K Fmea

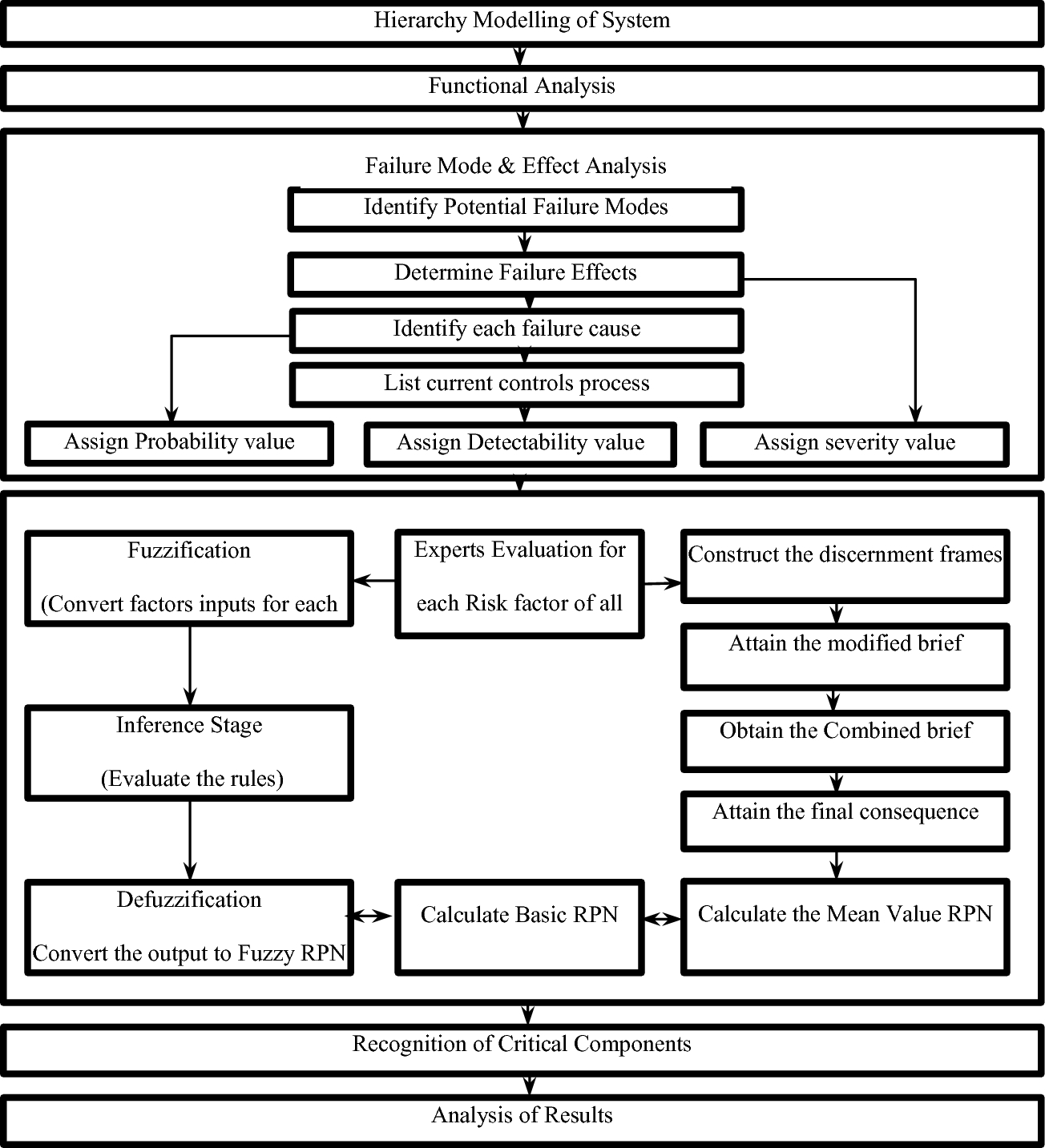

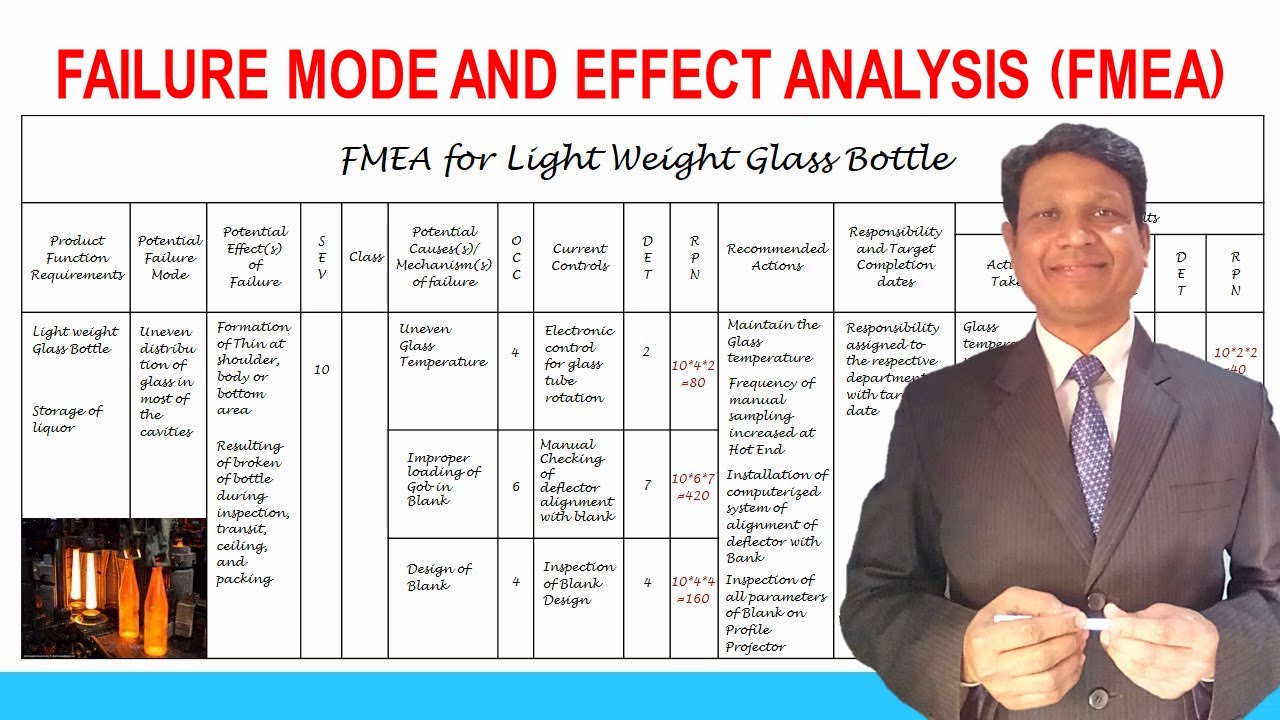

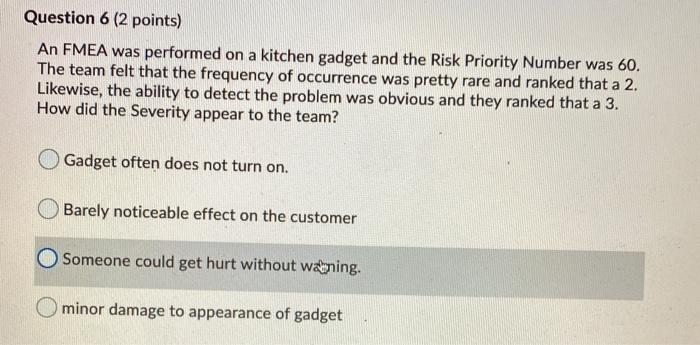

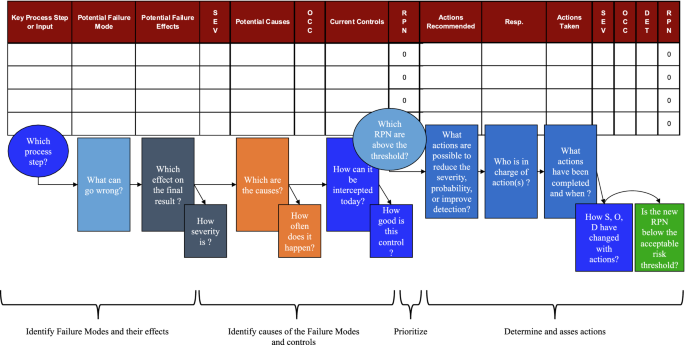

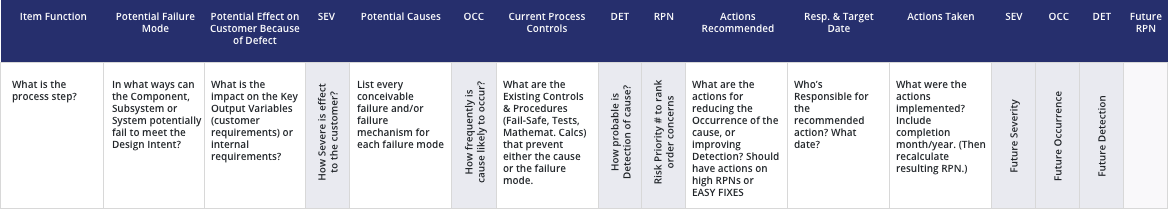

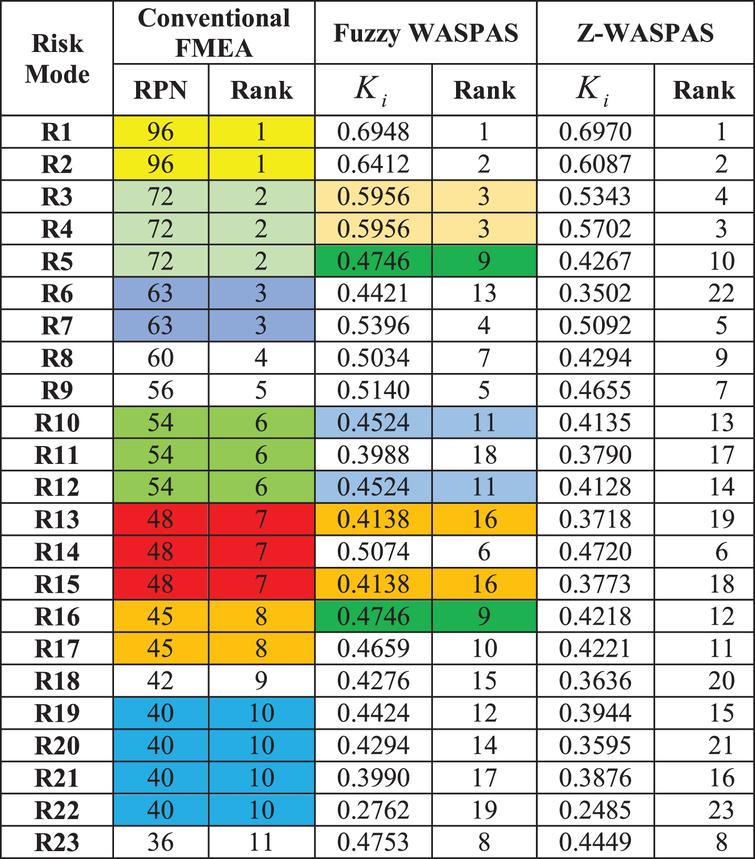

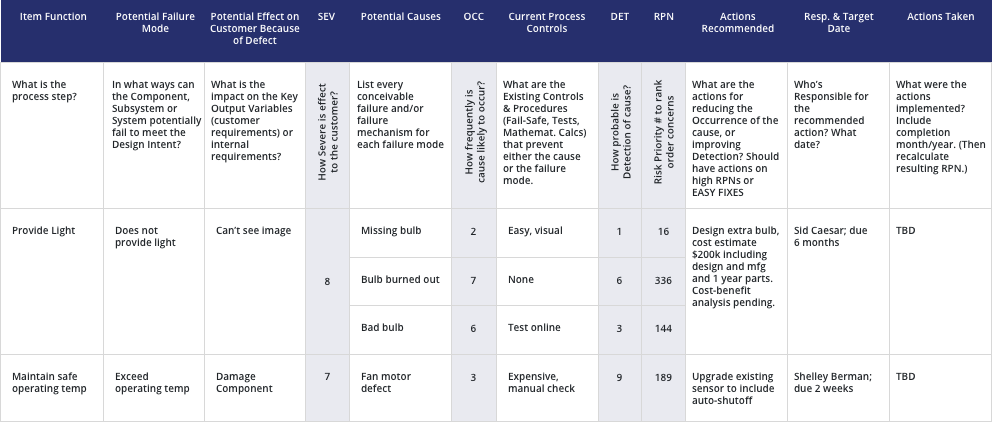

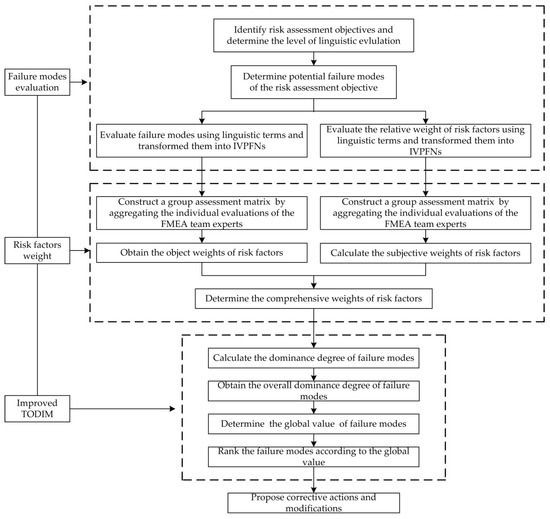

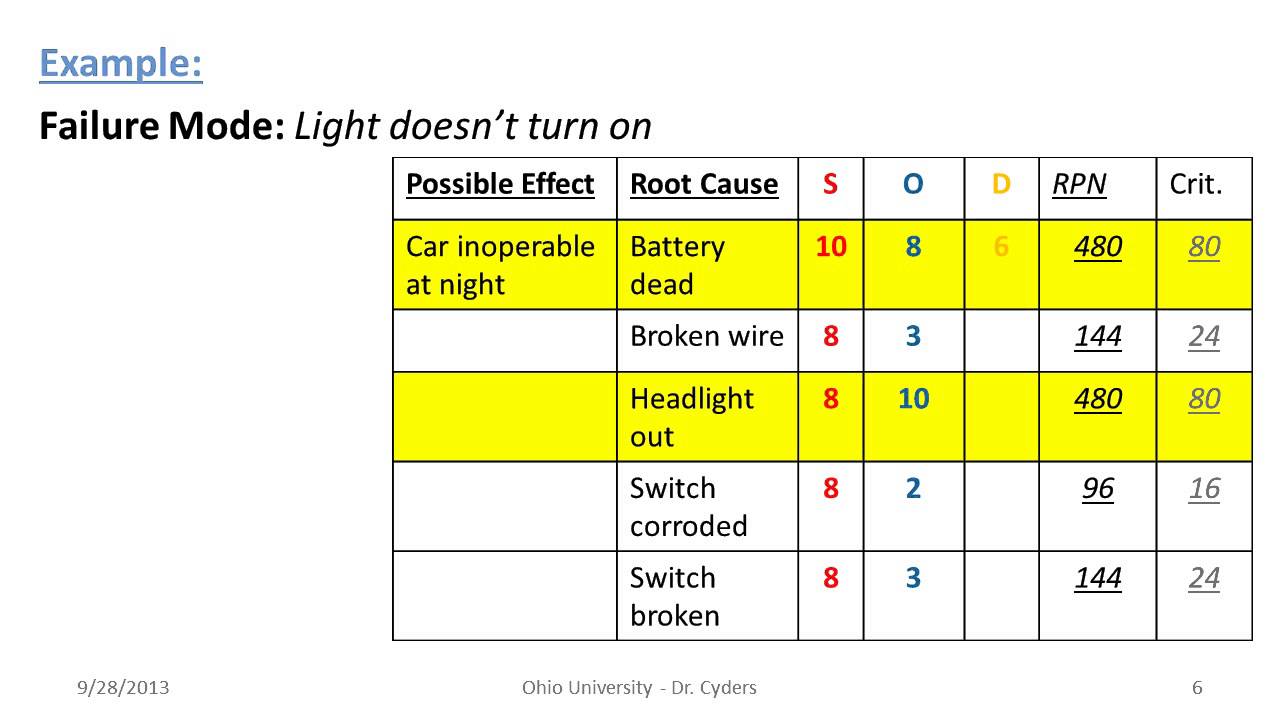

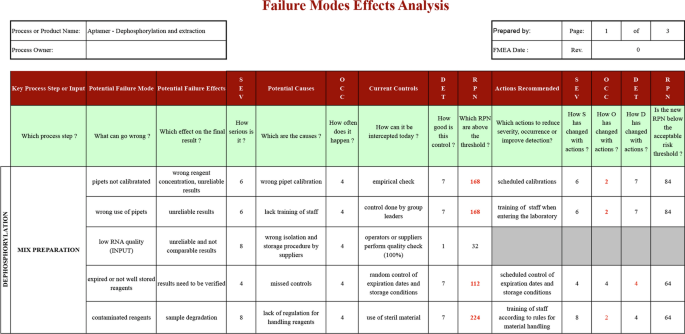

One of the most established risk assessment methods is Failure Mode and Effect Analysis (FMEA) – a reliability analysis and risk assessment tool widely used in various industries The traditional FMEA is using a Risk Priority Number (RPN) ranking system to evaluate and identify the risk level of failures, and to prioritize actions.

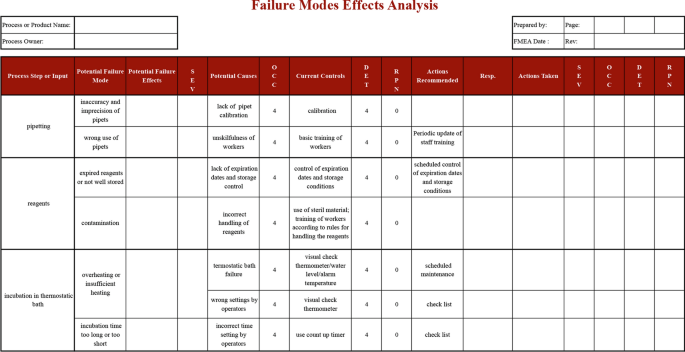

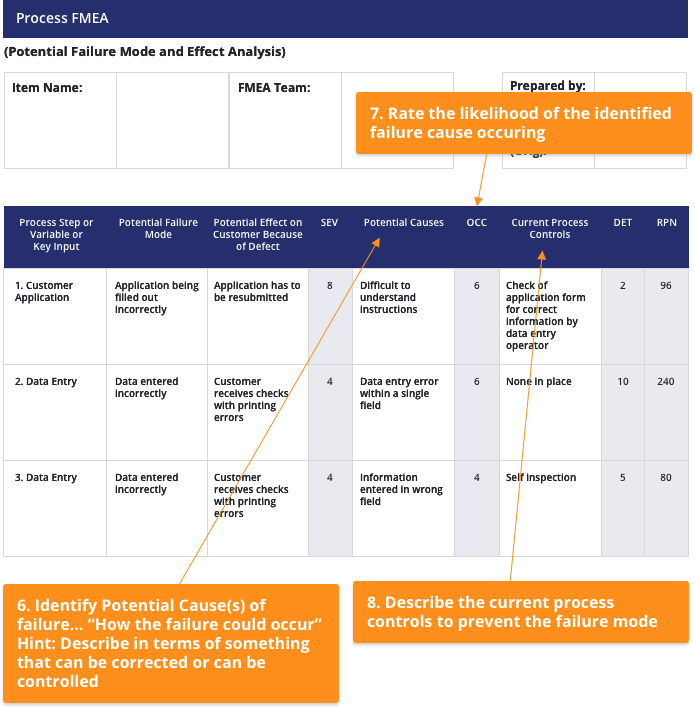

K fmea. How to implement of FMEA with ISO Failure Mode and Effects Analysis (FMEA) is a core aspect of risk management and risk analysis in medical devices FMEA is essentially about analyzing the reasons for which a problem arises and the effects it has on the