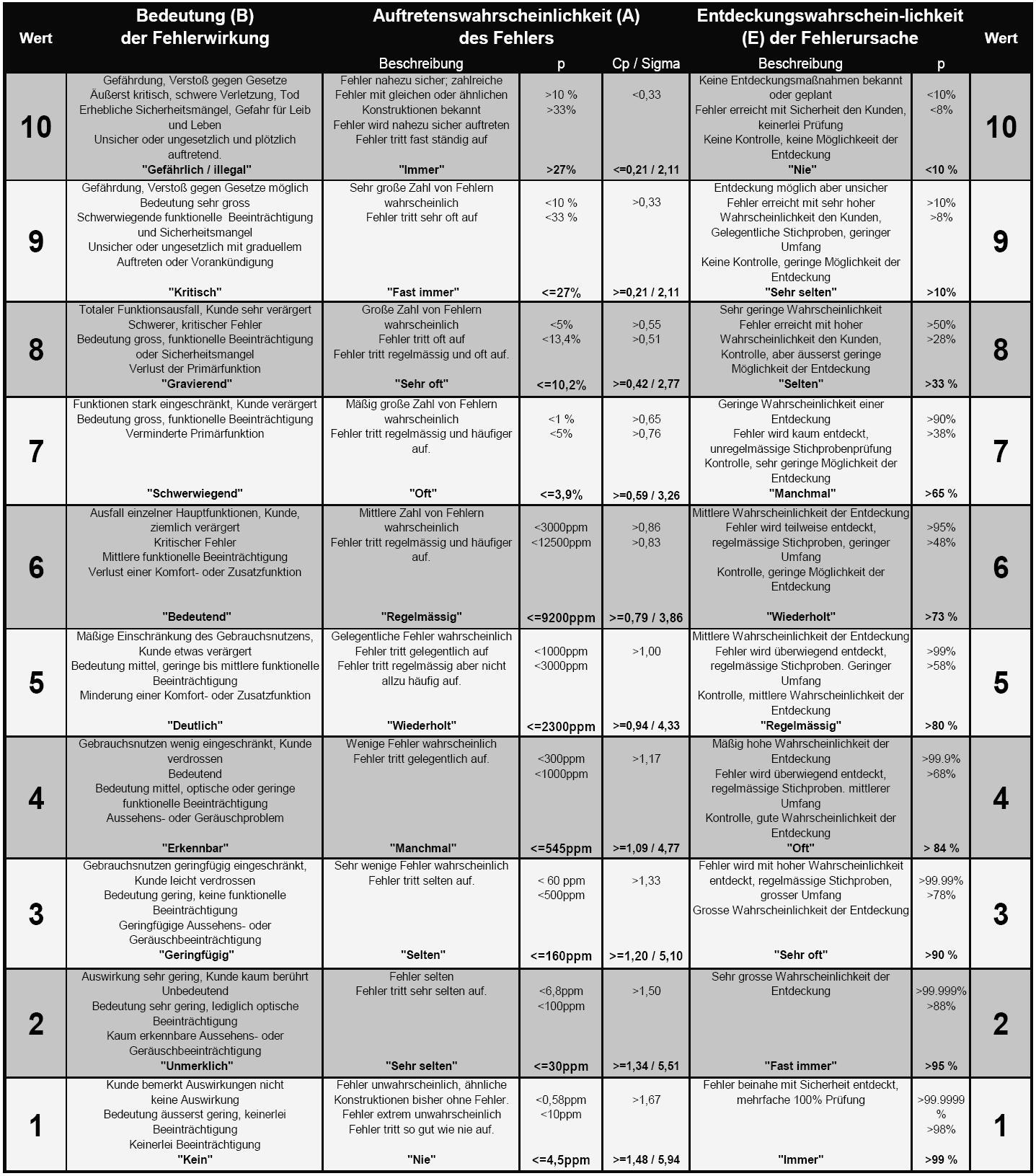

Automotive Industry Action Group (AIAG) FMEA Rating Definitions Severity Effect Criteria Severity of Effect Defined Ranking Hazardous Without Warning May endanger operator Failure mode affects safe vehicle operation and / or involves noncompliance with government regulation Failure will occur WITHOUT warning 10.

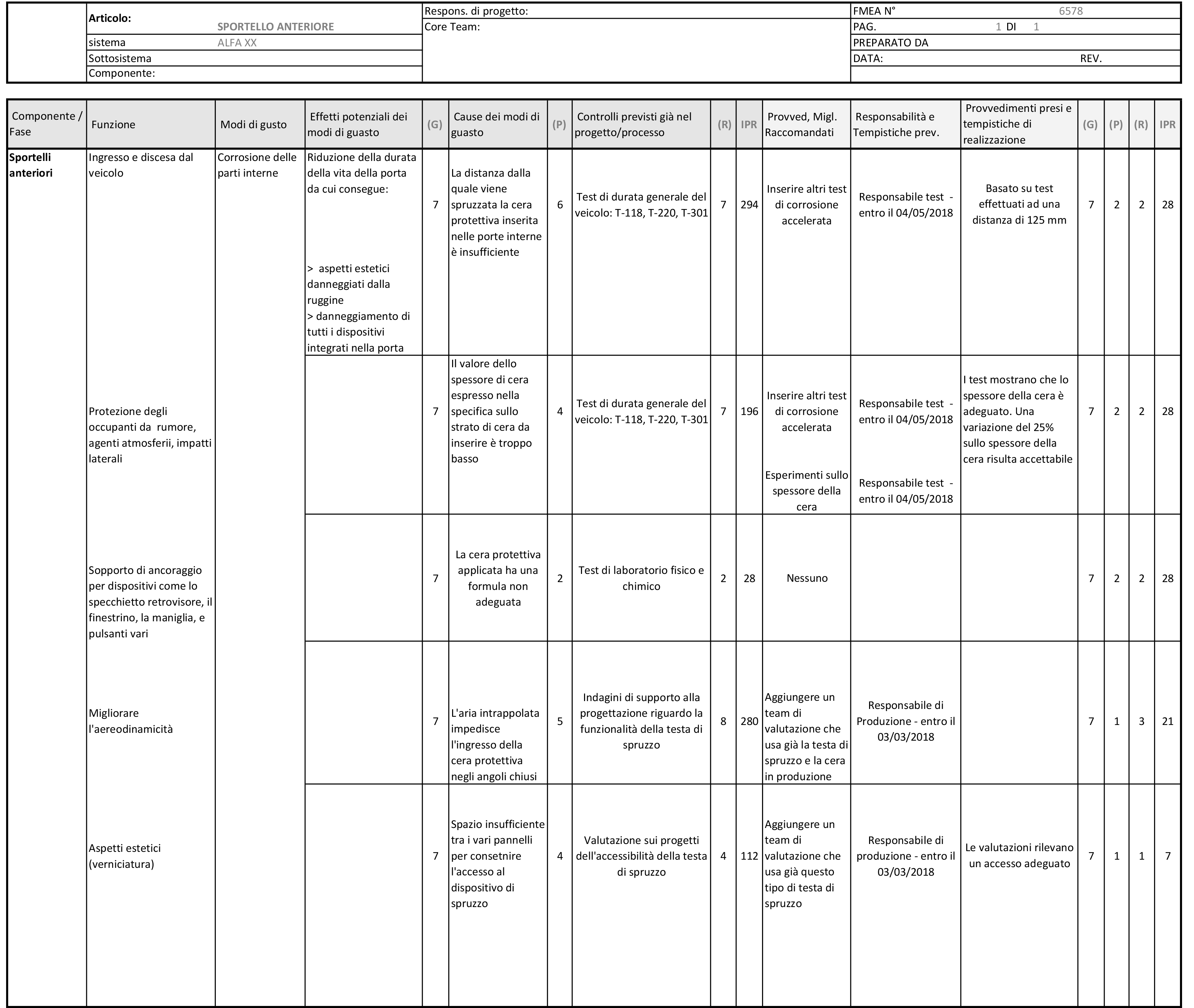

Fmea tabelle. Excel vorlage fmea Wir haben 19 Bilder über excel vorlage fmea einschließlich Bilder, Fotos, Hintergrundbilder und mehr 10 x 5 · jpeg fmea excel vorlage eueom mexico Download Image Mehr @ eueommexicoorg 770 x 560 · png plato scio fmea plato ag solutions software Download Image Mehr @ wwwplatode 632 x 853 · jpeg risikomanagement. L’FMEA è stata in passato utilizzata principalmente dalle case automobilistiche e dai loro fornitori come strumento di valutazione e la gestione dei rischi dei modi di guasto In altre parole valutare la probabilità che un evento accada e, se necessario, quali azioni intraprendere per fare in modo che la probabilità si abbassi. A brief overview of Failure Mode and Effects Analysis, with an example and explanation.

