Obsolescence Management

Obsolescence Management is the key to prevent many problems that may occur in an immediate future To solve this problem, different paths can be taken Create new expensive modern equipment.

Obsolescence management. Obsolescence management IEC provides requirements and guidance for obsolescence management applicable to any organization that is dependent on another organization to obtain value from the usefulness of the items that it provides A costeffective obsolescence management process and the activities used to implement the process are applicable throughout all phases of an item’s life cycle. Obsolescence management The life cycle of products is determined more or less actively by product availability and maintenance options The control of this “expiry time” is called obsolescence or cancellation management and regulates when a product, module or component becomes obsolete At FELA, obsolescence management follows the principle of “formfitfunction”. OBSOLESCENCE MANAGEMENT SYSTEM paths to follow The quick evolutionand spread of different kinds of hardware, digital encoding, operative systems or common and specialized softwares, made it possible that digital obsolescence became a problem of such large proportions Obsolescence Managementis the key to prevent many problems that may occur in an immediate future.

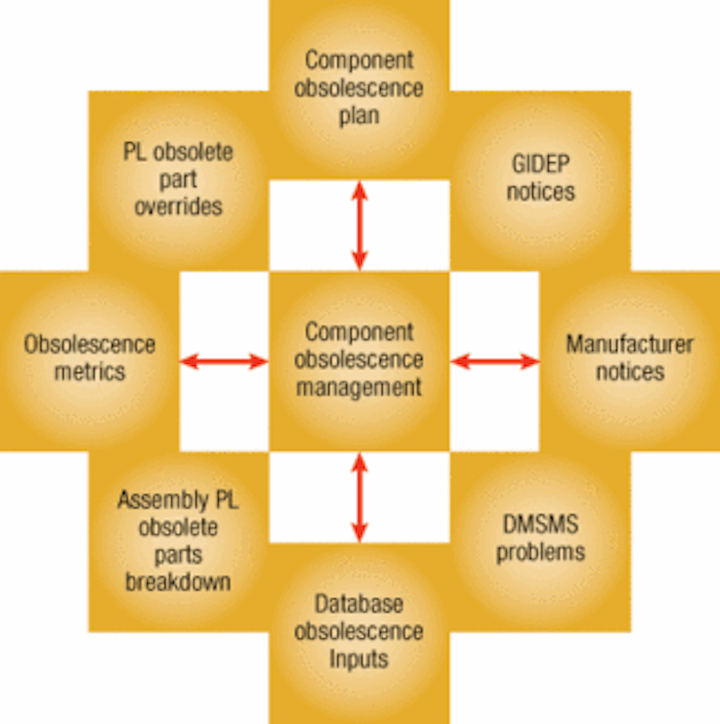

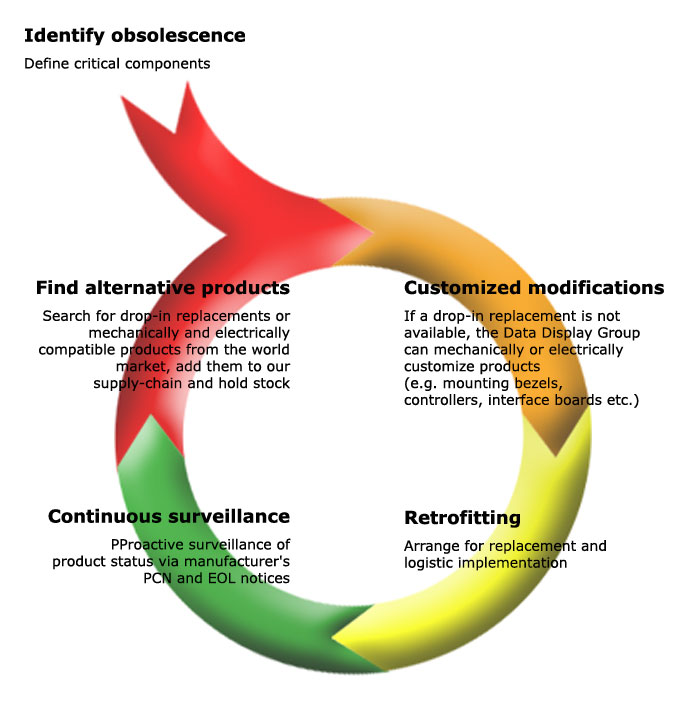

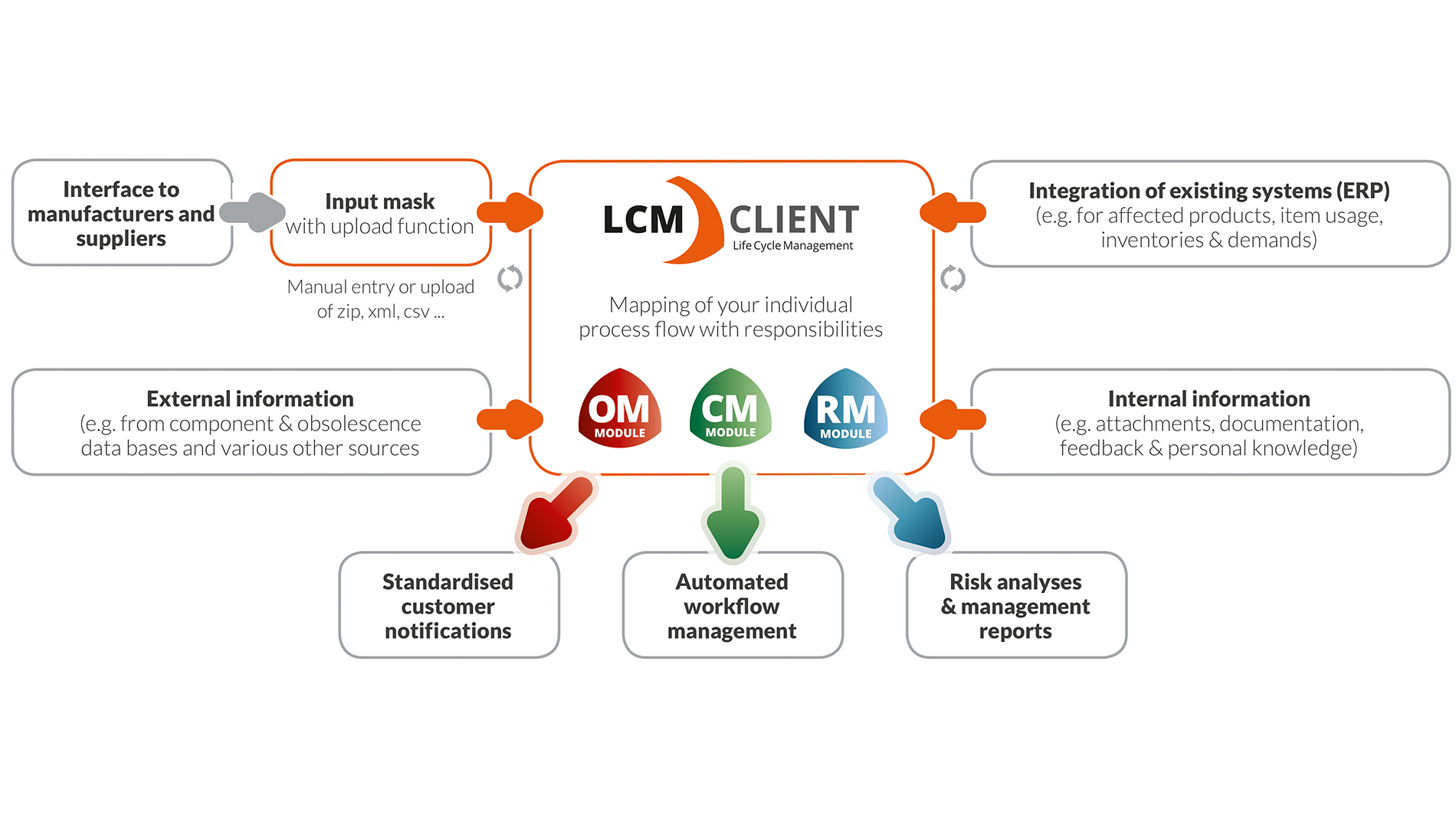

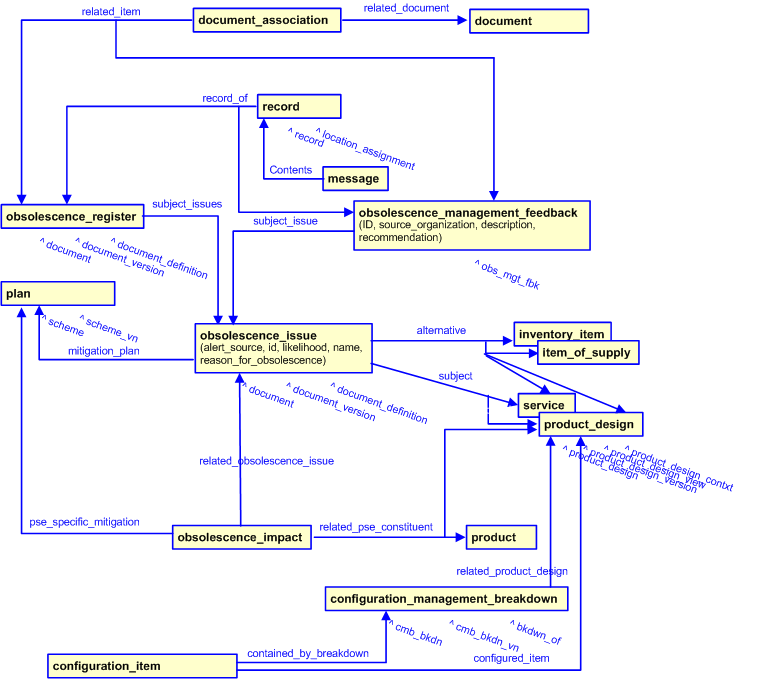

The objective of Obsolescence Management is to ensure that obsolescence is managed through out the defined useful life of a product by integrating an Obsolescence Management plan from as early as the product’s design and development phase, continues through production and exploitation phase and till the product’s defined life such that its financial and availability impact can be minimized throughout the product lifecycle. Effective proactive obsolescence management consists of an holistic cycle of planning, monitoring, mitigating and reviewing that is designed to minimise the impact of obsolescence on system support costs and availability, through the early identification and application of appropriate strategies, resources, tools and resolution options. Obsolescence Management Information System (OMIS) Updated 8/31/15 Launch Tool Obsolescence Management Information System (OMIS) 0 stars out of 5 based on 0 user ratings OMIS™ is a Department of Navy (DoN) owned and maintained proactive obsolescence management tool for identifying, managing, and monitoring Diminishing Manufacturing Sources and Material Shortages (DMSMS) issues.

