Raw Material Stock Formula

Raw materials, then, are the untouched clay of business, ready to be molded into economic art Here’s what you need to know about them What Is Raw Materials Inventory Raw Material Inventory Definition The raw material inventory definition is stock that hasn’t yet been used for manufacturing.

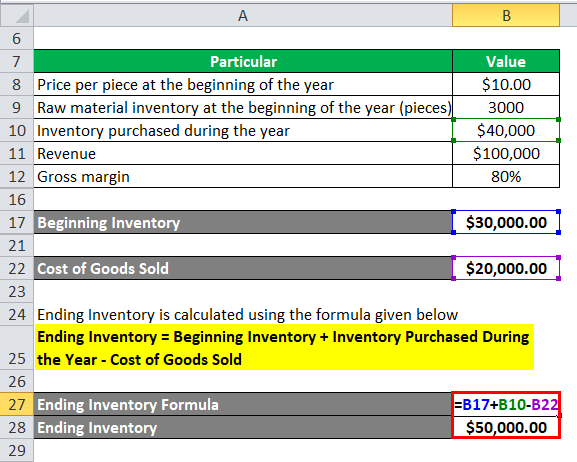

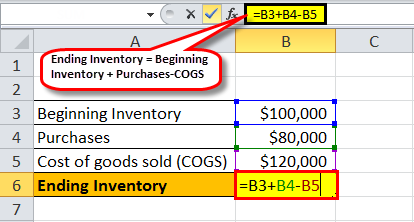

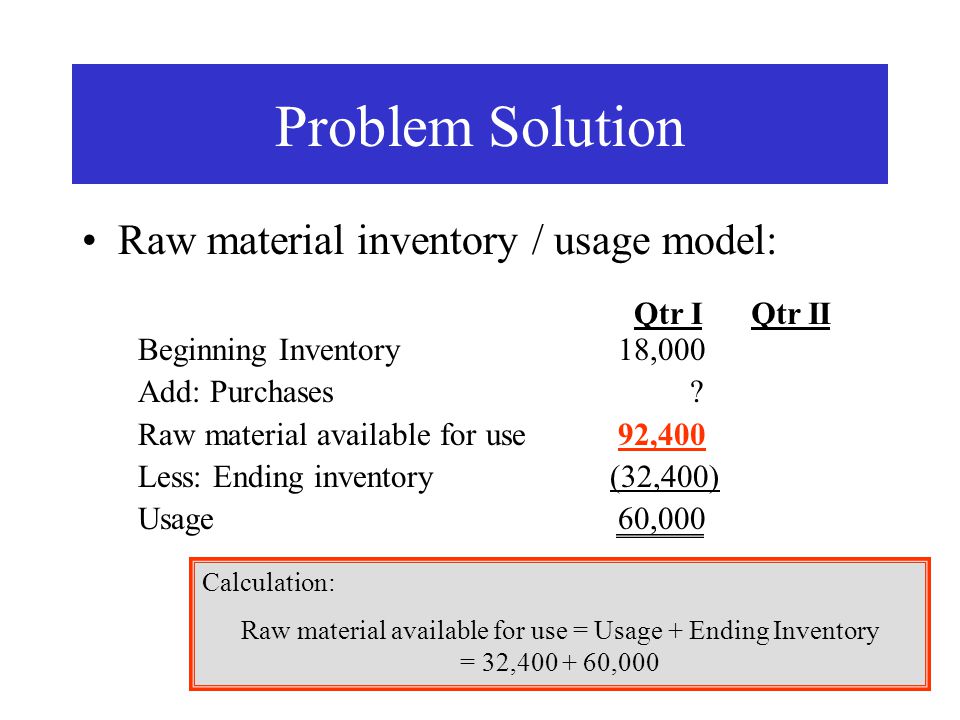

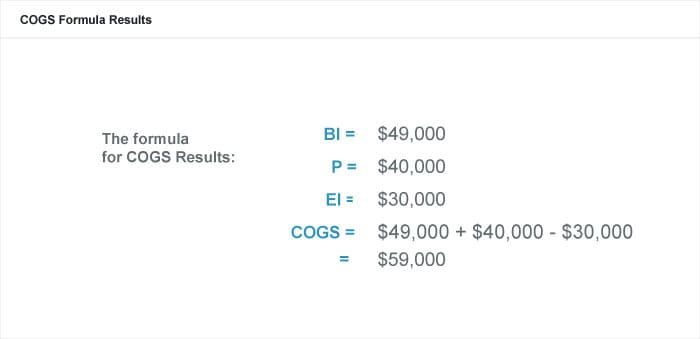

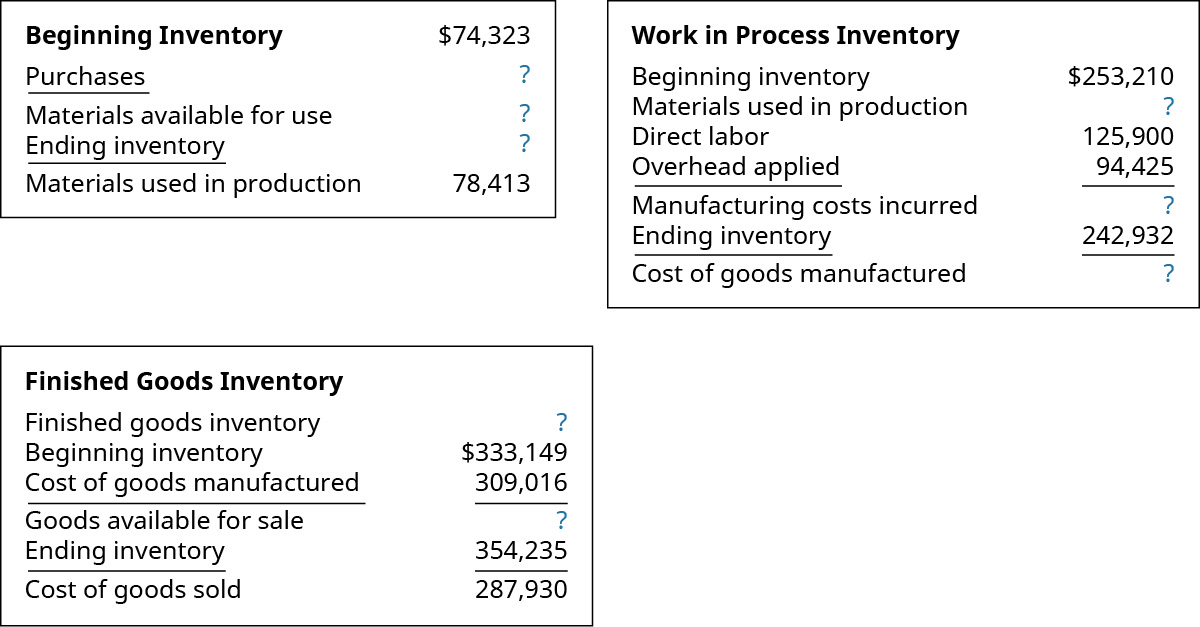

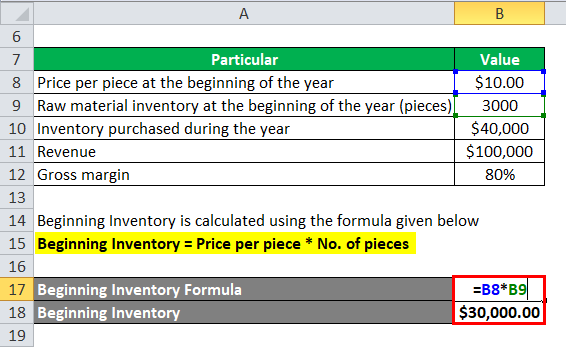

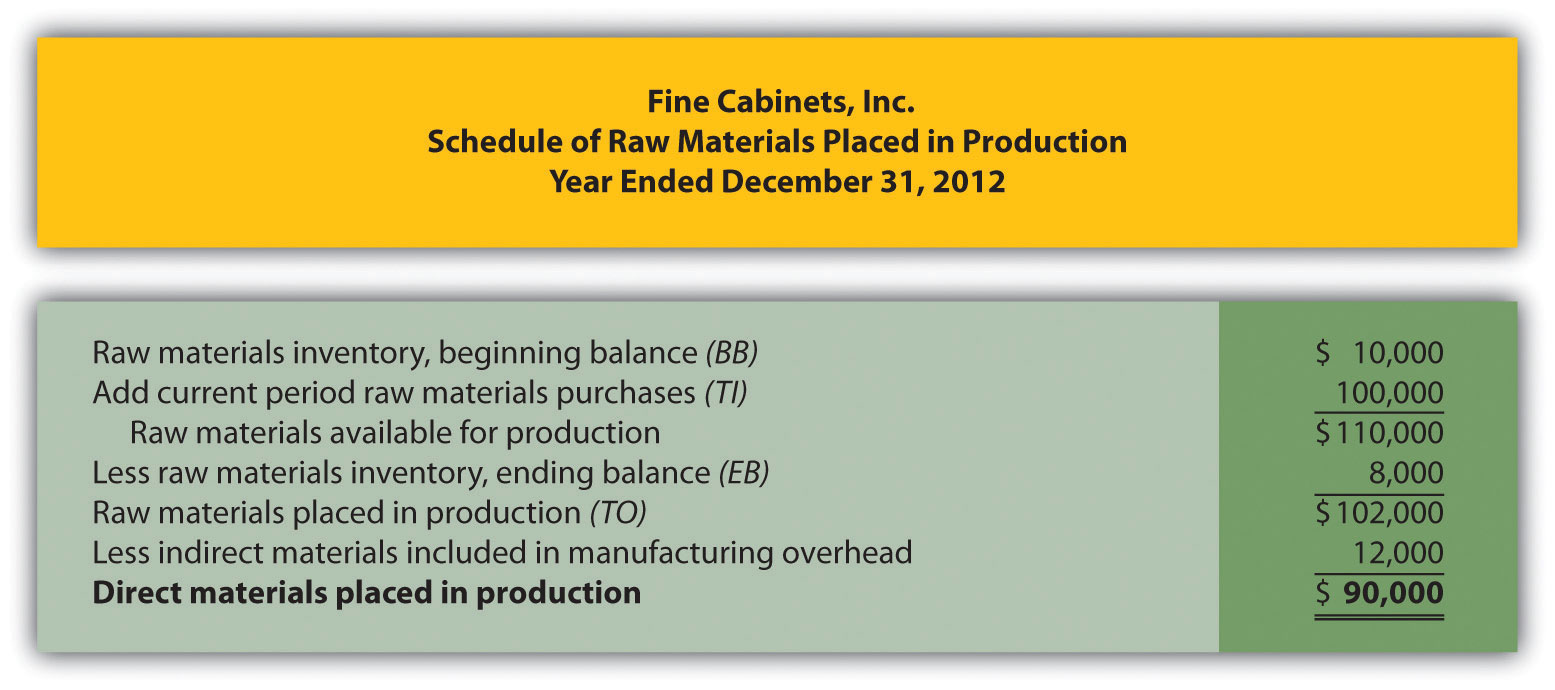

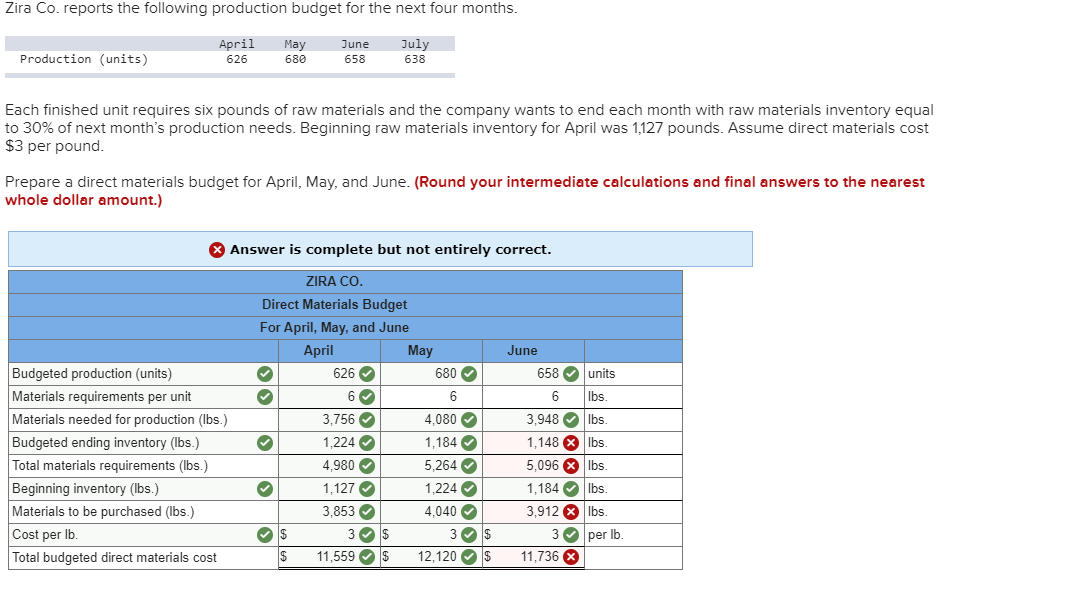

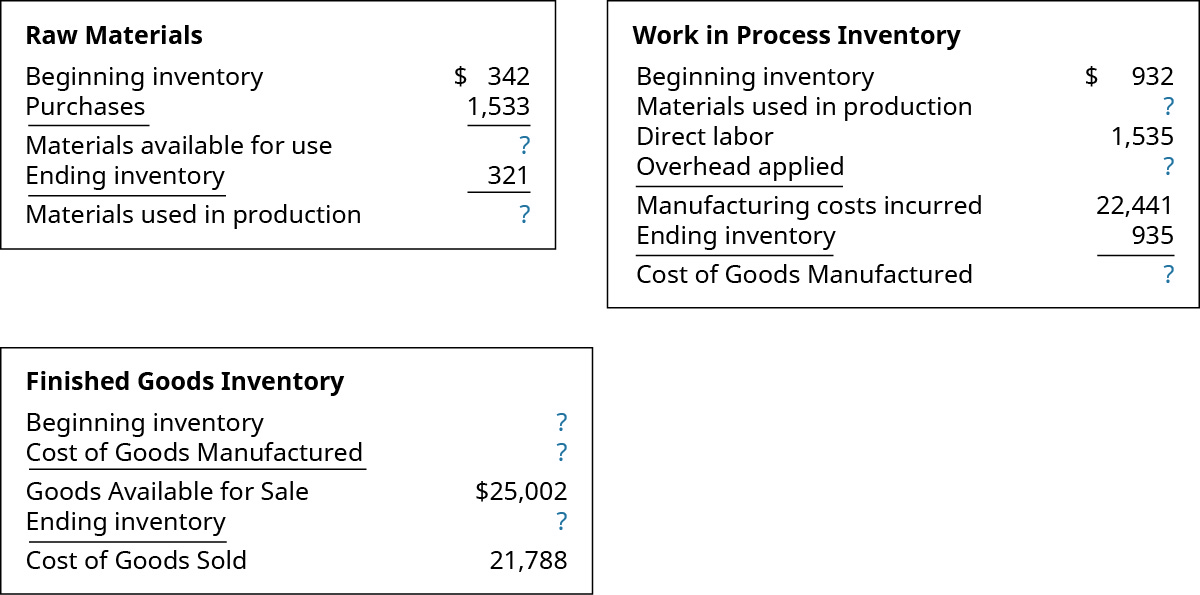

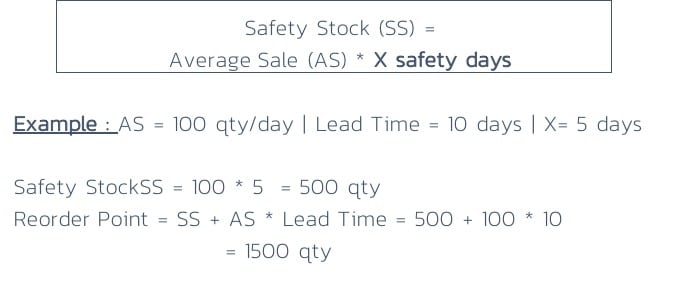

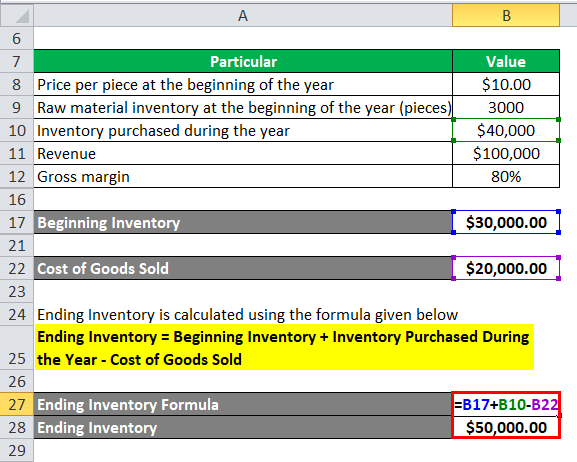

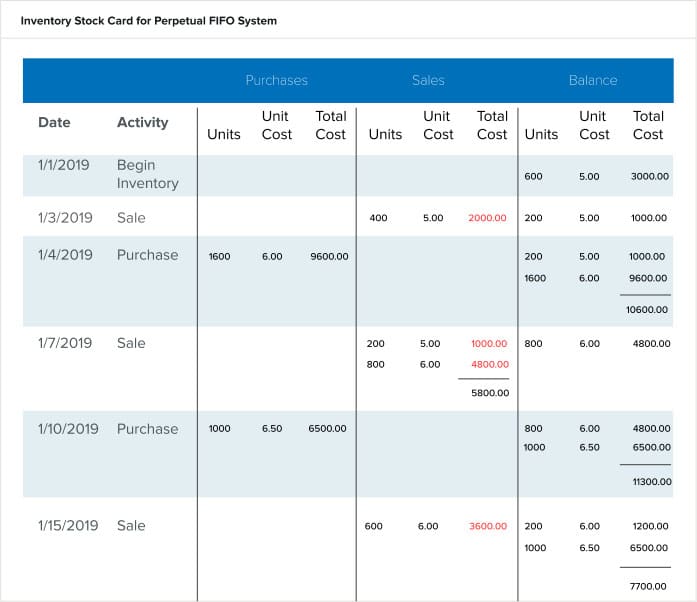

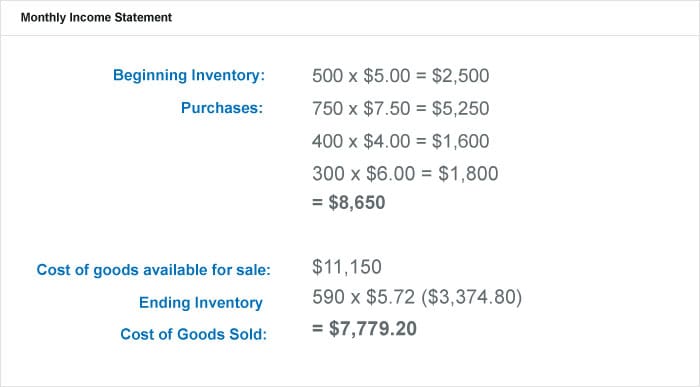

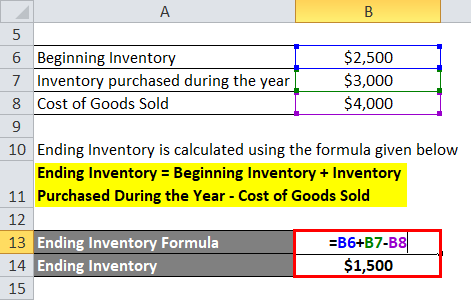

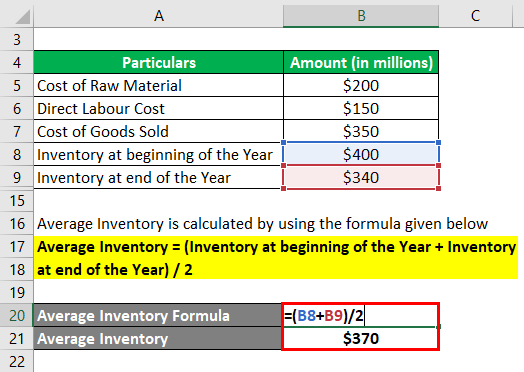

