Aluminium Casting

In aluminium castings, hydrogen is the only gas that dissolves in significant quantity, which can result in hydrogen gas porosity For casting that are a few kilograms in weight the pores are usually 001 to 05 mm ( to in) in size In larger casting they can be up to a millimeter (0040 in) in diameter.

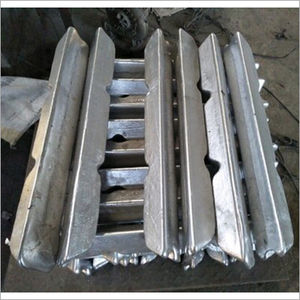

Aluminium casting. Ross Aluminum Castings is an Ohio based, US owned, stateoftheart aluminum foundry which has been producing aerospace castings, performance racing castings, diesel engine castings and power generation castings for almost eighty years. Aluminum castings of ant colonies of fire ants, carpenter ants, and others by Anthill Art This process captures the extreme detail of the tunnel and chamber structure of the colonies Also check out the new mushrooms casts. Aluminum Sow Casting and Charging Bulk aluminum intended for remelting is often cast in the form of large shapes, weighing 700 to 00 pounds, commonly known as sows The sowcasting process generally results in unavoidable internal shrinkage cavities, which can become reservoirs for collecting large amounts of water.

Mix a 50/50 mix of Plaster of Paris and sand in the container Add water slowly until it is just viscous enough to drip off the spoon without ease Put the pipe fitting through the hole and block it with newspaper Daub the mix on to the inside of the can. ALUMINUM CASTINGS US Aluminum Castings is a precision aluminum casting supplier located in Central Washington State As a full service foundry, we offer multiple casting processes as well as inhouse heat treat, machining, powder coating, and NDT Our castings are used in defense, aerospace, heavy truck, marine, and commercial applications. Once the aluminum has been extracted and processed, the next step involves casting it into product form Aluminum castings are formed by pouring molten metal into molds that have been shaped by a pattern of the desired final product.

Aluminium casting processes are classified as Ingot casting or Mould casting During the first process, primary or secondary aluminium is cast into rolling ingot (slab), extrusion ingot (billet) and wire bar ingot which are subsequently transformed in semi and finished products. Aluminium casting efficiently manufactured on using green sand process can be produced in any volume from high to low and in varying complexities from less demanding parts to safetycritical components Depending on the number of castings your foundry creates,. Aluminum Castings Company LLC is a high quality American aluminum sand casting foundry, specialized in supplying both cored and uncored parts in several aluminum alloys of all sizes and volumes, including prototype casting.

Further attempts to get that ultrarealistic facial scaringForget building a forge, foundry, flux capacitor, all you really need to melt aluminum is a pro. Traditionally, aluminium casting was achieved using a process called green sand casting This involved the use of wet sand in the creation of casting moulds As a method, it was efficient and costeffective, but not without its drawbacks. Mix a 50/50 mix of Plaster of Paris and sand in the container Add water slowly until it is just viscous enough to drip off the spoon without ease Put the pipe fitting through the hole and block it with newspaper Daub the mix on to the inside of the can.

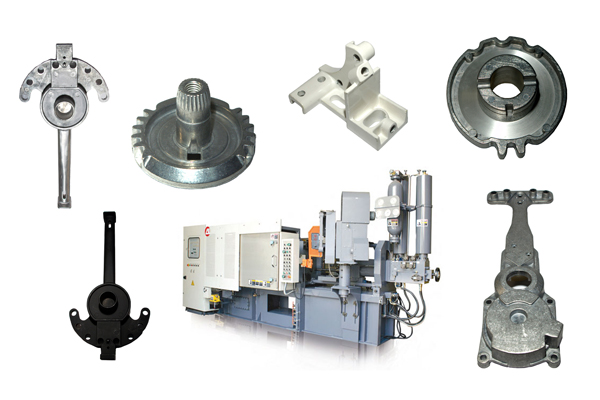

Backed by more than two decades of experience, we are an ISO certified company and providing our clients a wide assortment of Aluminum Casting, Gravity Die Casting, Plastic Die Moulds and components, Precision Machined Components and Turned Parts, Jigs and Fixtures, Zinc Casting and Pressure Die Casting DiesOur extensive assortment is made using fine grade raw materials procured. Aluminum die casting is the biggest die casting technique used nowadays to produce commercial, consumer and industrial products salable in the markets today Aluminum die casting is proven as beneficial to industrial products In this process, there are various modifications that can be made on the production. Aluminium alloys (or aluminum alloys;.