system. FMEA, or Failure Mode and Effects Analysis, is an organized, systematic approach for assessing potential system failures and the resulting consequences of those failures The objective of a FMEA is to evaluate the risk associated with the identified failure effects and come up with a plan to detect, prevent, or mitigate those deemed most critical. Http//wwwspasslerndenkshopde, Die Fehlermöglichkeits und Einflussanalyse (FMEA) & die Risikoprioritätszahl (RPZ).

Erstellung einer KFMEA / Design FMEAMehr Infos unter https//wwwqualityde/lexikon/fmea/FMEA Seminare https//wwwqualityde/seminare/fmea/. Begun in the 1940s by the US military, failure modes and effects analysis (FMEA) is a stepbystep approach for identifying all possible failures in a design, a manufacturing or assembly process, or a product or service It is a common process analysis tool "Failure modes" means the ways, or modes, in which something might fail. FMEA and Control Plans 0 Sep 2, 19 K AIAG/VDA FMEA & Process Control Plans FMEA and Control Plans 0 Aug 6, 19 D FMEAMSR in the AIAGVDA Aligned Handbook What is it?.

Funny Stuff Jokes and Humour 2 Jul 2, 19 AIAG VDA FMEA Handbook 19 something. How to implement of FMEA with ISO Failure Mode and Effects Analysis (FMEA) is a core aspect of risk management and risk analysis in medical devices FMEA is essentially about analyzing the reasons for which a problem arises and the effects it has on the system. Failure Mode and Effects Analysis (FMEA) is a method designed to Identify and fully understand potential failure modes and their causes, and the effects of failure on the system or end users, for a given product or process.

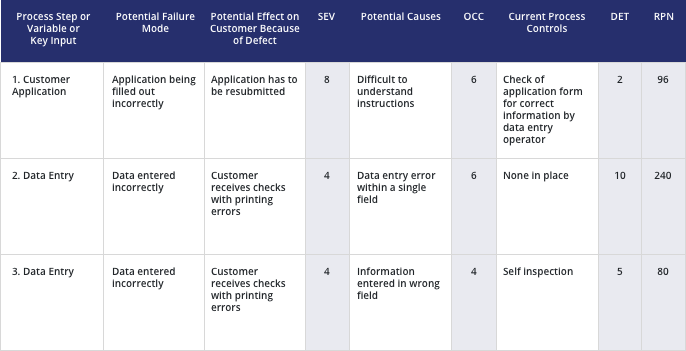

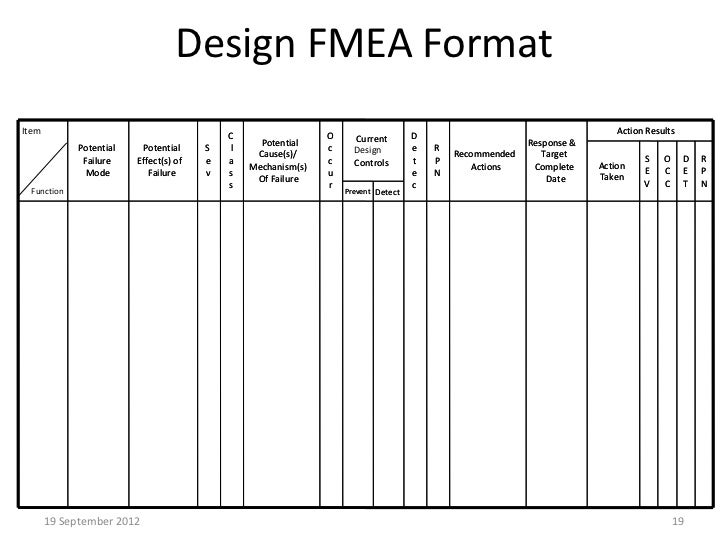

The failure modes, causes, and effects for each step;. FMEA — failure mode and effects analysis — is a tool for identifying potential problems and their impact Problems and defects are expensive Customers understandably place high expectations on manufacturers and service providers to deliver quality and reliability. Click on View Report to see the FMEA Tool of a specific organization or individual — including the detailed FMEA that outlines the steps in the process;.

