Lean Maintenance

It is imperative that the leadership and culture is focussed on being proactive rather than reactive, and is performance driven.

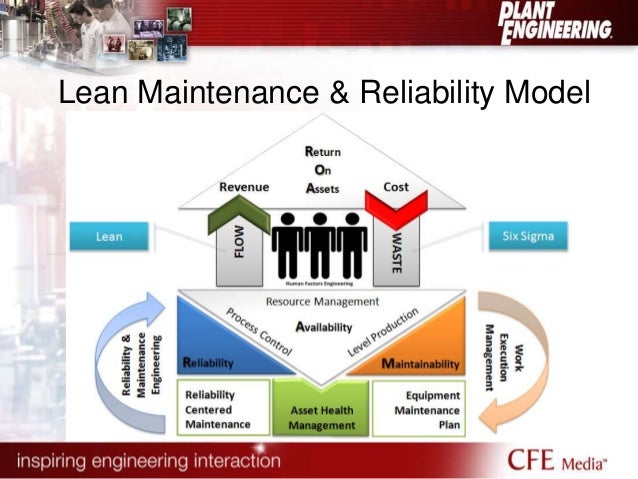

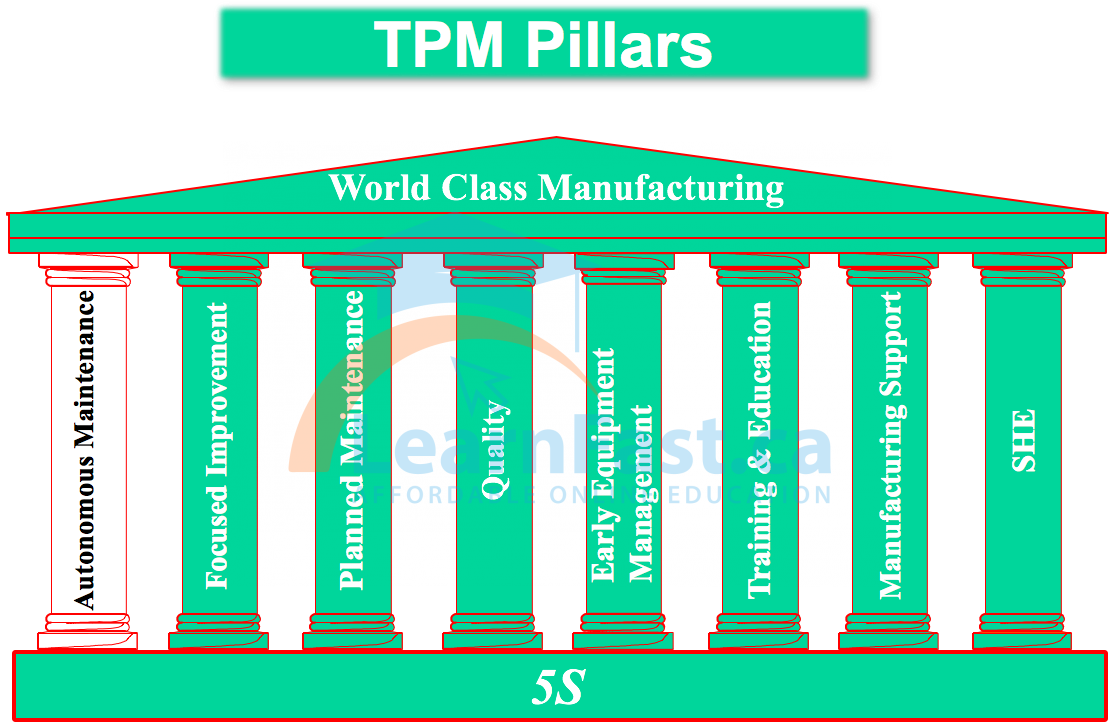

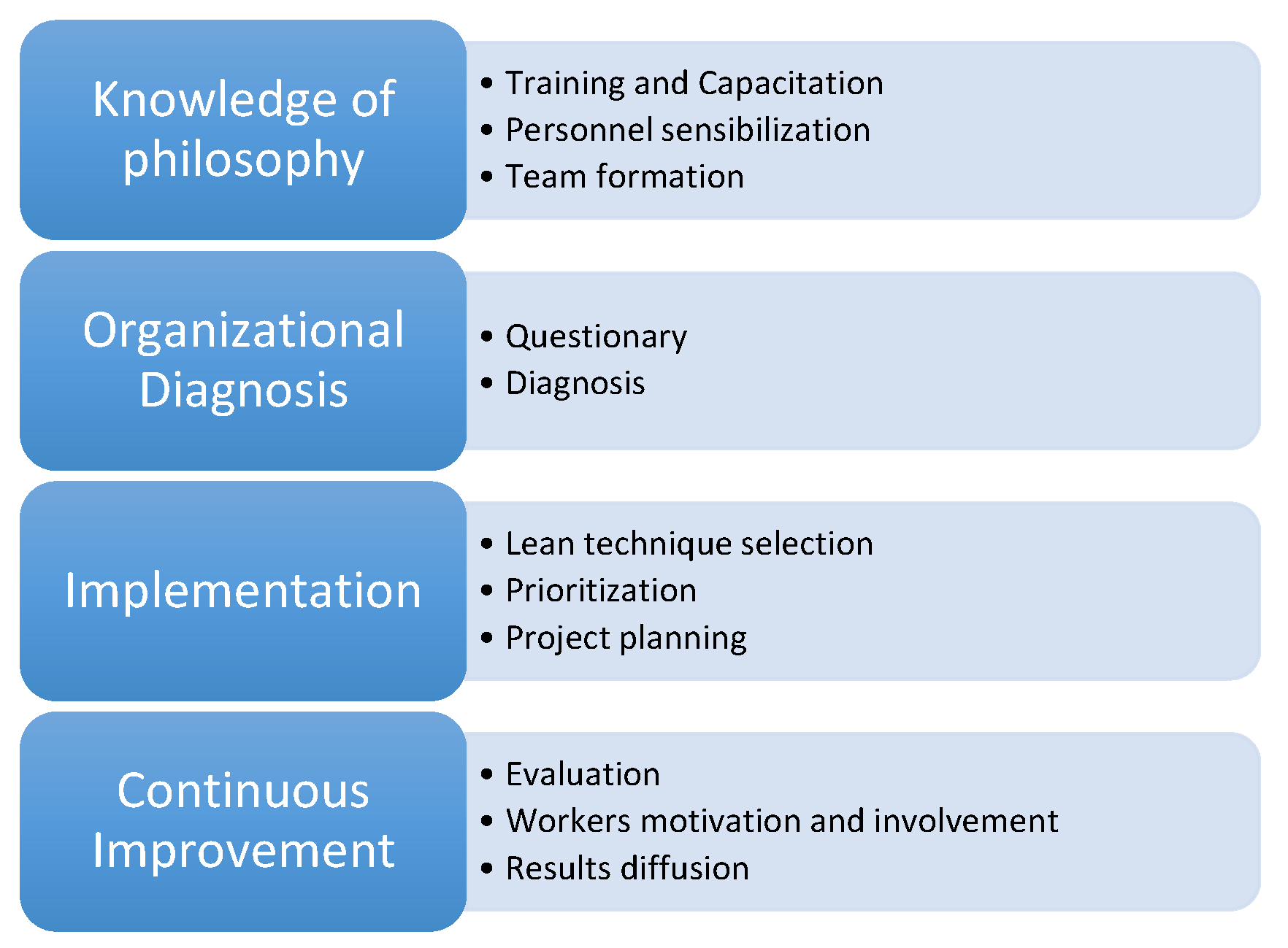

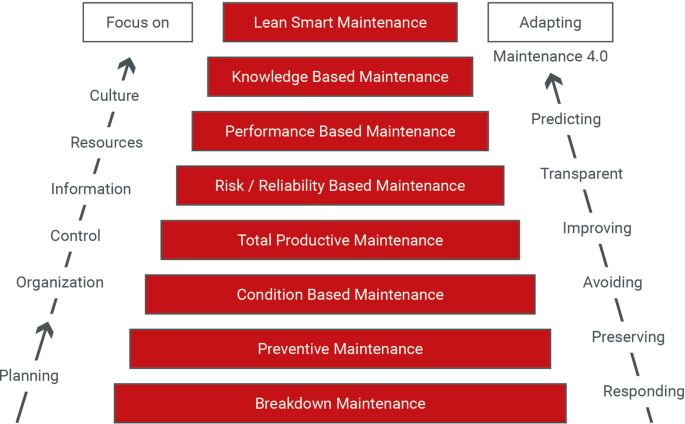

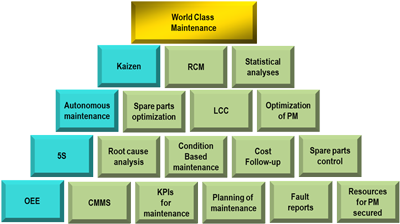

Lean maintenance. Method 2 Lean Maintenance While production staff are learning more and are increasingly involved with the management and improvement of equipment, the tasks of the maintenance staff should also be developed in parallel The aim should be to deliver an everimproving reliability at steadily reducing cost. What is "Lean?" Whether referring to manufacturing operations or maintenance, lean is about doing more with less less effort, less space, fewer defects, less throughput time, lower volume requirements, less capital for a given level of output, etc. Lean maintenance is a proactive strategy encompassing planned and scheduled maintenance through total productive maintenance (TPM) applying reliabilitycentered maintenance (RCM) logic Learn how to apply Lean concepts to your everyday work, use Lean tools in maintenance scenarios, utilize 5S, conduct valuestream mapping, use Kaizen Event to manage a Lean implementation, develop an effective Lean enterprise strategy, and much more.

Lean maintenance is a management strategy that aims to apply lean principles and goals to physical asset management The ultimate goal of lean thinking is to provide perfect value to the customer through processes that generate zero waste. Lean_Six_ Sigma_ Maintenance_pdf Free download as PDF File (pdf), Text File (txt) or view presentation slides online Scribd is the world's largest social reading and publishing site Open navigation menu. Lean and agile methods have much in common, but for maintenance activities the two approaches work best when they work side by side By understanding the different strengths of each approach, and applying them selectively across their organizations, maintenance functions are able to plan more effectively, resolve issues faster, and execute with.

