Bulge Test

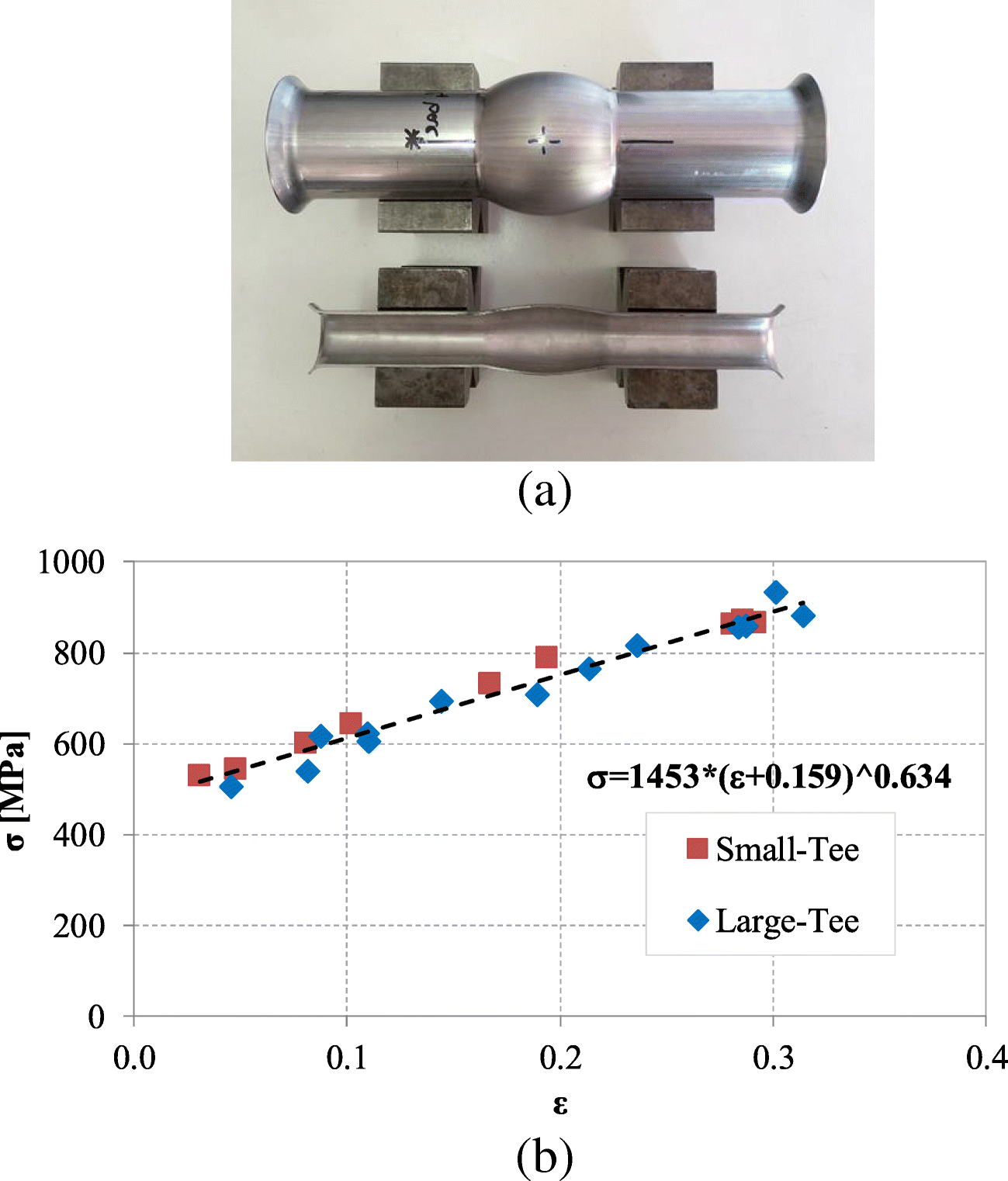

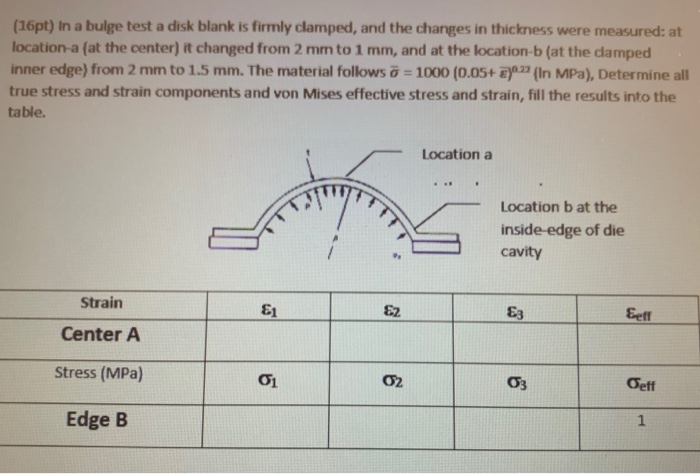

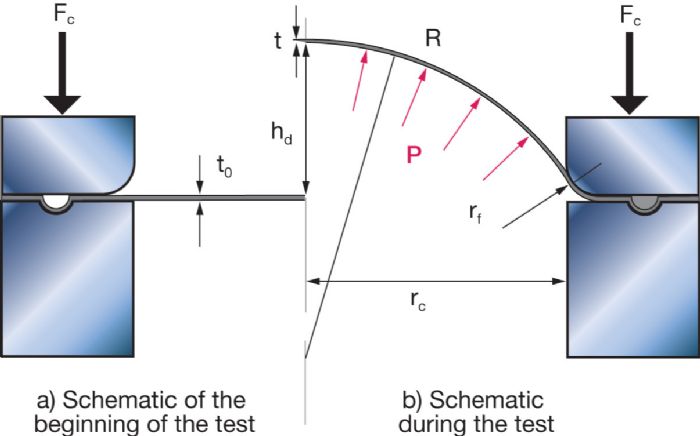

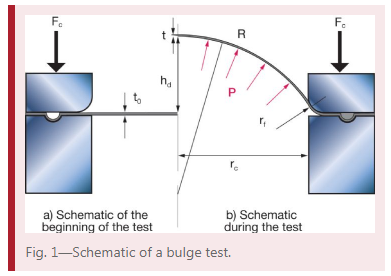

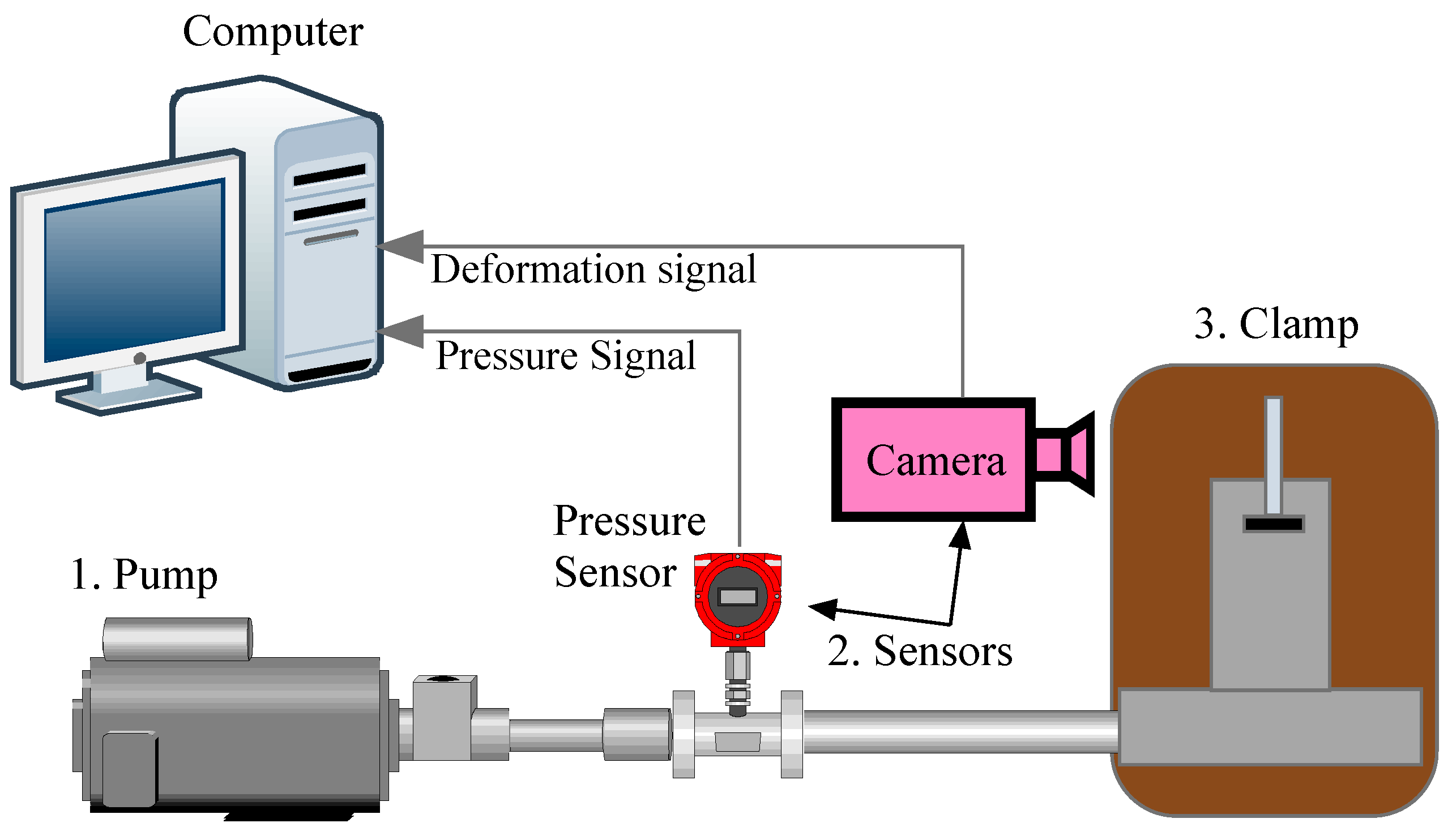

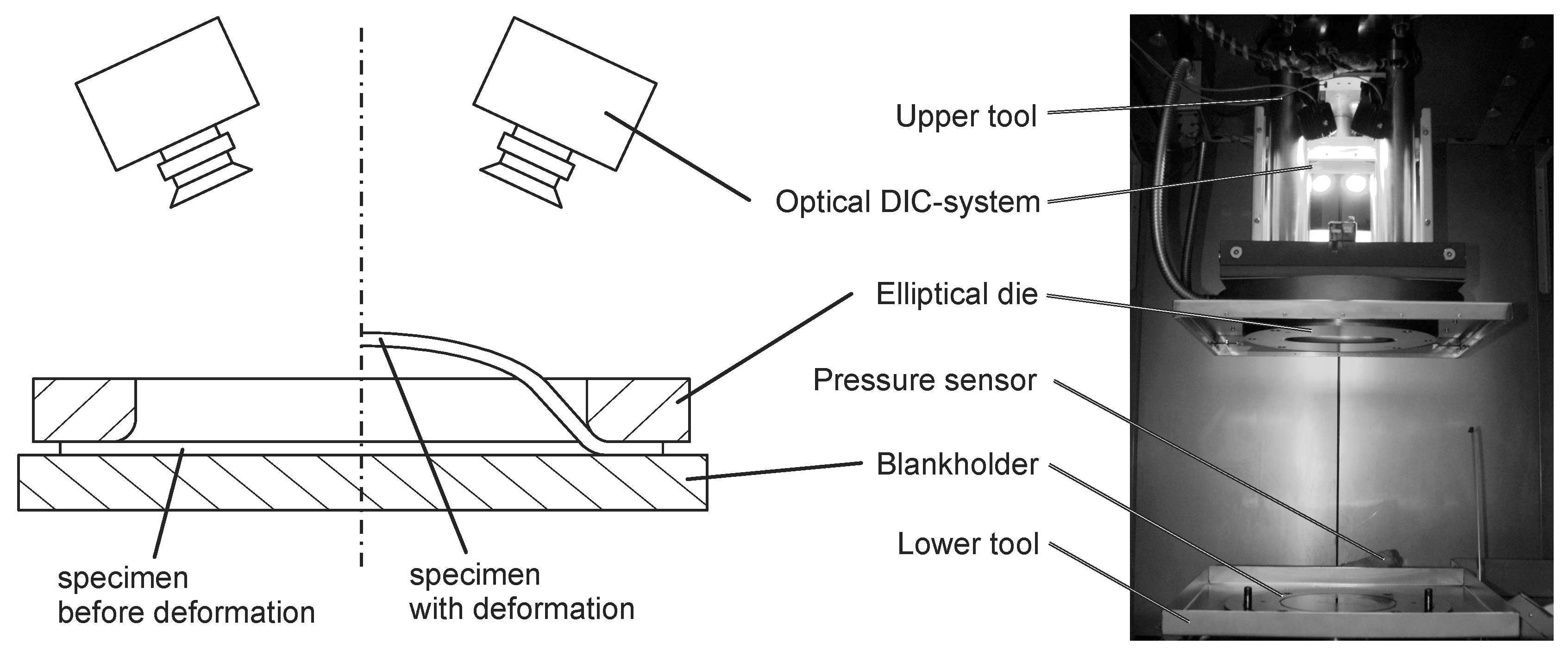

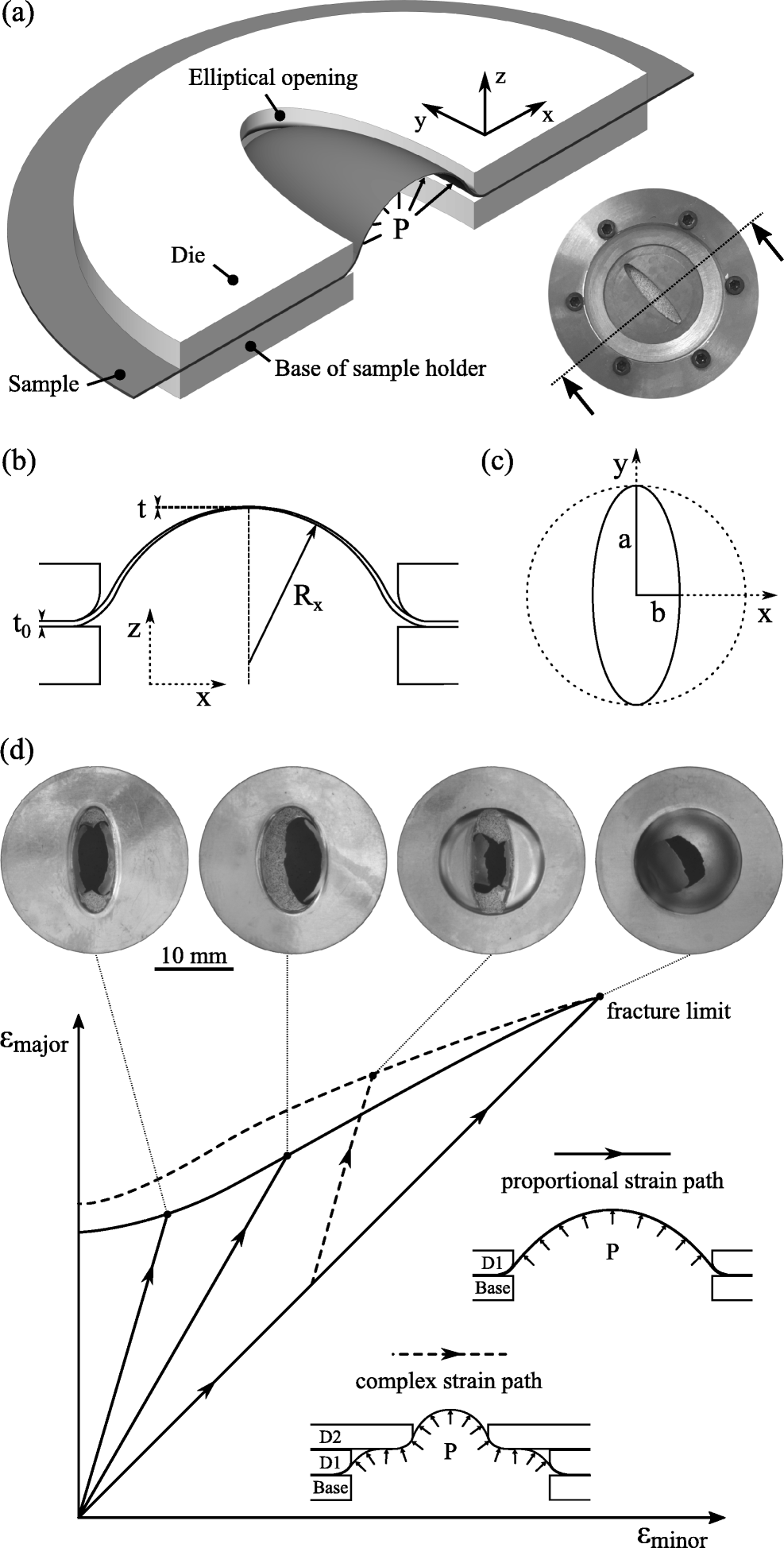

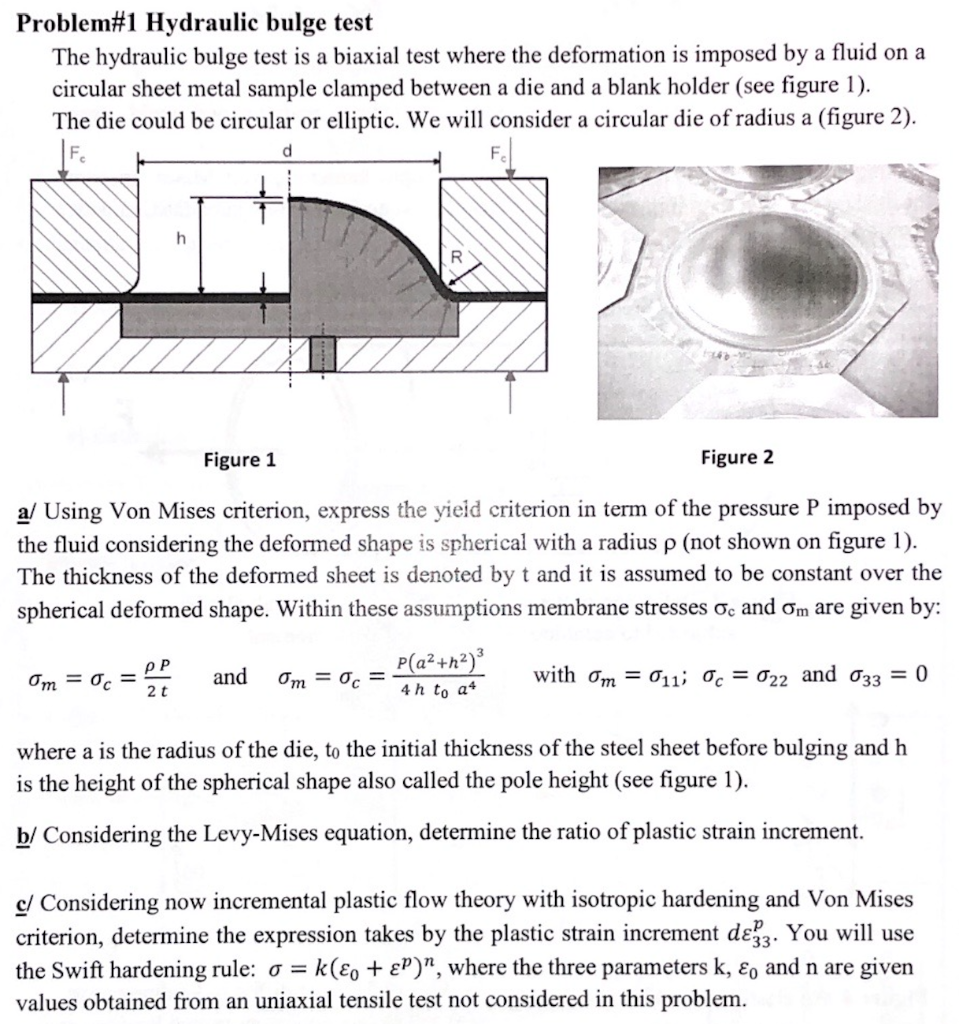

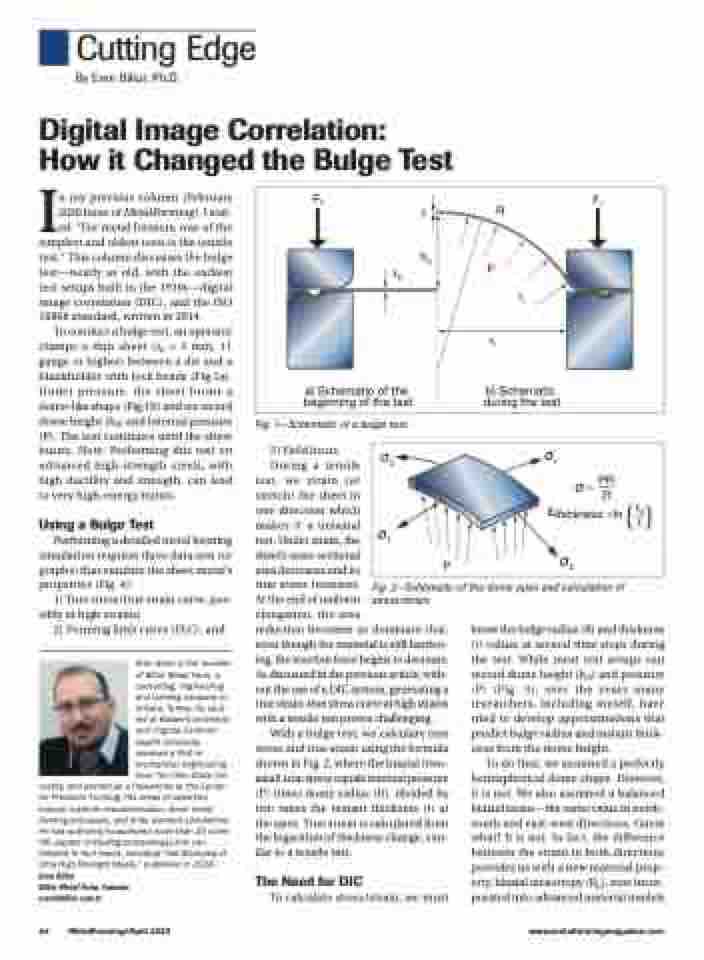

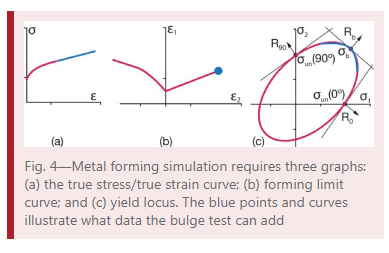

This column discusses the bulge test—nearly as old, with the earliest test setups built in the 1910s—digital image correlation (DIC), and the ISO standard, written in 14 To conduct a bulge test, an operator clamps a thin sheet (t 0 < 3 mm, 11 gauge or higher) between a die and a blankholder with lock beads (Fig 1a).

