Aluminium Casting Process

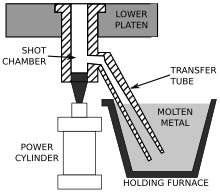

Die casting molds use steel dies or molds to produce a lot of identical castings With aluminum, as other metals, the molten metal is forced under high pressure into these types of molds for aluminum casting This is a versatile process that enables the production of a large quantity of small to mediumsize castings Shell Mold A shell mold is.

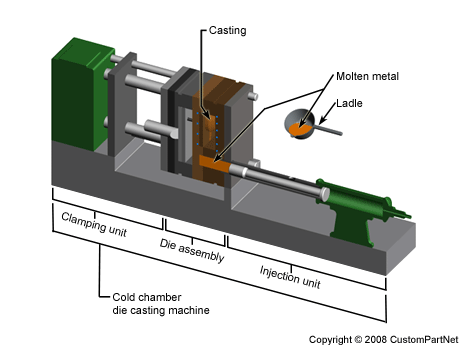

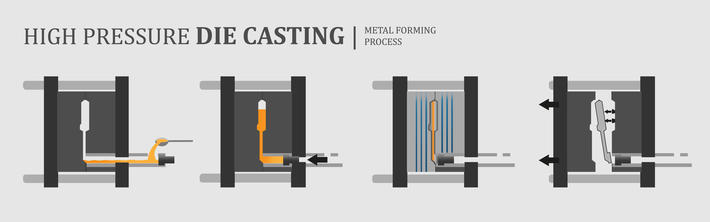

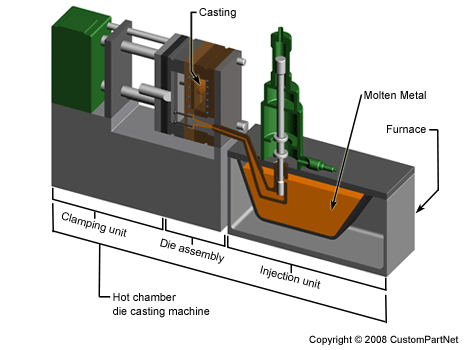

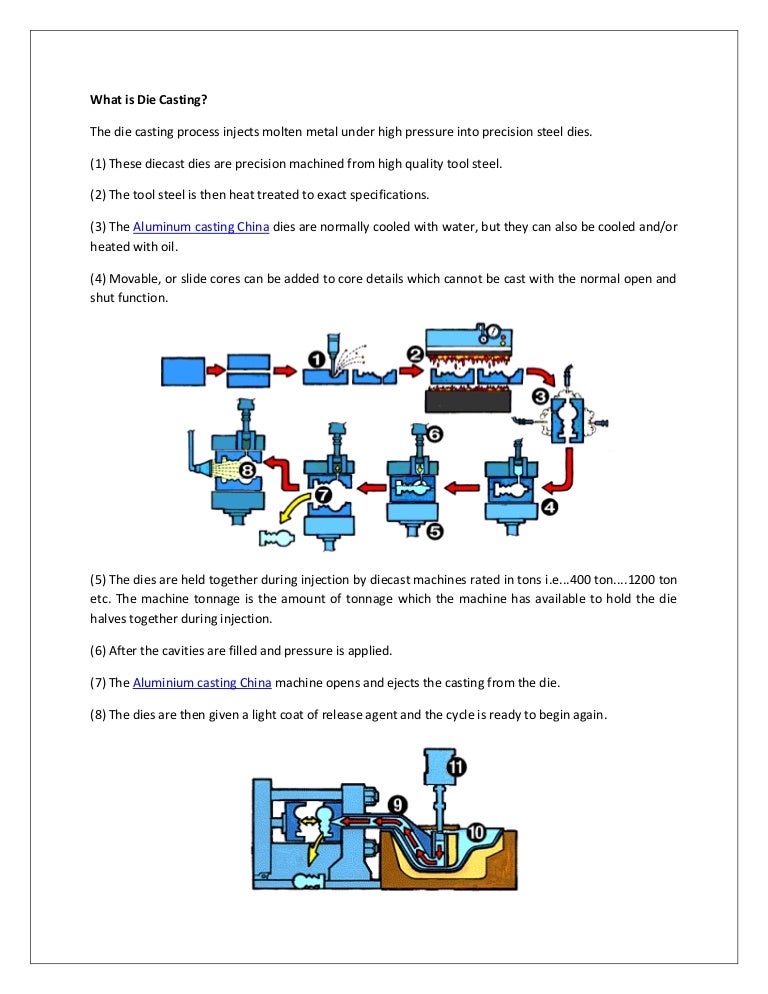

Aluminium casting process. The Die Casting Process Overview The basic die casting process consists of injecting molten metal under high pressure into a steel mold called a die Die casting machines are typically rated in clamping tons equal to the amount of pressure they can exert on the die Machines sizes range from 400 tons to 4000 tons. The Aluminum Casting Process Modern Aluminum Casting offers a variety of methods in the casting process that include sand, mold, and die to name a few Each of the various methods have their benefits and produce high quality parts When making a choice of the type of casting, several factors have to be considered such as the size of the part. The metal casting process is the oldest and popular method of manufacturing means of designing the desired shapes And is one of the first steps in manufacturing of most products Casting made from any metal that can be melt and can have any shape the designer desires The castings can produce in sizes ranging from a few mm to several meters.

