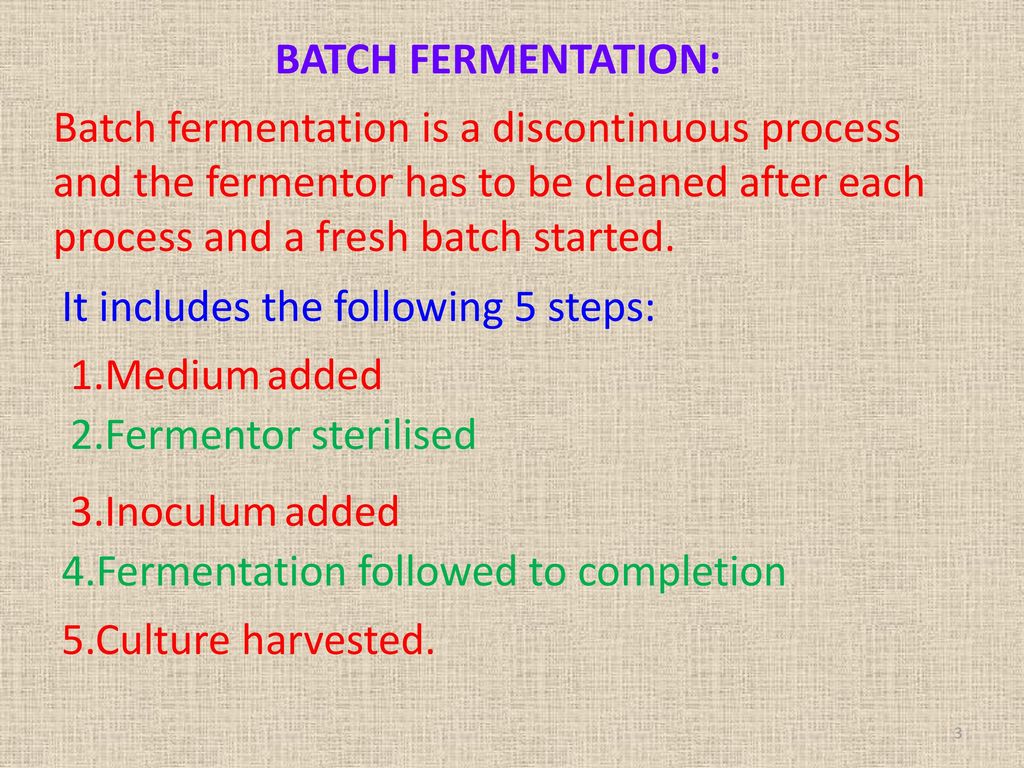

Batch Fermentation

What are the advantages and disadvantages for each process?.