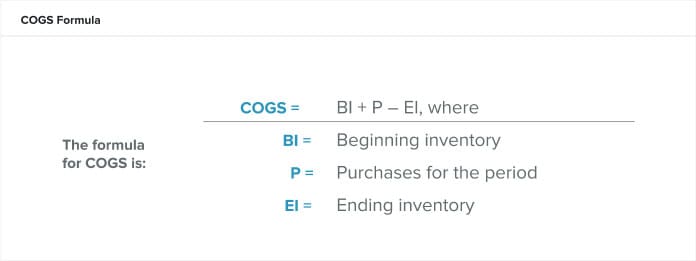

Raw material stock formula. The formula for this is as follows Ending Inventory = Beginning Balance Purchases – Cost of Goods Sold Higher sales (and thus higher cost of goods sold) leads to draining the inventory account The conceptual explanation for this is that raw materials, workinprogress, and finished goods (current assets) are turned into revenue. Average Stock Level can also be calculated by the formula Minimum Stock Level ½ of Reorder Quantity ADVERTISEMENTS A = 0 ½ x 300 = 350 units B = 150 ½ x 500 = 400 units Illustration 2 If the minimum stock level and average stock level of raw material A are 4,000 and 9000 units respectively, find out its reorder quantity. Using the three figures you have calculated above, you can now complete the safety stock formula To determine safety stock, simply multiply these three numbers 0128 x 8 days × 85 units = 8704 units Your inventory is now at 8704 units, or 870 as you would round decimals to the nearest number.