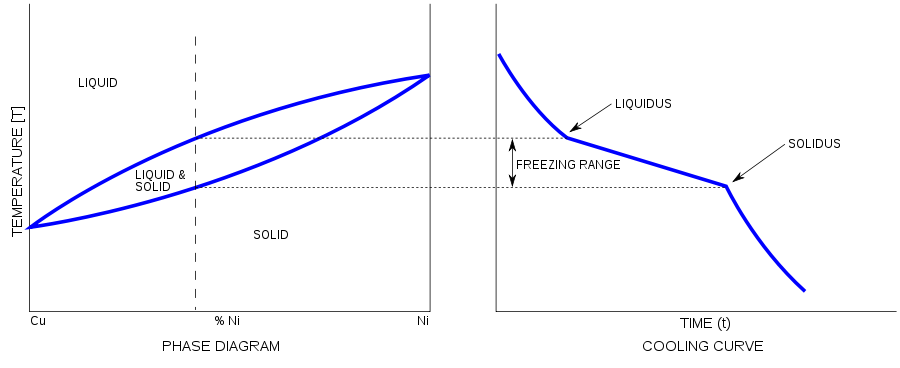

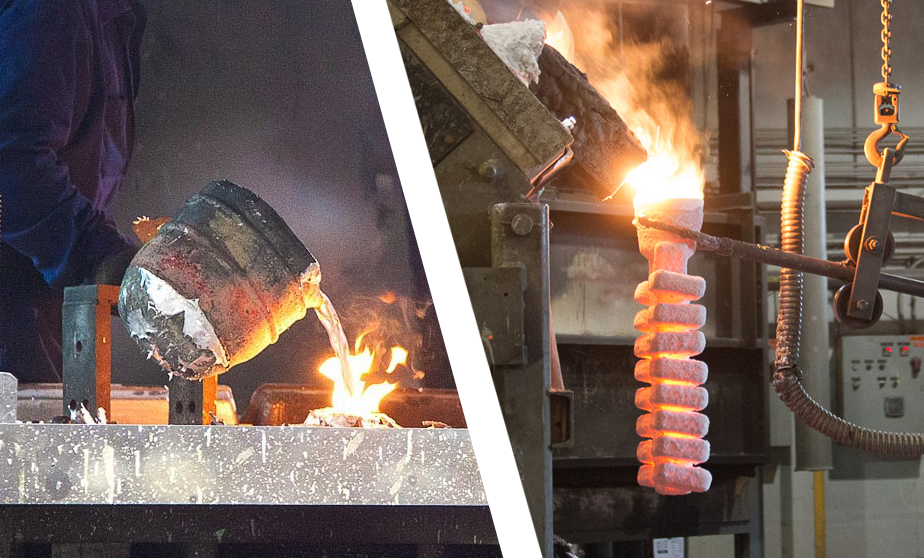

Aluminum Casting 101 The process of casting aluminum Casting is the original and most widely used method of forming aluminum into products Technical advances have been made, but the principle remains the same Molten aluminum is poured into a mold to duplicate a desired pattern The three most important methods are die casting, permanent mold casting and sand casting Die casting The die casting process forces molten aluminum into a steel die (mold) under pressure. The Die Casting Process Overview The basic die casting process consists of injecting molten metal under high pressure into a steel mold called a die Die casting machines are typically rated in clamping tons equal to the amount of pressure they can exert on the die Machines sizes range from 400 tons to 4000 tons. The process selected should be chosen according to how it meets all of the requirements The thermal characteristics required of the part – Each casting process has a group of alloys that are best suited for that process These alloys have different thermal characteristics See the Metal Casting Physical Properties table for more information.

Die casting molds use steel dies or molds to produce a lot of identical castings With aluminum, as other metals, the molten metal is forced under high pressure into these types of molds for aluminum casting This is a versatile process that enables the production of a large quantity of small to mediumsize castings Shell Mold A shell mold is. The process selected should be chosen according to how it meets all of the requirements The thermal characteristics required of the part – Each casting process has a group of alloys that are best suited for that process These alloys have different thermal characteristics See the Metal Casting Physical Properties table for more information. Metal Casting Process Casting process has been a significant part in various aspects of industrial development since the discovery of metals Other than assisting people to build equipment, casting process has also been instrumental in aiding feeding people, constructing infrastructure, and manufacturing cars and airplanes amongst other things.

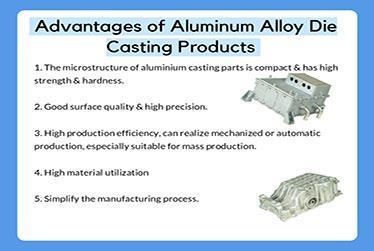

Aluminium casting method comparison – Pros and cons of different casting methods for aluminium parts Aluminium is a great material for producing metal parts, whether you have an entirely new product or need to produce more of an existing product when its demand is rising It is inexpensive and has great thermal and electrical conductivity. Aluminum die casting is the most common process to produce aluminum casting parts used in diverse industries As aluminum has excellent material flowability, highly corrosion resistant, and high dimensional stability with complex parts shape. Jingda > AI Page Sitemap > durable aluminium casting process series for sale Durable aluminium casting process series for sale Brand Jingda OEM/ODM Accept MOQ 500pcs Warranty 12 Month Trade Terms FOB Supply Ability pcs Port Xiamen Payment 40% as deposit, The balance to be paid before products shipment Packaging Detail.