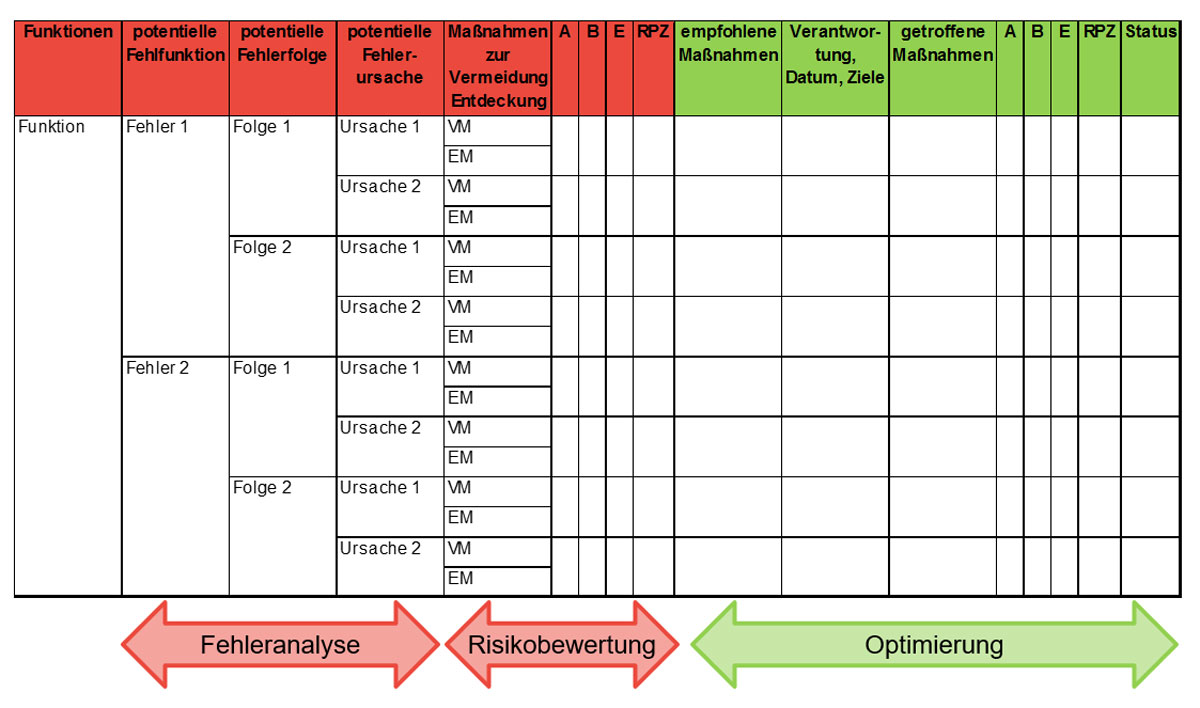

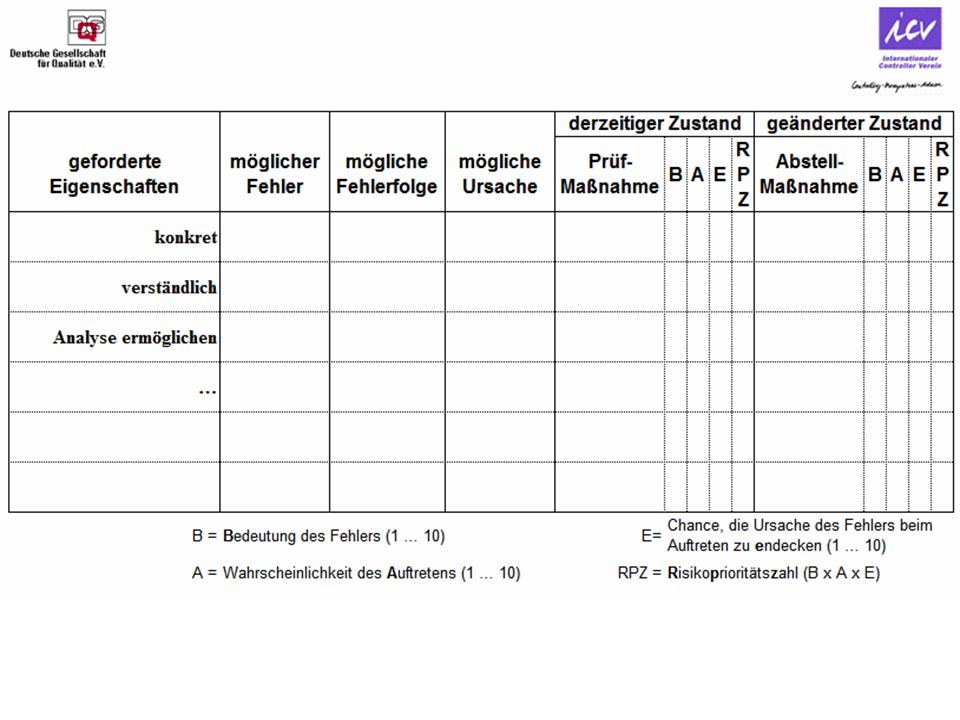

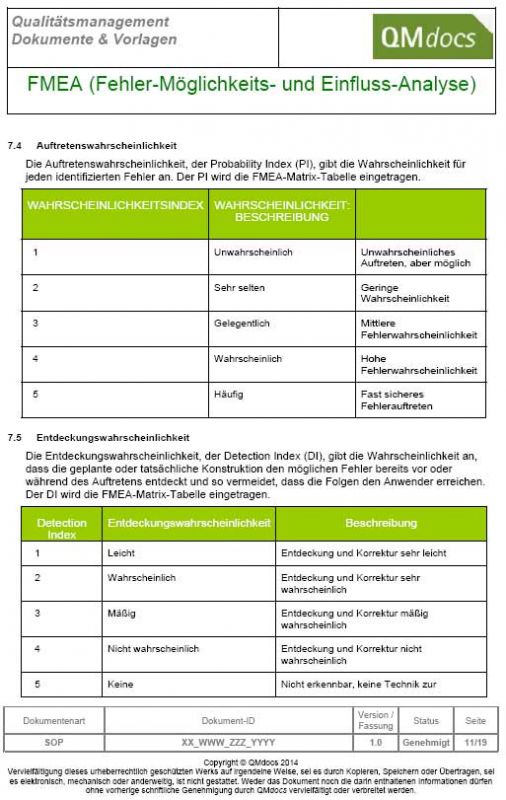

With an FMEA, each failure and its corresponding effect are rated on the three different scales and a Risk Priority Number (RPN) is calculated by multiplying the three ratings for each item This provides a powerful way to evaluate the risk of each failure against the others. FMEA Team New SEV New OCC New DET New RPN Printed , Page of 1000 1000 1000 1000 1000 1000 000 000 Title FMEA Worksheet Author Allan Tonkin Last modified by Pablo Baez Created Date 1/14/1997 PM Company CIBC Other titles. Tdistribution tDistribution Critical values from the tDistribution For the tdistribution, dF = n1, represents the degrees of freedomIf you have 29 samples, then dF = 28 The tdistribution is used instead of the zdistribution (standard normal distribution) when thePopulation standard deviation is unknown.