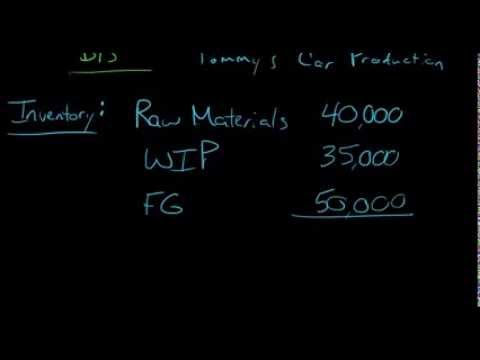

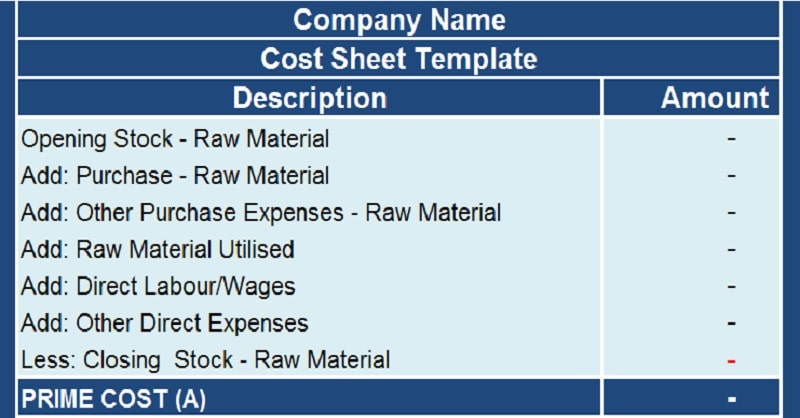

The closing stock can be in various forms such as raw materials, inprocess goods (WIP) or finished goods Here, the reporting period for a closing stock is usually the period for which the financial statements like Balance Sheet, Profit & Loss A/c are prepared Example and formula of closing stock. Safety Stock and Reorder Point formula safety stock principles can and should be applied for both raw materials and final products to ensure availability of input for production, and goods. There are 3 types of inventory that most manufacturers and merchants are likely to encounter These are Raw Materials, Work in process and Finished Goods Raw materials are the basic materials that a manufacturer purchases from suppliers in order to build finished products.