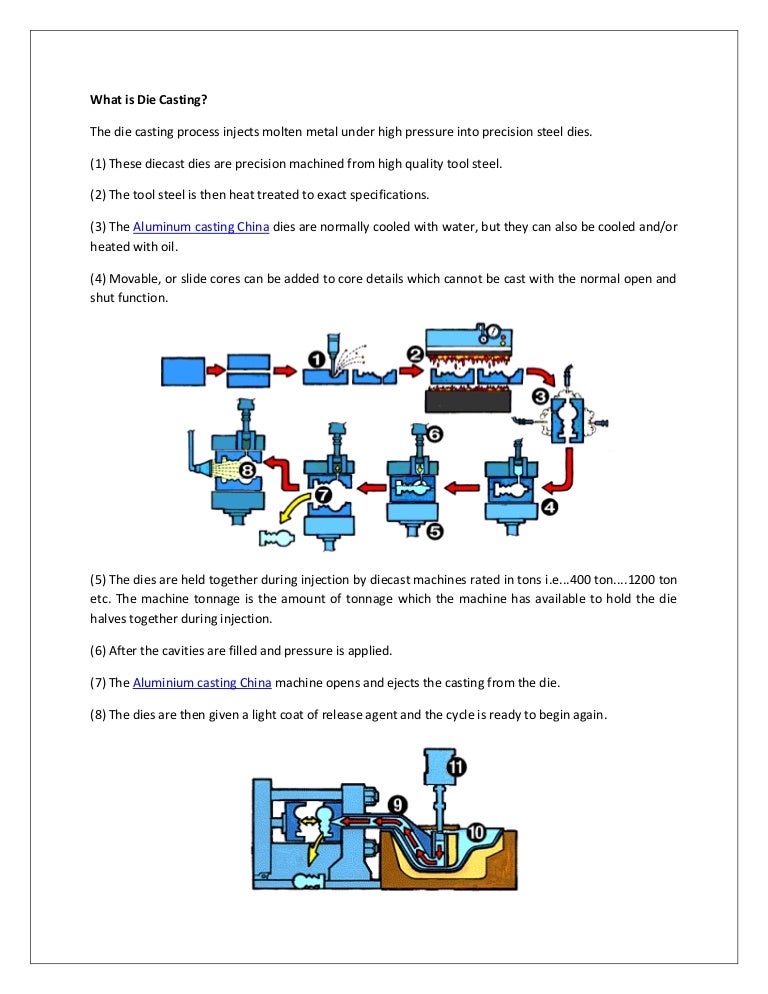

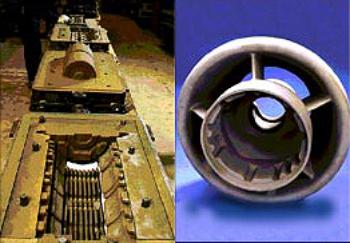

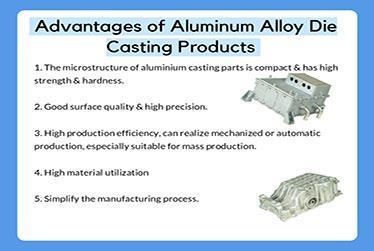

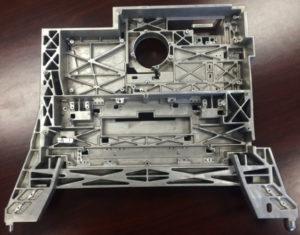

One of the most significant benefits of aluminum die casting is that it creates lighter parts—with more surface finishing options than other die cast alloys Aluminum can also withstand the highest operating temperatures of all the die cast alloys. In aluminum die casting process, metals are molten in the cavities of steel molds using high pressure technique Aluminum die casting can be done in a single or multiple cavities, unit die or a combination of dies depending on what is to be produced Before, aluminum die casting is done using a low pressure injection. Aluminum Die Casting is associated with the creation of products including windows, cladding, curtain walling, prefabricated buildings, shop partitions, and fittings Also, aluminum die casting products are used in aerospace operations or airplanes all around the world.