Bulge test. Objective To examine whether the presence of bulge sign or patellar tap was associated with frequent knee pain, progression of radiographic OA (ROA) and total knee replacement (TKR) Methods This study included 4344 Osteoarthritis Initiative participants examined at baseline for bulge sign and/or patellar tap The clinical signs were categorized as no (none at baseline and 2 years), resolved. Synthetic Bulge Test The new methods are first applied to a synthetic experiment, to allow for the verification of the procedure without having to deal with measurement uncertainties Only one half of the membrane is modeled with a Finite Element model using 15,000 8node quadratic thick shell elements. Tensile testing over time is the first step in determining property variation for new material forming However, industrial stamping processes often experience higher strain than what can be measured in a tensile test Bulge testing can dramatically improve the accuracy of the yield surface of new materials The EWI Forming Center recently developed the bulge.

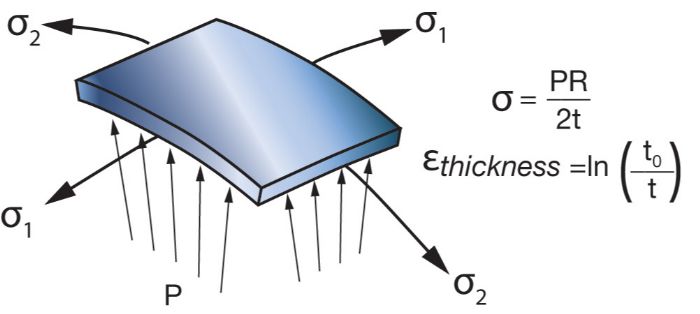

The bulge test mechanical system evaluates the strain and the curvature by using selected diameters as defined on Fig 1, Dst for strain calculation and Dcv for curvature calculation The objective of this study is to evaluate and understand the influence of such diameters on the. Bulge test, the necking phenomenon does not appear during testing due to the biaxial deformation This allows for the bulge test to be carried out without necki ng effects for the entire plastic deformation zone up to the failure and deliver more accurate results Figure 1 shows the main components of a bulge te st setup. The planestrain bulge test is a powerful new technique for measuring the mechanical properties of thin films In this technique, the stress–strain curve of a thin film is determined from the pressuredeflection behavior of a long rectangular membrane made of the film of interest.

Internal pressure–bulge height curve obtained by FE simulation of tube bulging test For validation, comparisons between numerical and analytical results are done They concern the hardening law, the evolution of pole thickness t (0) with bulge height and thickness variation along length of bulged part of the tube. The bulge test is frequently used experiment to characterize the material stressstrain response at the highest possible strain levels It consists of a metal sheet placed in a die with a circular. The Explosion Bulge Test has been used for over 60 years as a standard test for the assessment of steel toughness and deformation resistance under blast loading conditions 13 However, details of the test conditions vary considerably from one country to the other.