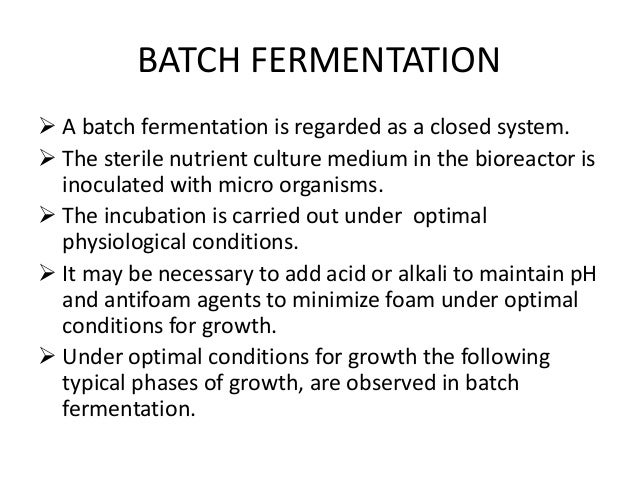

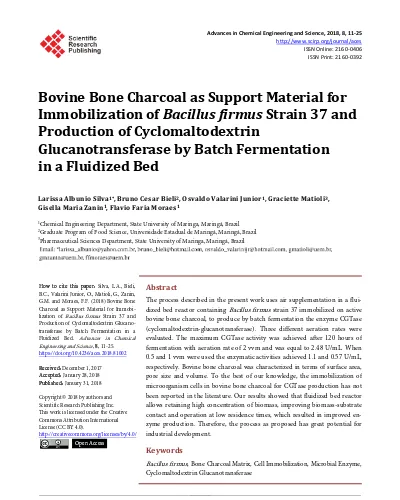

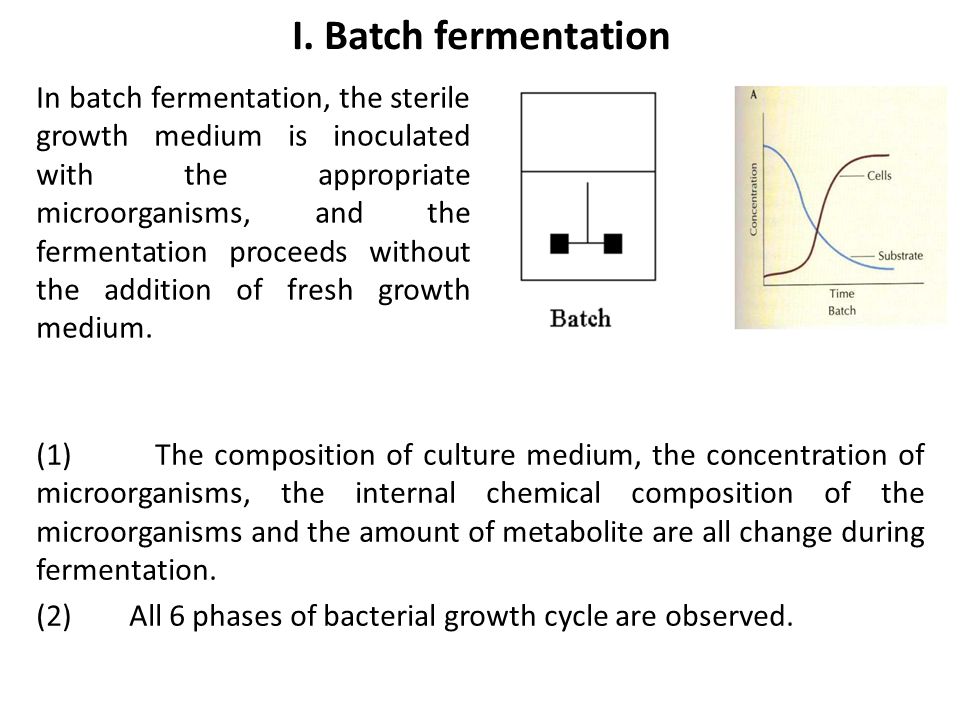

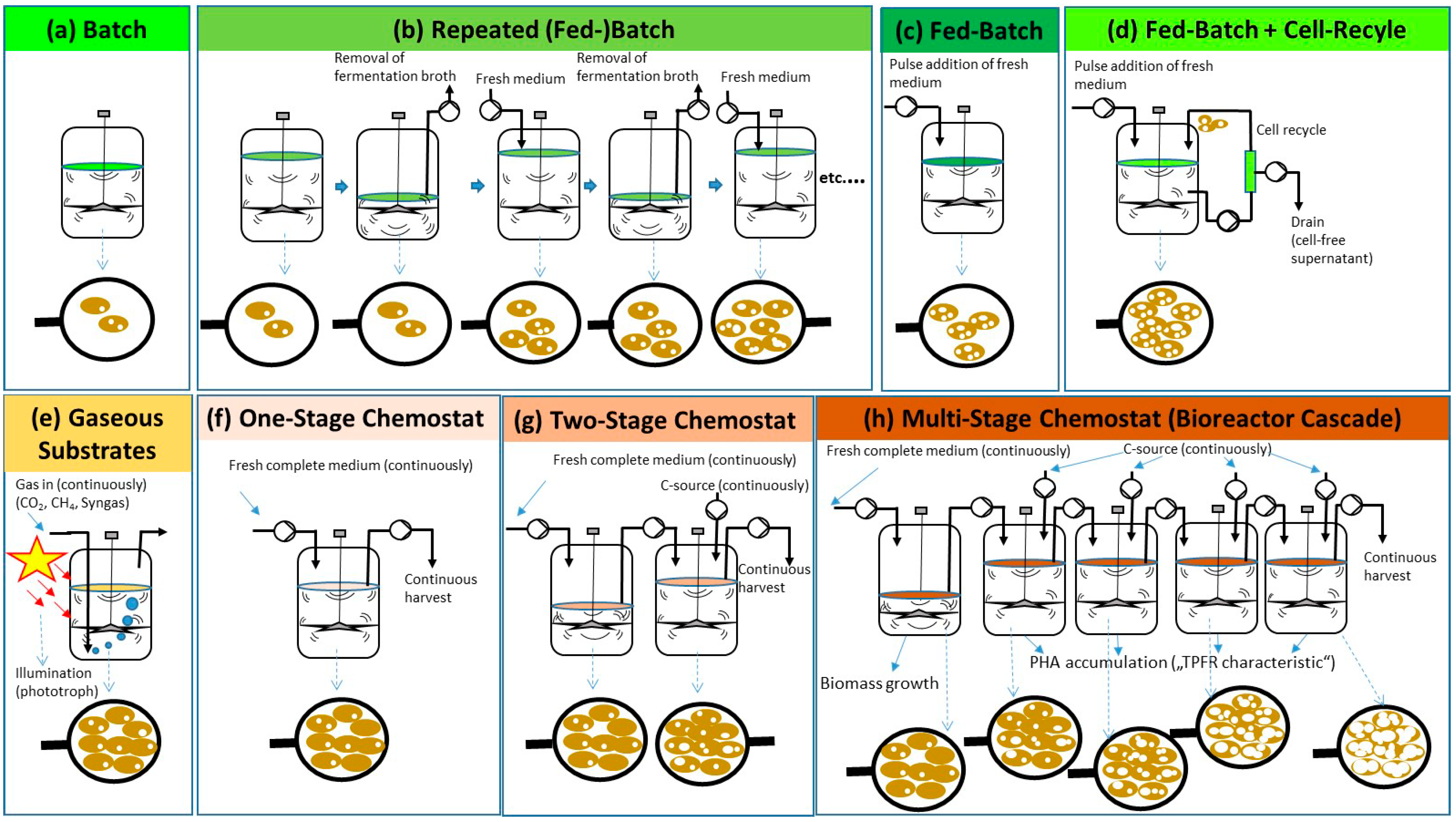

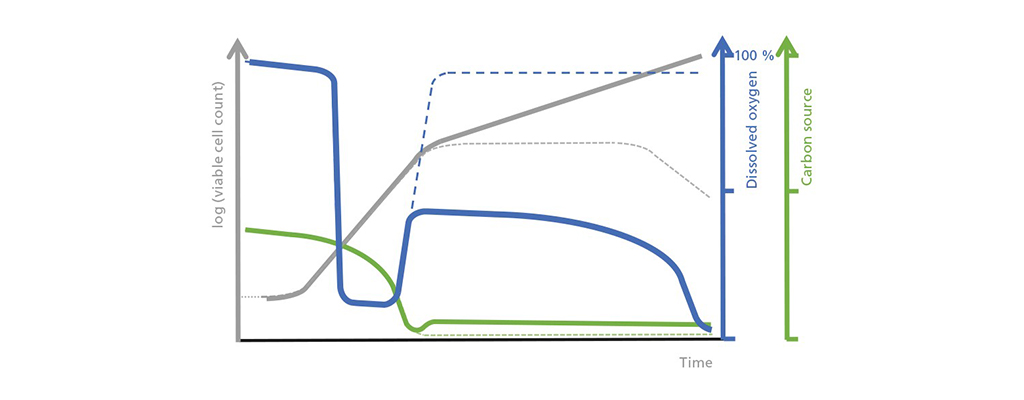

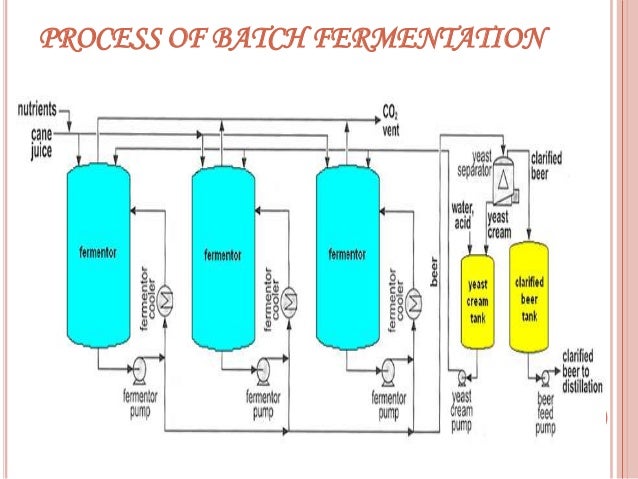

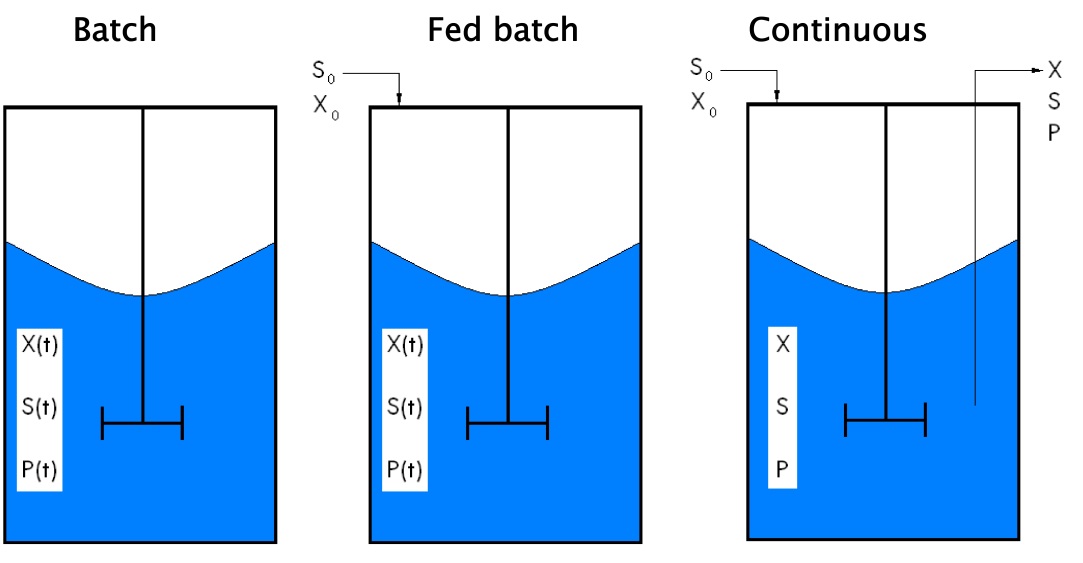

Batch fermentation. Both Batch and Continuous Fermentation are two industrial fermentation processes In both fermentations, fresh media are used to provide nutrients In both, an industrial fermentor is used In Batch and Continuous Fermentation,. This article concerns the comparison between batch and fedbatch fermentation based on productivity and including the analysis of the implications on product manufacturing cost The calculation method of productivity is based on the assumption that batch production rate data are applicable to fedbatch fermentation and that, within a certain range of concentrations, the percent rate of change. A batch fermentation is a closed culture system, because initial and limited amount of sterilized nutrient medium is introduced into the fermenter The medium is inoculated with a suitable microorganism and incubated for a definite period for fermentation to proceed under optimal physiological conditions.