Modern Aluminum Casting is dedicated to providing products that meet and exceed your expectations and requirements With over 100 years of experience in the casting industry, Modern Aluminum Casting has the facilities and staff to meet any requirements The process begins with you, the customer, by entering your specifications into our RFQ form. Aluminium sand casting Costefficient, smallvolume production and prototyping Sand casting is a method for low production volumes (1 to 5,000 units per year) as well as prototyping In this method, molten aluminium is poured into a resinbonded sand mould to produce castings of all sizes with low tooling costs. The sand is a cast part produced by forming a mold from a sand mixture and pouring molten liquid metal into the cavity in the mold After the process of cooling, the melted metal has been solidified At the last, a sand casting would be gotten just separated from the mold this sand casting is different from Aluminium Die Casting.

Aluminum Casting Aluminum casting is the process of creating aluminum shapes with a die caster Die casting is a very commonly used metal shaping process that is used to create metal shapes for use in industrial, commercial and consumer products contexts. PRECISION ALUMINUM CASTINGS US Aluminum Castings is a precision aluminum casting supplier located in Central Washington State As a full service foundry, we offer multiple casting processes as well as inhouse heat treat, machining, powder coating, and NDT Our castings are used in defense, aerospace, heavy truck, marine, and commercial applications With flexible. The oldest types of molds for aluminum casting are the molds that have been used since the time of the Egyptians These types of molds are made when a cavity is created in sand that is held in a box or “flask” Usually the original “pattern” is made out of wood, metal or other solid material.

Graphite Ingot Mold Metal Casting Mold, Melting Crucible Furnace for Gold Silver Aluminum Copper Brass Zinc Plumbum and Alloy Metals (85x45x30mm 665g Gold/3g Silver) 43 out of 5 stars 31 $1599 $ 15 99. One of the most significant benefits of aluminum die casting is that it creates lighter parts—with more surface finishing options than other die cast alloys Aluminum can also withstand the highest operating temperatures of all the die cast alloys. Most often aluminum casting is in combination with other metals such alloy which is said to be the commonest metal utilized and copper as well can be cast together with aluminum.

Bremer Manufacturing Company, Inc is an industryleading aluminum casting foundry in Wisconsin We specialize in custom aluminum sand casting, because it's the most versatile method available for casting aluminum parts & products Visit our site to browse our products and request a quote today!. Aluminum Casting Aluminum casting is the process of creating aluminum shapes with a die caster Die casting is a very commonly used metal shaping process that is used to create metal shapes for use in industrial, commercial and consumer products contexts. This specification covers aluminumalloy highstrength castings in the following designations A110, A, A, A, and A Castings covered by this specification are intended for use in airframe, missile, and other critical applications where high strength, ductility, and sound castings are required.