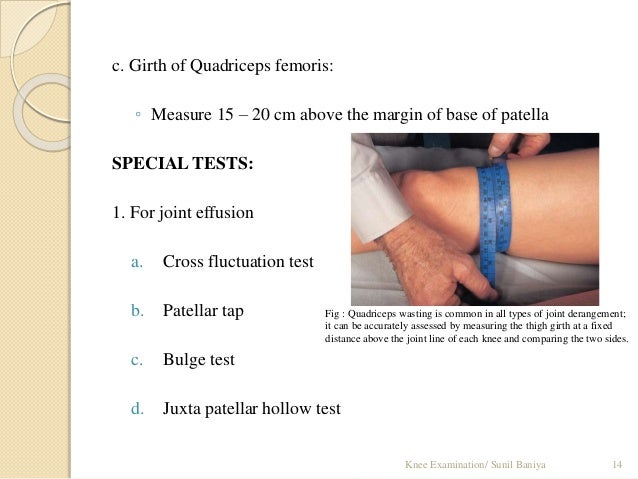

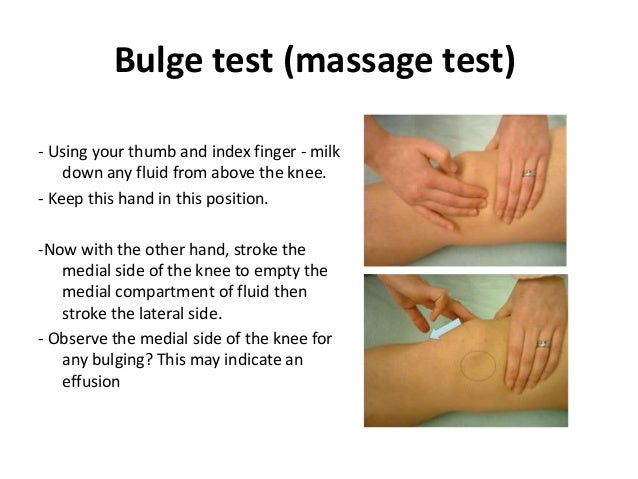

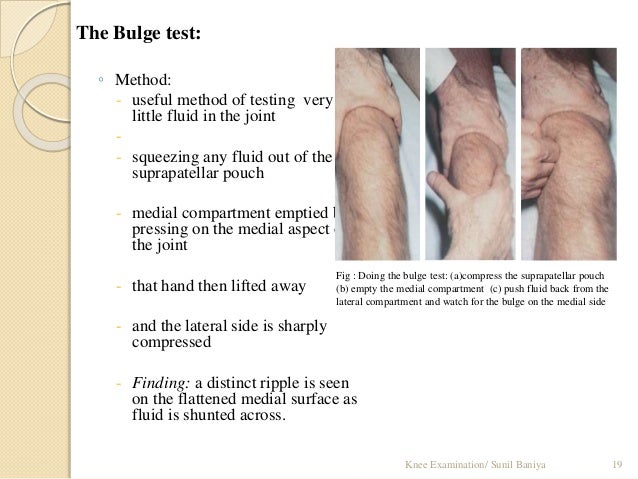

The bulge test is used to determine the presence of fluid in the knee joint What is the bulge sign test It is useful when only a little fluid is present in the joint The suprapatellar bursa is first emptied of fluid by squeezing distally from about 15 cm above the patella What is the bulge sign test. The use of the hydraulic bulge test for estimation of flow stress under biaxial stressstrain state is discussed hrenWaC In this paper the sheet thickness gradation in different points of the hemisphere formed in the bulge test is analysed , both theoretically and experimentally. If effusion is present, a bulge will be appear at the medial border of the patella because the effusion is milked back to the medial patella Assessment of range of motion Both the active and passive range of motion should be assessed The normal knee extension is between 0 to 10 degrees In McMurray test, the person should lie down in.

Extend the knee joint Milk the fluid from the lateral side of the knee, to the suprapatellar pouch, into the medial side of the knee Gently press onto the fluidfilled medial side of the knee. Bad years come and go, but a photo of a perky bulge — plastered all over the internet — is forever Advertisement Continue Reading Below 1 Justin Bieber's fake dick pic scandal. Of biaxial stressstrain curve by means of bulge test with optical measuring systems 1 Scope This International Standard specifies a method for determination of the biaxial stressstrain curve of metallic sheets having a thickness below 3 mm in pure stretch forming without significant friction influence.

The hydraulic bulge test to ISO is a test method used in materials testing for the determination of sheet metal forming properties In a bulge test biaxial stressstrain curves are determined on sheet metals using a hydraulic cupping test A metal blank (specimen) is fully clamped between the matrix and the blank holder. This column discusses the bulge test—nearly as old, with the earliest test setups built in the 1910s—digital image correlation (DIC), and the ISO standard, written in 14 To conduct a bulge test, an operator clamps a thin sheet (t 0 < 3 mm, 11 gauge or higher) between a die and a blankholder with lock beads (Fig 1a). Bulge test is an effective technique to measure the mechanical properties of thin films As the membrane size decreases to nanoscale, the surface effect plays a significant role in determining the mechanical behavior of the membrane, andthe techniques commonly used to measure the bulk materials properties arenot applicable.

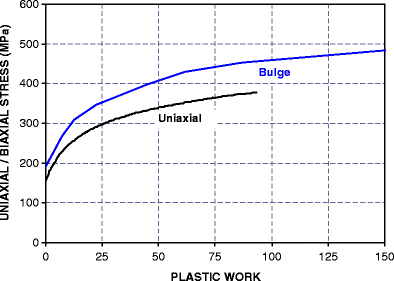

It is known that hot tensile tests are only evaluable until low strain levels Therefore, a hot gas bulge test for temperatures in the range of 600 °C to 900 °C and strain rates up to 1/s is being developed In order to design such a hot gas bulge test, the requirements (eg forming pressure) are estimated by finite element simulations. The tensile test and bulge test can be combined to obtain the flow stress data The yield point is calculated from the tensile test, and the rest of the curve is from the bulge test Figure 3 For the tested DP980, the bulge test can provide flow stress up to 035 strain value, while the tensile test can provide flow stress only up to 008 strain. Effusion was assessed by the bulge sign, balloon test, and patellar tap Of these tests the bulge sign was the most reliable ( Rc 0,97) However, the assessment of effusion by balloon test also achieved a post standardization PABAK of 0,99.