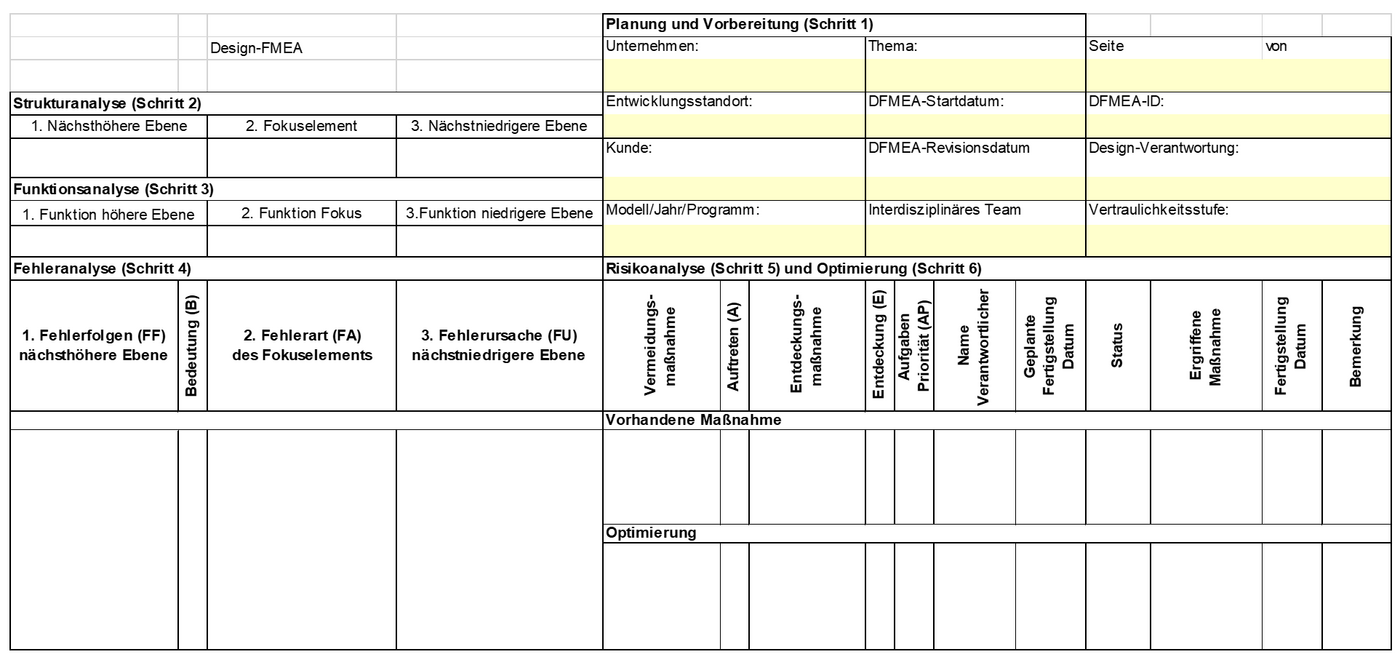

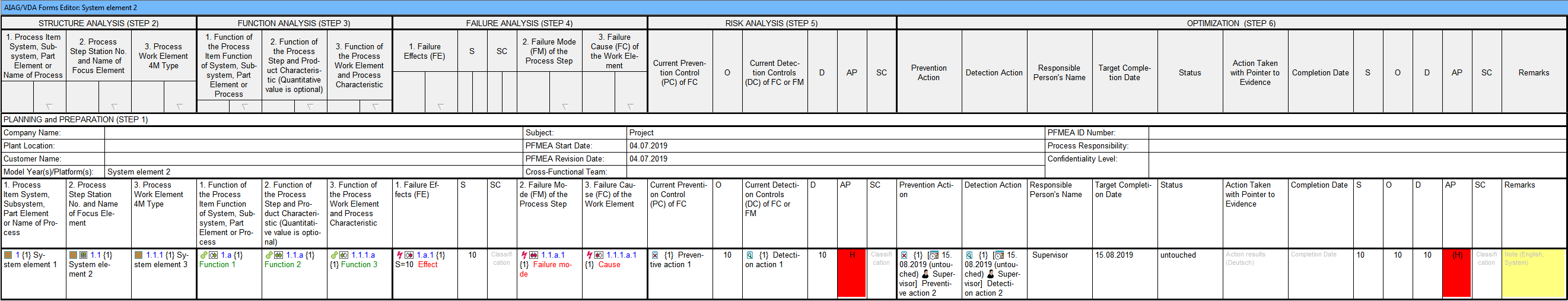

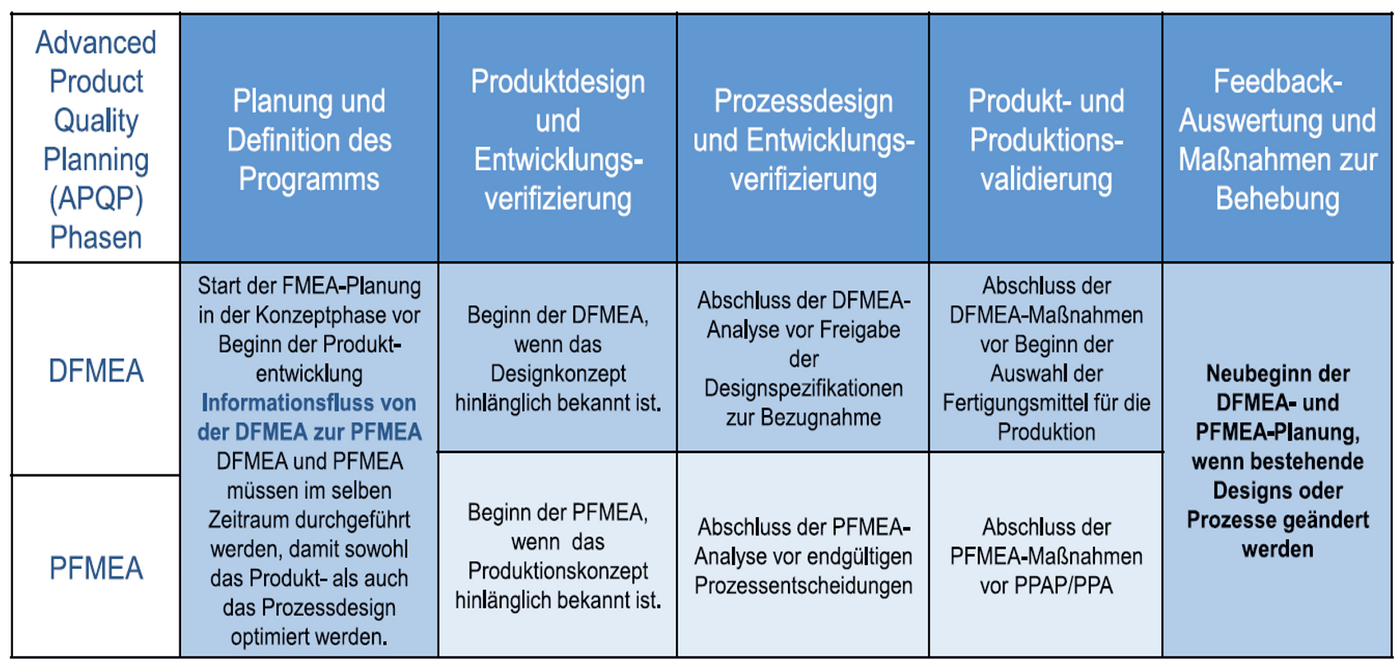

AIAG and VDA FMEA Essentials for Transitioning eLearning Bundle Exclusively through AIAG, you can register for the AIAG and VDA FMEA Essentials for Transitioning eLearning and receive an electronic copy of the new AIAG & VDA FMEA Handbook at a discounted rate!. Process FMEA (Function/ Requirements) Potential Failure Mode Potential Effect(s) of Failure S e v Potential Cause(s)/ Mechanism(s) of Failure O c c u r Current Controls Detection D e t e c R P N Recommended Actions S E V O C C U R D E T E C R P N To make a mark Makes no mark loss of primary function. In its usual systematic fashion, Six Sigma Methodology offers a tool called Process Failure Mode Effects Analysis (PFMEA) to achieve this objective PFMEA is a stepwise means of analyzing a process, in order to identify and rate its critical failure modes The tool is best utilized during the design phase of a project, and should be refreshed.

