Reflux Condenser Diagram

In this step we will cut the pipes connecting the column and condenser, along with the reflux pipes Start by cutting a 70mm section of 15mm piping This will connect the condenser and column of the still Next, cut two 150mm sections of 15mm pipe These will act as reflux points, and provide water to the condenser Cut a 70mm section of 28mm pipe.

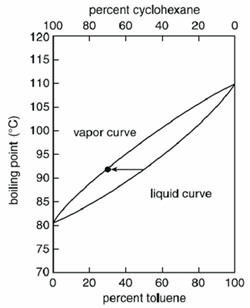

Reflux condenser diagram. Internal Valved Reflux While fundamentally the same as the external valved reflux still, the internal valved reflux still is a variation in which the forcing of reflux is brought inside the main column The result is a better, sleeker appearance, but this does not substantially alter the performance or basic operation of the column. The condenser is a total condenser, so it is not considered an equilibrium stage Set the external reflux ratio , as well as the methanol mole fractions in the distillate and bottoms streams, with sliders The number of stages is determined by stepping off stages starting at ;. Because a total condenser is used, the vapor leaving the top stage will have concentration y 1 =095 Consequently, it will have enthalpy H D =10,800 These values and the reflux ratio can be used to find the enthalpy coordinate for the D' point, H Dp R;D = 'quot(H;Dp , 3050) and so H Dp =,100 The D' point on the Hx diagram.