Healthcare failure mode and effect analysis (FMEA) is a method used to proactively detect risks to the patient in a particular healthcare process and correct potential errors before adverse events occur FMEA is a systematic, multidisciplinary teambased approach to error prevention and enhancing patient safety. FMEA Failure Mode and Effects Analysis (FMEA) is a methodology used to identify potential failure modes for systems, products or processes Risks are identified and ranked in terms of importance – each risk has one or more contingencies or corrective actions which would be used to address the most serious concerns. The FMEA Sample tab has the actual illustration an analysis of possible failure modes for a firewall The Guidelines provide additional notes on the FMEA method, including a stepbystep process outline The Severity, Probability and Detectability tabs have tables demonstrating scales commonly used to rank risks by these criteria.

FMEA is a systematic approach for evaluation and identification of potential failures associated with the design and operation of pipeline valves A literature review is included to provide more detailed information about the operation, components, and failure modes of pipeline ball valves. The FMEA method is also used for nonmanufacturing industries such as marketing, sales, management, maintenance, etc FMEA is applicable for analysis of types and consequences of failure of product, process, system, services, etc #KAGroup #KeepAhead #dictionary. Failure Mode and Effects Analysis, or FMEA, is a methodology aimed at allowing organizations to anticipate failure during the design stage by identifying all of the possible failures in a design or manufacturing process Developed in the 1950s, FMEA was one of the earliest structured reliability improvement methods.