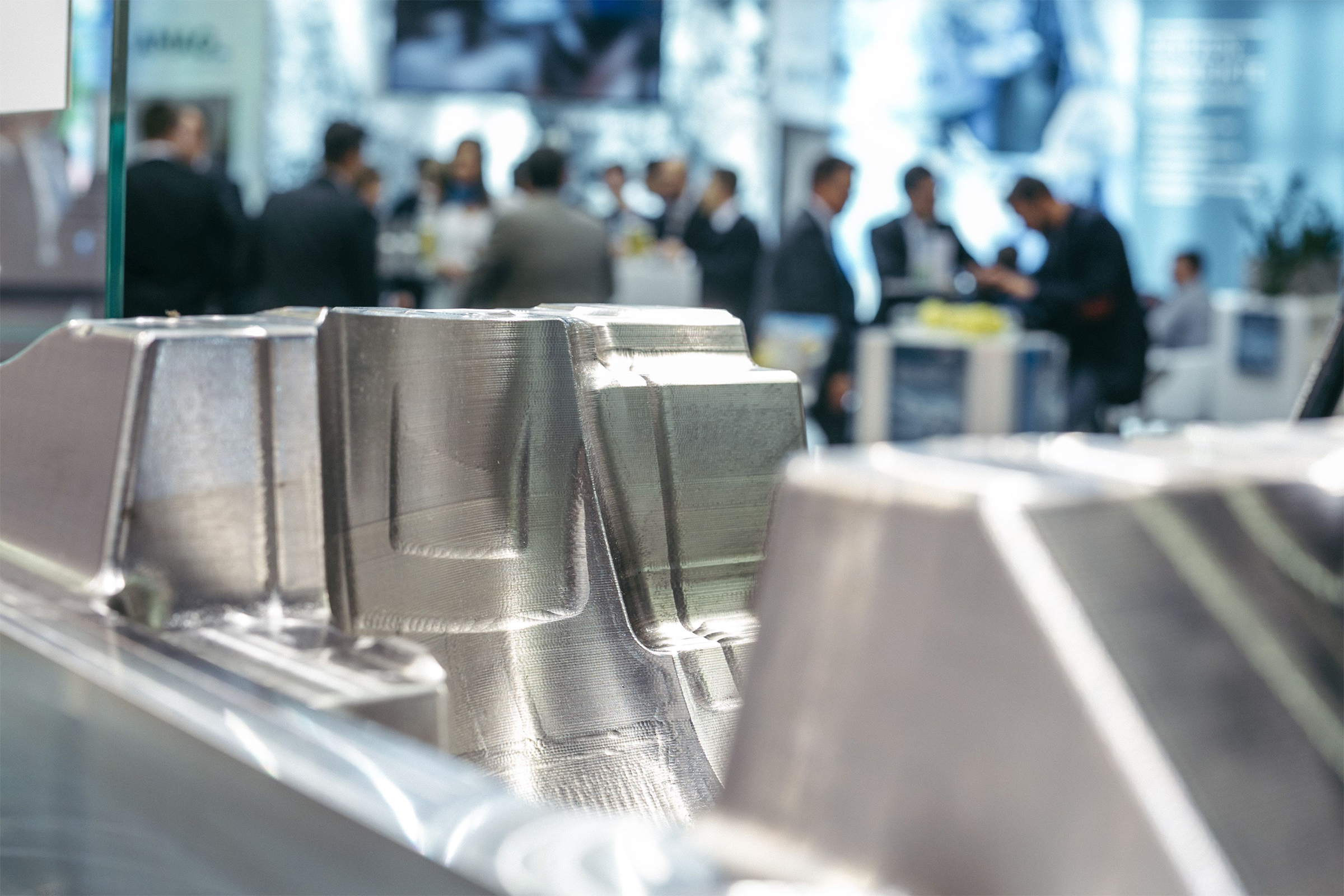

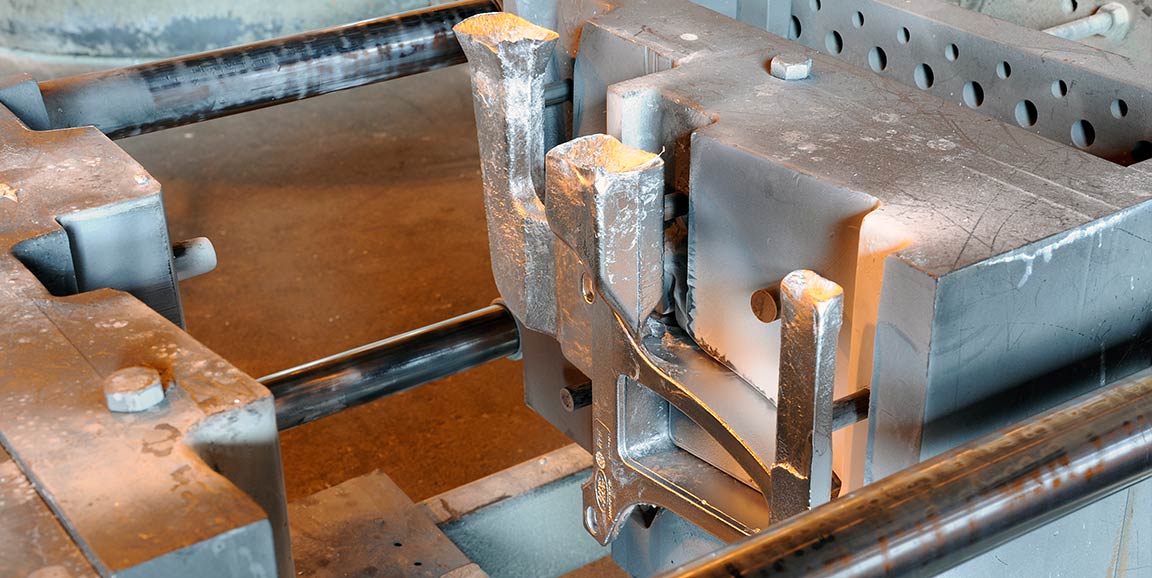

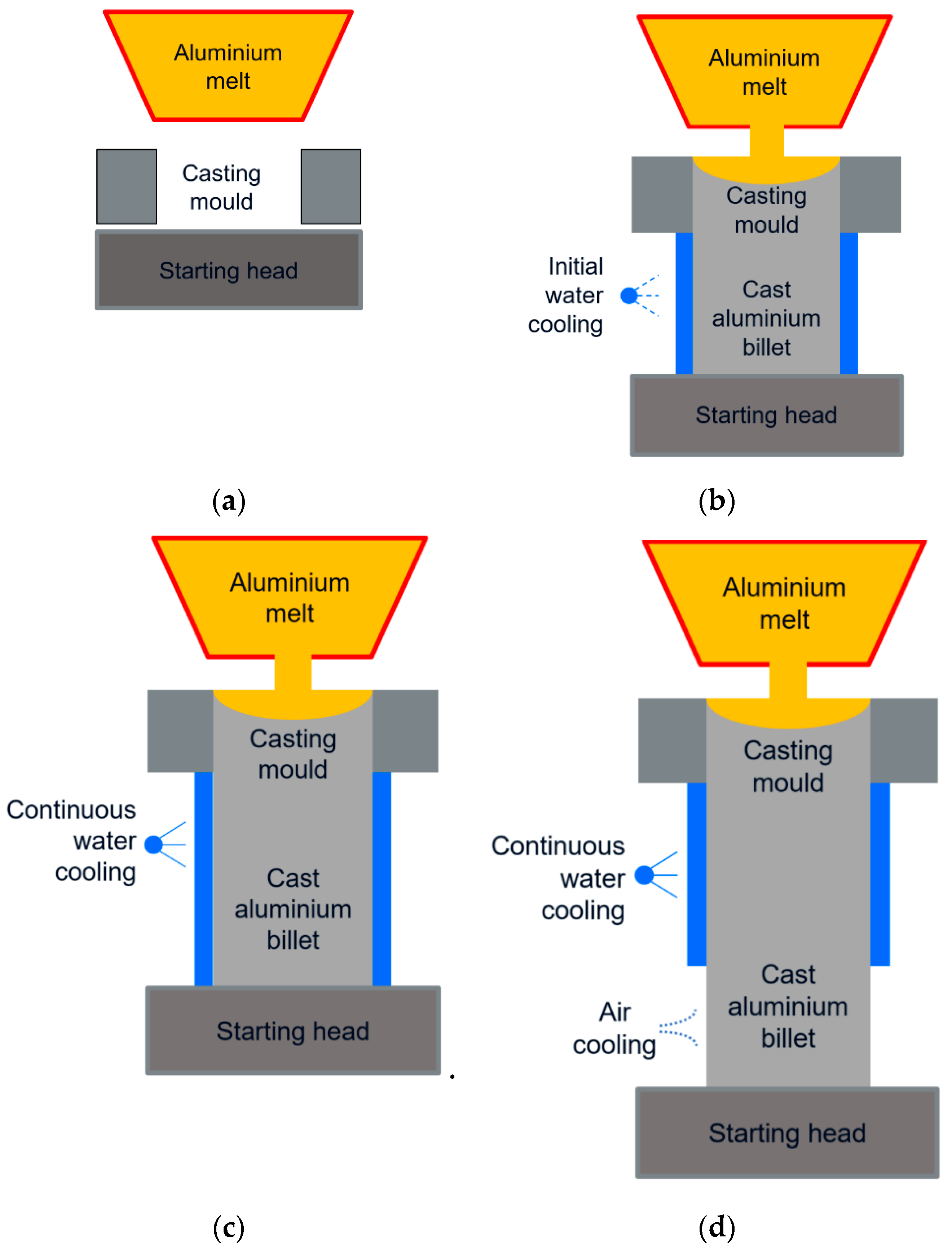

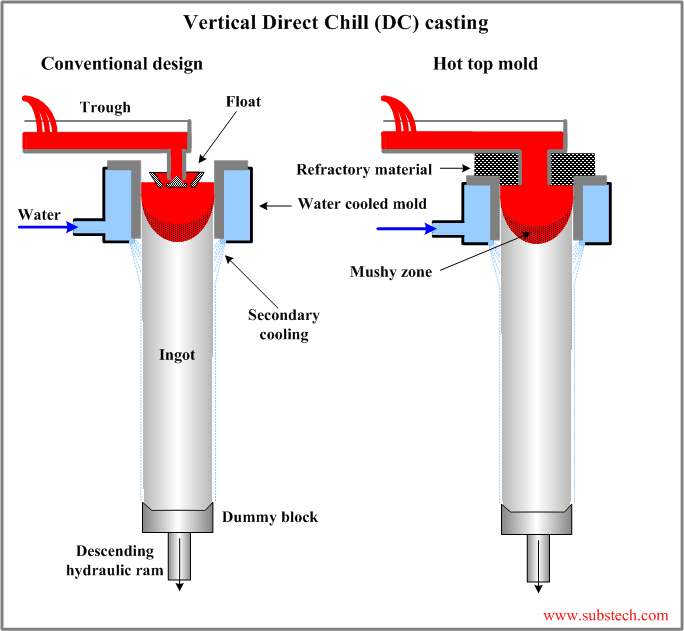

Aluminium casting processes are classified as Ingot casting or Mould casting During the first process, primary or secondary aluminium is cast into rolling ingot (slab), extrusion ingot (billet) and wire bar ingot which are subsequently transformed in semi and finished products. Metal casting is a process of smelting a metal into a liquid that meets certain requirements and pouring it into a mould After cooling and solidifying and finishing, a casting with a predetermined shape, size and performance is obtained Because the casting blank is almost formed, the purpose of avoiding machining or small amount of machining reduces the cost and time to a certain extent. At NovaCast, a large proportion of our castings are produced using Aluminium alloy The formation of Aluminium Oxide and the presence of nonmetallic inclusions, collectively known as dross, is an inherent part of the casting process and one that must be managed to achieve the highest quality castings.

Jingda > AI Page Sitemap > durable aluminium casting process series for sale Durable aluminium casting process series for sale Brand Jingda OEM/ODM Accept MOQ 500pcs Warranty 12 Month Trade Terms FOB Supply Ability pcs Port Xiamen Payment 40% as deposit, The balance to be paid before products shipment Packaging Detail. Metal casting refers to a manufacturing process in which liquefied metal is poured into the desired mold and allowed to solidify Then, the solid is removed from the mold to produce a fabricated casing, part, or object. Aluminum die casting is the most common process to produce aluminum casting parts used in diverse industries As aluminum has excellent material flowability, highly corrosion resistant, and high dimensional stability with complex parts shape.