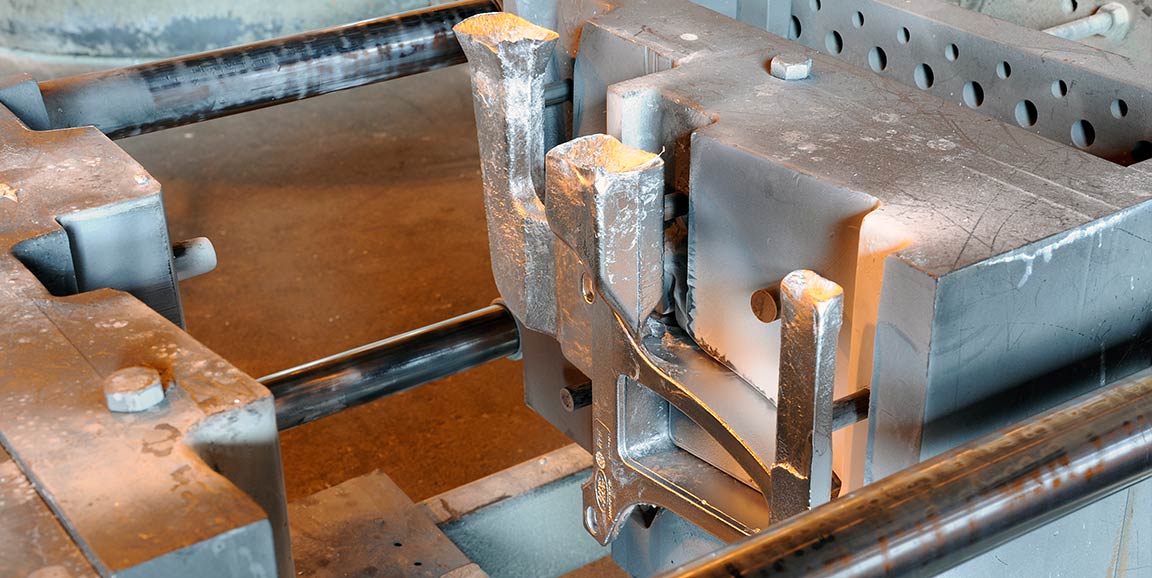

Permanent types of aluminum casting molds are made from metals such as steel and iron The molten aluminum is forced by gravity or a vacuum into the permanent mold cavity. Cast aluminum is a specific metal that has gone through one of the several processes known as casting Essentially, it is created when methods such as die casting, mold casting, or sand casting are used to temper the aluminum for use in creating components for many different types of products. We began as pattern makers and today offer complete design assistance for wood and metal patterns, including close tolerance aluminum castings Our specialized knowledge enables us to meet customer needs for aluminum sand castings requiring up to seven cores.

There are aluminum alloys tailored for permanentmold casting including 319, 356, A356, 413, and 535 In general, silicon (Si) is the most important alloying element for any aluminum casting. Backyard Metal Casting and Homemade Forges For thousands of years, man has worked metals Although some of the technology to work metals is relatively recent, the initial human drive to create is still with us. Backyard Metal Casting and Homemade Forges For thousands of years, man has worked metals Although some of the technology to work metals is relatively recent, the initial human drive to create is still with us.

Aluminum die casting alloys are lightweight and possess high dimensional stability for complex part geometries and thin walls Aluminum withstands good corrosion resistance and mechanical properties as well as high thermal and electrical conductivity, making it a good alloy for die casting. See spelling differences) are alloys in which aluminium (Al) is the predominant metal The typical alloying elements are copper, magnesium, manganese, silicon, tin and zincThere are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heattreatable and nonheattreatable. The Group diversified into aluminium castings by setting up a foundry in 1967,which was a very unique concept at that time Presently the group has 4 bases with most advanced machining, inspection and testing facilities in India which is backed with an efficient team of metallurgists and engineers.

Aluminium Die Casting SRL Viale Veneto, 48 350 Saonara (PD) Italy Phone 39 049 Fax 39 049 Email info@aluminiumcastingcom. ALUMINUM CASTINGS US Aluminum Castings is a precision aluminum casting supplier located in Central Washington State As a full service foundry, we offer multiple casting processes as well as inhouse heat treat, machining, powder coating, and NDT Our castings are used in defense, aerospace, heavy truck, marine, and commercial applications. Cast aluminum alloys are mostly the 300series (AlSiCu or AlSiMg) alloys, such as 319 for intake manifolds, cylinder heads and transmission housings, 3 for engine blocks, 356 for cylinder heads, and A356 for wheels and suspension arms From Advanced Materials in Automotive Engineering, 12.

There are many types of molds for aluminum casting that are used in casting molten aluminum into different shapes and forms Some molds are temporary, and others are permanent and can be used repeatedly These same types of molds are also used for many different metals and alloys besides aluminum. Aluminum casting is a type of metalworking process that involves pouring liquid metal into a mold or form Aluminum casting is a variation of this that uses only aluminum and aluminum alloys as the liquid metal that is poured into the mold Aluminum castings are used to make complex and detailed parts very efficiently. Aluminum Castings Company LLC is a high quality American aluminum sand casting foundry, specialized in supplying both cored and uncored parts in several aluminum alloys of all sizes and volumes, including prototype casting.

Cookware is also commonly made of cast aluminum because it is so strong, patio furniture is also another place that cast aluminum is easy to find It is a special type of metal alloy and before it can be used it has to go through what is called casting This is a process that adds durability and strength to the material, as well as makes it. Swastika Group Aluminium Casting People manufacturer of non ferrous casting in aluminium, copper, zinc and brass alloys in various processes like sand castings, gravity die castings, pressure die casting, centrifugal castings and forgings. We began as pattern makers and today offer complete design assistance for wood and metal patterns, including close tolerance aluminum castings Our specialized knowledge enables us to meet customer needs for aluminum sand castings requiring up to seven cores.