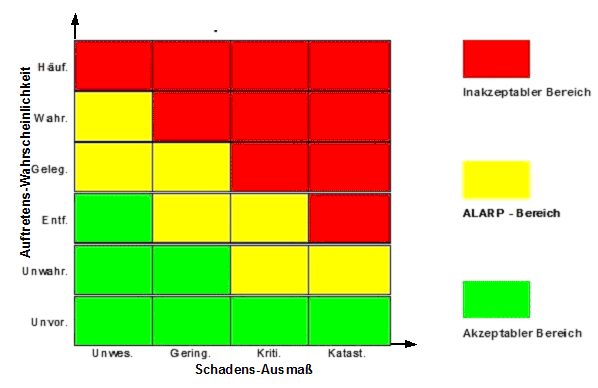

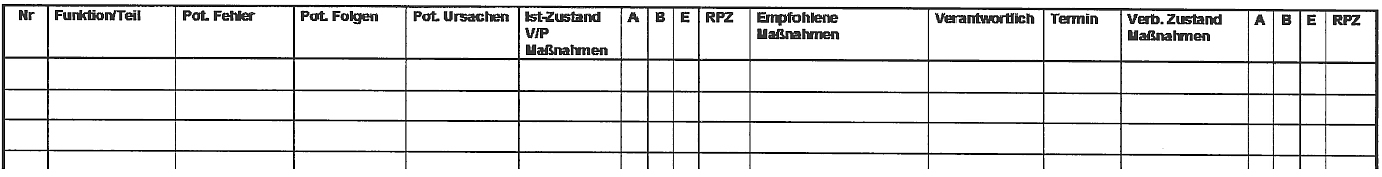

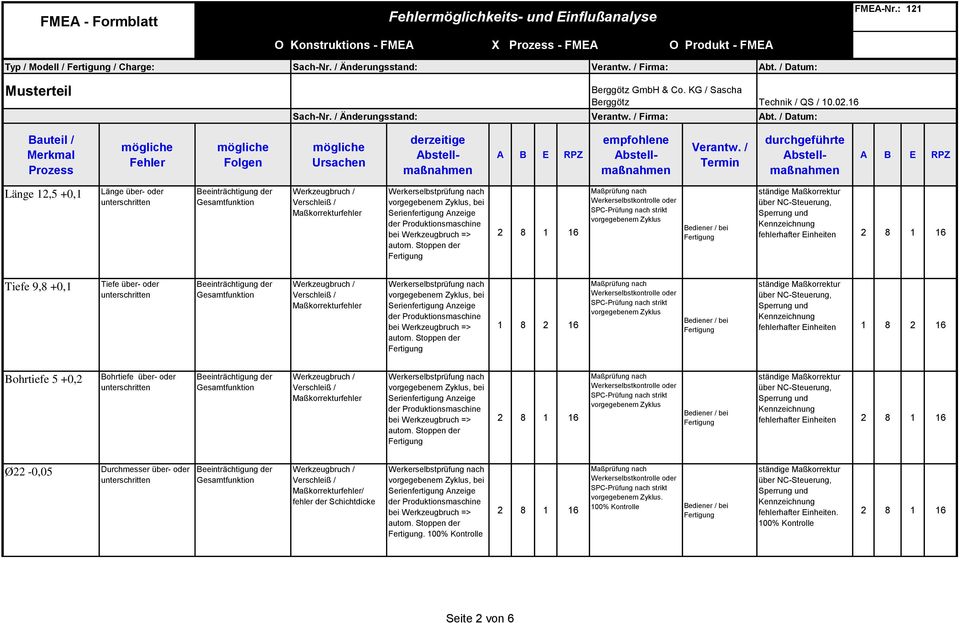

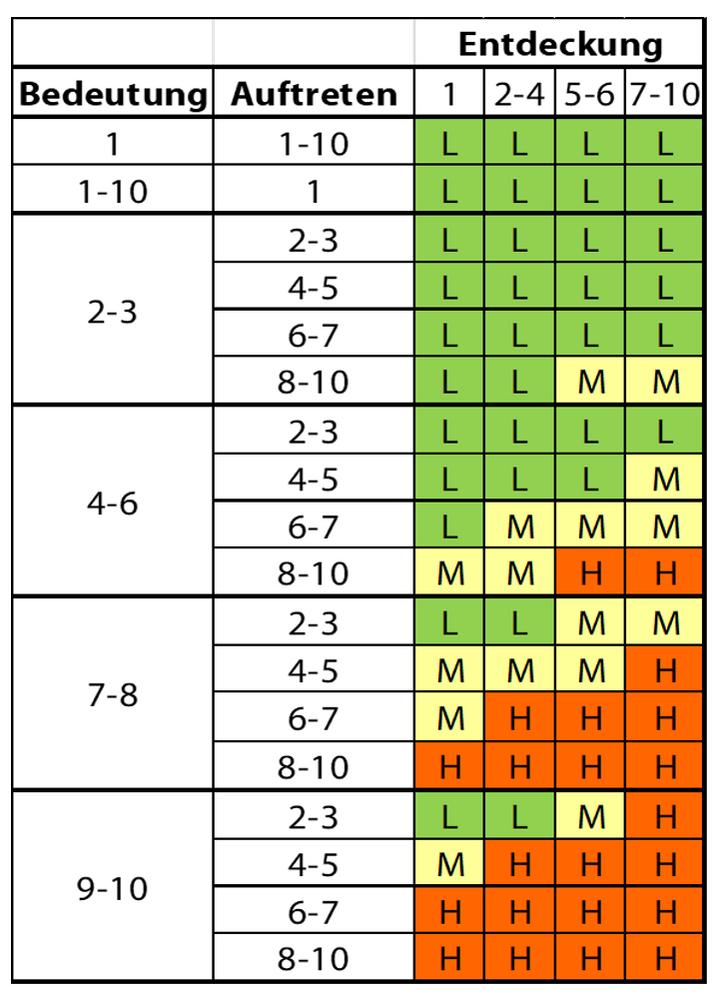

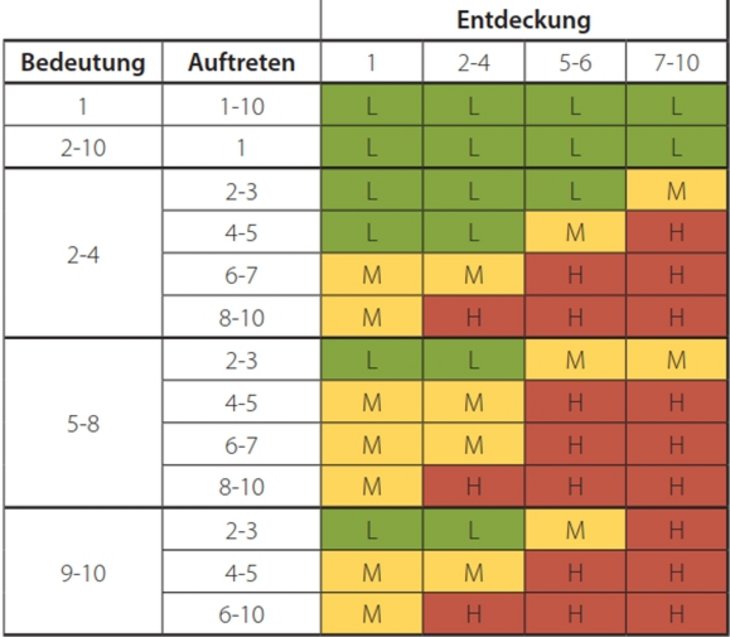

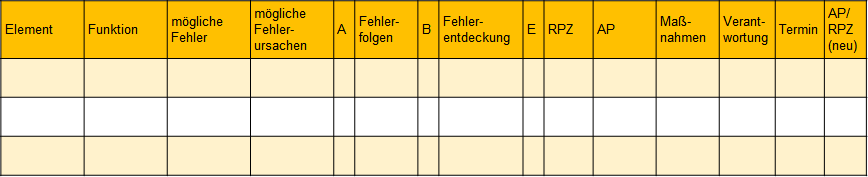

PFMEA Template (Download template) ;. FMEA APLogik Tabelle An dessen Stelle steht nun eine logische Aufgabenpriorisierung lt folgenden Tabellen Die Aufgabenpriorität (AP) basiert dabei weiterhin auf der Kombination von Bedeutung, Auftreten und der Entdeckungswahrscheinlichkeit, dient aber gleichzeitig auch der Priorisierung von Maßnahmen zur Risikoreduzierung. FMEA Failure Mode and Effect Analysis Links to FMEA Research The links are shown with a short description of what is on this site, in most cases this summary is an extract of the site The information is given for your information only The order of appearance is not to be considered as a ranking.

→ Severity Occurrence Detection and RPN Number is commonly used in FMEA Severity in FMEA → “Severity” is a ranking number associated with the most serious effect for a given failure mode, based on the criteria from a scale. Lastly, an FMEA should be sporadically done throughout the lifetime of a product or process;. FMEA in einer Weberei – fehlerkatalog vorlage 0D Wenn Sie geraume Vorlage ausgewählt besitzen, können Sie die erforderlichen Details eingeben und sogar die Farbe, Schriftart des weiteren Größe anpassen Diese eine, andere Möglichkeit, die Vorlage zu verwenden, besteht darin, den Teil einer Seite abgeschlossen ersetzen.

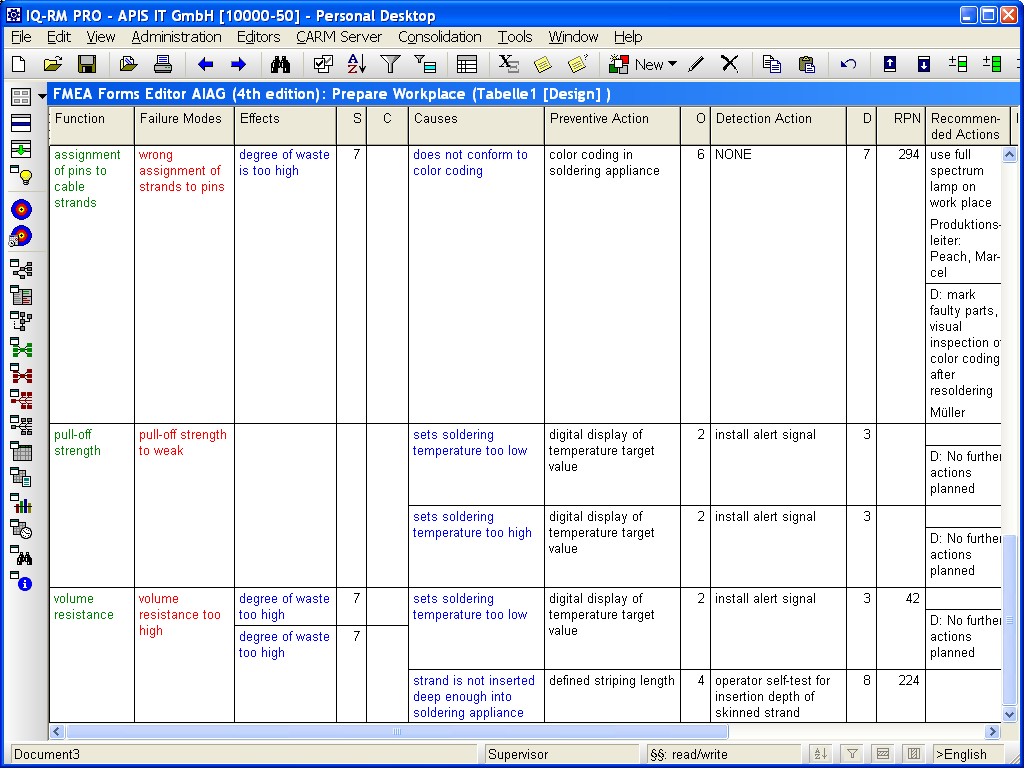

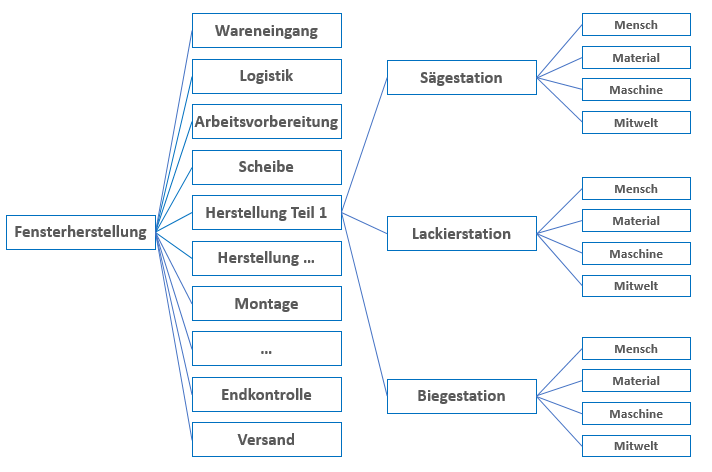

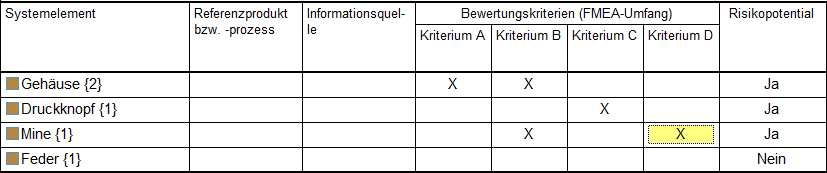

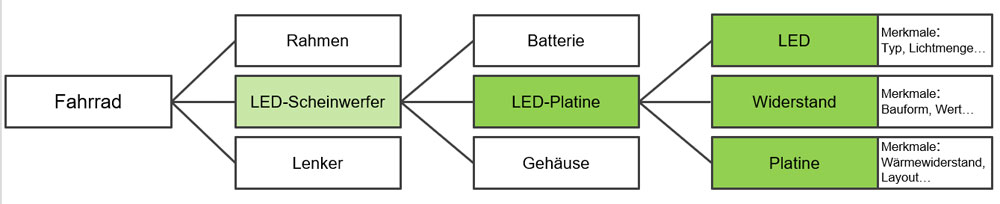

L’FMEA è stata in passato utilizzata principalmente dalle case automobilistiche e dai loro fornitori come strumento di valutazione e la gestione dei rischi dei modi di guasto In altre parole valutare la probabilità che un evento accada e, se necessario, quali azioni intraprendere per fare in modo che la probabilità si abbassi. FMEA Items should be described in an FMEA Table Since FMEA Tables are based on Generic Tables, the toolbar and the Criteria area work in the same manner An FMEA Table allows you to analyze the reliability aspect of your model, and provides you with a convenient way to fillin FMEA Item information using a spreadsheetlike tabular format. The failure modes, causes, and effects for each step;.

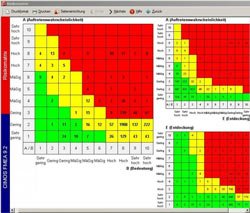

FMEA di prodotto (o a parità di IPR, di dare più peso all’indice “gravità” Si possono, in tal caso, anche costruire tabelle del tipo seguente Guasti con gravità 9/10 IPR ≥ 40 Guasti con gravità 7/8 IPR ≥ 100 Guasti con gravità 4/5/6 IPR ≥ 1. Quality Glossary Definition Failure mode effects analysis (FMEA) Also called potential failure modes and effects analysis;. FMEA AP, or Action Priority, is a rating method introduced in the AIAG & VDA Failure Mode and Effects Analysis FMEA Handbook The AP provides a priority level based on Severity, Occurrence, and Detection values While the RPN (Risk Priority Number) is a risk assessment value based on Severity x Occurrence x Detection, AP was developed in.

Process FMEA (Function/ Requirements) Potential Failure Mode Potential Effect(s) of Failure S e v Potential Cause(s)/ Mechanism(s) of Failure O c c u r Current Controls Detection D e t e c R P N Recommended Actions S E V O C C U R D E T E C R P N To make a mark Makes no mark loss of primary function. FMEA Team New SEV New OCC New DET New RPN Printed , Page of 1000 1000 1000 1000 1000 1000 000 000 Title FMEA Worksheet Author Allan Tonkin Last modified by Pablo Baez Created Date 1/14/1997 PM Company CIBC Other titles. Risk priority number (RPN) is a function of the three parameters discussed above, viz, the severity of the effect of failure, the probability of occurrence, and the ease of detection for each failure mode RPN is calculated by multiplying these three numbers as per the formula below,.

Each FMEA template has 2 parts Header (light green) and columns (light blue). AIAG/VDA’s FMEA Manual Is a Major Advance (my take on this subject) FMEA and Control Plans 2 Jan 15, B AIAGVDA FMEA When the new format will be required FMEA and Control Plans 5 Jan 8, M How to complete structure Analysis and Function analysis sections' columns of AIAGVDA DFMEA form FMEA and Control Plans 0 Nov 12, 19. Failure Mode and Effects Analysis, or FMEA, is a methodology aimed at allowing organizations to anticipate failure during the design stage by identifying all of the possible failures in a design or manufacturing process Developed in the 1950s, FMEA was one of the earliest structured reliability improvement methods.