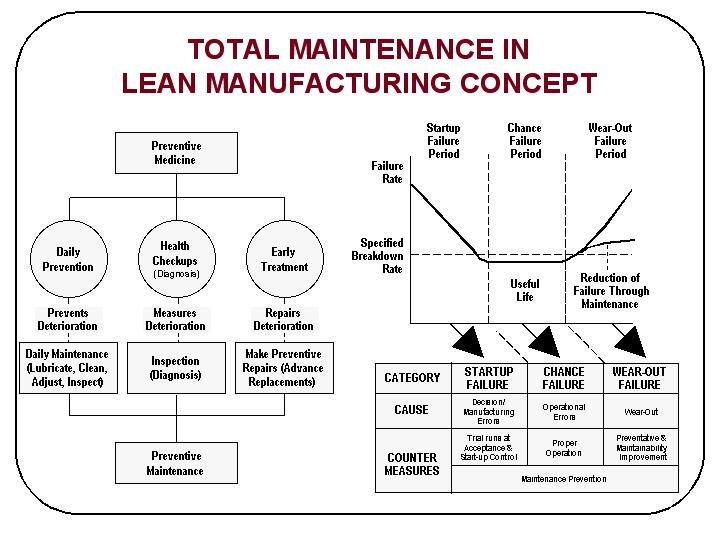

Manufacturing first embraced Lean and Six Sigma techniques — tools and strategies to improve business processes — in the 1980s, and the concepts are gaining ground in truck maintenance shops Those. In fact, in a lean production setup that is practicing TPM, you find it difficult to distinguish between normal operators and maintenance staff This is because they all are proactively involved in the maintenance of machines which leads to increased productivity, lower costs, improve quality and extended machine lifespan. What is "Lean?" Whether referring to manufacturing operations or maintenance, lean is about doing more with less less effort, less space, fewer defects, less throughput time, lower volume requirements, less capital for a given level of output, etc.