HighQuality Aluminum Casting Eagle Aluminum Cast Products specializes in casting aluminum alloys through the greensand casting process We have decades of experience in pattern making, casting and finishing–all provided within excellent lead times Eagle Aluminum also maintains certification to ISO standards. American Aluminum Casting Company is a privatelyheld, familyownedandrun metal casting business located in Irvington, NJ The Company provides highintegrity and commercial nonferrous castings to a wide variety of industries, with an emphasis on highquality cast aluminum parts Utilizing two colocated facilities strategically situated near major highways, the Ports of New Jersey & New. Casting is a simple, inexpensive and versatile way of forming aluminum into a wide array of products Such items as power transmissions and car engines and the cap atop the Washington Monument were all produced through the aluminum casting process Most castings, especially large aluminum products, are usually made in sand molds.

HighQuality Aluminum Casting Eagle Aluminum Cast Products specializes in casting aluminum alloys through the greensand casting process We have decades of experience in pattern making, casting and finishing–all provided within excellent lead times Eagle Aluminum also maintains certification to ISO standards. The most common aluminum casting alloys are the heattreatable 3XX0 series, such as 3560, 3570, and 3190 These are aluminumsiliconmagnesium (AlSiMg) alloys, but some, 3190, for example, also contain copper (Cu) The good news is that these alloys are all readily weldable with 4043 serving as the correct filler. Permanent types of aluminum casting molds are made from metals such as steel and iron The molten aluminum is forced by gravity or a vacuum into the permanent mold cavity.

The Basic Aluminum Casting Company can be best described as an engineering company with one simple trait – creating die cast products from listening and understanding our customer’s needs A strong commitment to that and a focus on quality has enabled us to continue to be one of the best and oldest names in the industry. Aluminum die casting is the biggest die casting technique used nowadays to produce commercial, consumer and industrial products salable in the markets today Aluminum die casting is proven as beneficial to industrial products In this process, there are various modifications that can be made on the production. Cast aluminum is a specific metal that has gone through one of the several processes known as casting Essentially, it is created when methods such as die casting, mold casting, or sand casting are used to temper the aluminum for use in creating components for many different types of products.

You can melt down almost any kind of aluminum—cans, even—but a piece that has already been cast (such as a water pump, wheel, or intake manifold) will have an alloy that's better suited for.

Wpbg4xjy0gdm

Aluminium Casting Processing Nichias Europe

Q Tbn And9gcsr84yo7zuvocyiz Egqlhlp 21fcesrgu5jkwn1igqxxi5tphq Usqp Cau

Aluminium Casting のギャラリー

Aluminum Workshop How To Determine If An Aluminum Casting Is Weldable

China Aluminium Smelting Furnace And Billet Casting Machine China Aluminium Melting Furnace Aluminum Scrap Melting Furnace

Aluminium Casting Products Product Line Up Foundry Products Sintokogio Ltd

Die Casting Die Casting Molding Die Casting Mold Manufacturer In China

Aluminum Casting Jg Automotive Automotive Components Supplier

Casting Aluminium With Lost Pla Investment Mold 8 Steps With Pictures Instructables

Composition And Temperature Of The Flue Gases In Aluminium Casting Download Scientific Diagram

Aluminium Casting

Aluminium Casting

Log Casting Machine Aluminium Cast House Sistem Technic Industrial Furnaces Kocaeli City Turkey

Marine Engine Filter Aluminium Casting Manufacturer In Ningbo China By Ningboxinyumoldmanufacturingco Ltd Id 476

Pile Aluminium Casting Image Photo Free Trial Bigstock

China Aluminium Casting Aluminium Casting Manufacturers Suppliers Price Made In China Com

Aluminum And Aluminum Castings Metal Casting Resources

Aluminum Casting Jg Automotive Automotive Components Supplier

Aluminum And Aluminum Castings Metal Casting Resources

Aluminium Casting High Pressure Gravity And Sand Casting Methods

Rusal Inks Agreement With Sms Group To Develop Continuous Aluminium Casting Equipment Aluminium Insider