How is batch fermentation different from continuous fermentation?. It IS discouraging to have so many failures That is why I’m loving the Small Batch Fermenting method – so quick and easy I made another batch of cucumber pickles last night and it took me about 3 minutes Kraut takes a little longer, but not much if you have a mandolin slicer. Batch fermentation is an industrial fermentation where products are produced and harvested in batches The process tends to end after the production of each batch The process is quite easy to set up and run The fermenter needs to be washed before the subsequent step of fermentation is taken place.

The proper procedure for a batch fermentation is first to inoculate a small flask of nutrient broth with a pure culture from a Petri dish, a culture tube (containing liquid nutrient), or a slant tube (containing solid gel) The inoculated flask is constantly agitated in a temperature controlled flask shaker. How is batch fermentation different from continuous fermentation?. How is batch fermentation different from continuous fermentation?.

Continuous Fermentation Here the exponential growth rate of the microbes is maintained in the. Fedbatch Fermentation is primarily a practical guide for recombinant protein production in E coli using a Fedbatch Fermentation process Ideal users of this guide are teaching labs and R&D labs that need a quick and reproducible process for recombinant protein production It may also be used as a template for the production of recombinant. Define batch fermentation batch fermentation synonyms, batch fermentation pronunciation, batch fermentation translation, English dictionary definition of batch fermentation n 1 Any of a group of chemical reactions induced by microorganisms or enzymes that split complex organic compounds into relatively simple substances,.

Batch fermentation is defined as the liquid fermentation process in which the culture is inoculated into a sterile medium contained in a closed vessel In batch fermentation process, there is no addition of nutrients once the fermentation process starts This type of fermentation process can also be known as a closed culture system – since there are no nutrient additions once the process is. Illustrating techniques in model development, signal processing, data reconciliation, process monitoring, quality assurance, intelligent realtime process supervision, and fault detection and diagnosis, Batch Fermentation offers valuable simulation and control strategies for batch fermentation applications in the food, pharmaceutical, and chemical industries The book provides approaches for. Batch, FedBatch, Continuous Cultivation, Growth Kinetics, Substation Utilisation, Product Formation, Luedeking Piret Model, Effect of pH, Effect of Temperatur Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising.

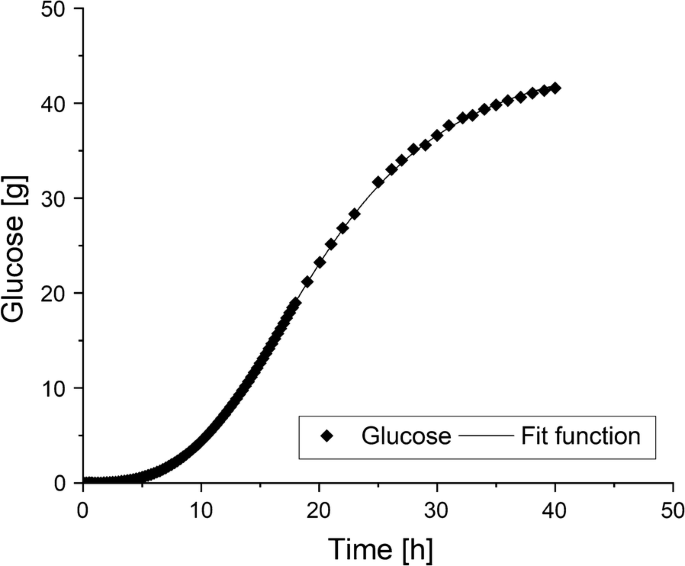

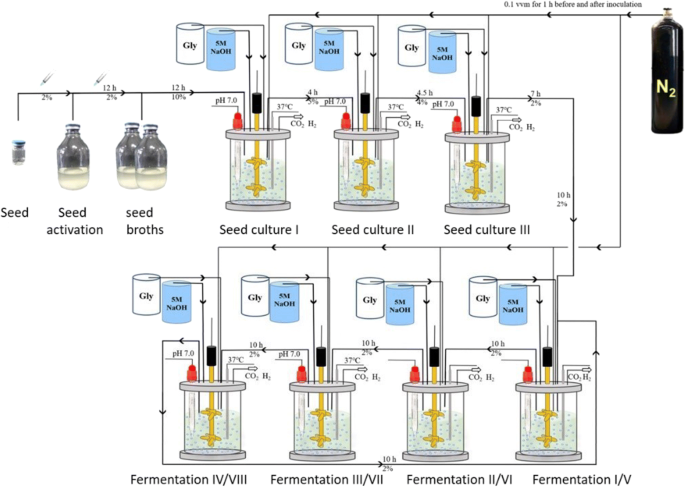

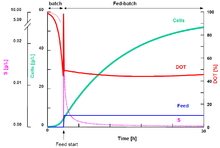

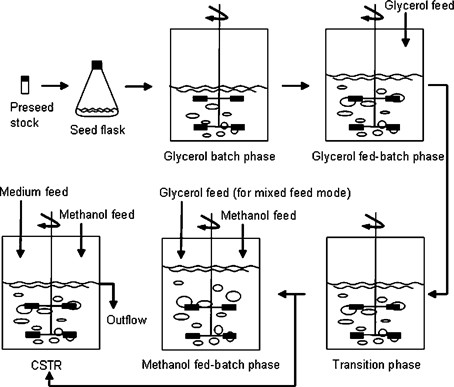

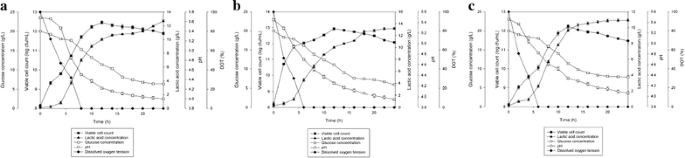

Fedbatch fermentation is a combination of batch and continuous mode in which there is intermittent addition of substrate without removing the medium, and therefore, substrate concentration is. What are the Similarities Between Batch and Continuous Fermentation?. Fedbatch fermentation of E coli MC4110 The fermentation is performed in a 2 l bioreactor (Bioengineering, Switzerland), using a mineral medium, in Institute of Technical Chemistry, University of Hannover Before inoculation a glucose concentration of 25 g·l1is established in the medium Glucose in feeding solution is 100 g·l1.

Illustrating techniques in model development, signal processing, data reconciliation, process monitoring, quality assurance, intelligent realtime process supervision, and fault detection and diagnosis, Batch Fermentation offers valuable simulation and control strategies for batch fermentation applications in the food, pharmaceutical, and chemical industries. How is batch fermentation different from continuous fermentation?. Carolyn, I feel your pain!.