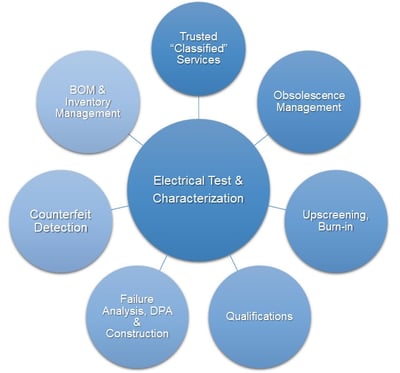

Having an active or proactive approach towards obsolescence management is of course highly beneficial for any maintenance and reliability manager The more you plan and predict obsolescence in advance, the easier you will be able to control risks When implementing proactive obsolescence management, attention should be paid to the following measures. Equipment no longer meets the needs, requirements or standards When managing assets, we must be aware of any current or potential obsolescence so that we can take the necessary steps to ensure that these issues don’t result in an unplanned or unexpected interruption to services. OBSOLESCENCE MANAGEMENT Integra provides a complete portfolio of services to support Military/Space/Aerospace companies threatened with diminishing sources of supply for semiconductor and related EEE parts We specialize in Obsolescence Management Solutions including Procure Parts, Valueadd Testing, Kitting & Inventory Management.

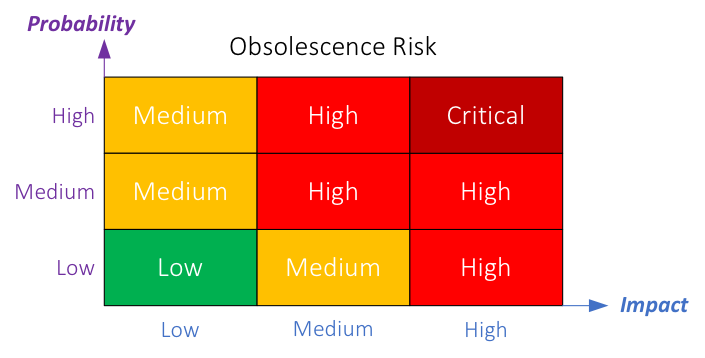

Manage Obsolescence Risk The most common methods of the past for managing obsolete electronic components have entailed very manual or reactive processes that lead to chaos, human error, long lead times and excessive costs to the organization. The objective of Obsolescence Management is to ensure that obsolescence is managed through out the defined useful life of a product by integrating an Obsolescence Management plan from as early as the product’s design and development phase, continues through production and exploitation phase and till the product’s defined life such that its financial and availability impact can be minimized throughout the product lifecycle. Obsolescence Management This Defence Standard establishes a framework for contracting for Obsolescence Management and provides guidance in planning a cost effective obsolescence management process, that is applicable.

Devised and delivered an innovative approach to obsolescence management that resulted in a 75% improvement in parts availability Led the introduction of the upgraded AESA radar to Fleet users. Obsolescence is too big a problem to take on alone One reason we developed the Future of Obsolescence Management was to create a community that could share solutions to shared problems The Future of Obsolescence Management puts you in touch with a global network of obsolescence management experts. Obsolescence management is even more critical in the military, because it can happen at any point in a component’s life This particularly applies to electronic components, which have a relatively short lifespan in comparison to hardware and other major parts, but a long lead time to deliver.

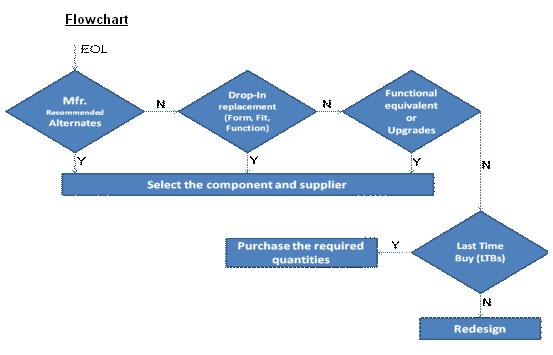

The minister of state for Defra, Lord Zac Goldsmith, has said the government plans to tackle “planned obsolescence”, adding it’s likely that Latest sponsored by LATEST Waste Management Goldsmith vows to tackle ‘planned obsolescence’. Obsolescence Management takes into account the life span of all the moving pieces of your complex system with a plan to replace obsolete parts as they age, before it becomes a crisis This is not a simple process Challenges include parts availability, diminishing materials, counterfeit avoidance and knowing where to look to find what you need. Obsolescence management, also referred to as "Diminishing Manufacturing Sources and Material Shortages" (DMSMS), is defined as to the activities that are undertaken to mitigate the effects of obsolescence Activities can include lasttime buys, lifetime buys, and obsolescence monitoring See also.