The casting process used at Bonnell Aluminum is called direct chill casting because the cooling of the log is taking place in the mold itself where water is running through the mold After all criteria are met the drop can begin Before tapping the furnace safety equipment must be put on. 04 We used four pieces of 1x6inch scrap lumber to make a casting flask The strips of wood in the middle anchor the casting sand, since we'll need to flip the flask over during the mold process. Die Casting (Metal Casting Process) Die casting is a method of molding materials under high pressure and usually involves nonferrous metals and alloys, such as zinc, tin, copper, and aluminum The reusable mold is coated with a lubricant to help regulate the die’s temperature and to assist with component ejection.

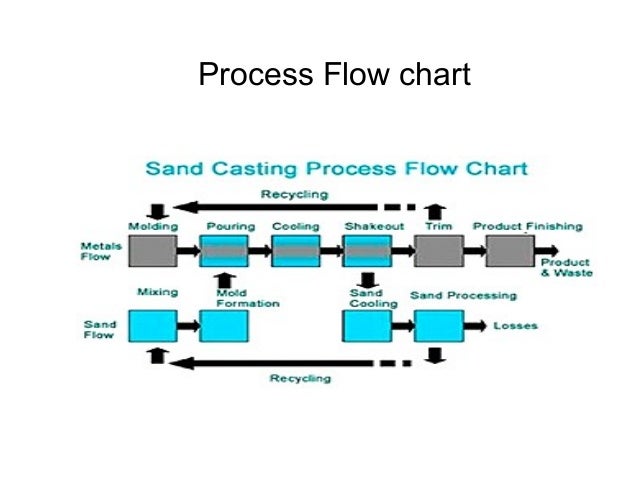

The liquid pressure forming (LPF) process may be used to produce composites with aluminium, magnesium and lead alloys and the reinforcing materials listed in Table 16 109 The process is based on lowpressure die casting and uses gas pressure to force molten metal into a preform housed in a split steel die which has previously been evacuated. Jingda > AI Page Sitemap > durable aluminium casting process series for sale Durable aluminium casting process series for sale Brand Jingda OEM/ODM Accept MOQ 500pcs Warranty 12 Month Trade Terms FOB Supply Ability pcs Port Xiamen Payment 40% as deposit, The balance to be paid before products shipment Packaging Detail. The traditional green sand casting process, combined with highspeed moulding lines, is a very flexible process with high productivity for the manufacture of aluminium castings Automatic patternchange stations enable complete sets to be changed within the cycle time For automotive applications, the process is used to cast Intake manifolds.