Manufacturing – inventory and sales manager – excel template – v2 free download raw material stock format in excel__/LINKS\_ Facebook https//www. Closing Stock of Raw Material The value of closing stock of raw material is arrived at based on its type Raw Materials directly introduced into the process This is the stock left out of the stock of raw material acquired from sources outside the processes and introduced into the process during the current period. The formula is = Actual voulme (Qty) of Production divided by actual volume (Qty) of Raw materials consumed Now, coming to Percentage yield Percentage yield = Actual Yield divided by Standard yield.

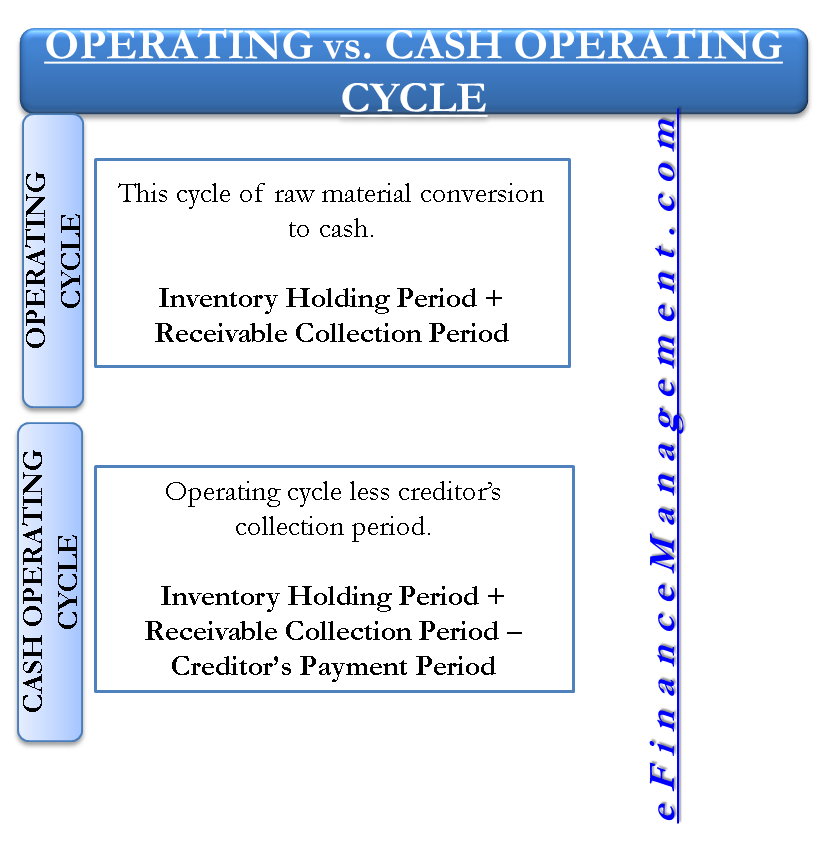

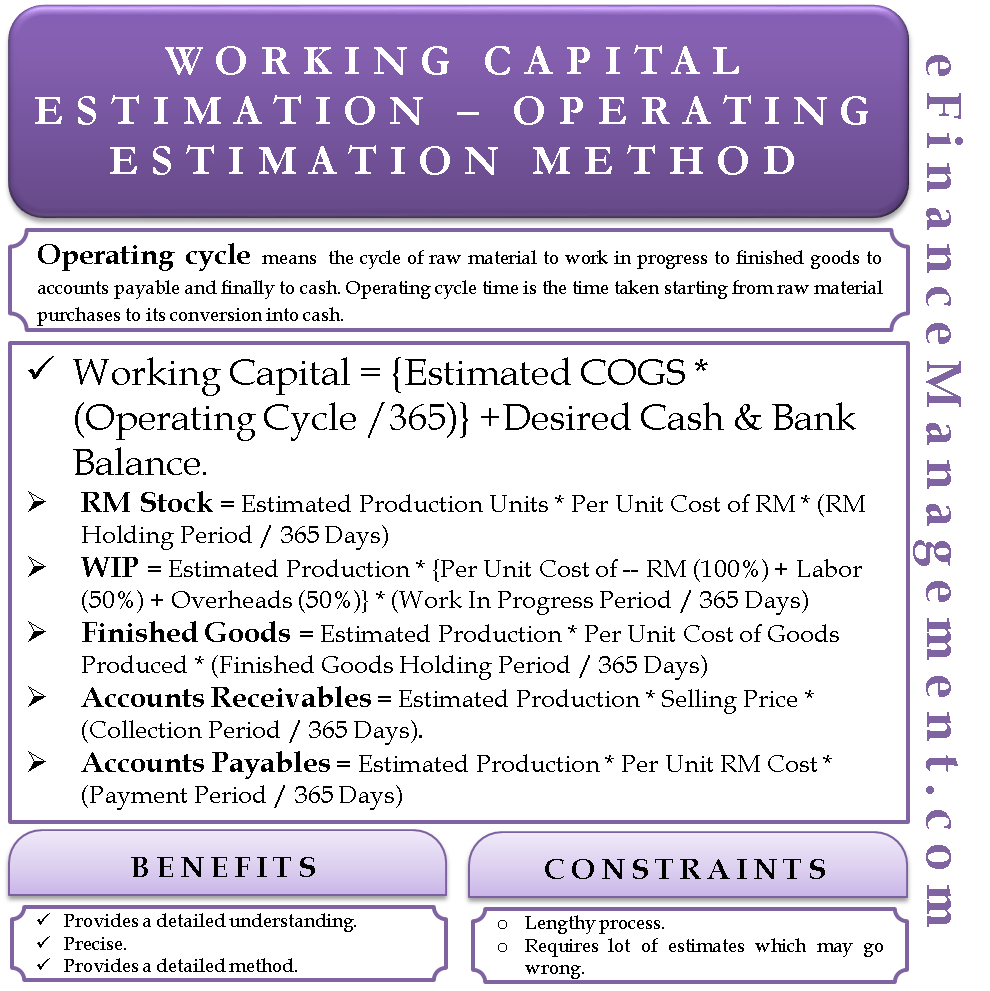

Thus, if raw materials remain in store for, say, 30 days, the conversion or processing period is 45 days, finished goods remain in store for 30 days and debts collection period is 40 days then the total of this period (ie, 30 45 30 40 or 145 days) is referred to as Gross Operating Cycle. So if this type of situation arises and in that instance, if your inventory has got safety stock, then you’ve no idea how much money will be saved. There are two different categories of raw materials — direct and indirect The formula to calculate the total cost of your raw materials inventory is Total Raw Materials = Beginning inventory Purchases added – Ending inventory Let’s say you own a scooter manufacturing company For this quarter, your starting inventory was worth $,000.

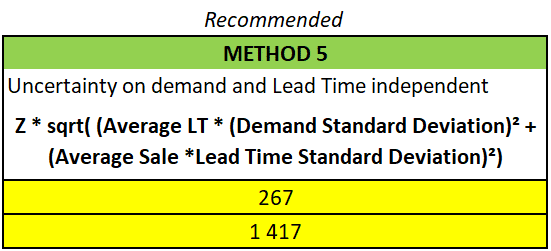

Safety stocks prevent stock outs when there is a high variation in demand and supply But what if the prices of the raw material whose product you sell sharply increases?. The formula of this safety stock (maximum sale x maximum lead time) – (average sale x average lead time) Taking the previous data, this gives you a safety stock of 427 For the order point, it is always the same formula Safety stock average sale (or average forecast) x average lead time This gives us here 1578. Closing Stock of Raw Material The value of closing stock of raw material is arrived at based on its type Raw Materials directly introduced into the process This is the stock left out of the stock of raw material acquired from sources outside the processes and introduced into the process during the current period.