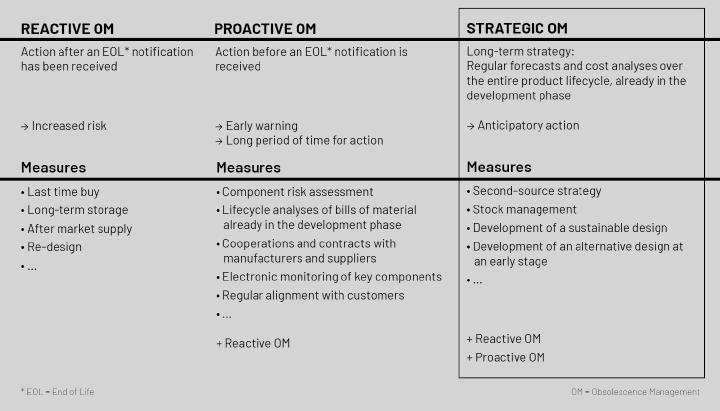

Without proper obsolescence management, you may not receive your product on time — or at all — because the components you need aren’t readily available or are only available on the gray/black market We at Matric want to communicate with the customer before it reaches this point of no return. Obsolescence Management – “coordinated activities to direct and control an organisation with regard to obsolescence” The principle aim of Obsolescence Management is to avoid the costly resolutions when an obsolescence issue occurs Careful planning can minimize the impact of obsolescence and its potentially high costs. The obsolescence management strategy shall be defined and communicated throughout the company The obsolescence management process shall be subject to regular reviews to make ensure that the strategies and processes remain fully applicable and effective To prevent these risks of obsolescence following three management strategies are established.

Actively manage obsolescencerelated efforts including, but not be limited to, the acquisition of lifetime or lasttime component parts buys, the temporary acquisition of longlead material and. Obsolescence Management Information System (OMIS) Updated 8/31/15 Launch Tool Obsolescence Management Information System (OMIS) 0 stars out of 5 based on 0 user ratings OMIS™ is a Department of Navy (DoN) owned and maintained proactive obsolescence management tool for identifying, managing, and monitoring Diminishing Manufacturing Sources and Material Shortages (DMSMS) issues. The objective of obsolescence management is to ensure that obsolescence is managed as an integral part of all design, development, production and inservice support in order to minimize cost and detrimental impact throughout the product life cycle.

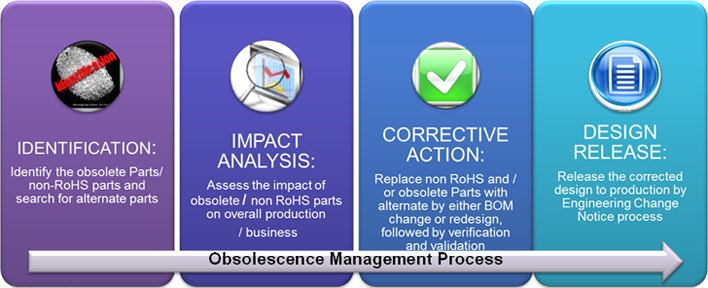

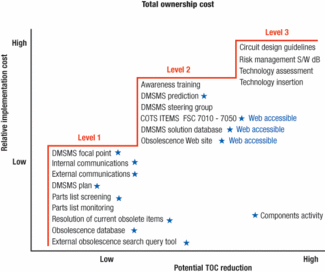

Developing an Obsolescence Management Plan (OMP) Developing strategies to minimize obsolescence during design Determining an obsolescence management approach Selecting obsolescence resolution and implementation Measuring and improving the performance of the outcomes of obsolescence management activities. The role of the parts obsolescence management team is to promote a process by which team leaders can predict parts, materials, and equipment shortagesand mitigate problemsto keep cost overruns. This guidebook, which was updated in January 16, highlights the most effective, proactive practices being used across DoD to help program managers reduce the risk of obsolescence The guidebook presents basic methodology to assist program managers with establishing DMSMS programs and analyzing the results in regard to the basic parameters of cost, schedule, and performance.

Obsolescence management in the military the holistic approach Obsolescence applies to a wide range of components, including mechanical, electrical, electronic and software, as well as skills, so. In a new video for Cosmo Tech, Renault’s Expert Leader Industrial System 40 Jean Goutierre explains how Cosmo Tech’s Simulation Digital Twin brought a new approach to asset obsolescence management and maintenance and reduced capital costs over 5 years from €10 million per year down to 2 and 5 million euros per year. Obsolescence management is a discipline in and of itself As the service life of a product extends beyond the technology life cycle incorporated in the design, problems with obsolescence and DMSMS arise Both the defense and commercial markets must find ways to plan for and manage obsolescence and DMSMS because every product is subject to their effects.