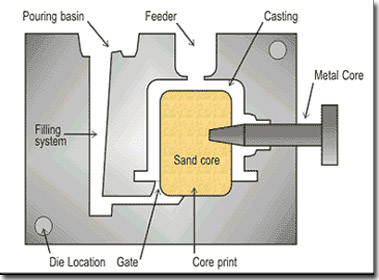

The aluminum die casting process is based on rapid production that allows a high volume of die casting parts to be produced very quickly and more costeffectively than alternative casting processes Aluminum die casting has become the favored option for buyers worldwide Characteristics and Advantages of Aluminum Die Castings include. The castings that are created in this process can vary greatly in size and weight, ranging from a couple ounces to 100 pounds One common application of die cast parts are housings thinwalled enclosures, often requiring many ribs and bosses on the interior Metal housings for a variety of appliances and equipment are often die cast. Metal Casting Process Basics Molds, Patterns, Cores And Gating A mold is formed into the geometric shape of a desired part Molten metal is then poured into the mold, the mold holds this material in shape as it solidifies A metal casting is created.

Melting Aluminum Hard Drives Into Custom Ingot Bars Aluminum Sand Casting Process youtube 1h Sand Casting Aluminium Melting Aluminum Custom Ingot Ingot Bars Next Comments / 0 Cooking and baking with aluminum foil is fast and convenient, and makes cleanup a cinch, but are there health risks?. What is Metal Casting?. Aluminum castings are formed by pouring molten metal into molds that have been shaped by a pattern of the desired final product Three common types of molding methods are used to produce castings die casting, permanent mold casting, and sand casting.

The process selected should be chosen according to how it meets all of the requirements The thermal characteristics required of the part – Each casting process has a group of alloys that are best suited for that process These alloys have different thermal characteristics See the Metal Casting Physical Properties table for more information. The process selected should be chosen according to how it meets all of the requirements The thermal characteristics required of the part – Each casting process has a group of alloys that are best suited for that process These alloys have different thermal characteristics See the Metal Casting Physical Properties table for more information. The Die Casting Process Overview The basic die casting process consists of injecting molten metal under high pressure into a steel mold called a die Die casting machines are typically rated in clamping tons equal to the amount of pressure they can exert on the die Machines sizes range from 400 tons to 4000 tons.

VPROCESS is a unique process that is competitive and favorable with any aluminum sand casting process in regards to pricing, surface finish, tolerances, and wall thickness Any way you shape it, we bring a new dimension to aluminum casting That's crucial in today's CNC machining environment. The process selected should be chosen according to how it meets all of the requirements The thermal characteristics required of the part – Each casting process has a group of alloys that are best suited for that process These alloys have different thermal characteristics See the Metal Casting Physical Properties table for more information. The traditional green sand casting process, combined with highspeed moulding lines, is a very flexible process with high productivity for the manufacture of aluminium castings Automatic patternchange stations enable complete sets to be changed within the cycle time For automotive applications, the process is used to cast Intake manifolds.

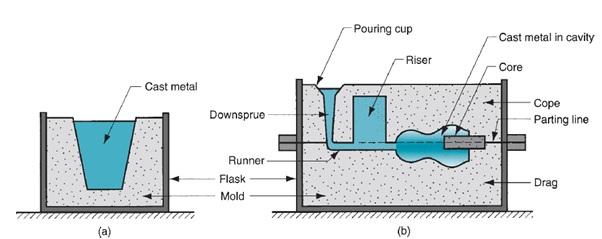

Aluminum is one of the few metals that can be cast by all of the processes used in casting metals These processes, in decreasing order of amount of aluminum casting, are die casting, permanent mold casting, sand casting (green sand and dry sand), plaster casting, investment casting, and continuous casting. Sand casting aluminum with a charcoal furnace Sand casting is the process of casting molten metal into a mold cavity formed in sand There are really only two basic requirements that the sand has a cavity in the shape of the object you wish to cast, and that there is a channel you can pour metal into that will lead to the cavity. Sand casting is a very versatile process and can produce castings of extreme complexity in a wide range of aluminium alloys Interest in light weighting and improvements in the technology of sand casting has driven the average weight and size of aluminium sand castings upward, with many parts weighing over 50 kg and with some parts as large as 100 m 3.

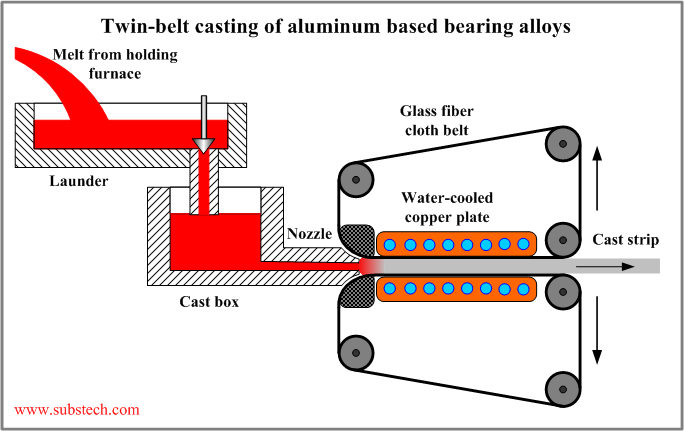

ALUMINUM CASTING PROCESS COMPARISON 0 000 1000 SAND VPROCESS PERM MOLD LOST FOAM DIE CAST PROCESS COST (US Dollars) Conventional sand casting offers the lowest cost tool with the Vprocess having comparable costs for simple tools but varying with complexity The Lost Foam process allows a wide range of. Here are the five main types of irregularities found in aluminium castings Shrinkage – Shrinkage defects occur during the solidification process Open shrinkage defects are found on the surface of castings, whereas closed shrinkage defects are formed within the casting, when isolated pools of liquid are allowed to form within the solidified. Continuous casting processes converts molten aluminium alloys directly into an endless coiled strip suitable for cold rolling or wirebars for wiredrawing They effectively eliminate the operations associated with traditional mould casting (discontinuous process) or DC casting (a semicontinuous process) and subsequent hot mill deformation.