Batch fermentation can be defined as the process of microbial growth, wherein there is a limited supply of the nutrient media to the organisms The product is harvested, once all the process has been completed. Fedbatch Fermentation is primarily a practical guide for recombinant protein production in E coli using a Fedbatch Fermentation process Ideal users of this guide are teaching labs and R&D labs that need a quick and reproducible process for recombinant protein production It may also be used as a template for the production of recombinant. Batch fermentation Continuous fermentation Batch fermentation ;.

Findings indicate that the batch fermentation process with yeast recycle is superior for the following main reasons The process parameters are more easier to measure and invariably control and. Readership Students, Researchers and Teachers based in teaching and research and development laboratories that need a quick and reproducible process for recombinant protein production. Fed batch fermentation is defined as the liquid fermentation process in which growth nutrients are periodically added in the fermentation medium during fermentation The process is akin to batch fermentation process except that small concentrations of nutrients are added at the beginning of the process, and there is a continuous addition of nutrients during the process in small amounts.

Last Updated on Tue, 05 Jan 21 Batch Fermentation Batch operation is characterized by two key elements (i) the physical configuration that consists of various reactors, tanks, and the network of pipelines available to transfer material between various tanks and production units, and (ii) the sequence of processing tasks. That covers fermentation vessels and water locks, now we still need a small batch siphon and bottling equipment For halfgallon and onegallon batches, I use an auto siphonJust a pump of two and the siphon action begins in seconds and your wine can be moved effortlessly into a clean container. What are the advantages and disadvantages for each process?.

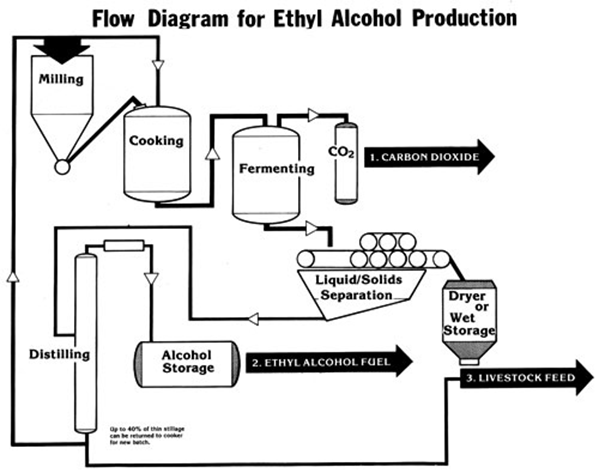

Immobilized Cell Bead Morphology Observation after Each Batch Fermentation To evaluate the immobilized cell beads viability, scanning electron microscope (SEM, HITACHI S3400N, Japan) was employed to observe the morphology changes of immobilized cell beads after five batch fermentation rounds. Fermentation is the process by which yeast converts the glucose in the wort to ethyl alcohol and carbon dioxide gas giving the beer both its alcohol content and its carbonation To begin the fermentation process, the cooled wort is transferred into a fermentation vessel to which the yeast has already been added. Fedbatch fermentation is a modified version of batch fermentation It is the most common mode of operation in the bioprocess industry Microorganisms are inoculated and grown under batch regime for a certain amount of time, then nutrients are added to the fermenter in increments throughout the remaining duration of fermentation to feed them.

The fedbatch fermentation described in this book is a robust process and can be easily scaled for CMO production of protein product;. The scaleup of microbial batch and fedbatch fermentation processes Microorganisms are important for both human health and to industry so the fedbatch cultivation of microbial strains, often over expressing recombinant or natural proteins, to high cell density has become an increasingly important technique throughout the field of biotechnology, from basic research programmes to largescale pharmaceutical production processes (Hewitt et al, 1999). Batch fermentation is highly dynamic yet a closed system in which all the medium components, except gases such as oxygen, acid or base for pH control, and antifoaming agents, are placed in the reactor at the start of the cultivation During the process there is neither any addition nor any withdrawal of nutrients.

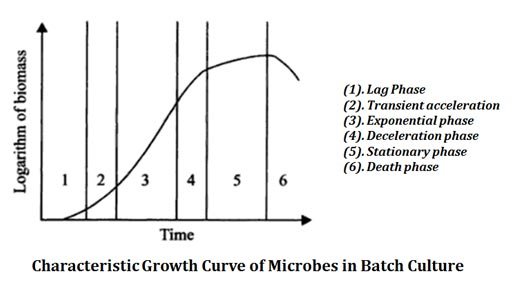

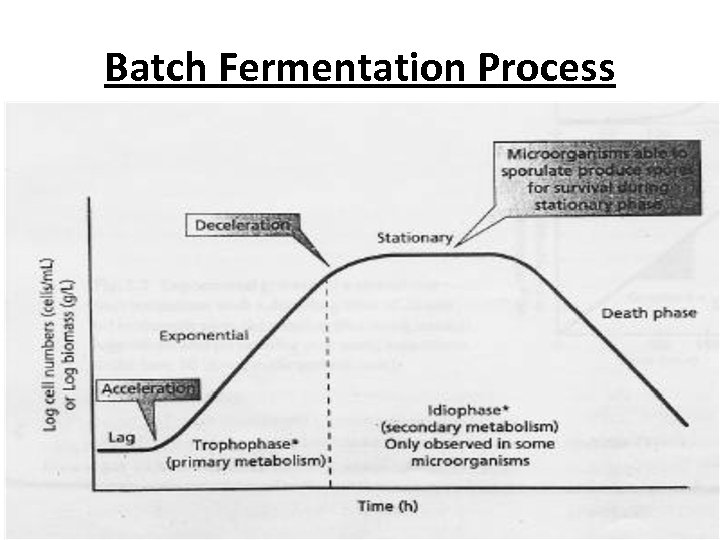

Accelerated batch fermentation Accelerated Batch Fermentation is an attempt to gain economic advantage through the production of more beer with the same equipment in less time If even a few days can be shaved off of the fermentation period needed to produce beer, there can be considerable increases in a brewery’s overall capacity. Batch fermentation goes through a series of phases There is a lag phase in which cells adjust to their environment;. The calculation method of productivity is based on the assumption that batch production rate data are applicable to fedbatch fermentation and that, within a certain range of concentrations, the percent rate of change of batch production rate with respect to time is proportional to the difference of product concentration at maximum production rate minus instant concentration.

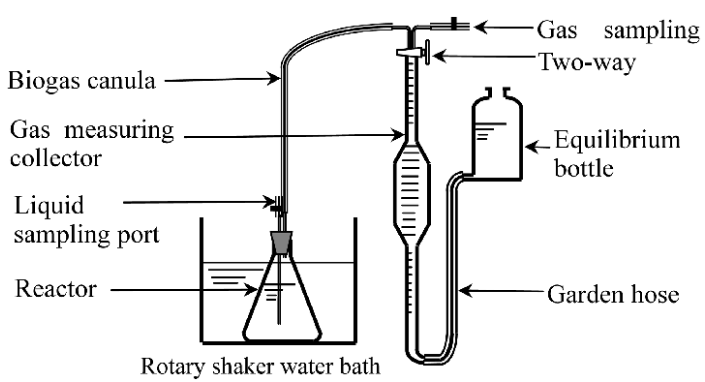

Batch Fermentation Definition Batch fermentation is an industrial fermentation where products are produced and harvested in batches The process tends to end after the production of each batch The process is quite easy to set up and run The fermenter needs to be washed before the subsequent step of fermentation is taken place. The RITTER Biogas Batch Fermentation System enables the investigation of multiple fermentation processes with data acquisition in real time. The fermentation process is carried out batchwise in batch culture technique After each and every batch, fermenter is cleaned and used freshly for the next batch In continuous culture, microorganisms are provided with adequate levels of fresh nutrients continually to always maintain the microbes at log phase to extract primary metabolites of the microorganisms.