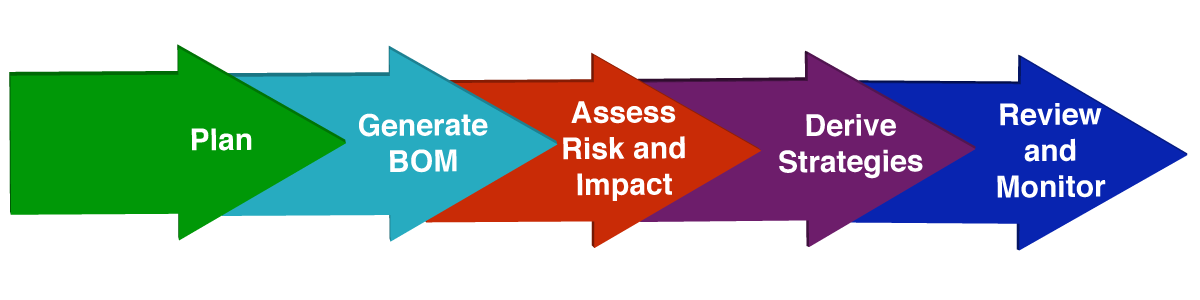

Having an active or proactive approach towards obsolescence management is of course highly beneficial for any maintenance and reliability manager The more you plan and predict obsolescence in advance, the easier you will be able to control risks When implementing proactive obsolescence management, attention should be paid to the following measures. Introduction Obsolescence management of hardware components can be well understood and implemented You generate a Bill of Materials (BOM) of all the components of your systems You then assess risks of obsolescence of these components to prioritise and develop strategies to deal with obsolescence, then continually monitor and review. Obsolescence management, also referred to as "Diminishing Manufacturing Sources and Material Shortages" (DMSMS), is defined as to the activities that are undertaken to mitigate the effects of obsolescence Activities can include lasttime buys, lifetime buys, and obsolescence monitoring See also.