Metal casting refers to a manufacturing process in which liquefied metal is poured into the desired mold and allowed to solidify Then, the solid is removed from the mold to produce a fabricated casing, part, or object. For any casting procedure, choice of right alloy, sizing, shape, thickness, tolerance, structure, and weight, is really important Special needs such as, magnetism, deterioration, stress distribution also have an impact on the selection of metal casting process. Melting Aluminum Hard Drives Into Custom Ingot Bars Aluminum Sand Casting Process youtube 1h Sand Casting Aluminium Melting Aluminum Custom Ingot Ingot Bars Next Comments / 0 Cooking and baking with aluminum foil is fast and convenient, and makes cleanup a cinch, but are there health risks?.

Aluminium casting processes are classified as Ingot casting or Mould casting During the first process, primary or secondary aluminium is cast into rolling ingot (slab), extrusion ingot (billet) and wire bar ingot which are subsequently transformed in semi and finished products. Metal casting is a modern process with ancient roots In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold Metal casting is arguably the earliest and most influential industrial process in history. Metal casting refers to a manufacturing process in which liquefied metal is poured into the desired mold and allowed to solidify Then, the solid is removed from the mold to produce a fabricated casing, part, or object.

The Aluminum Casting Process Modern Aluminum Casting offers a variety of methods in the casting process that include sand, mold, and die to name a few Each of the various methods have their benefits and produce high quality parts When making a choice of the type of casting, several factors have to be considered such as the size of the part. 04 We used four pieces of 1x6inch scrap lumber to make a casting flask The strips of wood in the middle anchor the casting sand, since we'll need to flip the flask over during the mold process. Sand casting aluminum with a charcoal furnace Sand casting is the process of casting molten metal into a mold cavity formed in sand There are really only two basic requirements that the sand has a cavity in the shape of the object you wish to cast, and that there is a channel you can pour metal into that will lead to the cavity.

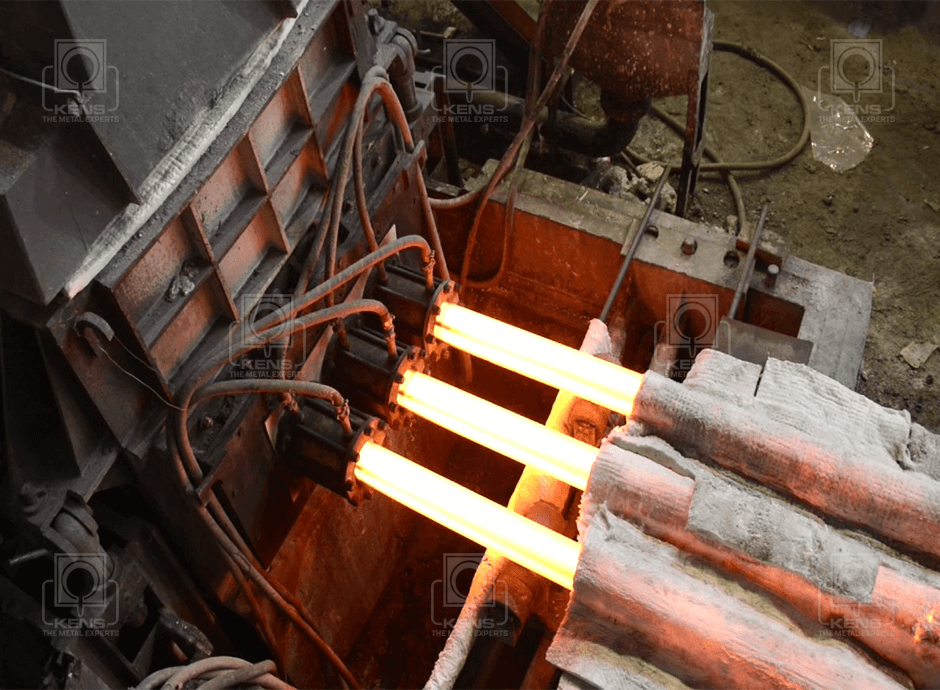

Metal casting refers to a manufacturing process in which liquefied metal is poured into the desired mold and allowed to solidify Then, the solid is removed from the mold to produce a fabricated casing, part, or object. Continuous Casting Process Details Molten metal from an induction furnace is fed directly into a mold with the required shape (1) The molten metal enters the die through a series of holes in the upper portion of the mold Heat is extracted by the watercooled jacket surrounding the mold, and the metal solidifies The molten metal above the. The aluminum die casting process is based on rapid production that allows a high volume of die casting parts to be produced very quickly and more costeffectively than alternative casting processes Aluminum die casting has become the favored option for buyers worldwide Characteristics and Advantages of Aluminum Die Castings include.

Alloys of aluminum are used in die casting more extensively than alloys of any other base metal In the United States alone, about 25 billion dollars worth of aluminum alloy die castings is produced each year The die casting process consumes almost twice as much tonnage of aluminum alloys as all other casting processes combined. Metal casting is a process of smelting a metal into a liquid that meets certain requirements and pouring it into a mould After cooling and solidifying and finishing, a casting with a predetermined shape, size and performance is obtained Because the casting blank is almost formed, the purpose of avoiding machining or small amount of machining reduces the cost and time to a certain extent. The castings that are created in this process can vary greatly in size and weight, ranging from a couple ounces to 100 pounds One common application of die cast parts are housings thinwalled enclosures, often requiring many ribs and bosses on the interior Metal housings for a variety of appliances and equipment are often die cast.

How the aluminum casting process works But regardless of the method that is used, aluminum sand casting should result in a mold cavity being formed These air set molds can be formed using a casting flask that has both a bottom and a top part Next, the sand mixture is pressed together around the pattern of the mold cavity. Precedents on aluminium casting First plaster mold aluminium casting video First Lost PLA in plaster mold aluminium casting video This videos show the learning curve and the improvements that I made on my process, and the actual project will add even more improvements, I will try to show you all the information that is relevant to you don´t. Aluminum sand casting is a metal casting process where sand is used to mold material together Currently, a majority of metal castings are produced by the sand casting process This is largely because aluminum sand casting is a very cheap and effective means of molding material together Sometimes for increased durability, the sand will be mixed with clay.

Launder for Casting is an important part of the aluminum casting process After the molten aluminum in the holding furnace is processed in the furnace, it is transferred from the holding furnace to the online refining device, and then enters the casting machine through the launder for casting. The liquid pressure forming (LPF) process may be used to produce composites with aluminium, magnesium and lead alloys and the reinforcing materials listed in Table 16 109 The process is based on lowpressure die casting and uses gas pressure to force molten metal into a preform housed in a split steel die which has previously been evacuated.