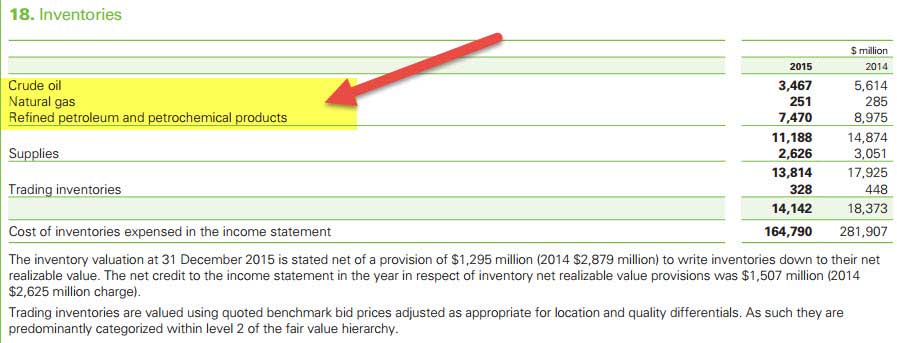

Days of Raw Materials Inventory may be calculated using value or volume Valuebased is preferred as AE focuses on the efficient use of capital Volumebased calculations may overstate the importance of inventories of lowvalue materials Community Importance Rating 000 (0 votes) Hierarchy ID Name Level x;. Letter by CA~ Estimate of fees for carrying on Internal Audit;. A Raw materials (i) opening stock;.

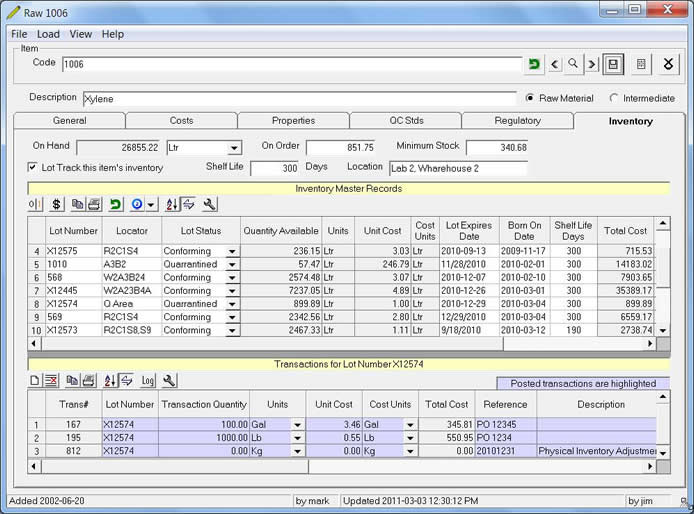

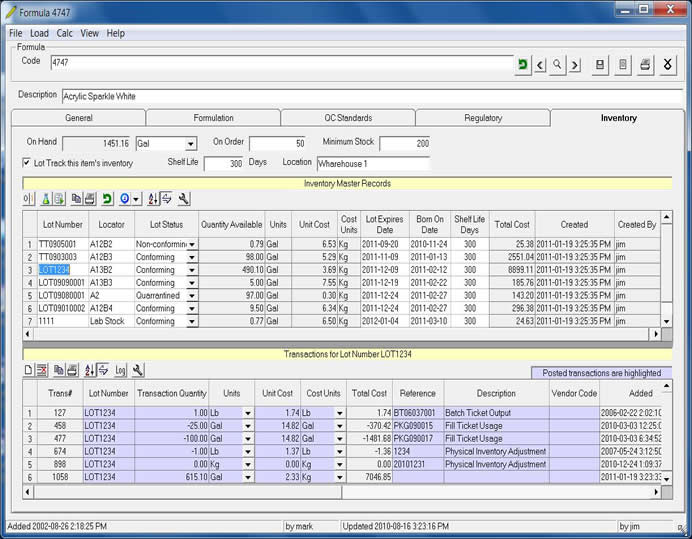

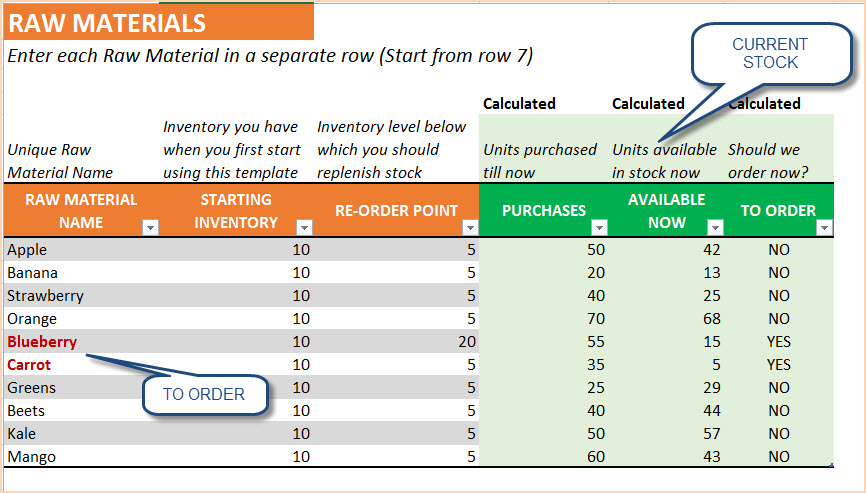

Warehouse Inventory Excel Template The template is for companies who have warehouses and put their raw materials in bins of different sizes in different bin locations The template has three tabs—Inventory List, Inventory Pick List, and Bin Lookup The Inventory List tab tracks the quantity of SKUs in different bins and locations and flags SKUs that need to be reordered. Safety stock, or buffer stock, is the amount of extra inventory you need to keep avoid a shortfall of materials It is important to calculate your safety stock carefully because while too little stock will result in shortages, too much stock will inflate your inventory costs. Safety stock is a term used by logisticians to describe a level of extra stock that is maintained to mitigate risk of stockouts (shortfall in raw material or packaging) caused by uncertainties in supply and demand Adequate safety stock levels permit business operations to proceed according to their plans Safety stock is held when uncertainty exists in demand, supply, or manufacturing yield.

So if this type of situation arises and in that instance, if your inventory has got safety stock, then you’ve no idea how much money will be saved. Closing Stock of Raw Material The value of closing stock of raw material is arrived at based on its type Raw Materials directly introduced into the process This is the stock left out of the stock of raw material acquired from sources outside the processes and introduced into the process during the current period. Definition Raw materials are the inputs or resources that a company uses to manufacture its finished products In other words, this is the unprocessed material like metal stock, rubber blanks, or unrefined natural resources that companies use in there manufacturing processes to produce finished goods to sell to consumers What Does Raw Materials Mean?.

The closing stock can be in various forms such as raw materials, inprocess goods (WIP) or finished goods Here, the reporting period for a closing stock is usually the period for which the financial statements like Balance Sheet, Profit & Loss A/c are prepared Example and formula of closing stock. Stock maintain template holds great importance in different businesses due to benefits enjoyed if proper stock management is carried outCosts incurred by companies if operations are stopped due to lack of raw material in the store effects production budget, sales budget and schedules prepared for the specific project or as a whole. Safety stocks prevent stock outs when there is a high variation in demand and supply But what if the prices of the raw material whose product you sell sharply increases?.