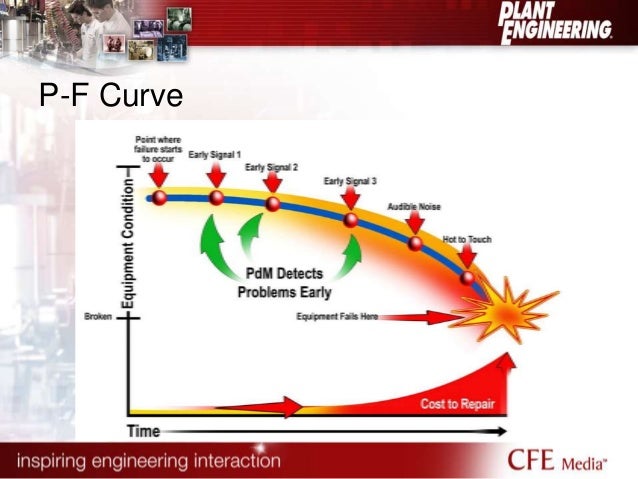

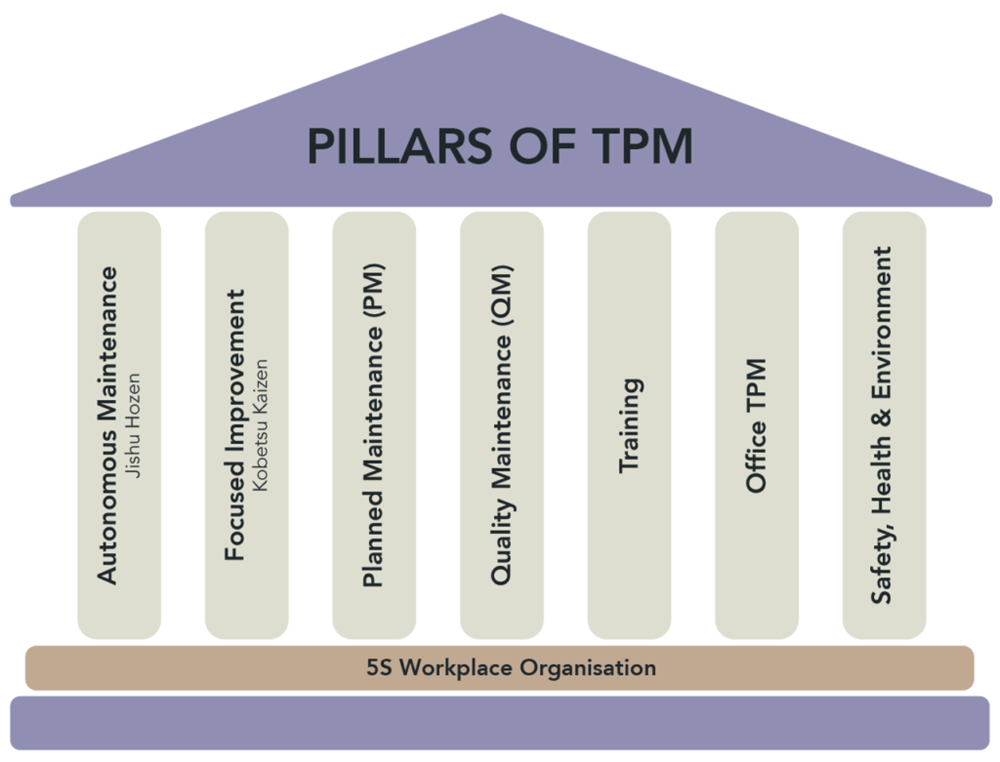

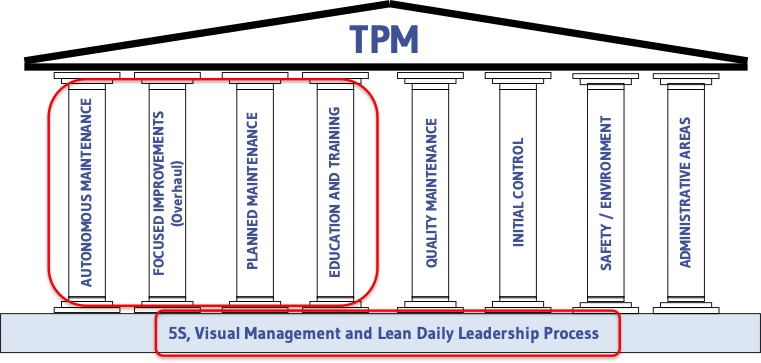

Lean Maintenance Planning, Scheduling, and Inventory Control, Using Applied Technologies Workshop April 13 & 14, 15. Lean maintenance brings together a series of techniques and tool s whose o bjective is to reduce or eliminate the unnecessary wastes (Muda in Japanese) Some examples of such lean tools are visual. Lean maintenance is a proactive strategy encompassing planned and scheduled maintenance through total productive maintenance (TPM) applying reliabilitycentered maintenance (RCM) logic.

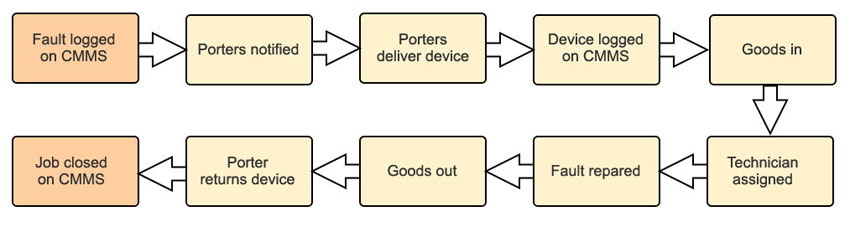

Lean maintenance is a precondition for successful lean manufacturing Applied the proactive concept of TPM and other kaizen tools, lean maintenance emphasizes the importance of a close link between maintenance and all the other company’s teams to ensure equipment reliability, minimize downtime and increase profitability. The maintenance work that gets done every day in factories around the world is typically inefficient, from a Lean perspective time is wasted, different tasks are not properly coordinated, job durations are overestimated and job plans, when they exist, are thus "inflated" to cover up the inefficiency. Lean maintenance is proactive maintenance operation that employs scheduled and planned maintenance activities through total productive maintenance (TPM) practices utilizing strategies that were developed through the application of reliability centered maintenance (RCM) decision ideas and performed by selfdirected action teams employing the lean management improvement principles as follows.

As a practical book, Lean Maintenance will take the reader on a journey from uncovering waste, designing projects to address the waste, selling the projects to management and delivering the projects Every area in maintenance is covered, including your TPM effort, storeroom, PM tasking, work orders and computer systems. Feature coverage of lean maintenance as part of lean manufacturing efforts, which in general seeks to avoid waste. Lean Maintenance is a practical book that almost instantly can contribute to your organization’s success It also is intended to be part of a larger effort to reduce the environmental footprint of the maintenance effort Lean Maintenance will take the reader on a journey from uncovering waste, designing projects to address the waste, selling the projects to management, and finally, delivering the projects.

Leaner manufacturing maintenance practices don’t just spawn out of recognizing waste They’re the product of progressive improvement, measured by Key Performance Indicators (KPIs) Identifying waste in the manufacturing process and using KPI drivers to eliminate waste is the fundamental approach of any lean maintenance program. Managers, and maintenance engineers can also take it The course works best when people from different levels, jobs or plants take it together. 5 Keys to Lean Maintenance and Improving Maintenance Productivity Part 5 Environment for Success In the first in this series of articles, we mentioned that any improvement process is headed for failure without the buyin and support of all those involved;.

Lean Maintenance – a 21st Century Approach This course is designed for all levels of maintenance personnel, particularly maintenance workers, supervisors, planners;. How the Y = f(x) thought process can lead the way to lean maintenance reliability T oo many times in lean manufacturing and other lean environments, 1040 year old equipment is redeployed, moved, and organized into lean cells without adequate concern or attention to maintenance reliability In a lean cell, unscheduled equipment downtime usually costs 10 times what the same equipment downtime costs in a traditional batch processing or functional department. Applying lean thinking to the maintenance of train bogies FEATURE – A Dutch company that maintains and overhauls train bogies has realized that in order for lean to work, a focus on continuous learning must be established Here is how they are trying to get there.