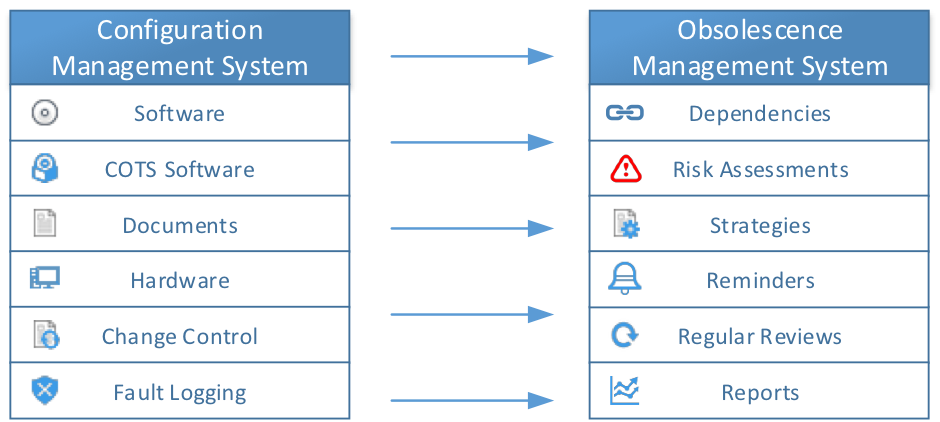

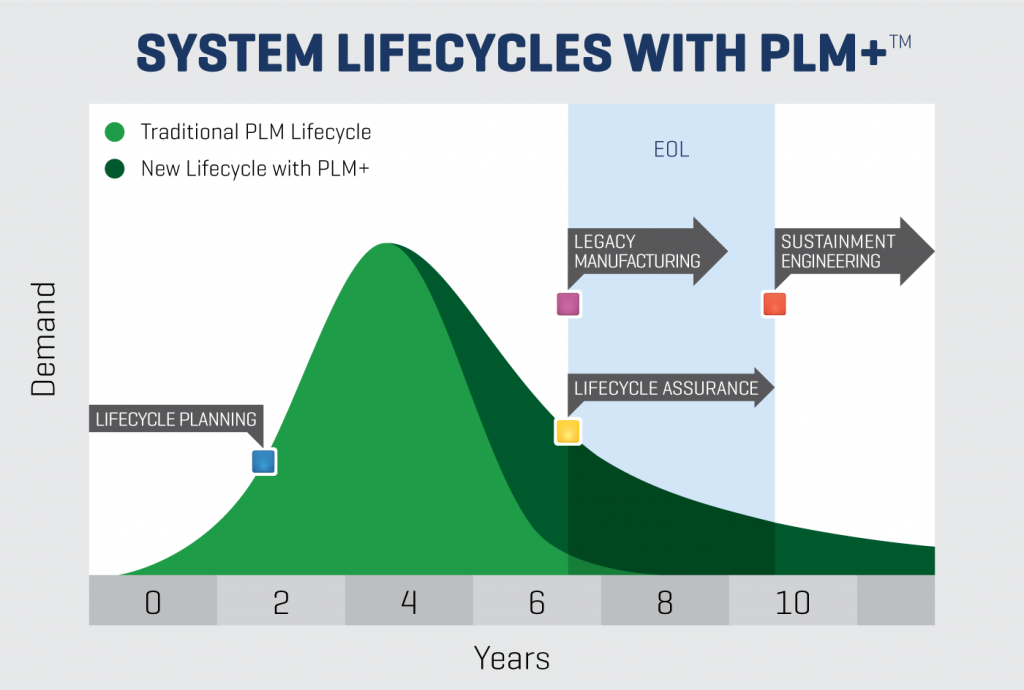

Obsolescence in order to achieve the required performance outcome(s) These long term PBL agreements/contracts lower provider risk and allow for DMSMS mitigation efforts life of type buys, establishment of long term contracts with subcontractors, and return on investment for redesigns Additionally, A PBL provider may be able to leverage off of. Any obsolescence management plan will include a variety of different elements These may include the following Technology roadmap One key element of any obsolescence plan is to look at a technology roadmap This enables the development team to identify, evaluate, and select technologies that are less likely to be affected by obsolescence and also it may suggest alternatives that can have a longer design life. Life Cycle Control includes configuration and obsolescence management, ideal for customers with long project lifecycles Along with the Change Control configuration management offered in Level 2, XES proactively monitors obsolescence notification sources and issues an obsolescence notification form to designated customer contacts Life Cycle Control provides options to lengthen the life of projects as products age and their components reach EndofLife (EOL).

Customers globally use SiliconExpert’s solutions to manage risk, avoid redesigns, and mitigate obsolescence in innovative industries such as, but not limited to, consumer electronics, telecommunications, automotive, medical, and aerospace. •Obsolescence management plan •The prime contractor produces a Obsolescence Management Plan (OMP) •The OMP describes the proactive approach to be taken by the contractor to manage, mitigate and resolve obsolescence issues across the lifecycle of the program (DoD, 05). Rohde & Schwarz obsolescence management monitors the availability of all your system components and spare parts as well as the presence of inhouse software and service skills No hidden costs, no risks With our obsolescence management service packages, you determine which services you wish to use Service & support request.

Obsolescence Management by BHS Corrugated can help We can help you achieve high operational reliability and keep your corrugator uptodate – all while potentially shrinking your inventories thanks to standardized components Obsolescence Management gives your corrugator and corrugated production operation total security in every aspect Process. Obsolescence management is carried out from the planning to retirement phase During frontend planning, measures can be taken to preempt obsolescence issues and delay their onset in the life cycle of the system Proactive measures can also be put in place through contracting mechanisms This article presents the principles and. A sophisticated Obsolescence Management Plan is constituted by five interacting mechanisms active through all stages of the life of each product Component Lifecycle Status Matrix For all products, especially for all the enterprise and industrialgrade product lines, the constituent material component lifecycle matrix information is required and obtained from suppliers.

Obsolescence management is the discipline that addresses obsolescence and Diminishing Manufacturing Sources and Material Shortages (DMSMS) as the service life of a product extends beyond the technology life cycle incorporated in the design. At FortéOne, we work with your inventory management personnel to create an obsolescence management process that reduces unsaleable inventory by working with new product development and sales to establish two processes one for sunsetting low selling SKUs and another for moving inventory prior to it becoming unsaleable. The Future of Obsolescence Management community is powered by individuals and organizations that care about the challenges of managing obsolescence in your supply chain The best way to tackle these growing demands in our market is through collaboration and sharing ideas.

5 BOM Obsolescence Management Tips Tweet In today’s market, it can often feel like parts become obsolete the second after they are designed in It is important to carefully analyze your Bill of Materials (BOM), and discover any obsolescence risks within your assembly, before it becomes a problem Through this 5 step process, you can properly check your BOM and identify high risk components before they become a problem in your manufacturing. Obsolescence management places significant pressure on internal development teams that should be focused on developing new products and building a future pipeline Nevertheless, if a medical device company approaches obsolescence management differently, it can avoid the bad rap of high costs and avoid the need to invest significant resources in such efforts. Advanced Component Obsolescence Management (AVCOM) is a webenabled tool and service that allows users to forecast when a part will become obsolete or too expensive, and then finds a suitable replacement from across the marketplace Given AVCOM’s access to an obsolescence management database, comprised of more than 100 million parts, AVCOM is the goto resource for military and commercial customers.

Obsolescence Management Objective Advantages And Processes At Product Stages

Future Of Obsolescence Management For Electronics Converge

Managing Obsolescence Takes Commitment To Best Practices Military Aerospace Electronics

Obsolescence Management のギャラリー

What Is Obsolence Mgt

Obsolescence Management Aitech Website

Electronic Components Life Cycle Management Part 6

Obsolescence Management For Railway Systems On Vimeo

Cost Effective Obsolescence Management Of Control Systems Asset Guardian Solutions Limited

Why Is Obsolescence Management Important Today Electrical Components Blog

General Obsolescence Management Process 2 Download Scientific Diagram

Flying High With Obsolescence Management Automated

Tpp Electronic Component Obsolescence Management Environmental Compliance

Obsolescence Management Jema

About Iiom Us Chapter

Obsolescence Management Of Software Components Asset Guardian Solutions Limited

Risk There S More To Obsolescence Management Than Proactive Component Monitoring Cmca Uk

What Is Obsolescence Management Gdca

Introducing The Book Of Obsolescence Management By Eu Automation

Obsolescence Management The Impact On Reliability

Pcb Obsolescence Management Service In Banjara Hills Hyderabad Argus Embedded Systems Private Limited Id