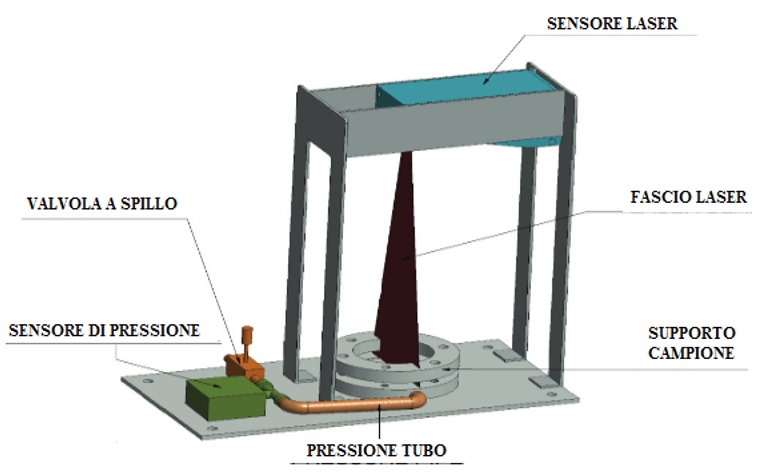

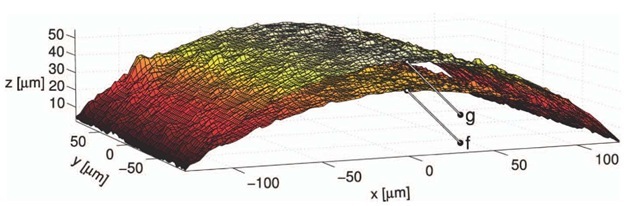

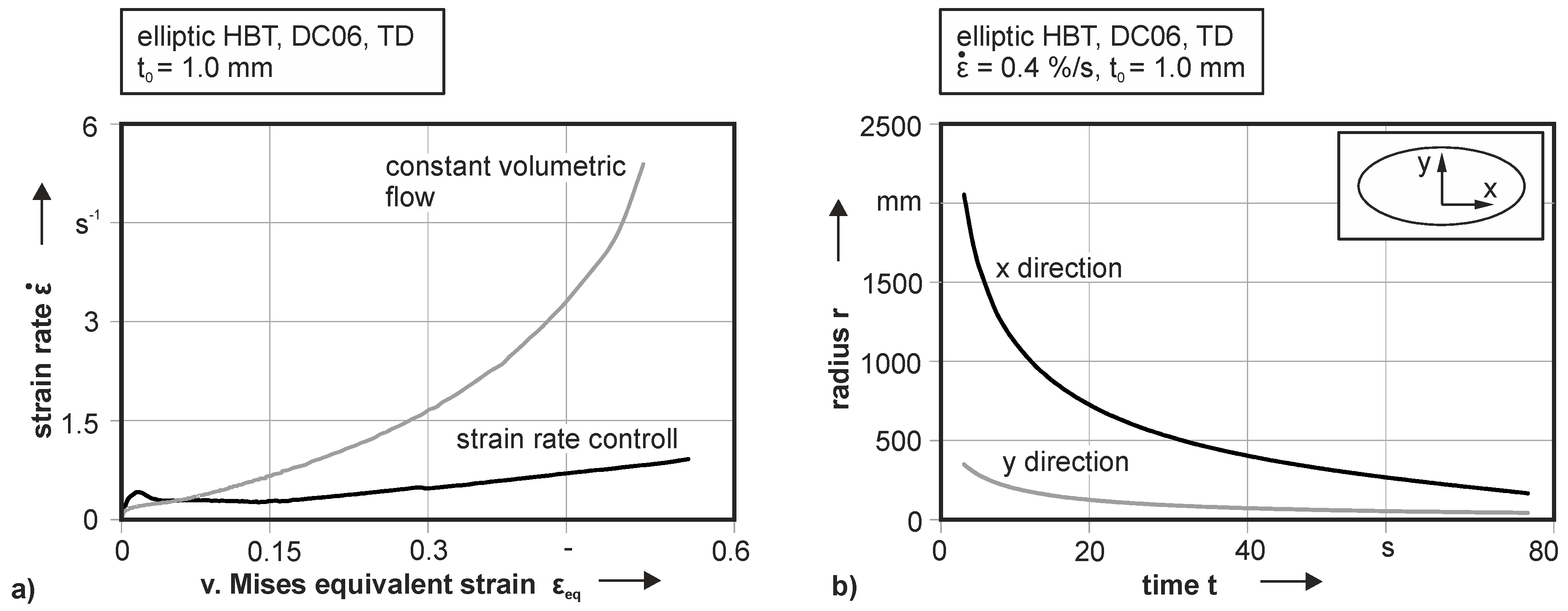

This paper aims at determining the mechanical properties such as Poisson ratio, biaxial modulus, and residual stress of polymer membranes using the bulge test and fringe projection Under this idea, a bulge test apparatus has been developed for robust usage, under the room temperature, in industrial environments that are usually noisy and full of all kinds of vibrations A setup of the bulge. Tests, namely circular bulge test, elliptical bulge test 1 and elliptical bulge test 2 The effect of the shear stress (r 45) can be studied by placing the sheet such that the rolling direction of the sheet is at an angle of 45o to the major and minor axis of the die, Figure 1 Elliptical bulge test 1 Elliptical bulge test 2 Elliptical bulge. The bulge test is a commonly used experiment to establish the material stressstrain response at the highest possible strain levels It consists of a metal sheet placed in a die with a circular opening It is clamped in place and inflated with hydraulic pressure In this thesis, a bulge testing apparatus was designed, fabricated, calibrated and.

The sweep test is also known as knee hydrops test, knee effusion test, effusion wave test, bulge test, patella sweep test, brush test It is used to assess for joint effusion presence of increased intraarticular fluid in the knee area1The sweep test is often paired with the ballottement patella test (in which the examiner strokes the proximal hand on the thigh towards the knee and taps on. The bulge test is an alternative to obtain ranges of deformation higher than tensile test, thus being possible to obtain non‐extrapolated data for material behavior Several methods may be used to obtain stress‐strain data from bulge test, but a common concept is behind them, which needs the measurement of bulge pressure, curvature of bulge. Of biaxial stressstrain curve by means of bulge test with optical measuring systems 1 Scope This International Standard specifies a method for determination of the biaxial stressstrain curve of metallic sheets having a thickness below 3 mm in pure stretch forming without significant friction influence.

This paper aims at determining the mechanical properties such as Poisson ratio, biaxial modulus, and residual stress of polymer membranes using the bulge test and fringe projection Under this idea, a bulge test apparatus has been developed for robust usage, under the room temperature, in industrial environments that are usually noisy and full of all kinds of vibrations A setup of the bulge. Patellar Ballottement Test and Bulge Sign The Patellar Ballottement test is used when a large knee effusion is suspected With the patient’s knee in full extension, compress the suprapatellar pouch distally to force the fluid below the patella Now, press the patella into the trochlear groove and then release. A hernia occurs when a piece of skin or organ tissue (like the intestine) bulges through the outer tissue layer that normally holds the area in Several different hernia types exist — and some.

Tensile testing over time is the first step in determining property variation for new material forming However, industrial stamping processes often experience higher strain than what can be measured in a tensile test Bulge testing can dramatically improve the accuracy of the yield surface of new materials The EWI Forming Center recently developed the bulgeRead more. The most important advantage of the bulge test is its capability to attain very high levels of straining 1 The main problem of using the bulge test for the determination the stressstrain relationship is the measurement of the bulge radius and polar thickness of the specimen. A hernia occurs when a piece of skin or organ tissue (like the intestine) bulges through the outer tissue layer that normally holds the area in Several different hernia types exist — and some.

R&D Update Determining flow stress data by combining uniaxial tensile and biaxial bulge tests Tensile Test The tensile test is a standard test for determining the elastic and plastic behavior of material under a Bulge Test The hydraulic bulge test is used to evaluate formability and determine. Tests, namely circular bulge test, elliptical bulge test 1 and elliptical bulge test 2 The effect of the shear stress (r 45) can be studied by placing the sheet such that the rolling direction of the sheet is at an angle of 45o to the major and minor axis of the die, Figure 1 Elliptical bulge test 1 Elliptical bulge test 2 Elliptical bulge. The patellar bulge test is a relatively insensitive but highly specific clinical marker for joint effusion in OA A positive patellar bulge test at presentation is associated with greater pain, disability, a higher rate of corticosteroid injections and a 2 to 3fold increase in TKR within 5 years.

The Bulge Test A diagrammatic section of the bulge test device which is used in the Bulge/FLC Tester is shown in picture beside The test panel (2) is clamped between the drawing die (1) and the blank holder (3) The chamber underneath the test panel is filled with special oil (4). Specifically, the hydrodynamic bulge test relies on a pressure drop measurement across a rectangular microchannel with a deformable top wall We develop a mathematical model using firstorder shear deformation theory of plates with stretching and the lubrication approximation for the Newtonian fluid flow. Definition/description The sweep test is also known as knee hydrops test, knee effusion test, effusion wave test, bulge test, patella sweep test, brush test It is used to assess for joint effusion presence of increased intraarticular fluid in the knee area.

For webquest or practice, print a copy of this quiz at the World War II Battle of the Bulge webquest print page About this quiz All the questions on this quiz are based on information that can be found on the page at World War II Battle of the Bulge Back to History for Kids. Bad years come and go, but a photo of a perky bulge — plastered all over the internet — is forever Advertisement Continue Reading Below 1 Justin Bieber's fake dick pic scandal. The patellar bulge test is used to assess for an effusion of the knee joint, by attempting to move the fluid to one side of the knee How to Perform ;.