Nutrients are added in the fermentation for the single time only the growth continuous until the particular nutrient are exhausted. Define batch fermentation batch fermentation synonyms, batch fermentation pronunciation, batch fermentation translation, English dictionary definition of batch fermentation n 1 Any of a group of chemical reactions induced by microorganisms or enzymes that split complex organic compounds into relatively simple substances,. In this paper, fed‐batch fermentation with glucose syrup as an adjunct led to the overproduction of higher alcohols, except for isobutanol The assimilation of glucose after feeding caused an increase in yeast biomass and resulted in concentrations of n ‐propanol and isoamyl alcohol (5099 ± 277 and 144 ± 1384 mg/L, respectively) 2‐fold higher than the threshold values.

The scaleup of microbial batch and fedbatch fermentation processes Microorganisms are important for both human health and to industry so the fedbatch cultivation of microbial strains, often over expressing recombinant or natural proteins, to high cell density has become an increasingly important technique throughout the field of. The standard procedure for batch fermentation mode in shake flask was conducted by inoculating the flask (500 ml) that contained the optimized broth medium (250 ml) with a pure culture of the tested cells, and the initial optical density (600 nm) was fixed at ~ 03 then this flask incubated at 30degreesC under shaking condition (0rpm). Fedbatch culture technique Fedbatch culture is also called as semiclosed system of cultivation In this technique, at first nutrient media is prepared and it is inoculated with culture organism and then incubated for During the course of incubation a particular nutrient is added at intervals.

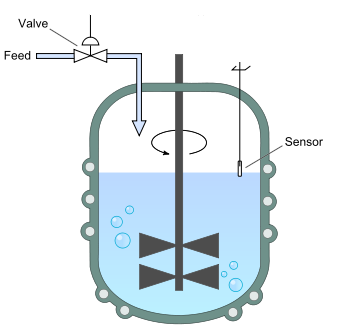

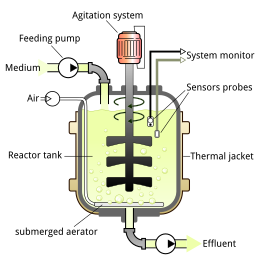

Start date Dec 5, ;. Small Batch Wine Equipment Winemaking generally requires a few basic pieces of equipment A fermentation vessel holds the brew while it’s fermenting, and it’s capped with a water lock The water lock allows the CO2 produced by the yeast to escape but prevents contamination from getting in and spoiling the wine. Batch fermentation is the simplest mode of fermentation, made up of a mechanically stirred vessel with other accessories such as a gas sparger and a heating/cooling jacket The substrates and supplementary nutrients are charged in the vessel, autoclaved at 1°C, cooled to 35–37°C, and inoculated with bacteria.

Help Support Homebrew Talk L LanigansBall Member Joined Dec 5, Messages 11 Reaction score 4 Dec 5, #1 I'm driving myself insane trying to figure this out alone, so I figured it was time to try out the forums The basic situation is. Illustrating techniques in model development, signal processing, data reconciliation, process monitoring, quality assurance, intelligent realtime process supervision, and fault detection and diagnosis, Batch Fermentation offers valuable simulation and control strategies for batch fermentation applications in the food, pharmaceutical, and chemical industries The book provides approaches for determining optimal reference trajectories and operating conditions;. Fermentation is a chemical reaction that takes place when yeast turns sugar into carbon dioxide and alcohol Obviously, this is a critical part of the entire process A yeast cell will turn approximately 55% of the sugar it eats into ethyl alcohol, and the remaining 45% into carbon dioxide gas and other byproducts.

Batch Fermentation Ø Microorganism is inoculated into a fixed volume of medium Ø As the growth takes place, the nutrients are consumed and the product of growth accumulates in the fermenter. A feeding technology that was suitable for improving the nisin production by Lactococcus lactis subsp lactis W28 was established The effects of initial sucrose concentration (ISC) in the fermentation broth, feeding time, and feeding rate on the fermentation were studied It was observed that a fedbatch culture (ISC = 10 g l (1)) with 100 ml sucrose solution (190 g l (1)) being evenly fed (910 ml h (1)) into the fermenter after 3h fermentation gave the best performance in terms of. What are the advantages and disadvantages for each process?.

A batch fermentation is a closed culture system, because initial and limited amount of sterilized nutrient medium is introduced into the fermenter The medium is inoculated with a suitable microorganism and incubated for a definite period for fermentation to proceed under optimal physiological conditions. The high cell density fermentation by fedbatch strategies is one of the most costeffective means of achieving high yields for the production of heterologous proteins, which is widely used in the bioindustry In fedbatch cultures, cell mass and productivity are maximized by controlling culture conditions such as the temperature and pH, the. However, little attention has been paid to applying a fed‐batch fermentation approach to high‐ethanol beer brewing This paper is a preliminary research report on fed‐batch fermentation profiles using glucose syrup as an adjunct at a later stage of the primary fermentation for high‐ethanol beer brewing.

In fedbatch fermentation, a specific growth rate cannot be maintained The dynamic process of control carried out in fedbatch fermentation systems makes the process to be capital intensive There is usually a lower productivity levels experienced in this system of fermentation due to the time it. Accelerated Batch Fermentation is an attempt to gain economic advantage through the production of more beer with the same equipment in less time If even a few days can be shaved off of the fermentation period needed to produce beer, there can be considerable increases in a brewery’s overall capacity There have always been many strategies for accelerating fermentations. Then a phase in which exponential growth occurs Once many of the nutrients have been consumed, the growth slows and becomes nonexponential, but production of secondary metabolites (including commercially important antibiotics.

BIC's bacterial fermentation services are available at any scale from 5 to 500L for both fedbatch and continuous cultivation There are three types of fermentation services standard fermentation service, high cell density fermentation (HCDF) service, and fermentation process optimization service Our services include codon optimization, gene synthesis, small scale expression test, fermentation process optimization and protein purification. In batch fermentation, this can occur during the initial gr owth phases while substrate concentrations are high • If this is a major problem, continuous or fedbatch fermentation methods should be considered • Product Inhibition • In batch fermentation, this can occur after induction of th e recombinant gene Shuler, p. A batch fermentation is regarded as a closed system The sterile nutrient culture medium in the bioreactor is inoculated with microorganisms The incubation is carried out under optimal physiological conditions (pH, temperature, O 2 supply, agitation etc).

In the fedbatch fermentation, substrate is added according to a predetermined feeding profile as the fermentation progresses In this book, we focus on the fedbatch operation mode, since it offers a great opportunity for process control when manipulating the feed rate profile affects the productivity and the yield of the desired product 2. Stuck fermentation with every batch so far Thread starter LanigansBall;. Difference between batch, fedbatch and continuous culture technique September 3, 17 Gaurab Karki Bacteriology , Microbiology 0 Difference between batch, fed batch and continuous culture technique.

A batch culture is a closed culture where microorganisms ferment a given amount of nutrients within a defined time period The optimal pH and the aeration are provided for these microorganisms The fermentation takes place in batches. Estimating final product quality. Batch fermentation Continuous fermentation Batch fermentation ;.