Proactive Vs Reactive Approaches To Obsolescence Management Siliconexpert

Proactive Vs Reactive Approaches To Obsolescence Management Siliconexpert

Managing Obsolescence Takes Commitment To Best Practices Military Aerospace Electronics

Hardware Obsolescence Management In The Biometrics Industry Kai

Obsolescence Management

Qtec Solutions Inc Obsolescence Solutions

How To Avoid An Obsolescence Crisis Patsnap

What Makes A Complete Obsolescence Management Strategy News

Qtec Solutions Inc Obsolescence Solutions

Obsolescence Management For Aerospace Components Phoenix Logistics

Obsolescence Management Opensvc 2 1 Documentation

5 Bom Obsolescence Management Tips

Obsolescence Management Another Perspective Military Embedded Systems

What Makes A Complete Obsolescence Management Strategy News

The Book Of Obsolescence Management Boom Proctor Mark Wilkins Jonathan Ebook Amazon Com

Obsolescence Management Opensvc 2 1 Documentation

Obsolescence Management Process At Various Product Life Stages Powerpoint Slides Diagrams Themes For Ppt Presentations Graphic Ideas

Solutions Plm Proactive Legacy Management Gdca

Component Obsolescence Management For Hardware Management Identification System Home Automation

Obsolescence Management For An Iot Home Security Solutions

Feature Effective Obsolescence Management Indmacdig Industrial Machinery Digest

Component Obsolescence The Unavoidable Problem Sparton

Pdf Obsolescence Management For Long Life Contracts State Of The Art And Future Trends Semantic Scholar

Obsolescence Management Revision Control In Sn Complex Bengaluru Akuva Infotech Private Limited Id

Obsolescence Management Critical Components With Continuous Surveillance Powerpoint Slides Diagrams Themes For Ppt Presentations Graphic Ideas

Tq Obsolescence Management

Electronic Components Obsolescence Management Microrel

Iiom Cpd Provided By Obsolescence Management Academy

Obsolescence Management

Excess And Obsolescence Management Techtrade Solutions Llc

Obsolescence Management

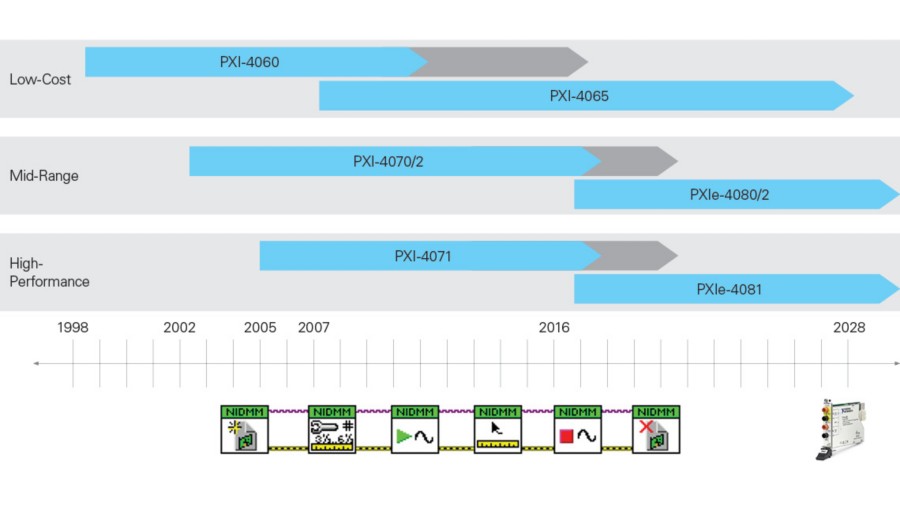

Solving Tomorrow S Obsolescence Management Challenges With System Design Ni

Different Types Of Proactive Approach For Obsolescence Management

Obsolescence Management I M Off Then

Proactive Vs Reactive Approaches To Obsolescence Management

1 4 Categorization Of Obsolescence Management Approaches Strategies To The Prediction Mitigation And Management Of Product Obsolescence Book