Casting Metalworking Wikipedia

Amazing Cast Aluminum Process Using Sand Mold Fast Melting Metal Casting Technology Working Youtube

Aluminium Casting Techniques Sand Casting And Die Casting Processes

Aluminium Casting Process のギャラリー

Continuous Casting Of Aluminum Based Bearing Alloys Substech

Getting Melt Into Shape Metal Working World Magazine

Casting Facilities Services Kens Metal Industries Ltd Nairobi Kenya

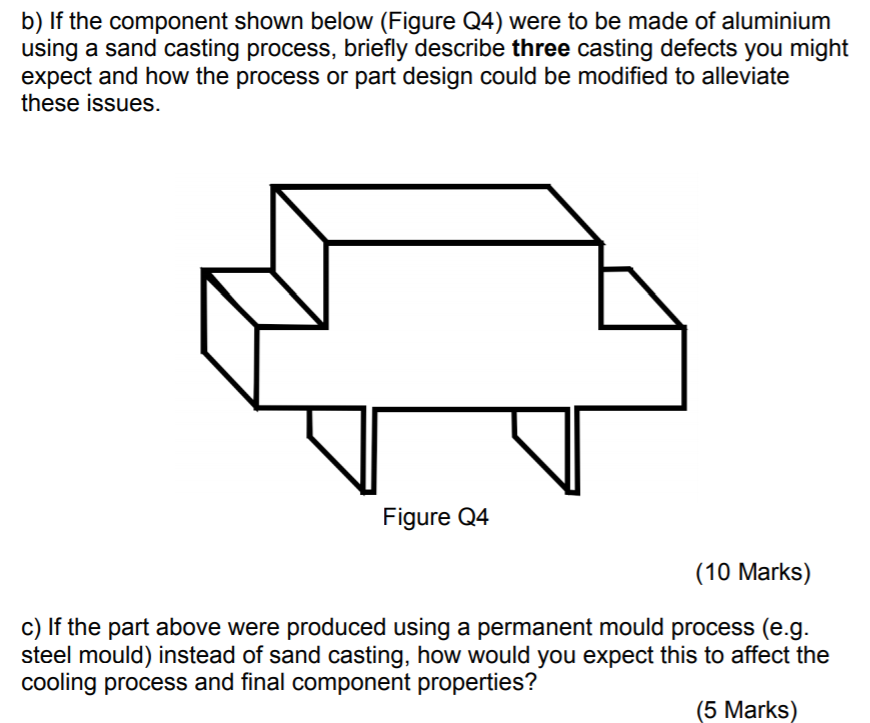

Solved B If The Component Shown Below Figure Q4 Were T Chegg Com

Q Tbn And9gcsoz4q8mlcxw0jyipppk5slkonqht4xb5tdorqm9z68pn7snpzo Usqp Cau

Die Casting Wikipedia

Aluminium Castings Gravity Die Castings Arrow Butler Castings

Distinctive Characteristics Of Aluminium Die Casting Process Came Spa

Sand Casting Process An Overview Sciencedirect Topics

China Customized Aluminum Cast Train Parts Cast Aluminum Solutions Factory

Q Tbn And9gcqydw9ef73x7jfanzzrjulc4xtdsuuojfyxpe Tbzlkigvekhtd Usqp Cau

Aluminium Casting Techniques Sand Casting And Die Casting Processes

Die Casting Process A Complete Die Casting Cycle Abdiecasting Com

Die Casting Of Aluminum Alloys Part One Total Materia Article

Aluminium Casting Process Youtube

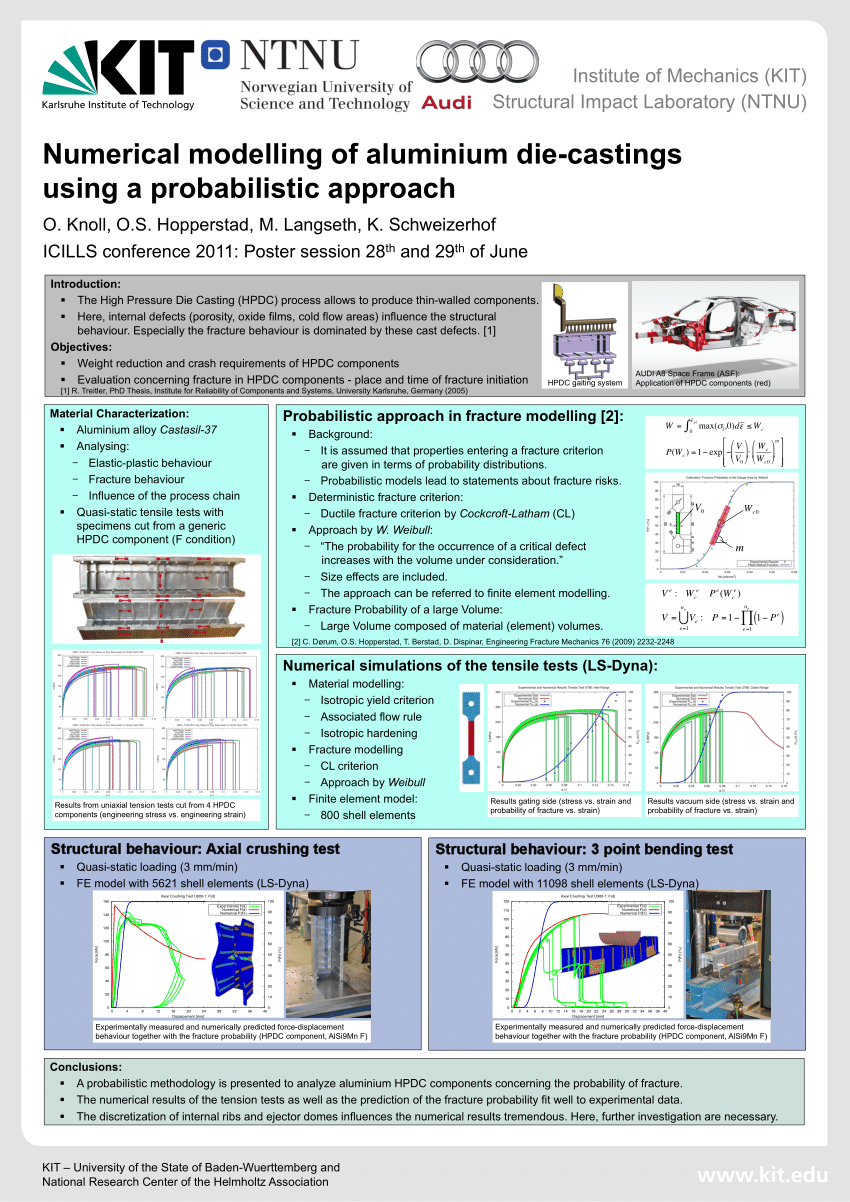

Pdf Numerical Modelling Of Aluminium Die Castings Using A Probabilistic Approach

Gravity Die Casting Openlearn Open University

What Is An Aluminium Foundry Easterneye

Aluminium Casting Techniques Sand Casting And Die Casting Processes

Process Improvements In Sand Casting Over The Past 60 Years Part 1 Haworth Castings Uk Aluminium Sand Castings And Gravity Die Castings Foundry