Example Generic FMEA Form 22 Ref Failure Mode Effect Analysis FMEA from Theory to Execution, Appendix A, Figure E10, D H Stamatis Generally, the results of an FMEA are captured in a table similar to this (c) Vitech Corporation 17. Hazard Analysis and Risk Assessment Because of the reference to SIL and because the ASIL incorporate 4 levels of hazard with a 5th nonhazardous level, it is common in descriptions of ASIL to compare its levels to the SIL levels and DO178C Design Assurance Levels, respectively The determination of ASIL is the result of hazard analysis and risk assessment. Compare All FMEA Courses Severity Evaluation Criteria FMEAs help us focus on and understand the impact of potential process or product risks A systematic methodology is used to rate the risks relative to each other An RPN, or Risk Priority Number, is calculated for each failure mode and its resulting effect(s).

FMEA Scales for Severity, Occurrence & Detection Severity Scale for Failure Modes & Effects (s cale of 1 least severe to 10 most severe for each effect) Occurrence Scale for Potential Root Causes (s cale of 1 least frequent to 10 most frequent for each root cause) Minor (Rank 1) Low (Rank 2 3) Moderate (Rank 4 6) High (Rank 7 8) Very High (Rank 9 10). Welcome at fmeacom Over years of quality for our clients Achieve goals and continue to evolvetogether with our customers together with our suppliers together in the project team together with each collegue Are you interested in inhouse training or individual training?. FMEA (Potential Failure Mode and Effects Analysis) 4th Edition Errata Sheet Page Original Language (see highlight) Corrected Version Language or explanation i Chapter III focuses on DFMEA (Design Failure Mode Effects and Analysis), Chapter III focuses on DFMEA.

The Process FMEA should result in actions which bring higher risks items to an acceptable level of risk It is important to note that acceptable risk is desirable and mitigation of high risk to lower risk is the primary goal ReRank RPN The new (reranked) RPN should be compared with the original RPN A reduction in this value is desirable. FMEA is a qualitative and systematic tool, usually created within a spreadsheet, to help practitioners anticipate what might go wrong with a product or process In addition to identifying how a product or process might fail and the effects of that failure, FMEA also helps find the possible causes of failures and the likelihood of failures being. And the Risk Priority Number (RPN) for each step as well as for the entire process.

PFMEA Template for FMEA AIAG/VDA (Download template);. Ask for help we will advise you FMEA (Failure Mode and effect. With an FMEA, each failure and its corresponding effect are rated on the three different scales and a Risk Priority Number (RPN) is calculated by multiplying the three ratings for each item This provides a powerful way to evaluate the risk of each failure against the others.

Click on View Report to see the FMEA Tool of a specific organization or individual — including the detailed FMEA that outlines the steps in the process;. Failure Mode and Effects Analysis Description The Failure Mode and Effects Analysis, FMEA, is a subjective screening tool that uses numerical assignments to determine the risk associated with each inputThe highest scored items add the highest risk to the problem (or present the highest risk to the process). In the classic FMEA model, mitigation activities are prioritized based on the calculated risk priority number But FMEA doesn't account for interdependent risks, or mitigation actions that can affect multiple risks Learn a method for overcoming these limitations.

FMEA APLogik Tabelle An dessen Stelle steht nun eine logische Aufgabenpriorisierung lt folgenden Tabellen Die Aufgabenpriorität (AP) basiert dabei weiterhin auf der Kombination von Bedeutung, Auftreten und der Entdeckungswahrscheinlichkeit, dient aber gleichzeitig auch der Priorisierung von Maßnahmen zur Risikoreduzierung. Welcome to Quality Excellence Hub channel This Video is all about AIAG VDA FMEA 1st Edition released in June 19 Latest Edition of Failure Mode and Effect. FMEA is a risk assessment tool, that evaluates the severity, occurrence and detection of risks to prioritize which ones are the most urgent The two most popular types of FMEAs are Process and Design Each category has a scoring matrix with a 110 scale Severity of 1 denotes low risk to the end customer, and a score of 10 denotes high risk to.

This course is a Webbased version of the Failure Mode Effects Analysis (FMEA) problem solving course offered at Ford Motor Company The goal of this online FMEA course is to provide the basic information necessary to generate Design, Process, and Concept FMEAs. This eLearning course provides participants with a clear understanding of the major. FMEA stands for Failure Mode and Effects Analysis, The FMEA a is a structured methodology used by business to help capture and evaluate risk and then monitor the success of mitigation actions (ideally improving the process by removing the opportunity for failure) Check out these case studies on how it’s used in the wild!.