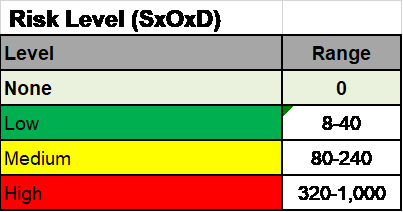

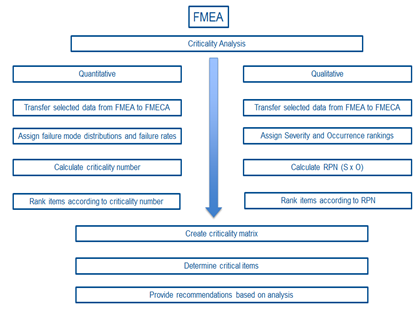

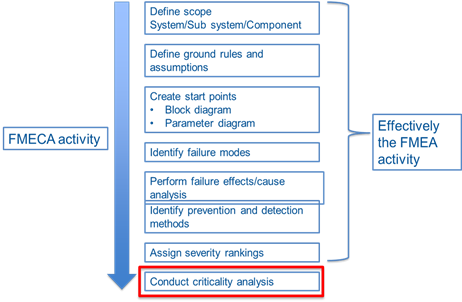

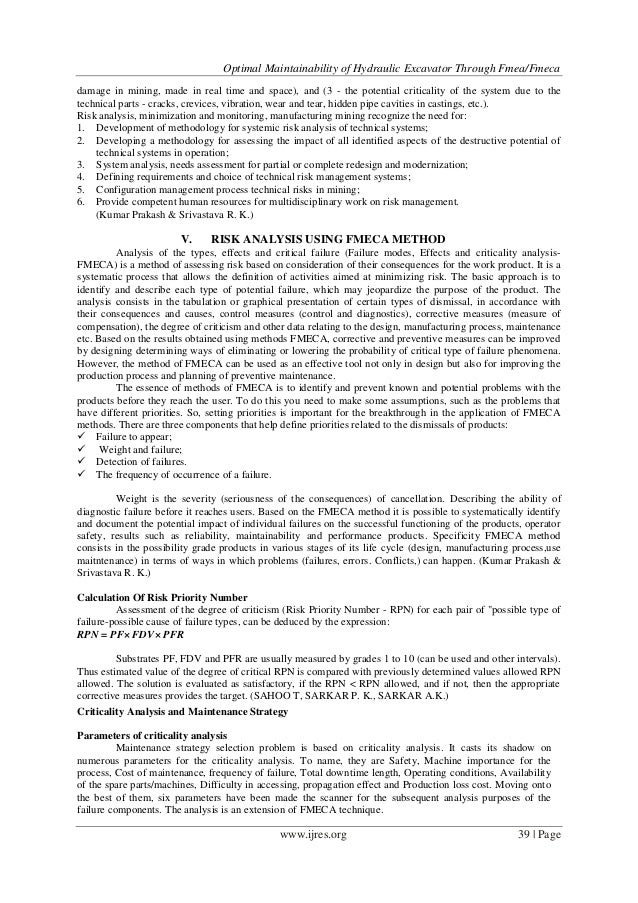

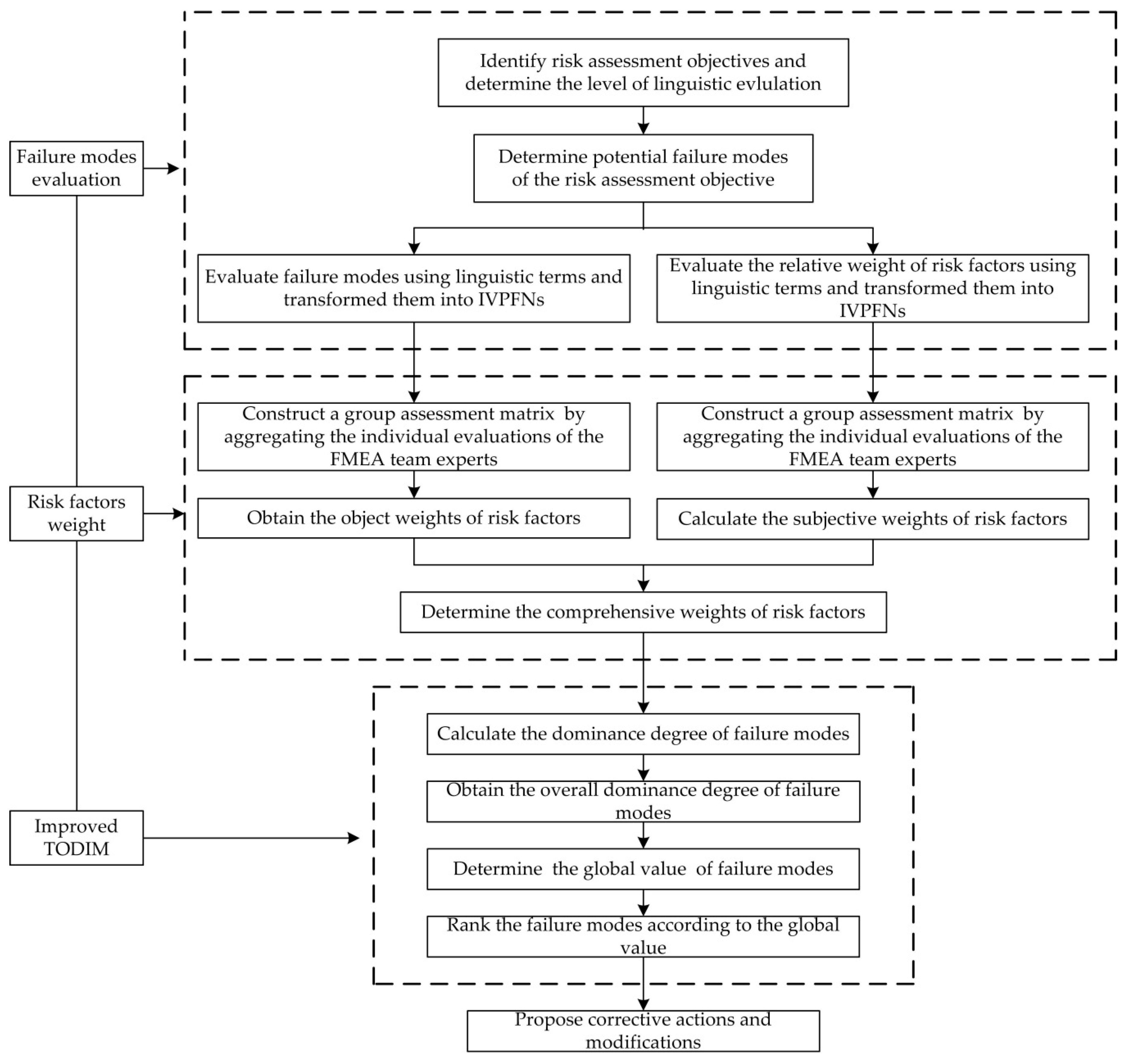

Failure Modes and Effects Analysis (FMEA) is a common technique used in several manufacturing and service industries for eliminating failures and potential problems using the evaluation of failure modes of a new or an existing product, process, or system. FMEA is a systematic method used to analyze manufactured products and processes by qualitatively determining their failure modes, and the causes and effects of these failure modes Subsequently, the risk is quantitatively classified to better prioritize corrective and preventive actions and the risk reduction measures required by the analysis. This type of analysis is a form of a family of reliability analyses called failure mode and effects analysis (FMEA) and FMECA The chief difference between the FMEA/FMECA and the fault hazard analysis is a matter of depth.

FMEA is a systematic approach for evaluation and identification of potential failures associated with the design and operation of pipeline valves A literature review is included to provide more detailed information about the operation, components, and failure modes of pipeline ball valves. – FMEA is a tool originated by SAE reliability engineers It continues to be associated by many with reliability engineering It analyzes potential effects caused by system elements ceasing to behave as intended In casual use, “FMEA” also means “FMECA”– the distinction between the two has become blurred. – FMEA is a tool originated by SAE reliability engineers It continues to be associated by many with reliability engineering It analyzes potential effects caused by system elements ceasing to behave as intended In casual use, “FMEA” also means “FMECA”– the distinction between the two has become blurred.

Erstellung einer KFMEA / Design FMEAMehr Infos unter https//wwwqualityde/lexikon/fmea/FMEA Seminare https//wwwqualityde/seminare/fmea/. FMEA stands for Failure Mode and Effects Analysis, and it represents a stepbystep approach one can take to identify all possible failures (in a certain design, product, process, or service) and assess the possible effects of those failures. And the Risk Priority Number (RPN) for each step as well as for the entire process Reports are sorted by Process Category, then.

Failure Modes and Effects Analysis (FMEA) is a systematic technique of identifying, analyzing and preventing product and process problems before they occur Its main and highlight activities that eradicate or decrease the probability of the possible breakdown event and document the reports of the advancement. A multidisciplinary and multiinstitutional working group applied the Failure Mode and Effects Analysis (FMEA) approach to assess the risks for patients undergoing Stereotactic Body Radiation Therapy (SBRT) treatments for lesions located in spine and liver in two CyberKnife® Centres. Click on View Report to see the FMEA Tool of a specific organization or individual — including the detailed FMEA that outlines the steps in the process;.

FMEAk készítéséhez a csapatmunka javasolt A rendszer vagy termék fe lelős irányítja az FMEA csapat munkáját A tervezet felelősnek be kell von nia minden érintett terület egyegy képviselőjét. FMEA is an effective proactive riskassessment tool and is a continuous process which can be continued in phases The corrective actions taken resulted in reduction in RPN, subjected to further evaluation and usage by others depending on the facility type. FMEA is a systematic approach for evaluation and identification of potential failures associated with the design and operation of pipeline valves A literature review is included to provide more detailed information about the operation, components, and failure modes of pipeline ball valves.

• Failure Mode and Effects Analysis (FMEA) is an engineering analysis tool used to identify and prevent failures before they actually happen • DFMEA are used early in the development phase while the design can be changed as a Design Verification method • The most efficient way to do a DFMEA is during the design review when, the entire design is being reviewed and the FMEA form can be used as a guide • DFMEA IS NOT A FORM TO FILL OUT FOR COMPLIANCE REASONS September 15, 16 Page 5. Erstellung einer KFMEA / Design FMEAMehr Infos unter https//wwwqualityde/lexikon/fmea/FMEA Seminare https//wwwqualityde/seminare/fmea/. • Failure Mode & Effects Analysis is an advanced quality improvement tool • FMEA is a technique used to identify, prioritize and eliminate potential failures from the system, design or process before they reach the customer • It provides a discipline for documenting this analysis for future use and continuous process improvement 6.

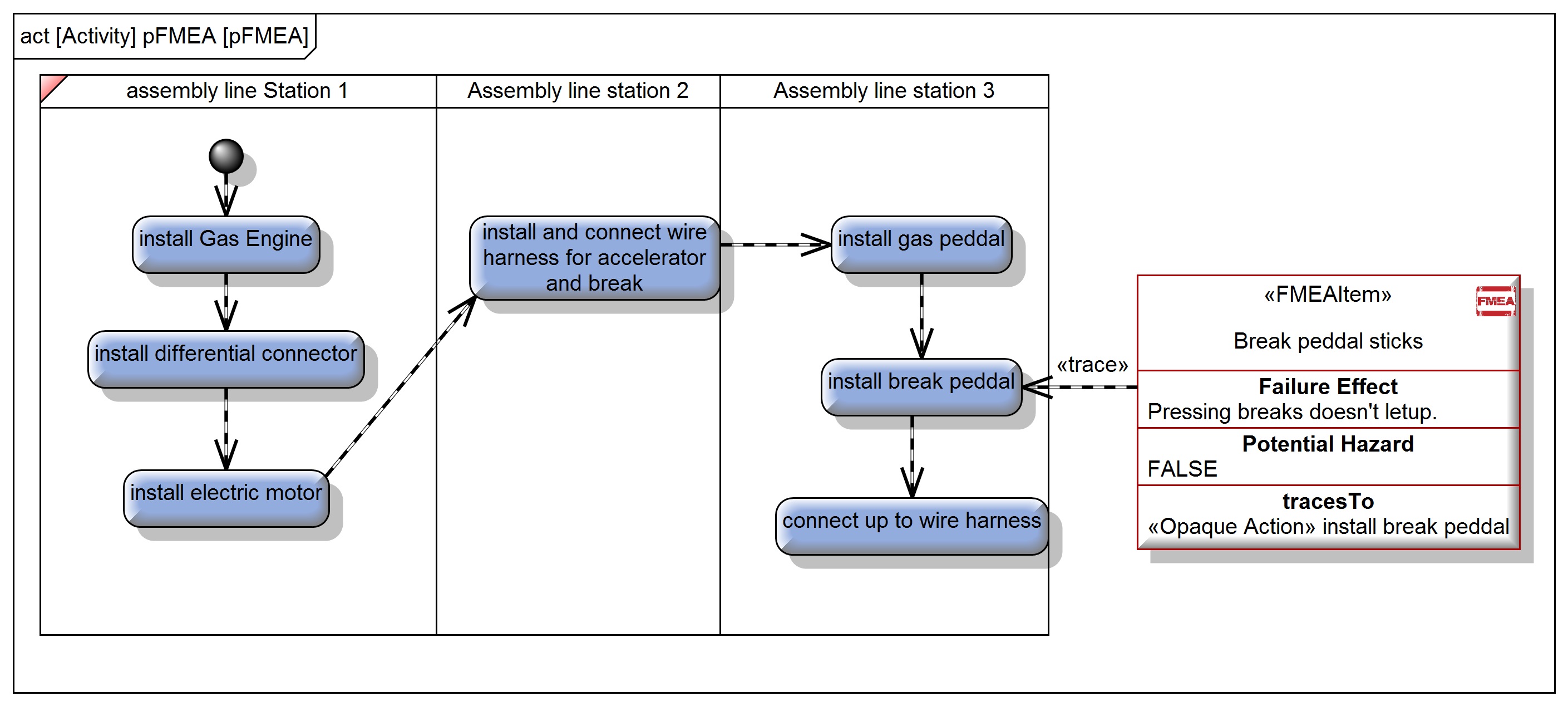

FMEA involves a multidisciplinary team mapping out a highrisk process of care, identifying the failures that can occur, and then characterising each of these in terms of probability of occurrence, severity of effects and detectability, to give a risk priority number used to identify failures most in need of attention. Abstract In order to reduce risks of failure, industries use a methodology called Failure Mode and Effects Analysis (FMEA) in terms of the Risk Priority Number (RPN) The RPN number is a product of ordinal scale variables, severity (S), occurrence (O) and detection (D) and product of such ordinal variables is debatable. A Process Failure Mode Effects Analysis (PFMEA) is a structured analytical tool used by an organization, business unit, or crossfunctional team to identify and evaluate the potential failures of a process PFMEA helps to establish the impact of the failure, and identify and prioritize the action items with the goal of alleviating risk.