The bulge test is used to determine the presence of fluid in the knee joint What is the bulge sign test It is useful when only a little fluid is present in the joint The suprapatellar bursa is first emptied of fluid by squeezing distally from about 15 cm above the patella What is the bulge sign test. The bulge test is used to determine the presence of fluid in the knee joint It is useful when only a little fluid is present in the jointThe suprapatellar. Young wrestlers and some obvious boners.

Specifically, the hydrodynamic bulge test relies on a pressure drop measurement across a rectangular microchannel with a deformable top wall We develop a mathematical model using firstorder shear deformation theory of plates with stretching and the lubrication approximation for the Newtonian fluid flow. The bulge test is an alternative to obtain ranges of deformation, higher than tensile test, thus permitting a better characterization for material behaviour This paper presents a sensitivity analysis for some influencing variables used in bulge measurements, thus giving some guidelines for the evaluation of the stressstrain curve from. The bulge test is used to determine the presence of fluid in the knee joint It is useful when only a little fluid is present in the joint The suprapatellar bursa is first emptied of fluid by squeezing distally from about 15 cm above the patella.

Bulge definition is to jut out swell How to use bulge in a sentence Synonym Discussion of bulge. It is known that hot tensile tests are only evaluable until low strain levels Therefore, a hot gas bulge test for temperatures in the range of 600 °C to 900 °C and strain rates up to 1/s is being developed In order to design such a hot gas bulge test, the requirements (eg forming pressure) are estimated by finite element simulations. This test is thought to be more sensitive than the anterior drawer sign Attempt to hyperextend knee by placing one hand superior to the patella and the other posterior to the heel More than 23cm (ie able to place one or two fingers beneath the heel when leg is extended and flat) is abnormal.

The bulge test is an alternative to obtain ranges of deformation, higher than tensile test, thus permitting a better characterization for material behaviour This paper presents a sensitivity analysis for some influencing variables used in bulge measurements, thus giving some guidelines for the evaluation of the stressstrain curve from. All bulges are ranked and measured on a scale of zero to five Jon Hamms Each celebulge was evaluated on its outline, girth, and prominence to determine its rank and the number of Hamms it. The bulge is the tangent of 1/4 of the included angle for the arc between the selected vertex and the next vertex in the polyline's vertex list A negative bulge value indicates that the arc goes clockwise from the selected vertex to the next vertex A bulge of 0 indicates a straight segment, and a bulge of 1 is a semicircle.

The bulge test is used to determine the presence of fluid in the knee joint It is useful when only a little fluid is present in the joint The suprapatellar bursa is first emptied of fluid by squeezing distally from about 15 cm above the patella. The patellar bulge test is used to assess for an effusion of the knee joint, by attempting to move the fluid to one side of the knee. Internal pressure–bulge height curve obtained by FE simulation of tube bulging test For validation, comparisons between numerical and analytical results are done They concern the hardening law, the evolution of pole thickness t (0) with bulge height and thickness variation along length of bulged part of the tube.

This demographic bulge will initially be reflected in an ageing workforce, then, from 10 onwards in a sharp increase in pensioner numbers and later in increased needs for health and longterm care eurlexeuropaeu. For webquest or practice, print a copy of this quiz at the World War II Battle of the Bulge webquest print page About this quiz All the questions on this quiz are based on information that can be found on the page at World War II Battle of the Bulge Back to History for Kids. The bulge test is frequently used experiment to characterize the material stressstrain response at the highest possible strain levels It consists of a metal sheet placed in a die with a circular.

The tensile test and bulge test can be combined to obtain the flow stress data The yield point is calculated from the tensile test, and the rest of the curve is from the bulge test Figure 3 For the tested DP980, the bulge test can provide flow stress up to 035 strain value, while the tensile test can provide flow stress only up to 008 strain.

Http Citeseerx Ist Psu Edu Viewdoc Download Doi 10 1 1 902 7457 Rep Rep1 Type Pdf

Figure 5 Characterization And Optimization Of The Hydroforming Process Of Aisi 316l Steel Hydraulic Tubes Springerlink

Test Setup For Explosion Bulge Testing The Small Cylinder On Top Is Download Scientific Diagram

Bulge Test のギャラリー

Equipment For Bulge Testing Metal Foils Using A Laser Scanner Metal Working World Magazine

Full Field Bulge Testing Using Global Digital Image Correlation Mems And Nanotechnology

Bulge Test An Overview Sciencedirect Topics

Sweep Test Physiopedia

Implicit Vs Explicit Formulation In Bulge Test Youtube

Research Group Materials Testing Rwth chen University Institute Of Metal Forming English

Onlinelibrary Wiley Com Doi Pdf 10 1002 Srin

Biaxial Tensile Strength Characterization Of Textile Composite Materials Intechopen

Improvement Of Specimen Preparation Process For Bulge Test Using

Projects Iq Harvard Edu Files Vlassakgroup Files Plane Strain Bulge Test For Thin Films Pdf

Knee Examination

Q Tbn And9gcrqr2kwjl16oq tnaq3kx4mj7wm3ynte4rjf6ahnq5zvu Ikp Usqp Cau

R D Update Determining Flow Stress Data By Combining Uniaxial Tensile And Biaxial Bulge Tests

Arxiv Org Pdf 1808

Bulge Test

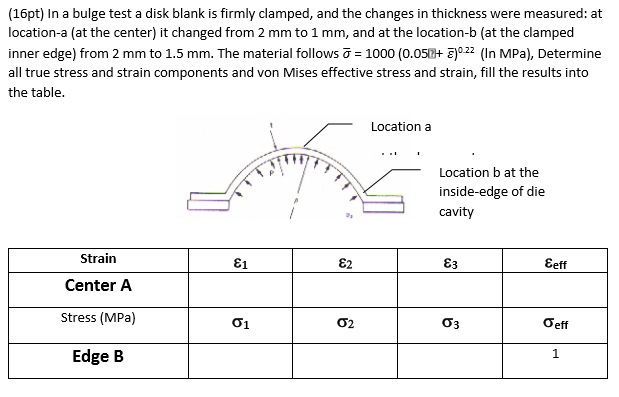

16pt In A Bulge Test A Disk Blank Is Firmly Clam Chegg Com

Materials Free Full Text Determination Of Material Strengths By Hydraulic Bulge Test

A Method Of Bulge Test For Determining The Work Hardening Characteristics Of Sheet Metals Scientific Net

Pdf A Bulge Test Based Methodology For Characterizing Ultra Thin Buckled Membranes Semantic Scholar

Digital Image Correlation How It Changed The Bulge Test Metalforming Magazine Article

Digital Image Correlation How It Changed The Bulge Test China Automotive Material Website

Material Hardening Of A High Ductility Aluminum Alloy From A Bulge Test Sciencedirect

Accurate Evaluation Method For The Hydraulic Bulge Test Scientific Net

Ptu Pneumatic Bulge Test Institute For Production Engineering And Forming Machines Technical University Of Darmstadt