Aluminium Casting Products Product Line Up Foundry Products Sintokogio Ltd

China Aluminium Die Casting Process Down Light Housing China Light Housing Housing

High Pressure Die Casting Openlearn Open University

Aluminium Casting Techniques Sand Casting And Die Casting Processes

China Aluminium High Pressure Die Casting Process China Adc12 Die Casting Part Aluminium Casting Alloy

Top 5 Safety Considerations For Metal Casting Harrison Castings

Permanent Mould Metal Mold Casting Process And Aluminum Castings

Billet Casting System

Depicting Aluminium Dc Casting By Means Of Dimensionless Numbers Intechopen

Aluminium Sand Casting Process

Different Types Of Casting Processes Used In Manufacturing

China Small Industry Mechanical Arm Housing Aluminium Die Casting Process China Die Casting Process Mechanical Housing

Rawmat International

Vacuum Die Casting An Overview Sciencedirect Topics

Casting Processes Of Aluminum Alloys

Aluminium Casting China Pages 1 2 Text Version Anyflip

Juan Co Ltd Products Aluminium Bar Be Extrusion

Casting Processes Of Aluminum Alloys

Die Casting An Overview Sciencedirect Topics

Die Casting Process Defects Design

Pdf Modern High Pressure Die Casting Processes For Aluminium Castings Semantic Scholar

Why Choose Cast Aluminum Than Other Materials

Manufacturing Process Uacj Thailand

Die Casting Process Defects Design

Aluminium Casting Method Comparison Pros And Cons Of Different Casting Methods For Aluminium Parts Alteams Aluminium Casting Method Comparison Production Volume Matters

Cast Aluminium Company Aluminum Alloy Precision Die Casting Process Adc12 Manufacturer And Supplier China Yili Machinery

China Die Cast Aluminium Bollard Lights Archiproducts China Led Lamp Light Frame

China Machining High Pressure Aluminium Die Casting Process Automobile Parts Auto Parts China Aluminium Die Casting Process Die Casting Parts

Advantages Of Aluminum Alloy Die Casting Products Emp Tech Co Ltd

The Aluminum Die Casting Process Youtube

China New Aluminium Die Casting Process Motor Parts Custom Aluminum Die Casting Part China Motorcycle Spare Parts Aluminum Casting

On Mechanism Of In Situ Microwave Casting Of Aluminium Alloy 7039 And Cast Microstructure Sciencedirect

Casting Knowledge Aluminum Ingot Casting Process

Die Casting Process Aluminum Zinc Kenwalt Die Casting Company Youtube

1

Aluminum And Aluminum Castings Metal Casting Resources

V Process Casting Tpi Arcade

Aluminium Casting Suppliers Harrison Castings Ltd

Pdf Modern High Pressure Die Casting Processes For Aluminium Castings Semantic Scholar

Aluminium Gear Box With Gravity Die Casting Process

Gravity Die Casting Precision Aluminium Castings

Metals Free Full Text On Numerical Simulation Of Casting In New Foundries Dynamic Process Simulations Html

Die Casting Wikipedia

Cold Chamber Die Casting Process Aluminium Pressure Die Castings Aluminum Die Casting एल य म न यम ड ई क स ट ग In Mumbai Aishwarya Tools Dies Id

What Is Aluminum Die Casting The Process Of Die Casting Phb Inc

Aluminum Casting Market Size Trends Industry Report 27

China Aluminum Sand Casting Manufacturers Oeform

China Aluminium For Die Casting Process China Die Casting Aluminum Die Casting

What Is High Pressure Die Casting

Aluminium Sand Casting Process

Aluminum Die Casting Market Size Share Trends Forecast

Aluminium Casting Techniques Sand Casting And Die Casting Processes

Cold Chamber Die Casting Process Machines

Amazing Automatic Melting Aluminum Manufacturing Factory Cast Aluminum Process Using Sand Mold Youtube

:quality(80)/images.vogel.de/vogelonline/bdb/1731000/1731094/original.jpg)

Magnetic Induction Casting New Low Pressure Casting Process Picture 1 5

Sand Casting Openlearn Open University

Squeeze Casting An Overview Sciencedirect Topics

Everything About Aluminum Die Casting Process Eco

Cold Chamber Die Casting Process Machines

How To Aluminum Sand Casting Process Manufacturing

Aluminum Billet Casting Machine Manufacture Aluminum Billet Casting Production Line Aluminum Billet Casting Machine Supplier

Gravity Die Casting

What Is Metal Casting Metal Casting Types How Does Metal Casting Work

Pdf Modern High Pressure Die Casting Processes For Aluminium Castings Semantic Scholar

Casting Process Advantages And Limitations Sand Casting It Cast Aluminum Molding

Aluminium Gear Box With Gravity Die Casting Process

Aluminium Castings Aluminium Die Castings And Aluminium Castings Manufacturer

Oem Aluminum Die Casting Part Aluminium Pressure Die Casting Process Processing Aliexpress

Aluminium Casting China

Aluminium Gravity Casting

Direct Chill Dc Casting Substech

Casting Metalworking Wikipedia

China Aluminium Die Casting Process Aluminium Die Casting Process Manufacturers Suppliers Price Made In China Com

Aluminum Casting Products

Aluminium Casting Techniques Sand Casting And Die Casting Processes

Process Comparisons Hazelett Corporation

Aluminum Casting Vs Steel Casting Choosing The Right Alloy For Your Cast Products

Die Casting 101 Aluminum Die Casting Process By Die Castings China Youtube

Aluminum Led Housing Precision High Power Aluminium Die Casting Process

Casting Of Aluminium Alloys Sciencedirect