Aluminium Castings Foundry Uneko Spol S R O

Aluminium Casting Techniques Sand Casting And Die Casting Processes

Aluminium Casting China

Q Tbn And9gcrcdaholqiz4vgyipnvpuhnnalaqhxxc1bvegrqfs4 Usqp Cau

Aluminium Casting Techniques Perla Alucast

Aluminium Casting And Why You Need To Be Careful 4 Steps With Pictures Instructables

Aluminium Casting Service Super Alloy Casting

Top Ten Aluminium Casting Manufacturers In The World

Aluminium Castings Aluminium Die Castings And Aluminium Castings Manufacturer

China Low Pressure Die Casting And Aluminium Casting Photos Pictures Made In China Com

Gravity Die Casting Precision Aluminium Castings

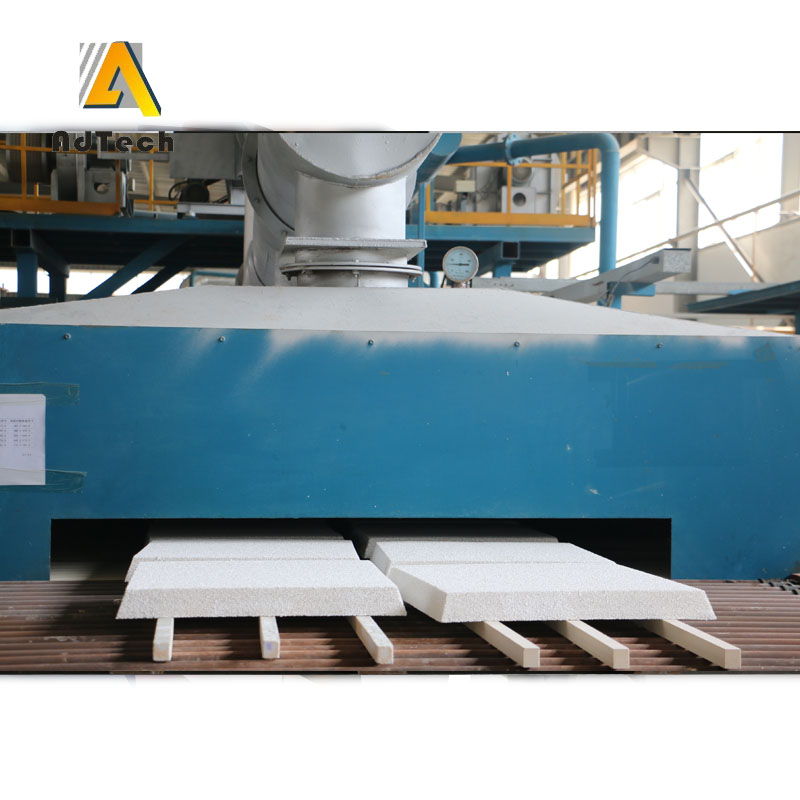

Ceramic Foam Filter Ceramic Filter Foam Filter Aluminium Foundry Casting

Suppliers And Exporters Of Aluminium Casting Alloy Trade

Distinctive Characteristics Of Aluminium Die Casting Process Came Spa

Aluminium Casting A Relief Wall Kikukawa

Aluminium Casting Manufacturer About Us Si Castings Si Castings

Die Casting Aluminium Parts Taiwantrade Com

Aluminium Casting And Machining For Injection Pump Stock Image Image Of Pouring Part

Aluminium Casting Sand Casting Investment Casting Cnc Machining In China

Die Casting Wikipedia

Which Scrap Aluminium To Use For Casting Flowering Elbow

Metal Qualities What Molds Are Used For Aluminium Casting Part 1

Covid 19 Impact Spanish Aluminium Die Casting Company Ruffini S A Resumes For Production Aluminium Extrusion Profiles Price Scrap Recycling Section

Aluminium Casting Techniques Sand Casting And Die Casting Processes

Aluminium Casting Styrofoam Cups And Heat Sinks It Cast Metal Working Styrofoam Cups

Aluminium Castings Ballantine Castings Ltd Iron Foundry Bo Ness

Aluminium Casting Manufacturers Aluminium Casting Companies Aluminum Die Casting And Webcam Parts