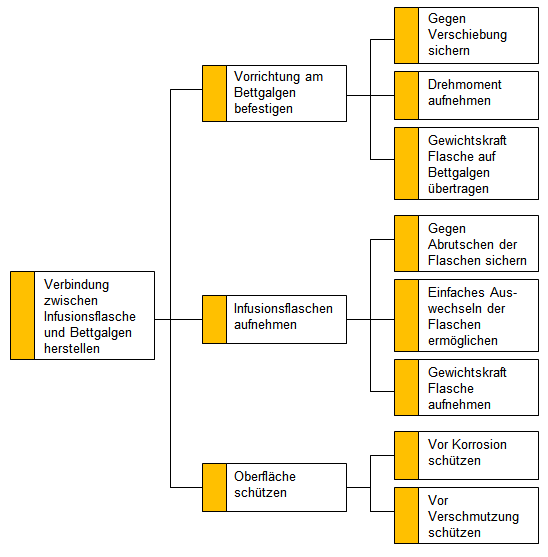

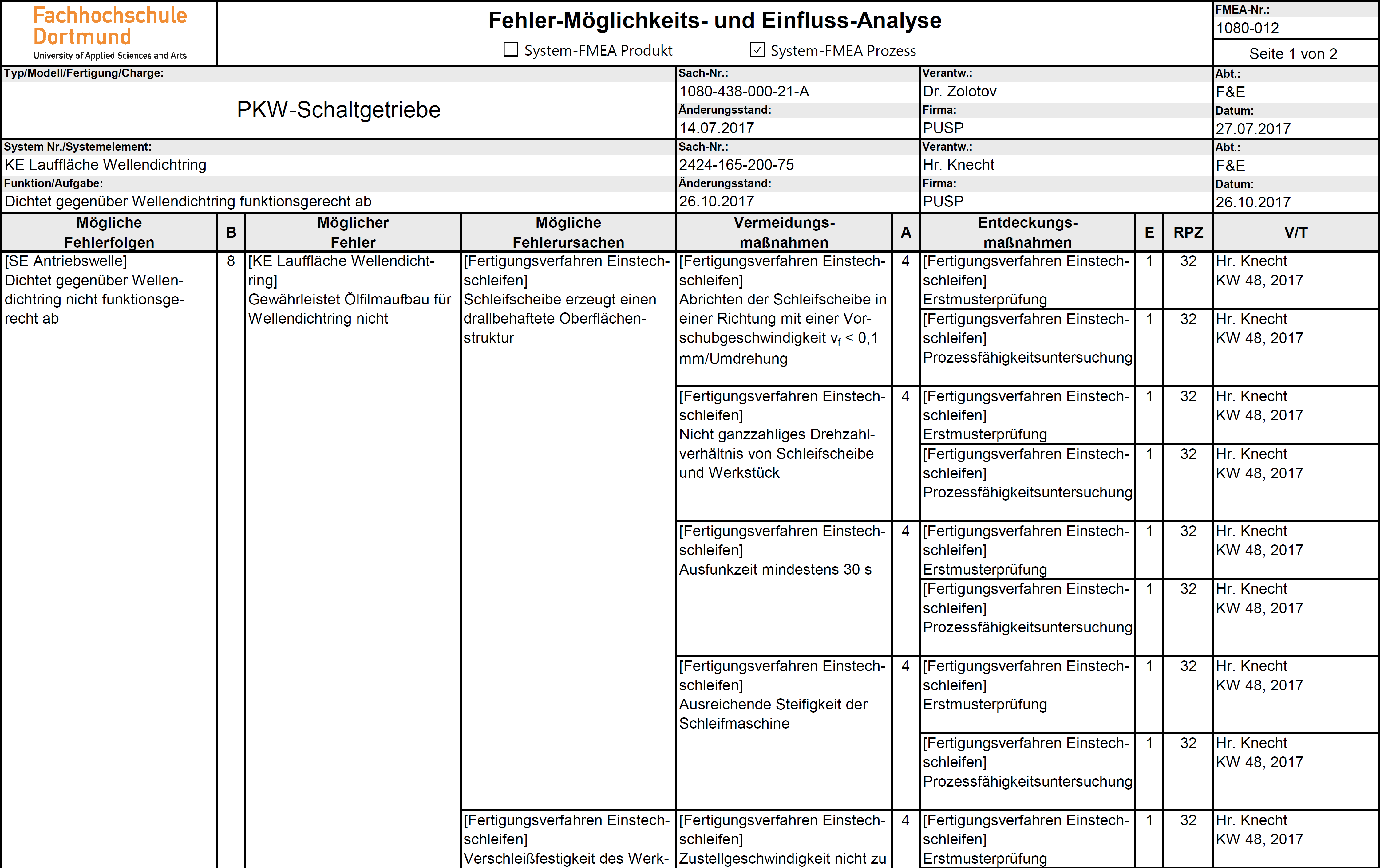

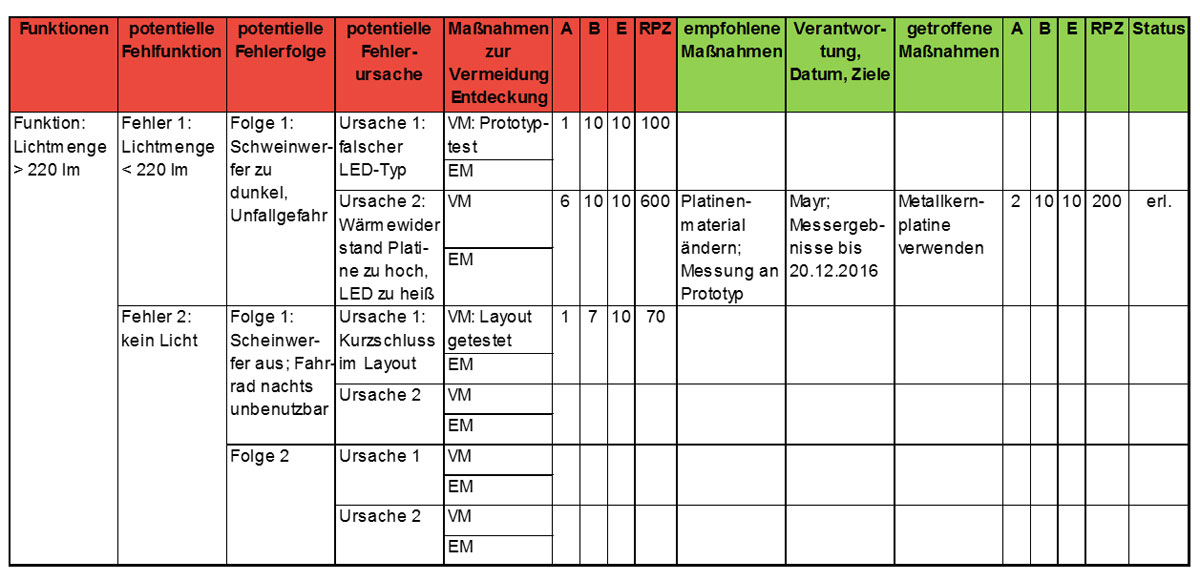

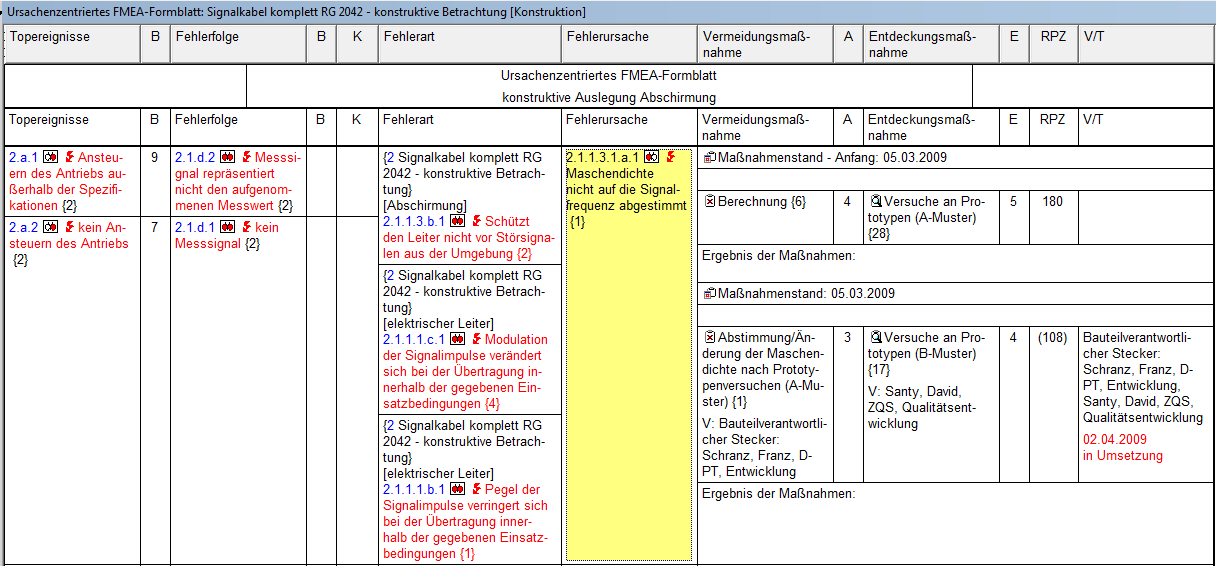

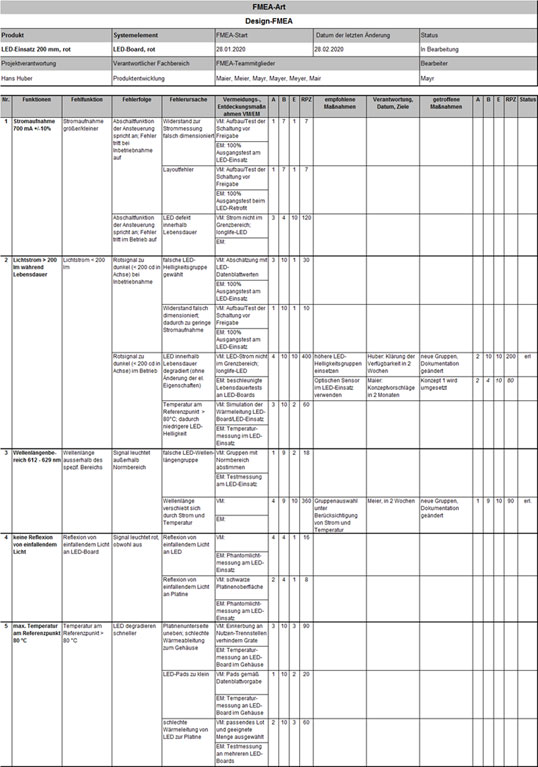

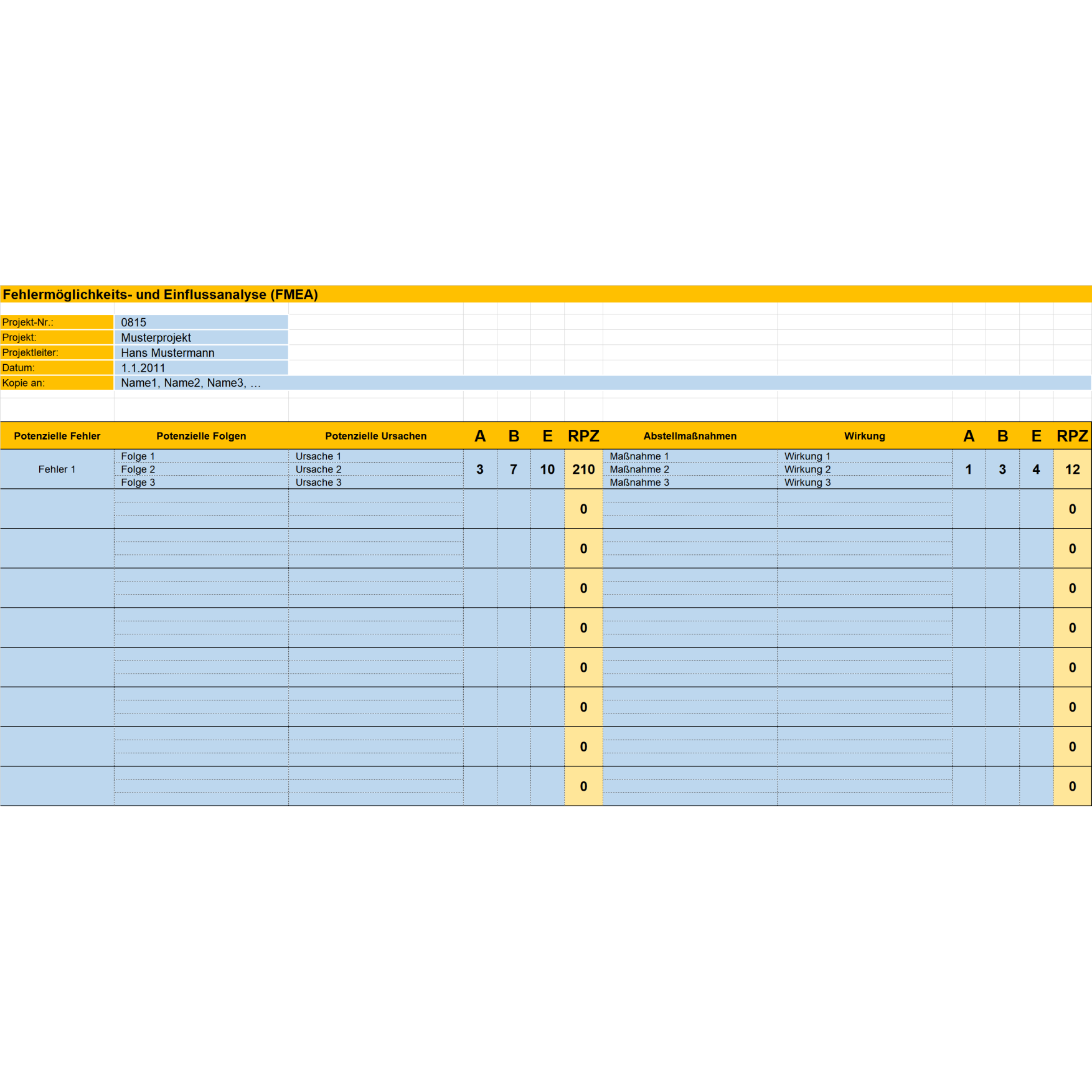

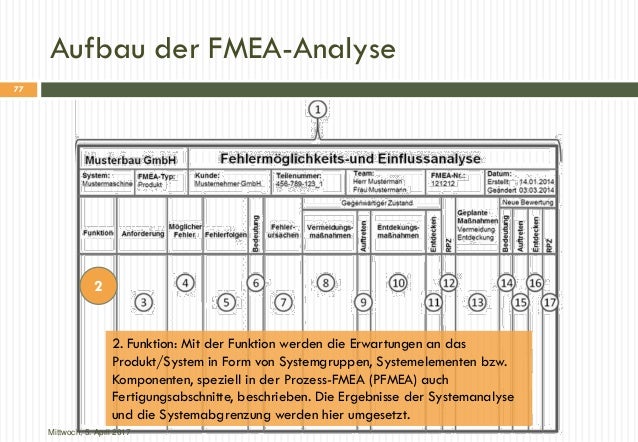

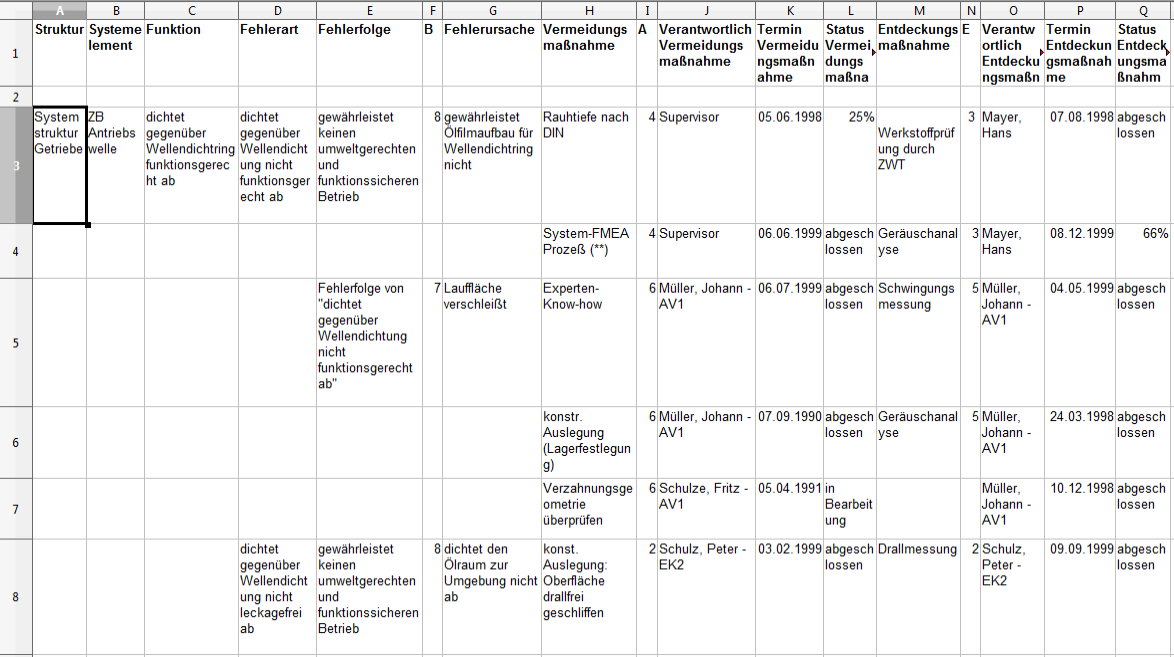

Am Ende der Durchführung werden die ausgefüllten FMEAFormblätter zu Dokumentationszecken archiviert, um jederzeit Zugriff auf die Ergebnisse der Untersuchungen zu haben und das Wissen im Unternehmen weitergeben zu können Ein Beispiel für ein FMEAFormblatt ist in Tabelle 2 dargestellt. Overview Failure Mode and Effects Analysis (FMEA) is a structured way to identify and address potential problems, or failures and their resulting effects on the system or process before an adverse event occurs In comparison, root cause analysis (RCA) is a structured way to address problems after they occur. FMEA stands for Failure Mode and Effects Analysis, The FMEA a is a structured methodology used by business to help capture and evaluate risk and then monitor the success of mitigation actions (ideally improving the process by removing the opportunity for failure).

Failure modes, effects and criticality analysis (FMECA) Begun in the 1940s by the US military, failure modes and effects analysis (FMEA) is a stepbystep approach for identifying all possible failures in a design, a. Failure mode effects analysis (FMEA) is a tool you can use in Six Sigma to quantify and prioritize risk within a process, product, or system and then track actions to mitigate that risk It’s valuable as a method for identifying and prioritizing which critical few factors you must address to improve the process in your. Fmea formblatt vorlage Wir haben 19 Bilder über fmea formblatt vorlage einschließlich Bilder, Fotos, Hintergrundbilder und mehr 10 x 5 · jpeg fmea excel vorlage eueom mexico Download Image Mehr @ eueommexicoorg 730 x 528 · jpeg fmea risknet risk management network Download Image Mehr @ wwwrisknetde 577 x 331 · jpeg qualitaetsmanagementhandbuch Download Image.