Lean Maintenance is written for anyone in a leadership position in maintenance, storeroom or production This unique book will also be found useful by vendors to the maintenance departments, including maintenance contractors, parts vendors, and various kinds of service providers A pragmatic book, Lean Maintenance will take the reader on a journey from uncovering waste, designing projects to address the waste, selling the projects to management and delivering the projects. Lean maintenance is a prerequisite for lean manufacturing systems The exhaustive literature review has been conducted to collect the uptodate maintenance strategies and activities, lean. Lean maintenance is built around the notion of employee empowerment a concept that can be very intimidating for maintenance shift supervisors who are used to being in charge By allowing recommendations and changes to bubble up from the lowest level, supervisors can feel they're losing control.

The MerriamWebster online dictionary defines efficient as being productive without waste Recently, we have seen many consultancies and companies starting to talk about terms such as LEAN Maintenance, an attempt to bring the same efficiency improvement approach into the world of physical asset management. This course is the first of its kind to focus exclusively on Maintenance, Repair and Overhaul organizations Participants will learn how to eliminate waste, improve quality, create flow, and enhance responsiveness to customer needs by applying lean principles plus the Theory of Constraints. While production staff are learning more and are increasingly involved with the management and improvement of equipment, the tasks of the maintenance staff should also be developed in parallel The aim should be to deliver an everimproving reliability at steadily reducing cost This process is known as Lean Maintenance.

Lean Maintenance is gaining traction as a sound strategy to keep equipment running and productivity humming The hardest part is getting started On Thursday, March at 1 pm CDT, Plant Engineering will present a Webcast that looks at the steps needed to implement a sound Lean Maintenance strategy on your plant floor and to begin to reap the benefits. Lean_Six_ Sigma_ Maintenance_pdf Free download as PDF File (pdf), Text File (txt) or view presentation slides online Scribd is the world's largest social reading and publishing site Open navigation menu. 5 Keys to Lean Maintenance and Improving Maintenance Productivity Part 5 Environment for Success In the first in this series of articles, we mentioned that any improvement process is headed for failure without the buyin and support of all those involved;.

Lean maintenance is built around the notion of employee empowerment a concept that can be very intimidating for maintenance shift supervisors who are used to being in charge By allowing recommendations and changes to bubble up from the lowest level, supervisors can feel they're losing control. Lean maintenance helps companies maximize uptime, yield, productivity and profitability The method builds in equipment reliability to existing production systems and reduces the need for maintenance troubleshooting and repairs It protects against the real causes of equipment downtime, not just their symptoms. Lean Maintenance is a practical book that almost instantly can contribute to your organization’s success It also is intended to be part of a larger effort to reduce the environmental footprint of the maintenance effort Lean Maintenance will take the reader on a journey from uncovering waste, designing projects to address the waste, selling the projects to management, and finally, delivering the projects.