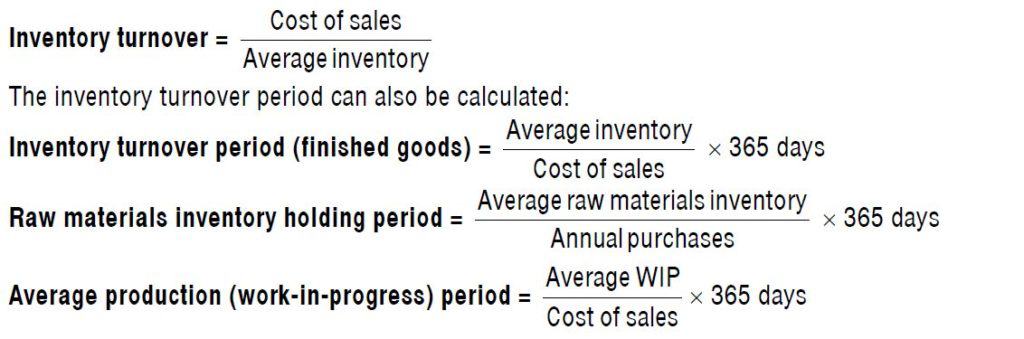

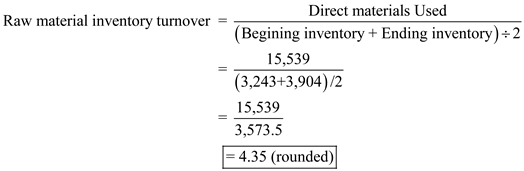

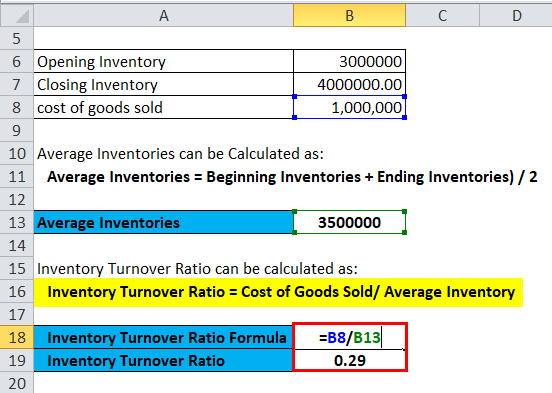

Materials stocks, as represented by the Materials Select Sector SPDR ETF (), have outperformed the broader marketThe XLB has provided a total return of 329% over the past 12 months, above the. Inventory Turnover (Raw Materials Only) measures the rate at which a company's inventory of raw materials is sold and replaced (ie, "turned") over a given period of time Download a report with benchmark data, a definition, and details for tracking this metric. Inventory / Stock Turnover Ratio (Or) Stock Velocity = (Average Stock x 365/12) / Cost of Sales NOTE If stock velocity is to be computed in period (days / months) than the last formula is used Average Inventory = (Opening Stock Closing Stock) / 2.

Thus, if raw materials remain in store for, say, 30 days, the conversion or processing period is 45 days, finished goods remain in store for 30 days and debts collection period is 40 days then the total of this period (ie, 30 45 30 40 or 145 days) is referred to as Gross Operating Cycle. (ii) purchases during the previous year;. Not an expert in Safety Stock models but from your question and notes it looks like you currently do not have a safety stock model in place but would like to implement one I did a quick search and found this APICS article which should get you goi.

However, if raw material stock is too low, companies risk losing out on sales due to stockouts, so safe levels of raw materials inventory must be maintained KPI Definition The total value of raw materials in the company's inventory divided by the average value of raw materials used in a single day. It lies in “Inventory Category” you must manage daily stock for reporting, otherwise, it’s difficult to manage bulk stock with particular date and time Mostly business especially product development warehouses specially design some template or software for managing. Stock of raw materials Once Raw Materials are issued whether the same has been converted in finished goods or WIP it is not a matter Just apply this formula Raw Mat Consumed=Op Stock of Raw MaterialsPurchase of Raw MaterialsCl Stock of Raw Materials faru faru faru faru (Querist) Follow.

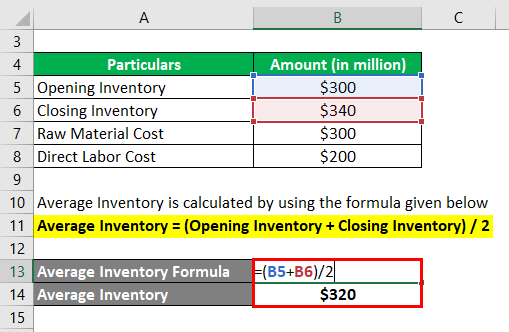

Average stock of materials = ½ ( Opening Raw material Computation of Purchase price of Raw Materials Overhead Costing Formula Like & Share Search for Search Recent Posts TCS Rate Chart for FY 19 and 21;. 1 find out how many units you need to produce 2 find out how much raw material or materials make up each unit 3 multiply the number of units by the amount of raw material in each unit and that is your answer Of course you take into account differ. The formula for this is as follows Ending Inventory = Beginning Balance Purchases – Cost of Goods Sold Higher sales (and thus higher cost of goods sold) leads to draining the inventory account The conceptual explanation for this is that raw materials, workinprogress, and finished goods (current assets) are turned into revenue.

The formula is = Actual voulme (Qty) of Production divided by actual volume (Qty) of Raw materials consumed Now, coming to Percentage yield Percentage yield = Actual Yield divided by Standard yield. Figure 3 Compare No Component Safety Stock with Component Safety Stock on One Part However, adding $9,064 of CSS for just the longleadtime material removes its 130 days from the cumulative lead time calculation As a result, only $113,277 of finished goods safety stock is required to provide the target service. This stock is then used in the production process (in case of raw materials) or sold (in case of finished goods) and then reordered again at the reorder level which again fills up the stock to the ‘maximum level’ This is an ongoing process Formula The formula to calculate maximum level of stock is given below.

There are two different categories of raw materials — direct and indirect The formula to calculate the total cost of your raw materials inventory is Total Raw Materials = Beginning inventory Purchases added – Ending inventory Let’s say you own a scooter manufacturing company For this quarter, your starting inventory was worth $,000. Thus, if raw materials remain in store for, say, 30 days, the conversion or processing period is 45 days, finished goods remain in store for 30 days and debts collection period is 40 days then the total of this period (ie, 30 45 30 40 or 145 days) is referred to as Gross Operating Cycle. Formula to manage inventory of raw materials Waiting on OP Close 1 Posted by 1 year ago Archived Formula to manage inventory of raw materials How can we keep track of total stock for the individual raw materials?.

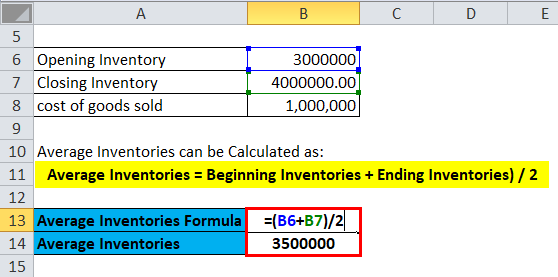

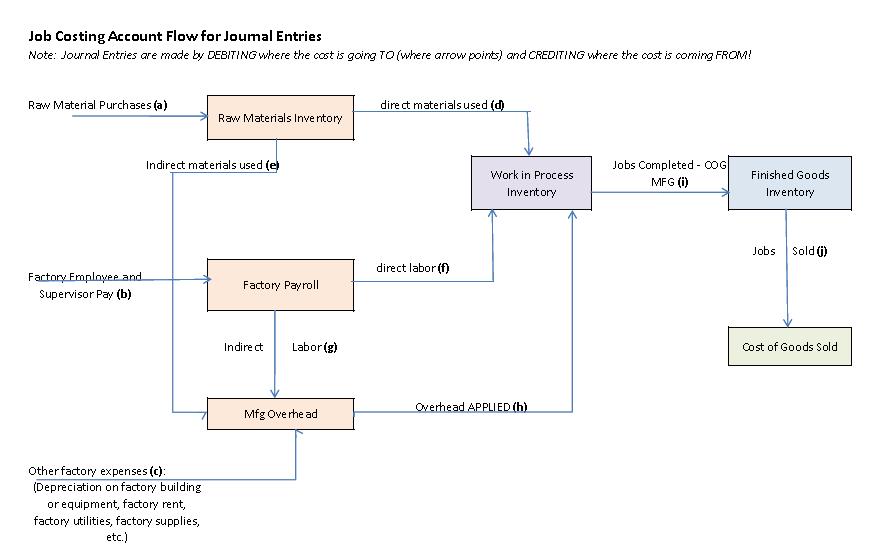

Average stock or average inventory is equal to stock at the beginning of the period plus stock at the ending of the period divided by two It represents the investment a business has made in inventory Formula Average stock is arrived at using the following formula It can be calculated for each class of stock, namely raw materials, work in progress Read moreAverage stock. You can also create stock items for raw materials with excise applicable 1 Go to Gateway of Tally > Stock Items > Create 2 In Name field enter the stock item Name For example, Bottom Plate12Ltr 3 Group the Stock item Under the Stock Group RM Cooker (if Stock group is not created use Alt C from Under field to create the stock group) 4. The raw materials inventory formula says that when you purchase raw materials, you debit your raw materials inventory asset account and credit accounts payable If you use up $100 of materials, you'd credit $100 to the raw materials account and debit $100 to works in progress or finished goods.