Relyence FMEA vs Excel Comparison Step #5 Establish the Recommended Actions The last portion of a FMEA is to define and execute Recommended Actions to reduce Severity or Occurrence, or improve Detection of a FMEA line item This is a critical portion of the FMEA process and allows you to continuously improve your product. Failure Mode Effects Analysis Revision 2 April 11, 07 Kristen Berger, Paul Bieniek, Dave Brooks, Marie Gill Advisor Ahmed AlGhoul 3 Title FMEA Table Author dmb29 Last modified by knb6 Created Date 12/12/06 1110 PM Company University of Pittsburgh Other titles. FMEA Scales for Severity, Occurrence & Detection Severity Scale for Failure Modes & Effects (s cale of 1 least severe to 10 most severe for each effect) Occurrence Scale for Potential Root Causes (s cale of 1 least frequent to 10 most frequent for each root cause) Minor (Rank 1) Low (Rank 2 3) Moderate (Rank 4 6) High (Rank 7 8) Very High (Rank 9 10).

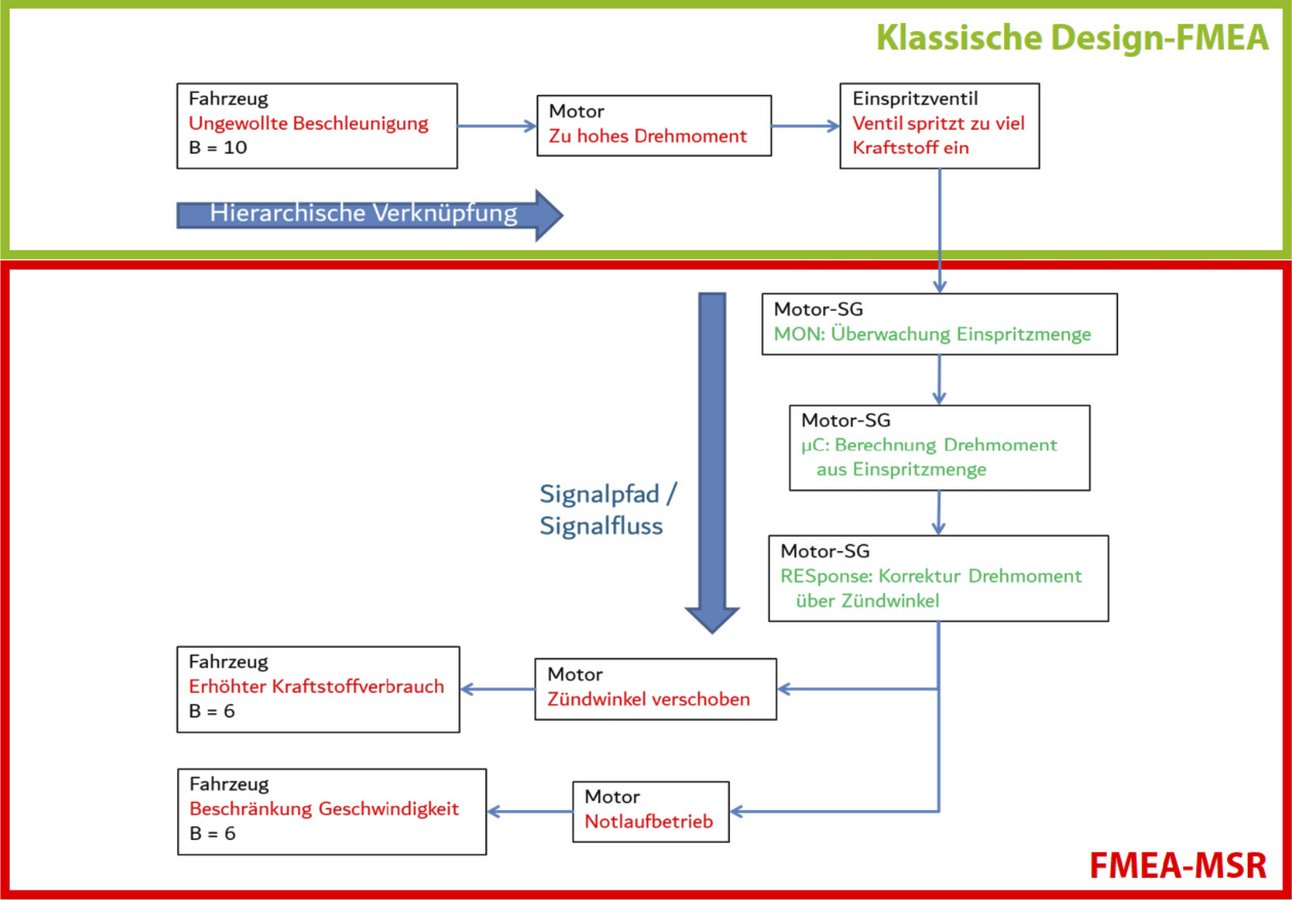

In the classic FMEA model, mitigation activities are prioritized based on the calculated risk priority number But FMEA doesn't account for interdependent risks, or mitigation actions that can affect multiple risks Learn a method for overcoming these limitations. FMEA Step 8 AIAG* Occurrence Guidelines * Note AIAG is the Automotive Industry Action Group, which currently compiles the FMEA standards for the North American Auto Industry Possible Failure Probability of Failure Rates Ppk Ranking Very High > 1 in 2 < 033 10 Failure almost inevitable 1 in 3 > 033 9 High Generally. The first difference between FMEA and FTA is their approach to failure FTA is a systematic, deductive, toptobottom method The starting point is the failure itself, and from then on it reaches a broader conclusion – like an investigation or a diagnosis.