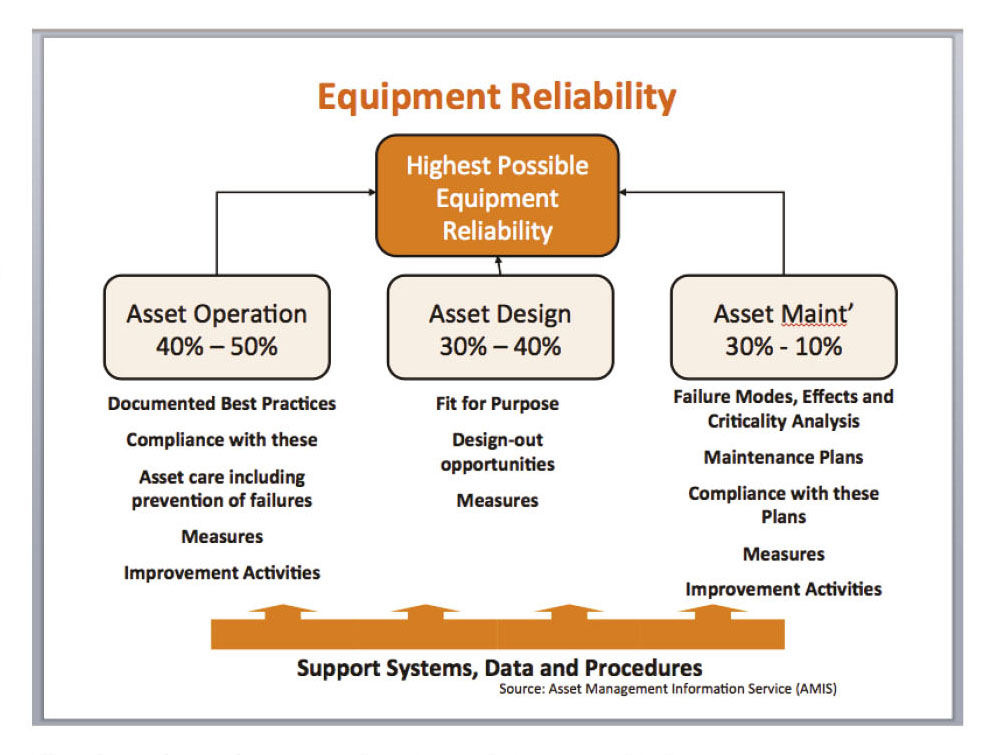

Lean Maintenance the Basics of Lean and ReliabilityBased Spare Parts Management In about 50% of organizations spare parts and materials stores reports to the maintenance organization In about 50 % of organizations spare parts and materials stores is part of the purchasing function One of the areas that are first attacked when an organization wants to become lean is the materials and spare parts areas. How the Y = f(x) thought process can lead the way to lean maintenance reliability T oo many times in lean manufacturing and other lean environments, 1040 year old equipment is redeployed, moved, and organized into lean cells without adequate concern or attention to maintenance reliability In a lean cell, unscheduled equipment downtime usually costs 10 times what the same equipment downtime costs in a traditional batch processing or functional department. Lean maintenance has a crucial key role in raising the part of reliability that is affected by the manufacturing equipment Since the manufacturing process is more and more dependent on atomization, good maintenance becomes more and more important.

Lean Maintenance Repair and Overhaul describes how MRO organizations can achieve significant improvement in financial performance by applying the Theory of Constraints (TOC) to guide the implementation of Lean manufacturing tools This Lean/TOC approach facilitates a growth strategy by providing customer value, such as faster turnaround times, that the competition cannot match. Lean maintenance training will help you learn how to effectively eliminate waste in your projects and daytoday facility maintenance operations A well designed program will teach you how to create a lean project from start to finish, how to develop strategies that instantly gain the support of top management executives and how to plan and execute a project that receives minimum resistance and maximum results. It is imperative that the leadership and culture is focussed on being proactive rather than reactive, and is performance driven.

Operations Lean Maintenance Operations, Lean & Maintenance Overview At GKN Aerospace we recognise that what we do well today, we can do even better tomorrow This culture of continuous improvement is at the heart of our operations across GKN Aerospace and we are constantly looking to improve our people, processes and products All our sites. Lean Maintenance Methodology The key objective of Lean Maintenance is to give your company the near 100% equipment uptime and reliability it demands while cutting your maintenance expense, often by 50% or more This is done by systematically surveying or analyzing each. With that in mind, Joel Levitt, a Lafayette Hill, Pabased maintenance consultant and author of another book titled "Lean Maintenance," defines "lean maintenance" as "delivery of maintenance services to customers with as little waste as possible, or producing a desirable maintenance outcome with the fewest inputs possible".

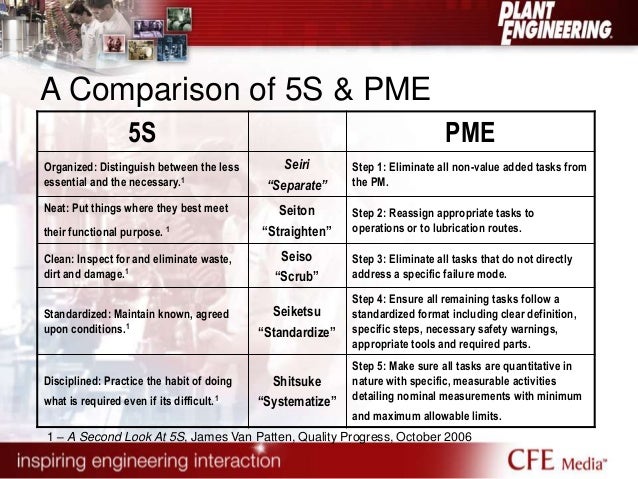

Lean Maintenance is a key ingredient to a successful Lean Manufacturing environment Like Lean Manufacturing, Lean Maintenance seeks to avoid waste Wasted maintenance activities that do not contribute to improving the availability of a machine Inefficient maintenance activities that should be performed more quickly or cheaply. In maintenance, the Lean process consists of simplifying routine duties involved in completing repairs In other words, these processes usually begin with a need for materials that go into storage somewhere along the line The steps between are all of the actions personnel take to complete an entire process. Lean maintenance is a proactive maintenance operation employing planned and scheduled maintenance activities through total productive maintenance (TPM) practices using maintenance strategies developed through application of reliability centered maintenance (RCM) decision logic and practiced by empowered (selfdirected) action teams using the 5S process, weekly Kaizen improvement events, and autonomous maintenance together with multiskilled, maintenance technicianperformed maintenance.

There are lean maintenance courses for all levels of maintenance personnel including managers, supervisors, maintenance workers and maintenance engineers You can transform your company from a traditional maintenance operation to a lean maintenance operation in less time than you think. The lean philosophy is focused exclusively on the customer, aiming to create efficiency by eliminating all processes and actions that do not directly create value for the buyer Maintenance — as a key component of any manufacturing operation — is an inherent part of this strategy and should not be overlooked Apply 5S Lean manufacturing and maintenance are based on Japanese principles of efficiency, and this shortcut applies corresponding Englishlanguage ideas to concepts from the. Whether referring to manufacturing operations or maintenance, lean is about doing more with less less effort, less space, fewer defects, less throughput time, lower volume requirements, less.