Magna To Open Aluminium Casting Facility In United Kingdom Aluminium Insider

G W P Ag Aluminum Sand Casting For Prototypes Sand Casting Foundry Aluminium Prototypes

Cast Vs Wrought Aluminium Matmatch

Production Of Aluminium Castings The Lightness Of The Future

What Is An Aluminium Foundry Easterneye

Aluminium Casting Ingot Manufacturer Supplier India

Tesla Ditching Robots For Giant Aluminium Casting Machines Carsifu

Aluminium Casting Turbocharger Compressor Housing

Aluminium Casting Die On Sales Quality Aluminium Casting Die Supplier

Amazing Cast Aluminum Process Using Sand Mold Fast Melting Metal Casting Technology Working Youtube

Aluminum Gravity Cast Auto Parts Sxlh Aluminum Gravity Casting

Aluminium Castings Manufacturer From Coimbatore

Top 5 Safety Considerations For Metal Casting Harrison Castings

Aluminium Castings Aluminium Die Castings And Aluminium Castings Manufacturer

Q Tbn And9gcrm8czamjm1u1bczbeg1qxbwwomowqpzjnmyqetdotd4pwrkae1 Usqp Cau

Advantages Of Aluminum Alloy Die Casting Products Emp Tech Co Ltd

Metef 17 To Highlight The Aluminium Foundry Casting Industry In Italy In 16

Aluminium Casting Process Youtube

Aluminium Casting Silver Aluminium Die Castings Parts Manufacturer From Mumbai

What Is Aluminium Casting Quora

Aluminium Casting Services In Tamil Nadu India

Zinc Aluminium High Pressure Die Casting Company In China

Aluminum Castings An Overview Sciencedirect Topics

China Aluminum Die Casting Couplings Clutches Aluminium Casting Mould Factory China Die Casting Aluminum

Aluminium Casting Puri Enterprises Home Facebook

Stencil Aluminium Casting Process By Julien Carretero

Aluminum Sand Casting Manufacturer In Tamil Nadu India By Jai Enterprises Id

Aluminium Casting Image Photo Free Trial Bigstock

Stencil Aluminium Casting Process By Julien Carretero

Aluminium Casting A Relief Wall Kikukawa

Company Overview Aluminium Die Casting

Aluminium Casting Techniques Sand Casting And Die Casting Processes

Global Aluminum Casting Market Dynamics Analysis Production Supply And Demand Covered In The Latest Research 25 focus

Aluminium Drives Corporate Wind Deals To New High Windeurope Recharge

Increasing Aluminium Slab Casting Capacity By Sourcing Secondary Aluminium Cru

Aluminium Casting Tap Cone Ceramic Fiber Cone Hole Shapes

Aluminum Gravity Cast Auto Parts Sxlh Aluminum Gravity Casting

What Is Metal Casting Metal Casting Types How Does Metal Casting Work

Machined Castings Aluminium Casting Manufacturer From Mumbai

Aluminium Casting Honeycomb Ceramic Filter Parameter Adtech China

Aluminium Casting Tubes Deelmanl

Aluminium Casting Custom Manufacturing Supplier Upmold Limited

Aluminum Casting Molds

Launder System Aluminium Casting Adtech China

Aluminium Casting Manufacturing Products Supplier Upmold Limited

Brass Metal Forging Manufacturing Foundry Brass Metal Aluminium Casting Png Klipartz

Aluminium Casting Foundry It Cast Foundry Melting Metal

Aluminium Gravity Die Casting Machining Deancast

Aluminium Casting Method Comparison Pros And Cons Of Different Casting Methods For Aluminium Parts Alteams Aluminium Casting Method Comparison Production Volume Matters

Casting Aluminum

Q Tbn And9gctzn5uxcydyvp Ec9qkdhbwqczl9yfdbt4l4roejl8cporp96dg Usqp Cau

Ssoss Cast Pte Ltd

Aluminium Casting And Machining For Injection Pump Stock Photo Image Of Shapes Mechanical

Casting Aluminium Using Lost Foam Method Youtube

Global Aluminium Castings Market To Expand At A Cagr Of 5 Over 17 25 As Constructions Industry Expands Finds Tmr

Aluminium Casting Component Custom Manufacturer Upmold