Topic Raw Material Stock Register Looking for some Raw material stock control template in MS Excel format?. The raw materials inventory formula says that when you purchase raw materials, you debit your raw materials inventory asset account and credit accounts payable If you use up $100 of materials, you'd credit $100 to the raw materials account and debit $100 to works in progress or finished goods. It lies in “Inventory Category” you must manage daily stock for reporting, otherwise, it’s difficult to manage bulk stock with particular date and time Mostly business especially product development warehouses specially design some template or software for managing.

Average Stock Level can also be calculated by the formula Minimum Stock Level ½ of Reorder Quantity ADVERTISEMENTS A = 0 ½ x 300 = 350 units B = 150 ½ x 500 = 400 units Illustration 2 If the minimum stock level and average stock level of raw material A are 4,000 and 9000 units respectively, find out its reorder quantity. Knowing the true value of manufactured stock is an important factor in reducing wastage of materials, determining profitability, and optimising inventory management processes Learn how to streamline your manufacturing processes Start a free 14day trial of QuickBooks Commerce's inventory management software today. Safety stock Safety stock describes the amount of inventory a business keeps in the warehouse to protect against spikes in demand or shortages in supply From a manufacturer’s perspective, safety stock principles can and should be applied to both raw materials and final products.

So if this type of situation arises and in that instance, if your inventory has got safety stock, then you’ve no idea how much money will be saved. I have been looking at this problem for a few days now and cannot figure it out I gave it a try with a bunch of different. The formula for ending inventory can be simply calculated by using the following four steps Step 1 First, determine the inventory of the company at the beginning of the year from the stock book and confirm with the accounts department It will consist of finished, semifinished and raw material inventory.

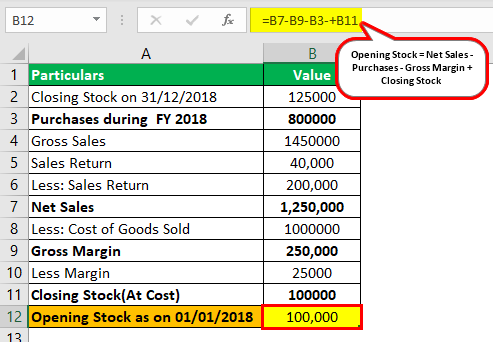

The raw material consumption is measured by opening stock of RM plus Purchase of RM minus closing stock of RM c) The holding period of Rawmaterials is mainly dependent on the lead time involved in the procurement and quantity required to ensure uninterrupted production. Topic Raw Material Stock Register Looking for some Raw material stock control template in MS Excel format?. Opening Stock Formula = Raw Material Cost Work in Progress Values Finished Goods Cost #2 – When current year closing stock is given along with sales and cost of goods sold and gross profit figures Opening Stock Formula = Sales – Gross Profit – Cost of Goods Sold Closing Stock Examples of Opening Stock.

Once you have those numbers, you can calculate raw material inventory turnover by dividing the actual value of raw materials used by the raw materials inventory balance For example, if during the fiscal year raw materials amounting to $1 million were used, and the ending raw materials balance was $0,000, the raw material turnover ratio would equal $1 million divided by $0,000, or 50. Safety stocks prevent stock outs when there is a high variation in demand and supply But what if the prices of the raw material whose product you sell sharply increases?. Raw material stock statement is considered necessary these days, as it shows the real worth of the assets Reporting template excel is also asked by the board of directors as well as loan providing bodies to consider whether the company is able to return the loan with interest amount regularly or not These sheets are also required by project managers to determine whether working on the.

The raw material consumption is measured by opening stock of RM plus Purchase of RM minus closing stock of RM c) The holding period of Rawmaterials is mainly dependent on the lead time involved in the procurement and quantity required to ensure uninterrupted production. Raw material stock statement is considered necessary these days, as it shows the real worth of the assets Reporting template excel is also asked by the board of directors as well as loan providing bodies to consider whether the company is able to return the loan with interest amount regularly or not These sheets are also required by project managers to determine whether working on the. Inventory Turnover (Raw Materials Only) measures the rate at which a company's inventory of raw materials is sold and replaced (ie, "turned") over a given period of time Download a report with benchmark data, a definition, and details for tracking this metric.

Calculators, engineering calculators Enter value, select units and click on calculate Result will be displayed. The minimum level of stock is a certain predetermined minimum quantity of raw materials or merchandise inventory which should always be available in stock in the normal course of business The minimum level of inventory is a kind of a precautionary level of inventory which indicates that the delivery of raw materials or merchandise may take more than the normal lead time. Finish Goods,Raw Material Consupmtion Formula This query is Resolved Report Abuse Follow Query Ask a Query Sushil Shinde Sushil Shinde 29 March 10 For Raw material consumption = Opening stock of R/M Purchase of R/M Closing stock of R/M For Finished Goods= Opening Stock Production closing stock Message likes 2 times.

(ii) purchases during the previous year;. Sales = 100 x 5 = 500 Cost of Goods Sold = 500 x (140%) = 300 Closing Stock ($) = 940 – 300 = 640 The drawback of this method is that the estimation of gross profit in step 2, base on the historical estimate, which may not necessarily be the case in the future. To monitor stock and identify slow moving inventory or that is not converting, stock ageing analysis reports are made The most common stock ageing analysis involve determining the age of product on the basis of data of purchase and particular date ie today’s date or any other date Following is the stock ageing analysis based on today’s.

What is Raw materials inventory?.

Inventory Model Simulation With Spreadsheets Datacamp

Opening Stock Meaning Examples Top 3 Types Of Opening Stock

Inventory Turnover Ratio Formula Calculator Excel Template

Raw Material Stock Formula のギャラリー

Opening Stock Meaning Examples Top 3 Types Of Opening Stock

Days Inventory Outstanding Top 2 Examples With Excel Template

How To Maintain Fabric Trim And Accessory Record In An Excel Sheet

What Is Inventory Turnover Inventory Turnover Formula In 3 Steps

Understanding P L Statement Part 2 Varsity By Zerodha

Inventory Management Software For Manufacturing Mrpeasy

1

Opening Stock Meaning Examples Top 3 Types Of Opening Stock

Ending Inventory Formula Step By Step Calculation Examples

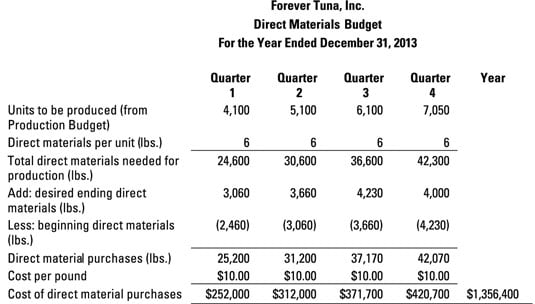

Set A Direct Materials Budget As Part Of Your Master Budget Dummies

Assume You Are The Management Accountant For The F Chegg Com

Inventory Cost Accounting Methods Examples Netsuite

Materials Accounting Powerpoint Slides

Demonstration Problem Ppt Download

Ratio Analysis

Cost Of Goods Manufactured Cogm How To Calculate Cogm

Inventory Days Formula Meaning Example And Interpretation

Finding The Closing Stock Valuation Using A Single Formula Stack Overflow

Managerial Accounting Spring 19 Lab 2 Chapter 3 Excel Computer Problem The Following Data Refer To Miller Widget Company For The Year X1 Course Hero

Inventory Turnover How To Calculate Inventory Turns

3 Types Of Inventory Raw Materials Wip And Finished Goods Youtube

Periodic Inventory System Methods And Calculations Netsuite

Calculating Cost Of Goods Sold In Manufacturing Mrpeasy

What Is Closing Stock Examples Calculations Tally Solutions

Ending Work In Process Double Entry Bookkeeping

10 Inventory Metrics You Need To Know Inventory Management Metrics

Sample Excel Sheet Calculating Inventory Holding Costs Driveyoursucce

Compute The Cost Of A Job Using Job Order Costing Principles Of Accounting Volume 2 Managerial Accounting

Materials Purchases Budget Accounting Education

3 Types Of Inventory Raw Material Wip Finished Goods

Calculate Ending Inventory Formula Explanation Video Lesson Transcript Study Com

Stock Of Finished Goods In Accounts And Finance For Managers Tutorial 21 January 21 Learn Stock Of Finished Goods In Accounts And Finance For Managers Tutorial 9131 Wisdom Jobs India