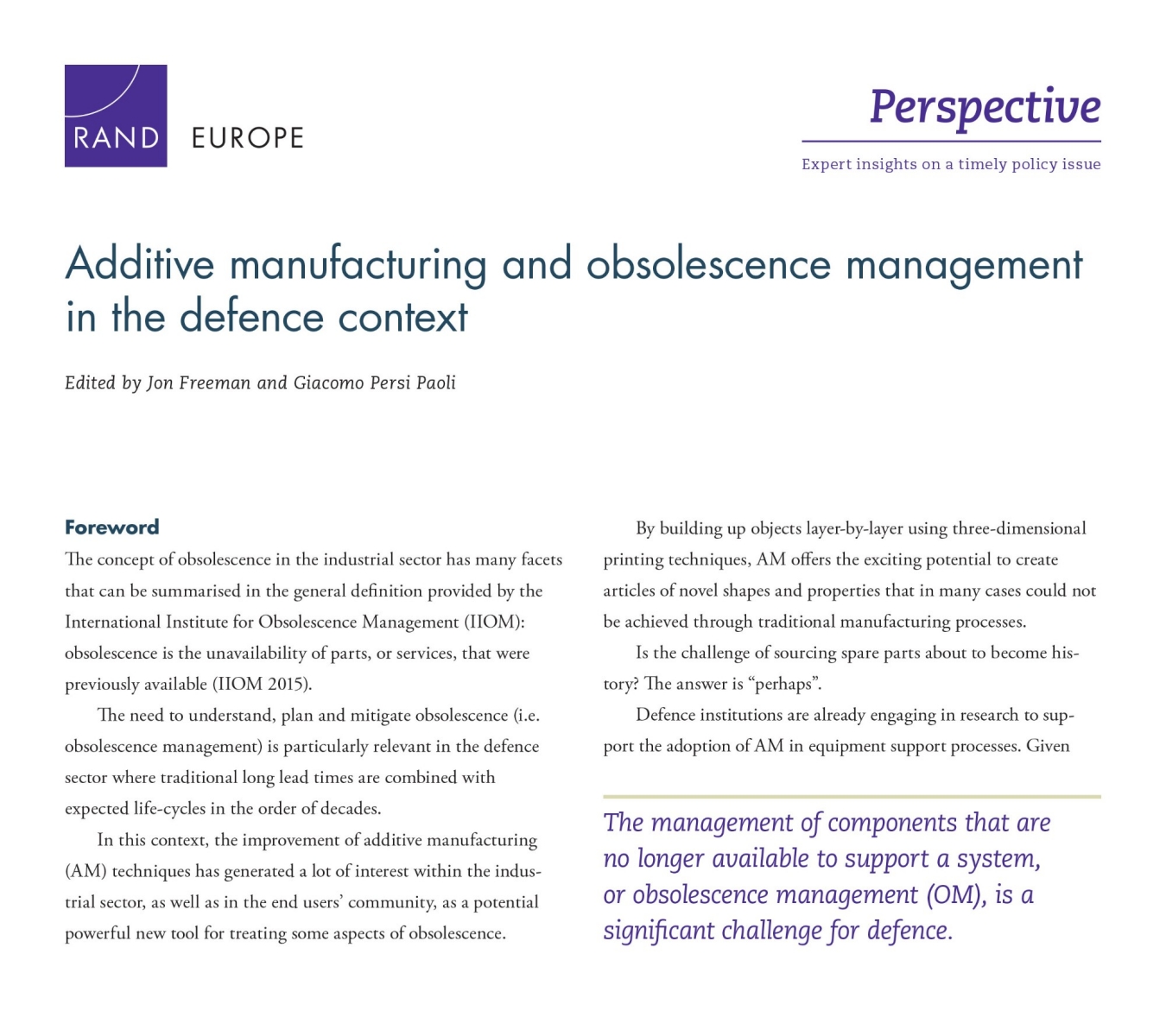

Additive Manufacturing And Obsolescence Management In The Defence Context Rand

Integra Obsolete Parts Management

Comparison Of The Main Obsolescence Management Tools Download Table

Cmca Uk Assured Total Obsolescence Management

Digital Obsolescence Management Korber Digital

Key Proactive Approach For Obsolescence Management Powerpoint Slides Diagrams Themes For Ppt Presentations Graphic Ideas

Obsolescence Management Of Electronic Components Throughout Product Lifetime Bom Blog Altium

Do Your Ecm S Obsolescence Management Procedures Look Like This

Strategic Obsolescence Management Pays Off Stw Sensor Technik Wiedemann Gmbh Press Release Pressebox

4 Reasons Component Obsolescence Is A Growing Part Of Supply Chain Management

9 6 Strategic Obsolescence Management Guidelines Strategies To The Prediction Mitigation And Management Of Product Obsolescence Book

Obsolescence Management Solution Ilensys

Obsolescence Management Portal Obsolescence Spare Parts

Obsolescence Management Strategies For A Long Product Life

Creating A Proactive Obsolescence Management System Framework Through The Systems Engineering Continuum Pobiak 14 Systems Engineering Wiley Online Library

The Role Of Obsolescence Management In Reducing The Threat Of Counterfeits Stuart Kelly Anti Counterfeiting Forum 19 Th February Ppt Download

Pdf Obsolescence Management For Long Life Contracts State Of The Art And Future Trends Semantic Scholar

Obsolescence Management Environmental Compliance

Obsolescence Management Who Wants To Live Forever By Ian Blackman Service In Industry Hub

Obsolescence Management Definition By Technosoftinnovations Issuu

Obsolescence Management Flex Engineering Services

Obsolescence Management

International Institute Of Obsolescence Management Archives Aerospace Manufacturing

What Is Obsolescence Management For Electronics

Obsolescence Management Done Right Youtube

Implementing An Obsolescence Management Strategy Automated

3 Simple Characteristics Of A Successful Obsolescence Management Strategy News

Obsolescence Management Vs Planned Obsolescence Tls

Tq Obsolescence Management

Iiom International Institute Of Obsolescence Management Linkedin

Part Selection And Management Benchmarking Services Center For Advanced Life Cycle Engineering

Managing Obsolescence Asset Guardian Solutions Limited

Importance Of Alert And Obsolescence Management On Space Projects

Developing An Obsolescence Management Plan Sut Past Events

Managing Obsolescence Asset Guardian Solutions Limited

Obsolescence Management