The FMEA method is also used for nonmanufacturing industries such as marketing, sales, management, maintenance, etc FMEA is applicable for analysis of types and consequences of failure of product, process, system, services, etc #KAGroup #KeepAhead #dictionary. What is FMEA (Failure Mode and Effects Analysis)?. • Failure Mode and Effects Analysis (FMEA) is an engineering analysis tool used to identify and prevent failures before they actually happen • DFMEA are used early in the development phase while the design can be changed as a Design Verification method • The most efficient way to do a DFMEA is during the design review when, the entire design is being reviewed and the FMEA form can be used as a guide • DFMEA IS NOT A FORM TO FILL OUT FOR COMPLIANCE REASONS September 15, 16 Page 5.

The failure modes, causes, and effects for each step;. Often written with "failure modes" in plural) is the process of reviewing as many components, assemblies, and subsystems as possible to identify potential failure modes in a system and their causes and effectsFor each component, the failure modes and their resulting effects on the rest of the system are recorded in a specific FMEA worksheet. FMEA also serves to systematically analyze existing defect images and thus enables product or process improvement after the planning phases have already been completed The systematic approach is.

Kindle File Format Aiag Fmea 5th Edition This is likewise one of the factors by obtaining the soft documents of this aiag fmea 5th edition by online You might not require more mature to spend to go to the book inauguration as competently as search for them. FMEA and Control Plans 2 Mar 30, 19 N PFMEA repetitive failure modes in subsecuent stations FMEA and Control Plans 1 Mar 24, 19 T DFMEA/PFMEA and SCCAF alignment FMEA and Control Plans 19 Feb 13, 19 N. The factors considered in traditional failure mode and effect analysis (FMEA) for risk assessment are frequency of occurrence (Sf), severity (S) and detectability (Sd) of an item failure mode.

FMEA FMEA (Failure Mode and Effects Analysis, analýza možného výskytu a vlivu vad) je analytická metoda, jejímž cílem je identifikovat místa možného vzniku vad ve výrobě Tato metoda je často používaná při výrobě díky jejímu možnému převedení jako standardu pro ostatní výrobky. FMEA and Control Plans 4 Jul 30, 19 Catching up on the new FMEA book!. Healthcare failure mode and effect analysis (FMEA) is a method used to proactively detect risks to the patient in a particular healthcare process and correct potential errors before adverse events occur FMEA is a systematic, multidisciplinary teambased approach to error prevention and enhancing patient safety.

And the Risk Priority Number (RPN) for each step as well as for the entire process Reports are sorted by Process Category, then. The factors considered in traditional failure mode and effect analysis (FMEA) for risk assessment are frequency of occurrence (Sf), severity (S) and detectability (Sd) of an item failure mode. FMEAk készítéséhez a csapatmunka javasolt A rendszer vagy termék fe lelős irányítja az FMEA csapat munkáját A tervezet felelősnek be kell von nia minden érintett terület egyegy képviselőjét.

Kindle File Format Aiag Fmea 5th Edition This is likewise one of the factors by obtaining the soft documents of this aiag fmea 5th edition by online You might not require more mature to spend to go to the book inauguration as competently as search for them. Failure mode and effects analysis (FMEA;. Teoh PC, Case K (04) FMEA through knowledge modeling J Mater Process Technol –260 Article Google Scholar 44 Teoh PC, Case K (05) An evaluation of failure modes and effect analysis generating method for conceptual design Int J Comput Integr Manuf 18(4)279–293.

→ "FMEA (Failure Mode and Effects Analysis) is an Analytical Technique that combines the technology and Experience of People in identifying predictable failure modes of a Product or Process and planning for its elimination" ➥ FMEA can be explained as a group of activities intended to. One of the most established risk assessment methods is Failure Mode and Effect Analysis (FMEA) – a reliability analysis and risk assessment tool widely used in various industries The traditional FMEA is using a Risk Priority Number (RPN) ranking system to evaluate and identify the risk level of failures, and to prioritize actions. The Ultimate Guide to 510(k) Submissions aims to put the requirements in easytounderstand terms and includes some helpful, actionable and practical tips you can begin to implement immediately The goal of this guide is to provide you stepbystep guidance through each part of the FDA 510(k) submission process and help improve your time to market.

Failure Modes and Effects Analysis (FMEA) is a systematic technique of identifying, analyzing and preventing product and process problems before they occur Its main and highlight activities that eradicate or decrease the probability of the possible breakdown event and document the reports of the advancement. FMEA is a tool that will allow nursing homes to proactively identify and reduce potential failures within an existing or a proposed process FMEA is very similar to what most people do every day We try to anticipate what might go wrong and do what we can to prevent this from happening or minimize the effects. Failure Mode and Effects Analysis is an established instrument for identifying and correcting errors or potential sources of errors in the design of products and the associated manufacturing and assembly processes Due to the distinction between system, design and process FMEA, Porsche Engineering takes all potential error sources into account.

FMEA and Control Plans 1 Apr 15, 19 K PFMEA (Process FMEA) Can be common for 3000 products?. The Design FMEA analyzes the functions of a system, subsystem, or component of interest as defined by the boundary shown on the Blo ck/Boundary Diagram, the r elationship between its underlying elements, and to external elements outside the system boundary. FMEA Facilitation, Software & FMEA Methodology Trainings "Gavin has a great enthusiasm for his work and was a pleasure to work with on the project DB11, Taraf & Vulcan, his knowledge and skill in Failure Mode and Effect Analysis is an asset to any company he works with He is also a nice chap with a great sense of humour!.

Fmea Dr K Baranidhran

Konstruktions Fmea

Www Designsociety Org Download Publication Application Of The Fmea During The Product Development Process E2 80 93 Dependencies Between Level Of Information And Quality Of Result

K Fmea のギャラリー

A Novel Multiple Criteria Decision Making Based Fmea Model For Risk Assessment Sciencedirect

2

Fmea Functional Safety Porsche Engineering

Process Failure Mode And Effect Analysis Planning Preparation Step1 Systems Theory Systems Science