Sample Excel Sheet Calculating Inventory Holding Costs Driveyoursucce

Ending Inventory Formula Calculator Excel Template

Raw Materials Inventory Definition Formula And Turnover

Inventory Manager

Operating Cash Operating Cycle Formula Calculation Example Analysis

Understanding P L Statement Part 2 Varsity By Zerodha

Accounting Finance And Economics Cost Of Goods Sold For A Manufacturing Company

Working Capital Requirements In A Manufacturing Business Plan Projections

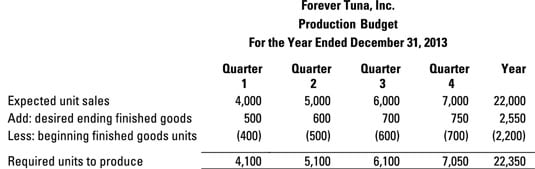

Production Budget Definition Explanation And Examples Play Accounting

Set A Direct Materials Budget As Part Of Your Master Budget Dummies

Chapter 7 Working Capital Management

3 Types Of Inventory Raw Material Wip Finished Goods

Valuing Inventory Boundless Accounting

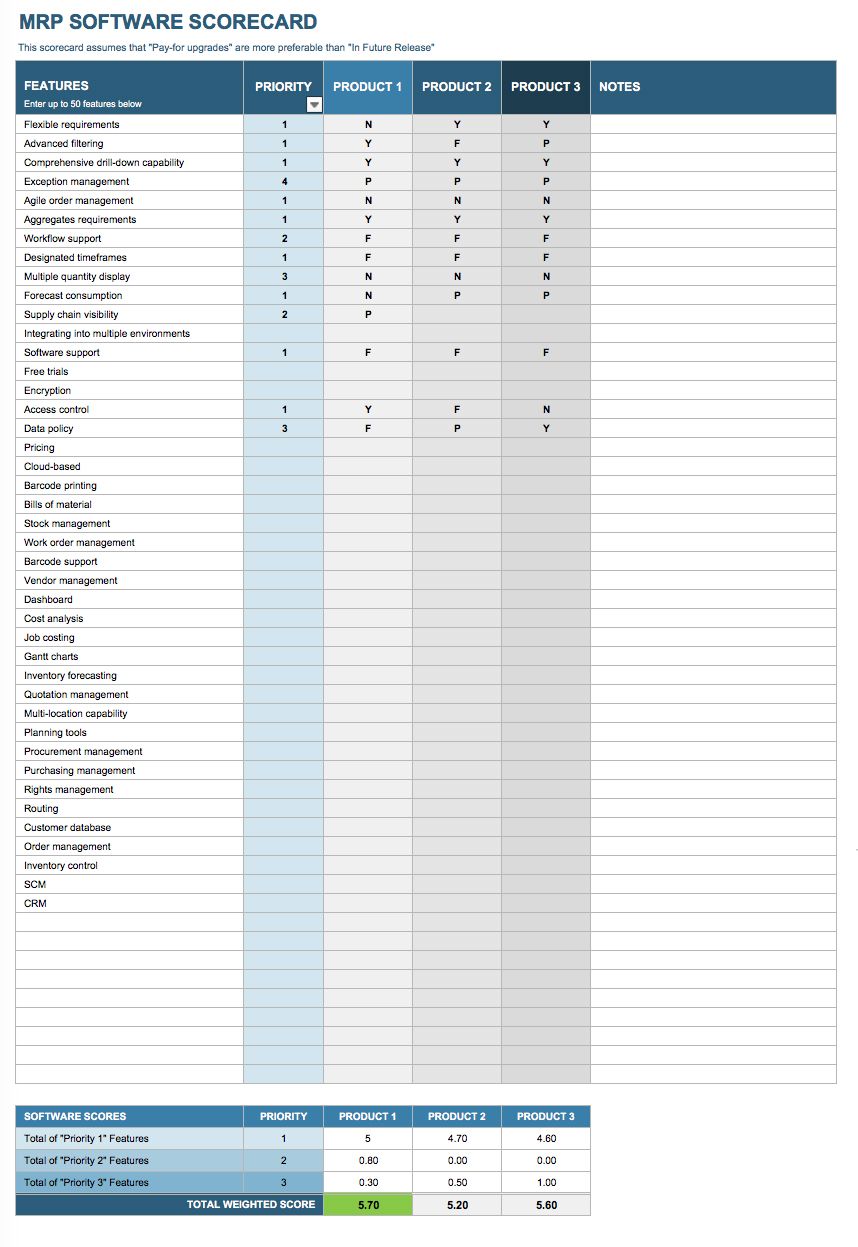

Everything You Need To Know About Material Requirements Planning Mrp Smartsheet

Income Statements For Manufacturing Companies

Raw Material Inventory Management The Definitive Guide

Days Inventory Outstanding Formula Guide And How To Calculate

Working Capital

Answered Zira Co Reports The Following Bartleby

Q Tbn And9gcrmqhdna9e6pjrfc98otgvqcfsjklqi 3kze2pdkxdcz4jhw4 Usqp Cau

Compute The Cost Of A Job Using Job Order Costing Principles Of Accounting Volume 2 Managerial Accounting

Raw Material Supply An Overview Sciencedirect Topics

Lead Time Overview Components And How To Reduce Lt

What Is Safety Stock

Relevant Cost Of Material Rules Example

6 Best Safety Stock Formulas On Excel Abcsupplychain

3 Types Of Inventory Raw Material Wip Finished Goods

Days Sales In Inventory Dsi Overview How To Calculate Importance

Days Inventory On Hand Lean Math

Excel Inventory Sheet Template Word Excel Templates

Inventory Flow Analysis Springerlink

Q Tbn And9gctsffkkggeosmusl4js1z1cvw7i8vjjomplkjatbzw7t8klufju Usqp Cau

Inventory Tracker Free Template Spreadsheet For Excel Tradegecko

Manufacturing Account Format Double Entry Bookkeeping

Working Capital Cycle Days Ratios Financial Edge Training

Inventory Days Calculator Excel Plan Projections Day Calculator Business Plan Template How To Plan

Ending Inventory Formula Calculator Excel Template

Working Capital Estimation Operating Cycle Method

Days Of Inventory On Hand Doh Overview How To Calculate Example

Solved Refer To Qs 18 12 And Compute Raw Materials Inventory T Chegg Com

Download Cost Sheet With Cogs Excel Template Exceldatapro

6 Best Safety Stock Formulas On Excel Abcsupplychain

Raw Material Inventory Management The Definitive Guide

Inventory Formula Inventory Calculator Excel Template

Ending Inventory Formula Calculator Excel Template

Manufacturing And Non Manufacturing Costs Online Accounting Tutorial Questions Simplestudies Com

Understanding P L Statement Part 2 Varsity By Zerodha

Www Jstor Org Stable

Periodic Inventory System Methods And Calculations Netsuite

Inventory Manager

Ready To Use Excel Inventory Management Template Free Download

Excel Inventory Template For Manufacturing Businesses Bill Of Materials

Periodic Inventory System Methods And Calculations Netsuite

Cost Of Sales Definition Formula How To Calculate

Ending Inventory Formula Step By Step Calculation Examples

Raw Material Inventory Meaning Types Industry Examples

Ending Inventory Formula Calculator Excel Template

Materials Accounting Powerpoint Slides

Inventory Turnover Ratio Meaning Formula How To Calculate

3 4 Journal Entries For The Flow Of Production Costs Managerial Accounting

Stock Of Finished Goods In Accounts And Finance For Managers Tutorial 21 January 21 Learn Stock Of Finished Goods In Accounts And Finance For Managers Tutorial 9131 Wisdom Jobs India

Chapter 4 Inventory

Stock Turnover Ratio Top 3 Examples Of Stock Turnover Ratio

Raw Material Inventory Management The Definitive Guide

3

Inventory Turnover Ratio Formula Calculator Excel Template

Periodic Inventory System Methods And Calculations Netsuite

Production Budget Definition Explanation And Examples Play Accounting

What Is Inventory Management 10 Guides To Mastering Commerce