Batch fermentation is more flexible with many biological systems and/or products There is reduced risk of contamination of the process – since nutrients are only added once at the start of the process Mutation of the microbial cell is minimal since the process does not last for a long time Batch. Nutrients are added in the fermentation for the single time only the growth continuous until the particular nutrient are exhausted Recommended Glyoxylate cycle PATHWAYS REACTION shylesh murthy VIRUSES CLASSIFICATION , LIFE CYCLE OF VIRUSES. Batch Culture Fermentation is carried out in a closed fermenter, with nothing added or removed during the process (except venting of gas) Microorganisms and nutrients are left for a set period of time, during which the nutrient stock is depleted.

Types Of Fermentation Ppt Download

High Cell Density Cyclic Fed Batch Fermentation Of A Poly 3 Hydroxybutyrate Accumulating Thermophile Chelatococcus Sp Strain Mw10 Applied And Environmental Microbiology

Fed Batch Ethanol Fermentation At Low Temperature As A Way To Obtain Highly Concentrated Alcoholic Wines Modeling And Optimization Sciencedirect

Batch Fermentation のギャラリー

Epb1 Combined Continuous Batch Fermentation Process Google Patents

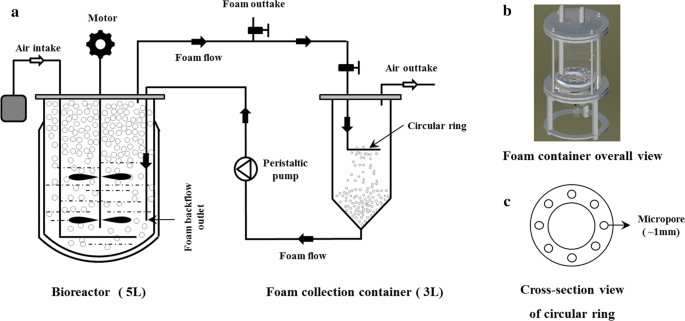

Enhanced Rhamnolipids Production Using A Novel Bioreactor System Based On Integrated Foam Control And Repeated Fed Batch Fermentation Strategy Biotechnology For Biofuels Full Text

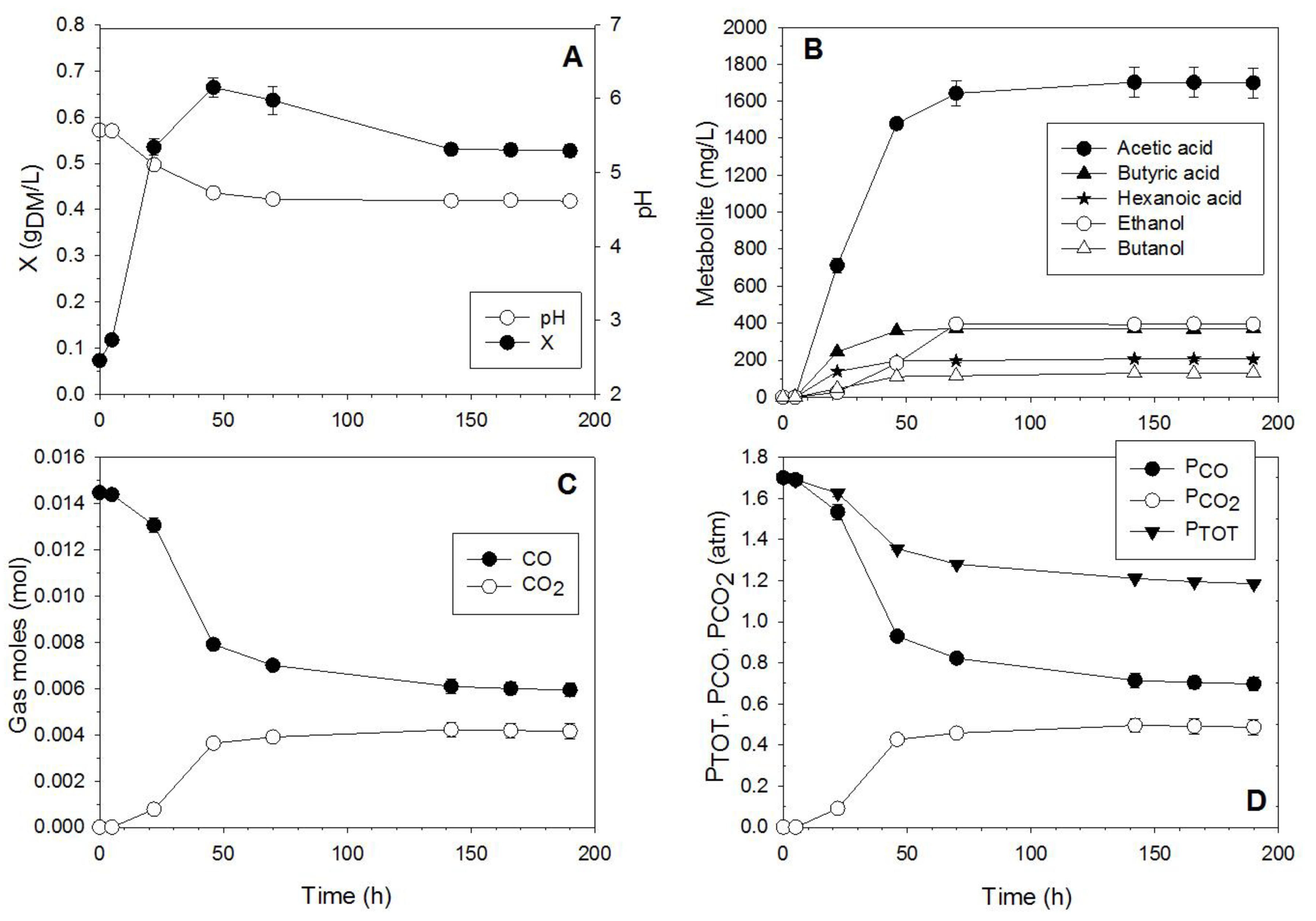

Processes Free Full Text Batch Syngas Fermentation By Clostridium Carboxidivorans For Production Of Acids And Alcohols Html

Fed Batch Fermentation Doc Biology Life Sciences

A Fed Batch Fermentation Coupled To Organophilic Pervaporation B Download Scientific Diagram

Cultivation Technique Of Bacteria Batch Fed Batch And Continuous Culture Technique Online Biology Notes

Batch Versus Continuous Culture Bioninja

Enhanced Production Of Glycyrrhetic Acid 3 O Mono B D Glucuronide By Fed Batch Fermentation Using Ph And Dissolved Oxygen As Feedback Parameters Sciencedirect