Irjet Risks Prioritization Using Fmea Method A Case Study

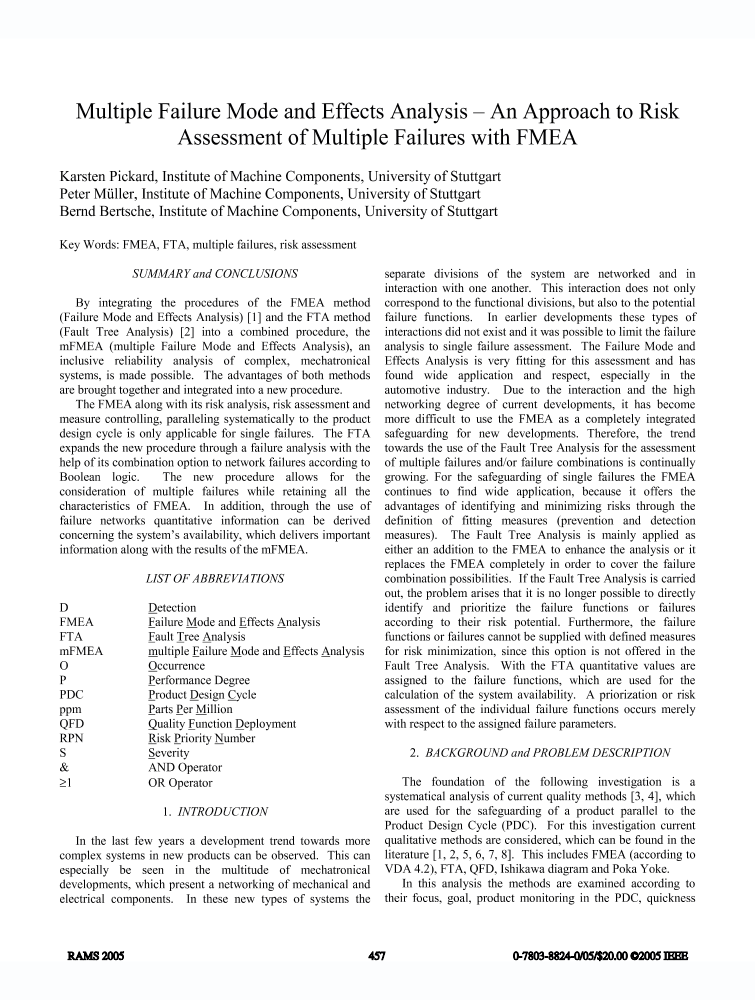

Multiple Failure Mode And Effects Analysis An Approach To Risk Assessment Of Multiple Failures With Fmea Ieee Conference Publication

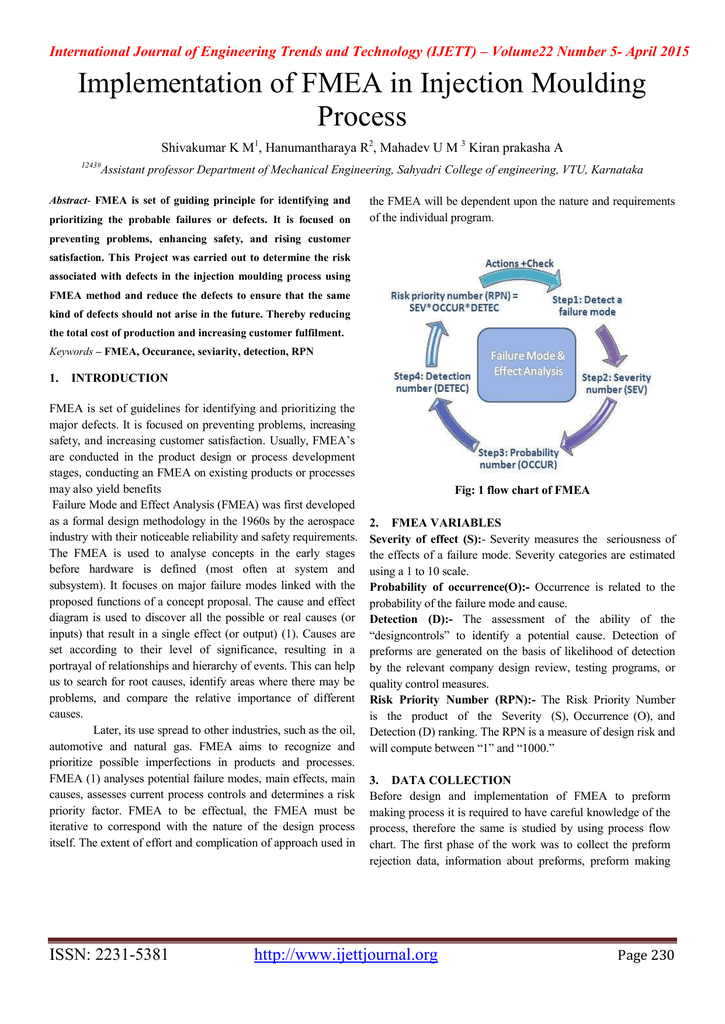

Implementation Of Fmea In Injection Moulding Process

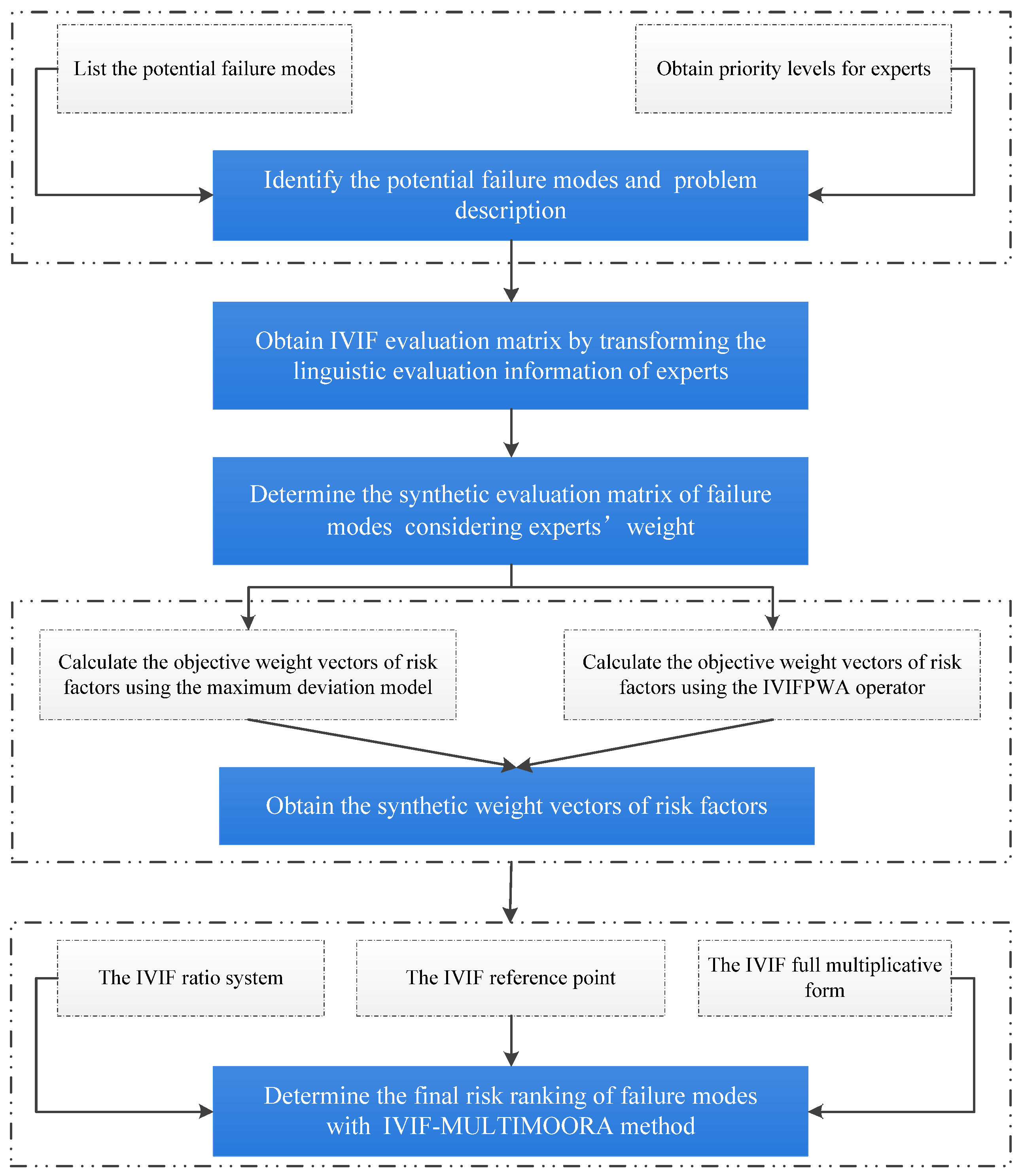

Information Free Full Text Failure Mode And Effect Analysis Fmea With Extended Multimoora Method Based On Interval Valued Intuitionistic Fuzzy Set Application In Operational Risk Evaluation For Infrastructure Html