Management and supervisory roles change from that of directing and controlling, to a role of supporting The lean maintenance organization is a flat organization with fewer layers of middle management and supervision because, with the establishment of empowered action teams, much of their direction comes from within. The lean philosophy is focused exclusively on the customer, aiming to create efficiency by eliminating all processes and actions that do not directly create value for the buyer Maintenance — as a key component of any manufacturing operation — is an inherent part of this strategy and should not be overlooked Apply 5S Lean manufacturing and maintenance are based on Japanese principles of efficiency, and this shortcut applies corresponding Englishlanguage ideas to concepts from the. Lean Maintenance is a journey not a destination It is an ongoing process of continuous improvement A lean system requires that you set priorities for delivering value and eliminating waste When a lean process includes all functioning members of a process combined with open, honest and blamefree communication, huge gains in productivity and profitability can be achieved.

The recent popularity in lean manufacturing has spilled over into the maintenance world, with more and more organizations attempting to apply the principles of lean to their asset management departments But it isn't that simple, says Reliability Expert Daryl Mather He explains which principles apply and which don't in his latest Web column. Lean_Six_ Sigma_ Maintenance_pdf Free download as PDF File (pdf), Text File (txt) or view presentation slides online Scribd is the world's largest social reading and publishing site Open navigation menu. The maintenance work that gets done every day in factories around the world is typically inefficient, from a Lean perspective time is wasted, different tasks are not properly coordinated, job durations are overestimated and job plans, when they exist, are thus "inflated" to cover up the inefficiency.

Lean maintenance is an approach based on lean thinking applied in maintenance operations (the term was coined at the Massachusetts Institute of Technology by Womack and Jones in the 1990s) It is. How the Y = f(x) thought process can lead the way to lean maintenance reliability Too many times in lean manufacturing and other lean environments, 1040 year old equipment is redeployed, moved, and organized into lean cells without adequate concern or attention to maintenance reliability In a lean cell, unscheduled equipment downtime usually costs 10 times what the same equipment downtime costs in a traditional batch processing or functional department. There are many lean strategies that can be applied to equipment maintenance processes for waste removal and safety, quality and productivity improvement Depending on the company’s strategy, TPM (total productive maintenance) can be considered as a kaizen tool or kaizen can be seen as one of the pillars of TPM.

Principles Of Lean Maintenance

Lean Facility Management Introducing The Kanban System

Toyota S Total Productive Maintenance Maintenance

Lean Maintenance のギャラリー

Figure 1 From Lean Maintenance Excellence In The Container Handling Industry A Case Study Semantic Scholar

Big Deals Lean Maintenance Reduce Costs Improve Quality And Increase Market Share Life Cycle Video Dailymotion

Principles Of Lean Maintenance

Lean Maintenance Management Reliability Engineering Lean Manufacturing

5 Keys To Lean Maintenance And Improving Maintenance Productivity Part 1 Introduction Assetivity

Creating A Lean Environment Strategic Finance

The Right Tools For Every Job Lean And Agile In Maintenance Mckinsey

Lean Eco Efficient Innovation In Operations Through The Maintenance Organisation Sciencedirect

Q Tbn And9gcsw9 Enlsrbyaort2kieew0villqtoy3xzo I4y6clsms 7jemh Usqp Cau

Pdf Lean Maintenance Siemens Head Repair Time Reductiont Amran Seeni Academia Edu

Www Mdpi Com 1996 1073 10 10 1653 Pdf

Make Lean Easy Today Lean Maintenance Guide

Pdf Lean Maintenance Roadmap Semantic Scholar

Principles Of Lean Maintenance

Figure 5 From Lean Maintenance Logistics Management The Key To Green And Sustainable Performance Semantic Scholar

Total Productive Maintenance Tpm Board Lean Manufacturing

Total Productive Maintenance Lean Manufacturing And Six Sigma Definitions

Plant Engineering Lean Maintenance

Meaning Goals Of Tpm Total Productive Maintenance Lean Six Sigma Quality Management Eng Youtube

Autonomous Maintenance Am Pillar Continuously Improving Manufacturing

Lean Production Waste And Analogous Waste Within Maintenance 6 Download Scientific Diagram

Principles Of Lean Maintenance

Buildings Lean Maintenance Implementation Model Topic Of Research Paper In Civil Engineering Download Scholarly Article Pdf And Read For Free On Cyberleninka Open Science Hub

Lean Maintenance Na Modalidade Elearning Elearning Clt Lean

Lean Maintenance Reduce Costs Improve Quality And Increase Market Share Smith Ricky Hawkins Bruce Amazon Sg Books

Lean Maintenance Less Repairing More Improving

Lean And Agile Factors In Maintenance Operations Download Scientific Diagram

Five Common Lean Maintenance Missteps Industryweek

Lean Shut Down Management In Lean Maintenance Idcon Reliability And Maintenance Consulting And Training

Lean Maintenance Sciencedirect

Lean Maintenance Can Release The Full Potential Of Your Maintenance Function Fdbusiness Com