1

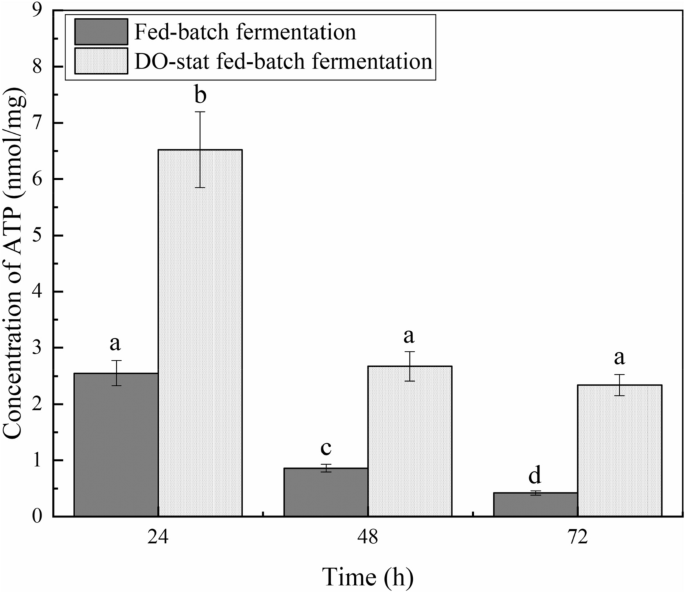

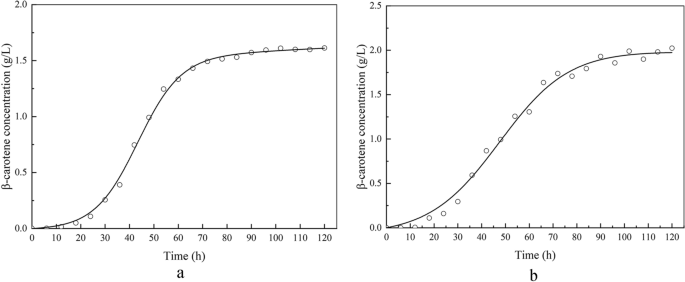

Dissolved Oxygen Feedback Control Fermentation For Enhancing B Carotene In Engineered Yarrowia Lipolytica Scientific Reports

The Difference Between Batch Fed Batch And Continuous Processes En Blog Infors Ht

Fed Batch Fermentation A Practical Guide To Scalable Recombinant Protein Production In Escherichia Coli By Garner G Moulton

Praj Fermentation Process Plant Ethanol Formation Using Fermentation

Glucose Limited Feed Strategy Leads To Increased Production Of Fusicocca 2 10 14 Diene By Saccharomyces Cerevisiae Amb Express Full Text

Batch And Continuous Fermentation Process Easy Biology Class

Inducible Fed Batch Fermentation Process Download Scientific Diagram

Food Biotechnology Fermentation

Continuous Operation A Realistic Alternative To Fed Batch Fermentation For The Production Of Recombinant Lipase B From Candida Antarctica Under The Constitutive Promoter Pgk In Pichia Pastoris Sciencedirect

1 Simplified Scheme Of A Batch B Fed Batch And C Continuous Download Scientific Diagram

Consider The Fed Batch Fermentation Process Used T Chegg Com

Fermentation Batch Fedbatch And Continous Culture Studocu

Top Pdf Batch Fermentation 1library

Core Ac Uk Download Pdf Pdf

Solved A Simple Batch Fermentation Of An Aerobic Bacteri Chegg Com

Submerged Fermentation Process Fed Batch And Continuous Fermentation Bio Science Youtube

Differentiate Between Fed Batch Fermentation And Continuos Fermentation Brainly In

Feeding Control Strategies On Fed Batch Fermentation With A Lambda Peristaltic Pump Peristaltic Pump Exponential Lambda

Pdf Production Of Ethanol By Fed Batch Fermentation Semantic Scholar

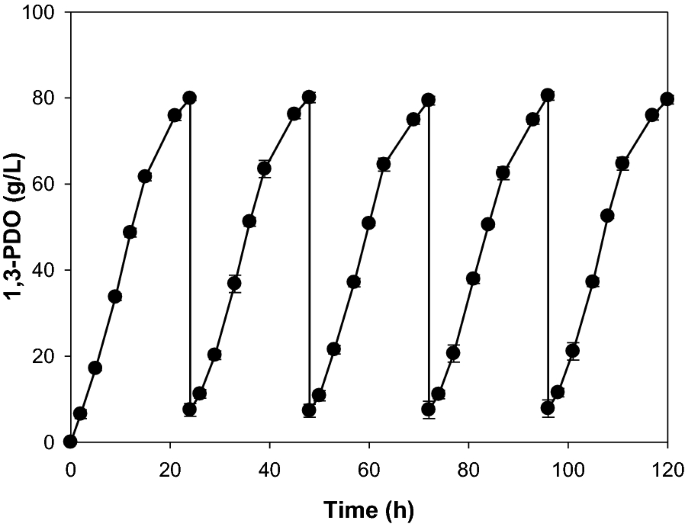

Sequential Fed Batch Fermentation Of 1 3 Propanediol From Glycerol By Clostridium Butyricum Dl07 Springerlink

Batch Fed Batch Continuous Culture System According To Mode Of Fermentation Youtube

Industrial Biotechnology Lesson 1 Fermentation Processes Types And

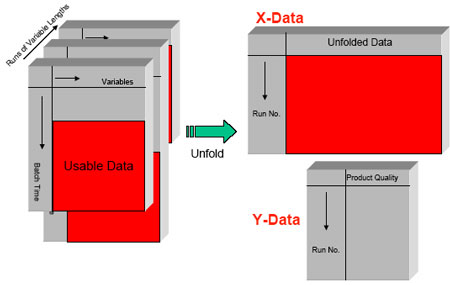

Integrated Multivariate Statistical Process Control And Condition Monitoring For Fed Batch Fermentation Processes

Fermentation System Batch Fermentation System Manufacturer From Pune

Optimization Of A Fed Batch Fermentation Process Control Of A Fed Batch Fermentation Process Ation Problems Remotely Over The Internet The Neos Server Has The Following

File Batch Fed Fermentation Jpg Wikipedia

Pdf Optimization Of Fed Batch Fermentation Processes Using The Backtracking Search Algorithm Semantic Scholar

Designing Batch Fermentation Reactors Design Basics Benebo Opubo G Amazon Com Books

Pilot Scale Repeated Fed Batch Fermentation Processes Of The Wine Yeast Dekkera Bruxellensis For Mass Production Of Resveratrol From Polygonum Cuspidatum Sciencedirect

A Simple Batch Fermentation Model Theme And Variations Ollis 19 Annals Of The New York Academy Of Sciences Wiley Online Library

Batch Fermentation Satish J Parcilekar Ccnk Undey Gtilnur Birol Download

Dynamic Models For L Histidine Fed Batch Fermentation By Corynebacterium Glutamicum Scientific Net

Q Tbn And9gcrkyfhvginw9lnorveflmjitjpnvkgha4yvmznkp6bnhjnwemak Usqp Cau

Difference Between Batch And Continuous Culture Pediaa Com

Batch Fermentation Process Batch Fermentation Buffalo Brewing Blog

Lec 8 Fermentation Biotechnology Ppt Video Online Download

Improved Lactic Acid Productivity By An Open Repeated Batch Fermentation System Using Enterococcus Mundtii Qu 25 Rsc Advances Rsc Publishing

Comparing A Dynamic Fed Batch And A Continuous Steady State Simulation Of Ethanol Fermentation In A Distillery To A Stoichiometric Conversion Simulation

1 Fermentation Methodologies A Batch Fermentation B Fed Batch Download Scientific Diagram

Continuous Addition Of Sugars In Fed Batch Fermentation Is Done To Nedu Latge 1 Produce Methane 25 Obtain Antibiotics 3 Purify Enzymes 4 Degrade Sewage

Fermentation Free Full Text A Review On Established And Emerging Fermentation Schemes For Microbial Production Of Polyhydroxyalkanoate Pha Biopolyesters

Advantages Of Fed Batch Fermentation Over Batch Fermentation For Life Sciences Science Mathematics