Solved 16pt In A Bulge Test A Disk Blank Is Firmly Clam Chegg Com

Figure 5 Mechanical Properties Measurement Of Polymer Films By Bulge Test And Fringe Projection

Effects Of Anisotropy On Material Hardening And Burst In The Bulge Test Sciencedirect

Exercises In Hydraulic Bulge Testing H S Kim H Lim Mike Sumption Ted Collings The Ohio State University Dept Of Materials Science And Engineering Center Ppt Download

Arxiv Org Pdf 1808

Formability The Limiting Dome Height Test

Investigation Of The Effective Parameters In The Bulging Process And Obtaining Forming Limit Curve Of The Stainless Steel Tube By The Gtn Criterion Tarbiat Modares University Journals System Modares Mechanical Engineering

Biaxial Bulge Testing Of Thin Films And Foils Miroslav Cieslar Faculty Of Mathematics And Physics Charles University Prague Czech Republic J L Martin Ppt Download

Http Congress Cimne Com Iacm Eccomas14 Admin Files Filepaper P2301 Pdf

Bulge Test Conditions Download Scientific Diagram

Q Tbn And9gcrrysxbztl9vqagegxxd2lvztqax4bpd 9aip2qtlvrfple93vq Usqp Cau

Pdf Plane Strain Bulge Test For Thin Films Semantic Scholar

Materials Free Full Text Determination Of Material Strengths By Hydraulic Bulge Test Html

Determination Of Flow Curve Using Bulge Test And Calibration Of Damage For Ito Goya Models Scientific Net

Figure 3 Mechanical Properties Measurement Of Polymer Films By Bulge Test And Fringe Projection

Bulge Test Conditions Download Scientific Diagram

Bulge Test Manufacturer In United States By The Nanosteel Company Inc Id

Pin On Rn

Bulge Test Youtube

Pdf Effect Of Explosion Bulge Test Parameters On The Measurement Of Deformation Resistance For Steel Semantic Scholar

Pdf Effect Of Explosion Bulge Test Parameters On The Measurement Of Deformation Resistance For Steel Semantic Scholar

Novel Scanning Electron Microscope Bulge Test Technique Integrated With Loading Function Review Of Scientific Instruments Vol 85 No 10

Onlinelibrary Wiley Com Doi Pdf 10 1002 Pen

Www Tandfonline Com Doi Pdf 10 1080 x

Q Tbn And9gcrqr2kwjl16oq tnaq3kx4mj7wm3ynte4rjf6ahnq5zvu Ikp Usqp Cau

Jmmp Free Full Text Improvement Of Numerical Modelling Considering Plane Strain Material Characterization With An Elliptic Hydraulic Bulge Test

Bulge Test A Valuable Tool For Material Formability Evaluation Ewi

Development Of A Gas Based Bulge Test For Glowing Metal Rwth chen University Institute For Fluid Power Drives And Systems English

Principle Of The Hydraulic Bulge Test With Utilization Of The Download Scientific Diagram

Schematic Views Of A Plane Strain Bulge Test Experiment A Slender Download Scientific Diagram

Locomotor System Clinical Gate

Material Property Variations In Tubes Used For Hydroforming

Design Of A Hydraulic Bulge Test Apparatus

On The Validity Regime Of The Bulge Equations Journal Of Materials Research Cambridge Core

2

Anisotropy And Plastic Flow In The Circular Bulge Test Sciencedirect

Hydraulic Bulge Test With Aluminum Alloy Sheet 51 O Youtube

Basic System For Tube Bulge Test Download Scientific Diagram

R D Update Determining Flow Stress Data By Combining Uniaxial Tensile And Biaxial Bulge Tests

Schematic Of The Working Of Hydraulic Bulge Test Download Scientific Diagram

Illustration Of Hydraulic Bulge Testing With The Aid Of Digital Image Download Scientific Diagram

Digital Image Correlation How It Changed The Bulge Test Metalforming Magazine Article

Mechanical Properties Testing Of Sheet Metal By Hydraulic Bulge Test

Explosion Bulge Test Of High Srength Low Alloy Steel Pfs 700 In Air And Underwater Scientific Net

Mechanical Properties Measurement Of Polymer Films By Bulge Test And Fringe Projection Topic Of Research Paper In Mechanical Engineering Download Scholarly Article Pdf And Read For Free On Cyberleninka Open Science

Commons Lib Niu Edu Bitstream Handle Sassi Niu 0162m 130 Pdf Sequence 1 Isallowed Y

2

Figure 1 Tracking Microstructure Evolution In Complex Biaxial Strain Paths A Bulge Test Methodology For The Scanning Electron Microscope Springerlink

Experimental And Numerical Investigation Of A Strain Rate Controlled Hydraulic Bulge Test Of Sheet Metal Sciencedirect

A Viscous Pressure Bulge Test For The Determination Of A Plastic Hardening Curve And Equibiaxial Material Data Springerlink

Mechanical Properties Testing Of Sheet Metal By Hydraulic Bulge Test

A Microfluidic Method To Measure Bulging Heights For Bulge Testing Of Polydimethylsiloxane Pdms And Polyurethane Pu Elastomeric Membranes Rsc Advances Rsc Publishing Doi 10 1039 C8rac

Figure 4 Mechanical Properties Measurement Of Polymer Films By Bulge Test And Fringe Projection

Hydraulic Bulge Test To Iso

Iopscience Iop Org Article 10 10 1742 6596 1063 1 0142 Pdf

Matin Wiki Hydraulic Bulge Test Hbt Compare

Bulge Fatigue Testing Of Freestanding And Supported Gold Films Journal Of Materials Research Cambridge Core

Bulge Test An Overview Sciencedirect Topics

Clinical Approch To Rheumatological Examination

On The Fracture Characteristics Of Advanced High Strength Steels During Hydraulic Bulge Test Sciencedirect

Bulge Test For The Knee Youtube

Jmmp Free Full Text Improvement Of Numerical Modelling Considering Plane Strain Material Characterization With An Elliptic Hydraulic Bulge Test

Brush Stroke Bulge Swipe Test Knee Swelling Youtube

3

Problem 1 Hydraulic Bulge Test The Hydraulic Bulge Chegg Com

Development Of A Gas Based Bulge Test For Glowing Metal Rwth chen University Institute For Fluid Power Drives And Systems English

Hydraulic Bulge Test With On Line Sensing Of Strain Strain Rate Download Scientific Diagram

Dissecting Defects Part Ii

Hydraulic Bulge Test Apparatus Download Scientific Diagram

Knee Examination

Pdf Numerical Simulation Of Underwater Explosion Bulge Test Raju Rajendran Academia Edu

2

Www Erichsen De En Gb Products Sheet Metal Testing Special Testing Special Testing 2 Bulge Flc Tester Model 161 Tbe 161 Pdf

Investigation Of A Bulge Test At High Temperatures And High Strain Rates Using A Finite Element Simulation Study Scientific Net

Scholar Uwindsor Ca Cgi Viewcontent Cgi Article 6921 Context Etd

Metalforming April

Digital Image Correlation How It Changed The Bulge Test China Automotive Material Website