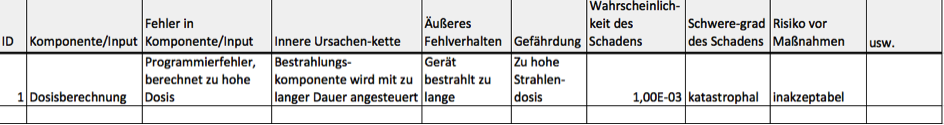

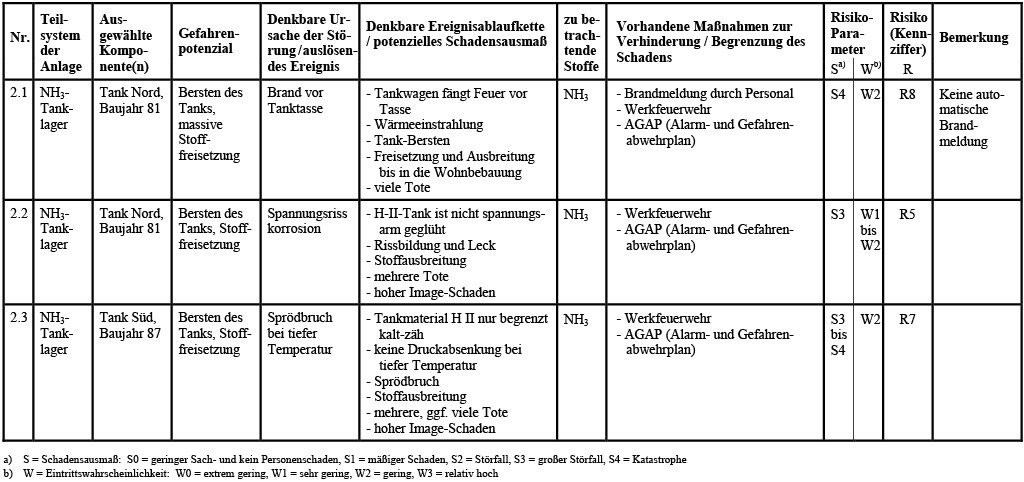

Hazard Analysis and Risk Assessment Because of the reference to SIL and because the ASIL incorporate 4 levels of hazard with a 5th nonhazardous level, it is common in descriptions of ASIL to compare its levels to the SIL levels and DO178C Design Assurance Levels, respectively The determination of ASIL is the result of hazard analysis and risk assessment. FMEA Risk Priority Ranking Reference The following tables are used by permission in iGrafx for FMEA Occurrence Rankings iGrafx uses the Automotive Industry Action Group (AIAG) Occurrence Rankings in the following table to calculate the possible failure rates in the FMEA, based on number of errors and number of samples. The model used for the figures of this page is the Medical FMEA and Hazard Analysis sample model that comes with Cameo Safety and Reliability Analyzer pluginTo open this model do one of the following Download Medical FMEA and Hazard Analysismdzip;.

Institute for Healthcare Improvement Cambridge, Massachusetts, USA Failure Modes and Effects Analysis (FMEA) is a systematic, proactive method for evaluating a process to identify where and how it might fail and to assess the relative impact of different failures, in order to identify the parts of the process that are most in need of change. Fmea failure mode and effects analysis quality one fmea failure mode and effects analysis quality one fmea failure mode and effects analysis quality one fmea table 30 off Share this Click to share on Twitter (Opens in new window) Click to share on Facebook (Opens in new window) Like this Like Loading Related Share. Failure Mode Effects Analysis Sample FMEA Template Item / Function Potential Failure Mode Potential Failure Effects S E V Potential Causes Mechanism(s) of Failure O C C Current Controls D E T R P N Actions Recommende d Resp Actions Taken S E V O C C D E T R P N 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0.

How to conduct Failure Mode and Effects Analysis For many, conducting a Failure Mode and Effect Analysis can be a daunting task However, in order to make everything simplified for you, we have provided a step by step guideline to help you through. The FMEA analysis is an common used Lean Six Sigma tool In the past, the FMEA method was initially used by NASA in aerospace and for highrisk technologies Since the 1980s, the tool has also been used in the automotive industry for Quality improvement Nowadays the FMEA is a widely used tool for risk assessment & evaluation mainly in the. Open the model from the \samples\Safety and Reliability Analysis directory.

FMEA RPN (Risk Priority Number) is a numerical assessment of the risk priority level of a failure mode in an FMEA analysis FMEA RPN helps the responsible team/individual to prioritize risks and make the decision on the corrective actions. FMEA Step 8 AIAG* Occurrence Guidelines * Note AIAG is the Automotive Industry Action Group, which currently compiles the FMEA standards for the North American Auto Industry Possible Failure Probability of Failure Rates Ppk Ranking Very High > 1 in 2 < 033 10 Failure almost inevitable 1 in 3 > 033 9 High Generally.

Fmea Konkret De Uploads Tx Magazine 17 09 Magazin Fmea Konkret Web Final Pdf

Risikoidentifikation Risikomanager

Smqe Qualitatsmanagement

Fmea Tabelle のギャラリー

Neuer Artikel

Systematik Und Durchfuhrung Der Fmea Fehler Moglichkeiten Und Fehler Einfluss Analyse Fmea Business Wissen De

Designpilot Fmea

Fmea In Einer Weberei Risikomanager

Harmonisierter Fmea Standard Babtec

Fehlermoglichkeits Und Einflussanalyse Fmea Nach Qs 9000 Qz Online De

Fmea Skriptum Elias Gmbhstudienbuch System Fmea

Was Ist Neu An Der Fmea Risknet The Risk Management Network

Rexs Risk Expert System

Q2 Management Development Ab Excel Qualitatswerkzeuge Design Und Prozess Fmea

Fmea Fehler Moglichkeits Und Einfluss Analyse Quality De

Fmea

Fmea Solutions Apis Iq Software Carm Carm Ng Server

Die Fmea Als Technik Zur Risikoanalyse

Rpz Risikobewertung Fmea Wiki

Fehlermoglichkeits Und Einflussanalyse Fmea Nach Qs 9000 Qz Online De

Fmea Definition Anleitung Beispiele

Smqe Qualitatsmanagement

Www Vtu Com De News Autoren Pdf Gbitzundfeil Tp 2 17 Zurverwendung Pdf M

Fmea Failure Mode And Effects Analysis

1

Was Ist Neu An Der Fmea Risknet The Risk Management Network

Bewertungskataloge Richtig Nutzen Apis Informationstechnologien Gmbh

Ursachenzentriertes Formblatt

Harmonisierter Fmea Standard Babtec

Fmea Software Zur Fehlervermeidung

10 Warten Was Kommt Stand Der Aiag Vda Fmea Harmonisierung Das Magazin Fur Erfolgreiche Entwickler Und Fmea Moderatoren Pdf Free Download

Bewertung In Der Fmea Ap Logik Statt Rpz

Http Link Springer Com Content Pdf 10 1007 2f978 3 48 01 8 3 Pdf

Fmea Downloads 19

Arbeitspakete Speichersicherheit

Smqe Qualitatsmanagement

Deckblatt Prozess Fmea Pdf Free Download

Fmea Definition Anleitung Beispiele

Apis Iq Software Version 7 0

Aufbau Und Entwicklung Von Fmea Formblattern Qz Online De

Risikomanagement Nach Fmea Medizinische Physik

Fehlermoglichkeits Und Einflussanalyse Fmea Nach Qs 9000 Qz Online De

Fmea Harmonisierung Vda Und Aiag Pdf Free Download

Fmea Downloads 19

Risikoanalyse Fmea Controllingwiki

/Unbenannt-2_1491902650.jpg)

Designpilot Fmea

Aesq Sae Itc Com Sites Default Files D304 review Booklet Ian Riggs v2 De no logo Pdf

M Mfea I Q

Fmea So Erkennen Und Vermeiden Sie Fehler Rechtzeitig Unternehmensberatung Axel Schroder

Fmea Fehlermoglichkeits Und Einfluss Analyse Qmbase

Excel Vorlage Fmea Formblatt Orgaimprove Gmbh Beratung L Schulung L Unterstutzung

Fmea

Der Neue Fmea Standard In Der Automobilindustrie Industryarena

Fmea Wirtschaftsperformance Com

Fmea Fehlermoglichkeits Und Einfluss Analyse Qmbase

Risikoanalyse Fmea Controllingwiki

Apis Iq Software Version 7 0

Fmea Ap Logik Tabelle

Link Springer Com Content Pdf 10 1007 2f3 540 0 4 Pdf

Smqe Qualitatsmanagement

Die Qm Werkzeugkiste Fmea

Www Vtu Com De News Autoren Pdf Gbitzundfeil Tp 2 17 Zurverwendung Pdf M

Was Ist Neu An Der Fmea Risknet The Risk Management Network

Was Ist Neu An Der Fmea Risknet The Risk Management Network

Fmea In Einer Weberei Risikomanager

Was Ist Neu An Der Fmea Risknet The Risk Management Network

Fmea So Erkennen Und Vermeiden Sie Fehler Rechtzeitig Unternehmensberatung Axel Schroder

Bewertung In Der Fmea Ap Logik Statt Rpz

Smqe Qualitatsmanagement

Fehler Vermeiden Statt Aufwendig Beseitigen Mit Der Fmea

Fehlermoglichkeits Und Einflussanalyse Fmea Nach Qs 9000 Qz Online De

Die Rpz Ist Tot Es Lebe Die Ap Risknet The Risk Management Network

/fmea_beispiel_1488440206.jpg)

Designpilot Fmea

Arbeitsanweisung Fmea Fehler Moglichkeit Einfluss Analyse

Fmea Definition Anleitung Beispiele

Fmea Formblatt Variante 2 Excel Tabelle Business Wissen De

Fmea Fur Risikoanalyse Qualitatsmanagement Definition Bewertung

Fehlermoglichkeits Und Einflussanalyse Fmea Nach Qs 9000 Qz Online De

Fmea I Q

Wird Mit Dem Neuen Fmea Handbuch Alles Besser

Fmea Downloads 19

Apis Iq Software Version 7 0

Fmea Definition Anleitung Beispiele

Fehlermoglichkeits Und Einflussanalyse Fmea

Risikoanalyse Fmea Controllingwiki

Fehlermoglichkeits Und Einflussanalyse Fmea

Neue Schritte Der Fmea Harmonisierung Iqs Caq Mit System

Fmea So Erkennen Und Vermeiden Sie Fehler Rechtzeitig Unternehmensberatung Axel Schroder

Industrielle Dienstleistungen Professionell Gestalten Service Fmea

Werkzeuge Fur Das Fmea Projekt Fehler Moglichkeiten Und Fehler Einfluss Analyse Fmea Business Wissen De

Rpz Archive Pdap By Jessenlenz

Losungen Apis Informationstechnologien Gmbh

Risikoanalyse Fmea Controllingwiki

Systematik Und Durchfuhrung Der Fmea Fehler Moglichkeiten Und Fehler Einfluss Analyse Fmea Business Wissen De

Fmea Fehlermoglichkeits Und Einfluss Analyse Qmbase

Tdc Software Sofwares For Product And Process Design Quality Risk Management Traceability And Methodology

Www Fmea Konkret De Uploads Tx Magazine 19 10 Magazin Fmea Konkret Das Grosse Warten Pdf

Smqe Qualitatsmanagement

Sps Magazin Die System Fmea Im Safety Projekt

Lebenszyklus Risikoanalyse In Der Qualifizierung Pdf Kostenfreier Download

Fmea Wirtschaftsperformance Com

Risikobewertung Von Betriebsbereichen In Der Praxis Ingenieur De