Lean World Class Maintenance Approach Industry 4 0 Cordence Worldwide

Lean Manufacturing Avoid The 7 Wastes

10 Top Tips For Lean Equipment Reliability Maintenance And Engineering

What Is Total Productive Maintenance Tpm Lucidchart Blog

Lean Maintenance Repair And Overhaul Mandyam Srinivasan

Lean Maintenance Management And Their Characteristic

5 Keys To Lean Maintenance And Improving Maintenance Productivity Part 1 Introduction Assetivity

Energies Free Full Text Lean Maintenance Applied To Improve Maintenance Efficiency In Thermoelectric Power Plants Html

Lean Maintenance Six Sigma Black Belt

How To Make Maintenance Processes More Efficient Using Lean Tools Springerlink

Lean Maintenance Repair And Overhaul By Srinivasan Mandyam Ebook

6 Important Kpis To Measure For Lean Manufacturing Maintenance Global Electronic Services

Scheme For Lean Maintenance Practices Download Scientific Diagram

How Is Lean Manufacturing Related To Maintenance Fiix

What S The Difference Between Lean Vs Six Sigma Fiix

Tpm Basics Lean Manufacturing Lean Manufacturing Consultants Kaizen Consultants Productivity Consultants Lean Coach Uk Mario Mason

Lean Smart Maintenance Value Adding Flexible And Intelligent Asset Management Springerlink

Tps Lean Manufacturing Glossary

Tpm And Lean Maintenance

Lean Maintenance Ricky Smith

Dimo Maint Less Repairing More Improving Learn How To Focus On Long Term Maintenance Solutions To Optimise Production Thanks To Lean Maintenance We Guide You Through The Main Steps Of

What Are The 7 Pillars Of Tpm Used In Lean Latest Quality

Q Tbn And9gcquzo41zblq Tg2yislk Dsmfdcswk5ci2 Wxwewkqjdtiez5og Usqp Cau

Tpm Total Productive Maintenance Overall Equipment Effectiveness Preventive Maintenance Lean Manufacturing Others Angle Text Logo Png Pngwing

Implementing Lean Maintenance System To Improve Factory Performance By Leanmaintainance Issuu

Tpm And Lean Maintenance Journal Archieves19 Webs

Read Online Books Lean Maintenance Repair And Overhaul Changing Th

Total Productive Maintenance Tpm The Maintenance Side Of Lean Strategos

Cmms And Kaizen The Importance Of Lean Maintenance In Today S Manufacturing Cmms Maintworld

Lean Maintenance Roadmap Topic Of Research Paper In Civil Engineering Download Scholarly Article Pdf And Read For Free On Cyberleninka Open Science Hub

Total Productive Maintenance Tpm The Maintenance Side Of Lean Strategos

Scheme For Lean Maintenance Practices Download Scientific Diagram

Guide To Lean And Six Sigma In Maintenance Strategies Plant Engineering

Proposed Lean Maintenance Process Download Scientific Diagram

Maintenance Process Mapping Templates And Examples

Design Tips For Creating A Lean Maintenance Workshop

Philosophy Lean Philosophy

Sisteplant Linkedin

Plant Engineering Lean Maintenance

Www Degruyter Com Downloadpdf Journals Eng Open Issue Article 10 1515 Eng 16 0055 Article 10 1515 Eng 16 0055 Xml

Maintenance Management Lean Maintenance And Tpm By Ben Leon

Lean Kanban Methodology To Application Support And Maintenance Agile Gnostic

Lean Farming Five Ways You Can Improve Productivity Txm Lean Solutions

Lean Maintenance Repair And Overhaul Changing The Way You Do Business Srinivasan Mandyam Bowers Melissa Gilbert Kenneth Amazon Sg Books

Lean Maintenance Anar Solutions Pvt Ltd

Lean Maintenance A Practical Step By Step Guide For Increasing Effic

Lean Facility Management Introducing The Kanban System

Items Of Lean Maintenance Download Scientific Diagram

Total Maintenance In Lean Manufacturing Concept

Lean Maintenance Management Training Course Online Training

Autonomous Maintenance Step 6 And 7 Standardization And Autonomous Management Continuously Improving Manufacturing

Lean Maintenance Framework And Its Application In Clutch Maintenance Semantic Scholar

Energies Free Full Text Lean Maintenance Applied To Improve Maintenance Efficiency In Thermoelectric Power Plants Html

How To Make Maintenance Processes More Efficient Using Lean Tools Springerlink

Total Productive Maintenance Strategos

Q Tbn And9gcq5ntzdtzposyzshaot7ebyjijymbo Rabd Lwptne Usqp Cau

Maintenance As An Essential Part Of Lean

Autonomous Maintenance Mudamasters

Tpm Total Productive Maintenance Lean Manufacturing Lean Six Sigma Lean Sigma

Leaner Manufacturing Starts With Lean Maintenance Global Electronic Services

File Lean Smart Maintenance Png Wikimedia Commons

Lean Maintenance Youtube

5 Keys To Lean Maintenance And Improving Maintenance Productivity Part 5 Environment For Success Assetivity

Maintenance Management Lean Maintenance And Tpm By Ben Leon

Lean Maintenance Pfizer Case Study Lean Manufacturing Reliability Engineering

Total Productive Maintenance Elearning Lean Manufacturing Training Amatrol

Lean Maintenance Taylor Francis Group

Visual Management For Maintenance Operations Leanguru

Lean Maintenance Industrial Press