What Is The Fmea And How To Do It Electronics Semiconductor

Correlating Failure Mode Effect Analysis Fmea Overall Equipment Effectiveness Oee Topic Of Research Paper In Materials Engineering Download Scholarly Article Pdf And Read For Free On Cyberleninka Open Science Hub

Failure Mode And Effect Analysis Fmea And Criticality Analysis Fmeca

Guide To Failure Mode And Effect Analysis Fmea Juran

ma Memberclicks Net Assets Docs Aiag Vda process fmea Pdf

The Consistency Analysis Of Failure Mode And Effect Analysis Fmea In Information Technology Risk Assessment Sciencedirect

Failure Mode And Effect Analysis Fmea Of Vertical Axis Wind Turbines Springerlink

Q Tbn And9gctoxyj5mkfwshi 7thxrecqumiodxakvlhrkydwppuntv0rf7rh Usqp Cau

Fmea Fehler Moglichkeits Und Einfluss Analyse Quality De

1

Risk Assessment For Qbd Why Fmea Fails Quality By Design For Biotech Pharmaceutical And Medical Devices

The Basics Of Fmea Semantic Scholar

Pdf Scenario Based Fmea A Life Cycle Cost Perspective Semantic Scholar

1

Design Fmea

Fmea K Sydster Et Al 08 Further Mathematics For Economic Analysis Pdf Document

Failure Mode And Effect Analysis Fmea Lean Six Sigma Total Quality Management Eng Youtube

Solved Question 6 2 Points An Fmea Was Performed On A K Chegg Com

Konstruktions Fmea

Www Lehigh Edu Intribos Resources Sae Fmea Pdf

Ssi Management Solutions Fmea

Fmea Dr K Baranidhran

Citeseerx Ist Psu Edu Viewdoc Download Doi 10 1 1 414 6274 Rep Rep1 Type Pdf

How To Complete The Failure Modes And Effects Analysis Fmea

Pdf Software System Reliability And Safety Assessment An Extended Fmea Approach

Q Tbn And9gcsn Etnnvz7ban 7 Ijgoc0iqadphcqqzfpshxionelmrct9npb Usqp Cau

How To Model Your Failure Mode Effects Analysis Fmea With Sysml

Risk Assessment For Blast Furnace Using Fmea

A Failure Mode And Effect Analysis Fmea Based Approach For Risk Assessment Of Scientific Processes In Non Regulated Research Laboratories Springerlink

Pdf Failure Mode And Effect Analysis On Safety Critical Components Of Space Travel

Application Of Failure Mode Effect Analysis Fmea For Efficient And Cost Effective Manufacturing A Case Study

Guide To Failure Mode And Effect Analysis Fmea Juran

Ijms Ut Ac Ir Article 2db7d26ebdad1c8a0 Pdf

Fmea Failure Mode And Effects Analysis

Www Designsociety Org Download Publication Application Of The Fmea During The Product Development Process E2 80 93 Dependencies Between Level Of Information And Quality Of Result

Www Designsociety Org Download Publication Application Of The Fmea During The Product Development Process E2 80 93 Dependencies Between Level Of Information And Quality Of Result

Failure Mode Effect Analysis Fmea Cips

Fmea Failure Mode And Effects Analysis Quality One

Fmea They Are Fantastic Here S Why Youtube

2

Why The Fmea Is My Equipment Not Reliable Road To Reliability

Fmea K Sydster Et Al 08 Further Mathematics For Economic Analysis Pdf Document

Globalplanninggroup Com Aiag Vda Alignment Training

A Failure Mode And Effect Analysis Fmea Based Approach For Risk Assessment Of Scientific Processes In Non Regulated Research Laboratories Springerlink

Fmea Archives Medical Device Academy Medical Device Academy

Design Fmea

Confused About Fmea And Fmeca Industry Forum

Relationship Of System Design And Process Fmea With C K Framework Download Scientific Diagram

A Novel Failure Mode And Effect Analysis Model For Machine Tool Risk Analysis Sciencedirect

Apem Journal Org Archives 18 Apem13 1 069 080 Pdf

Http Gvpress Com Journals Ijseia Vol12 No3 2 Pdf

Hse Risk Prioritization Of Molybdenum Operation Process Using Extended Fmea Approach Based On Fuzzy Bwm And Z Waspas Ios Press

Fmea Fehler Moglichkeits Und Einfluss Analyse Quality De

Full Text Evaluating Surgical Risk Using Fmea And Multimoora Methods Under A Sin Rmhp

Fmea K Fmea Design Fmea Youtube

Fmea Failure Mode And Effects And Criticality Analysis For Ghosting Part I Download Scientific Diagram

Fmea Design Process With C K Framework Download Scientific Diagram

Konstruktions Fmea

Www Designsociety Org Download Publication 369 From Fmea As A Problem Solving Method To A Design Oriented Process 3a Toward A Design Perspective Of Fmea

Expert System Supporting Failure Mode And Effect Analysis Fmea System Ekspertowy Wspomagajacy Analize Semantic Scholar

Failure Mode And Effect Analysis Software Softexpert Fmea

Why Should You Do An Fmea Innoval Technology Innoval Technology

Fmea Reliability Engineering Verification And Validation

What Is The Fmea And How To Do It Electronics Semiconductor

Fmea In Hindi Failure Mode And Effects Analysis Fmea Quality Management And Cute Images Meaning In Hindi

Optimal Maintainability Of Hydraulic Excavator Through Fmea Fmeca

Guide To Failure Mode And Effect Analysis Fmea Juran

Http Www Ijeit Com Vol 4 Issue 7 Ijeit 10 Pdf

Pcb Manfacturing Pcb Fabrication Pcba Pcb Assembly Application Of Fmea In Industry Production

Failure Mode And Effects Analysis Fmea How To Analyze Risks For Better Software Quality Satisfied Customers

Fmea Failure Mode And Effects Analysis Babtec

Pdf Modelling And Reasoning For Failure Modes And Effects Analysis Generation

Citeseerx Ist Psu Edu Viewdoc Download Doi 10 1 1 470 76 Rep Rep1 Type Pdf

Guide To Failure Mode And Effect Analysis Fmea Juran

Failure Mode And Effect Analysis Using Soft Set Theory And Copras Method Atlantis Press

The Consistency Analysis Of Failure Mode And Effect Analysis Fmea In Information Technology Risk Assessment Sciencedirect

Http Ijiet Com Wp Content Uploads 17 01 51 Pdf

Compare Apis Iq Software Iq Fmea Iq Fmea Pro Iq Rm Rm Pro

Mathematics Free Full Text Risk Assessment For Failure Mode And Effects Analysis Using The Bonferroni Mean And Todim Method Html

Solved Question 6 2 Points An Fmea Was Performed On A K Chegg Com

Severity Occurrence And Detection Criteria For Design Fmea Business Technology Engineering

Fmea What It Is And How It Works Youtube

Fmea Fehler Moglichkeits Und Einfluss Analyse Quality De

How To Complete The Failure Modes And Effects Analysis Fmea

Confused About Fmea And Fmeca Industry Forum

Optimal Maintainability Of Hydraulic Excavator Through Fmea Fmeca

Ieeexplore Ieee Org Iel7 17 Pdf

Fmea A Proactive Approach To Defect Prevention

Fmea How To Prevent The 100m British Airways Catastrophe Process Street Checklist Workflow And Sop Software

Mathematics Free Full Text Risk Assessment For Failure Mode And Effects Analysis Using The Bonferroni Mean And Todim Method Html

A Failure Mode And Effect Analysis Fmea Based Approach For Risk Assessment Of Scientific Processes In Non Regulated Research Laboratories Springerlink

How To Use Fmea For Risk Management In Iso 9001 15 By Gregorio Suarez Quality Road

What Is Fmea Failure Mode And Effective Analysis Definition From Whatis Com