Optimal Control Of The Penicillin G Fed Batch Fermentation An

Batch Fermentation Microdok Microbiology

Enhance 1 3 Propanediol Production From Crude Glycerol In Batch And Fed Batch Fermentation With Two Phase Ph Controlled Strategy Topic Of Research Paper In Chemical Engineering Download Scholarly Article Pdf And Read For Free On

Repeated Batch Lactic Acid Fermentation Using A Novel Bacterial Immobilization Technique Based On A Microtube Array Membrane Process Biochemistry X Mol

Batch Fermentation Biofuels Academy

Batch Fermentation Vs Continuous Fermentation What Is The Difference Viva Differences

Patent Report Us Fed Batch Fermentation Process And Culture Medium For The Production Of Plasmid Dna In I E Coli I On A Manufacturing Scale

Experimental Setup For Batch Fermentation Of Synthetic Mixed Sugar And Download Scientific Diagram

Http Citeseerx Ist Psu Edu Viewdoc Download Doi 10 1 1 452 1846 Rep Rep1 Type Pdf

Batch And Continuous Fermentation Process Easy Biology Class

Batch Fermentation An Overview Sciencedirect Topics

Using A Continuous Mpc Algorithm To Control An Unsteady Batch Fermentation Process Aiche

Comparing A Dynamic Fed Batch And A Continuous Steady State Simulation Of Ethanol Fermentation In A Distillery To A Stoichiometric Conversion Simulation

2

3

Fed Batch Fermentation Microdok Microbiology

Extended Fed Batch Fermentation Of A C5 C6 Optimised Yeast Strain On Wheat Straw Hydrolysate Using An Online Refractive Index Sensor To Measure The Relative Fermentation Rate Scientific Reports

Fed Batch Culture Wikipedia

Dissolved Oxygen Feedback Control Fermentation For Enhancing B Carotene In Engineered Yarrowia Lipolytica Scientific Reports

Continous Addition Of Sugars In Fed Batch Fermentation Is Done To Youtube

High Cell Density Fermentation Biologicscorp

Rational Design And Optimization Of Fed Batch And Continuous Fermentations Springerlink

Strategies For Improving Production Performance Of Probiotic Pediococcus Acidilactici Viable Cell By Overcoming Lactic Acid Inhibition Amb Express Full Text

The Difference Between Batch Fed Batch And Continuous Processes En Blog Infors Ht

Ethanol Production From Whey By Kluyveromyces Marxianus In Batch Fermentation System Kinetics Parameters Estimation Ariyanti Bulletin Of Chemical Reaction Engineering Catalysis

Fermentation System Batch Fermentation System Manufacturer From Pune

Q Tbn And9gcsxpkolitgasru0qbg3bufafnxdf3pygltkzygjes5rhh 8rlsj Usqp Cau

Fed Batch Fermentation Cell Culture Buffalo Brewing Blog

Batch Fermentation Taylor Francis Group

A Single Batch Fermentation System To Simulate Human Colonic Microbiota For High Throughput Evaluation Of Prebiotics

The Substratostat An Automated Near Infrared Spectroscopy Based Variable Feed System For Fed Batch Fermentation Of Grape Must Oeno One

What Is Fed Batch Fermentation Quora

Pdf Product Optimization Of A Fed Batch Fermentation Process Mohd Kamaruddin Abd Hamid Academia Edu

Typical Fed Batch Fermentation F Is The Feed Rate S Is Limiting Download Scientific Diagram

Epb1 Combined Continuous Batch Fermentation Process Google Patents

High Cell Density Cyclic Fed Batch Fermentation Of A Poly 3hb

Patent Report Us Fed Batch Fermentation Process And Culture Medium For The Production Of Plasmid Dna In I E Coli I On A Manufacturing Scale

Difference Between Batch Continuous Fermentation Easy Biology Class

Batch Versus Continuous Culture Bioninja

Optimal Control Of A Nonlinear Fed Batch Fermentation Process Using Model Predictive Approach Sciencedirect

H7cynurzfxp1bm

High Improvement In Lactic Acid Productivity By New Alkaliphilic Bacterium Using Repeated Batch Fermentation Integrated With Increased Substrate Concentration

Thermophilic Enterococcus Faecium Qu 50 Enabled Open Repeated Batch Fermentation For L Lactic Acid Production From Mixed Sugars Without Carbon Catabolite Repression Rsc Advances Rsc Publishing

Fermentation

Schematic Representation Of Fermentation Processes Fed Batch Cultures Download Scientific Diagram

Continuous Agave Juice Fermentation For Producing Bioethanol Intechopen

Study On Process Of Xylanase By Fed Batch Fermentation Scientific Net

Infoscience Epfl Ch Record Files Fulltext Pdf

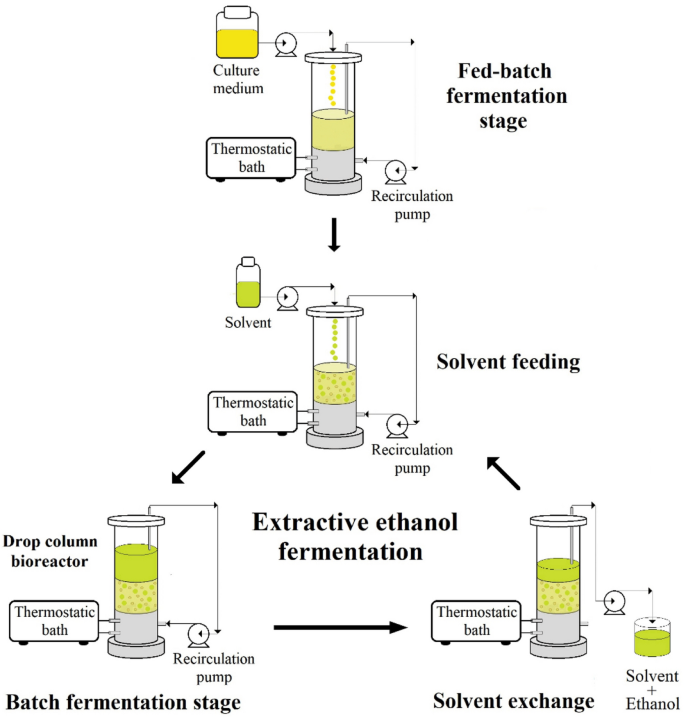

Improvement Of Ethanol Production By Extractive Fed Batch Fermentation In A Drop Column Bioreactor Springerlink

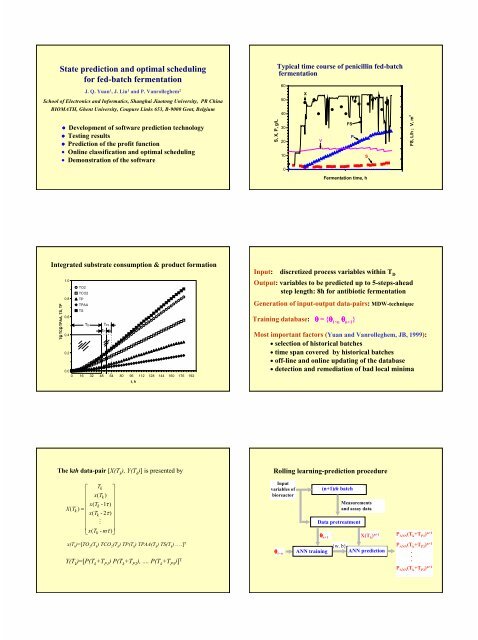

State Prediction And Optimal Scheduling For Fed Batch Fermentation