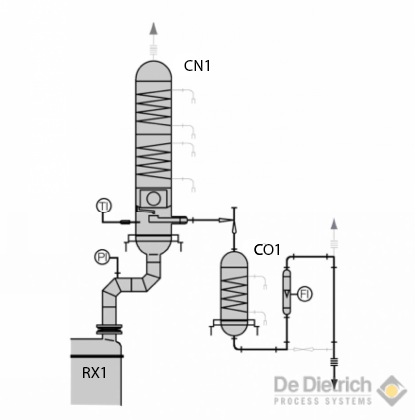

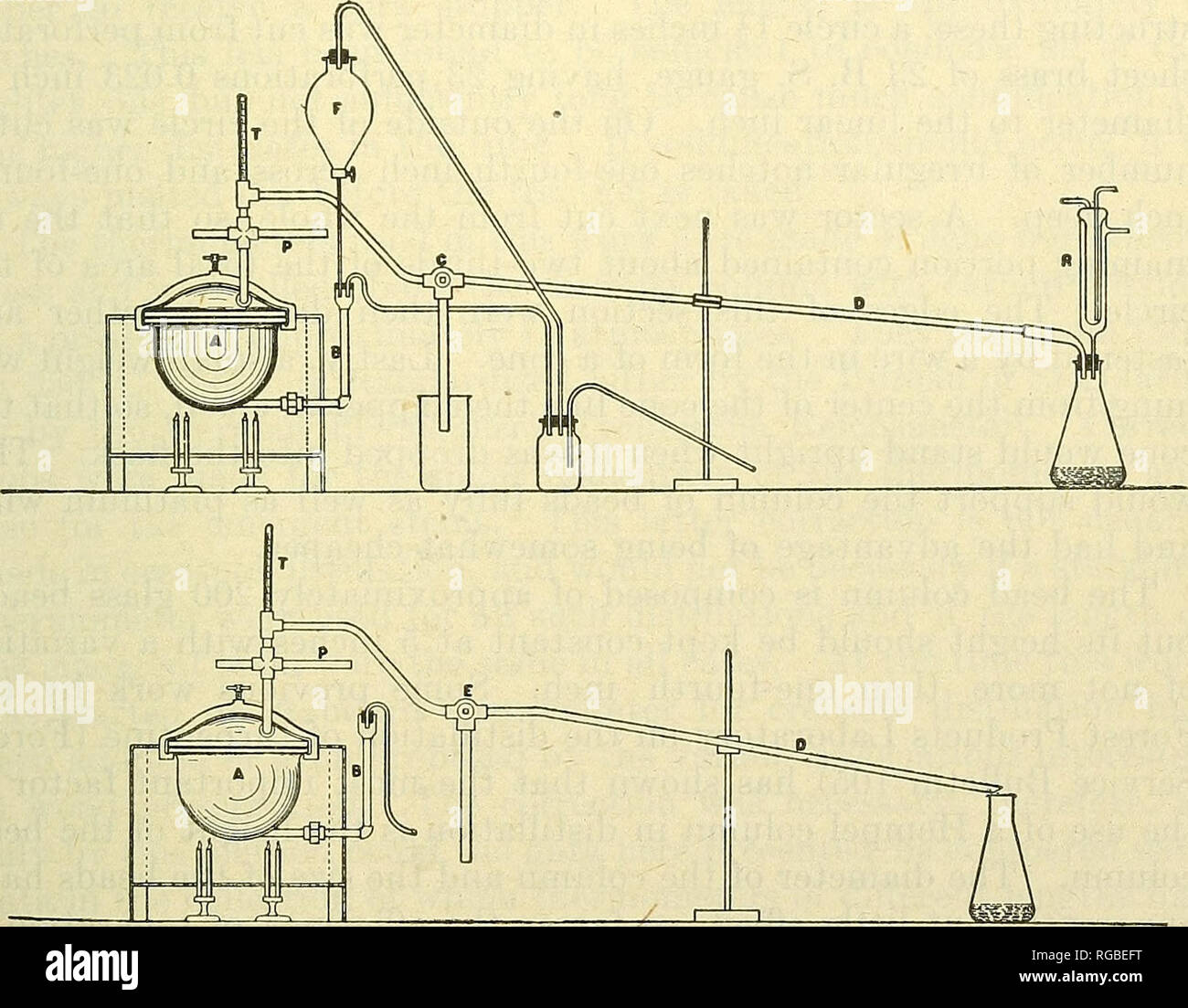

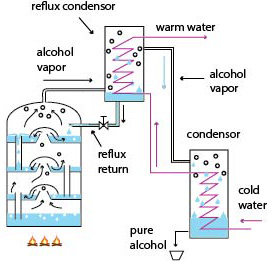

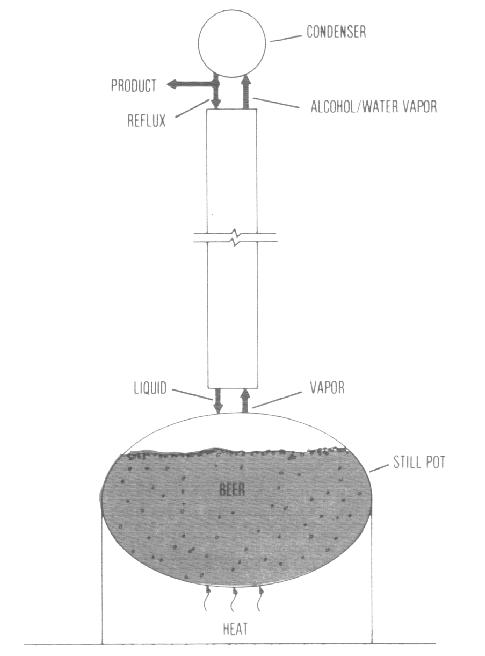

These plates will collect distillate from the condenser and allow it to exit the reflux still via the needle valve Using the template we printed off earlier trace out the slot on the column Use a hack saw or Dremel with a cutting wheel to cut the slot in the column If you use a grinder make sure the slot isn’t cut to wide. If you do this by design, then the vapor getting past the reflux condenser can be condensed by a second condenser and collected as product Consider the operation of the unit in diagram 414 Initially, tap A is wide open and tap B fully closed All the cooling water flows through the reflux condenser, and 100% reflux occurs. Pot Stills vs Column Stills The obvious starting point in any discussion of whiskey distillation is pot stills versus column stills A pot still at its simplest consists of a large kettle or pot which is heated from the bottom, boiling off the alcohol and allowing the vapors to be sent to a condenser and separated.

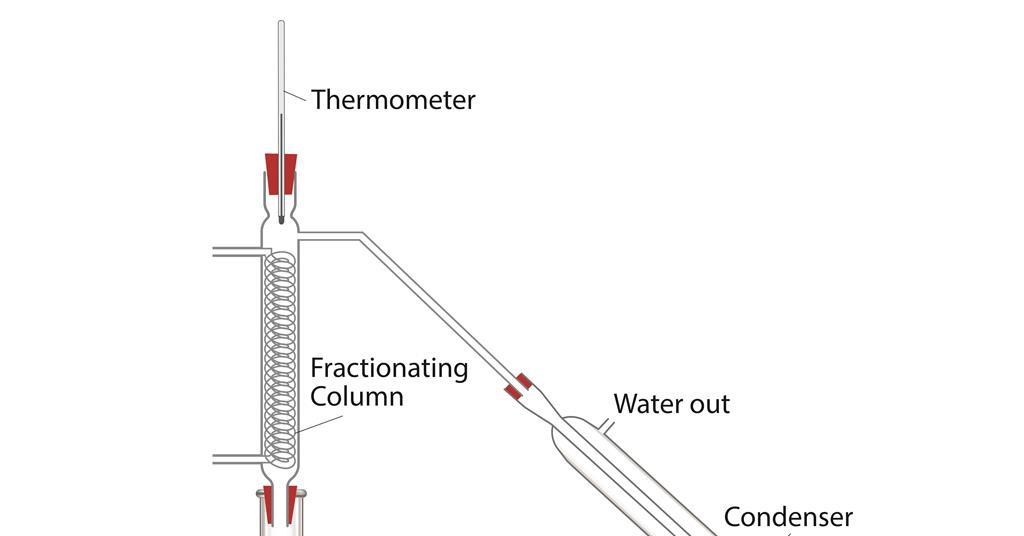

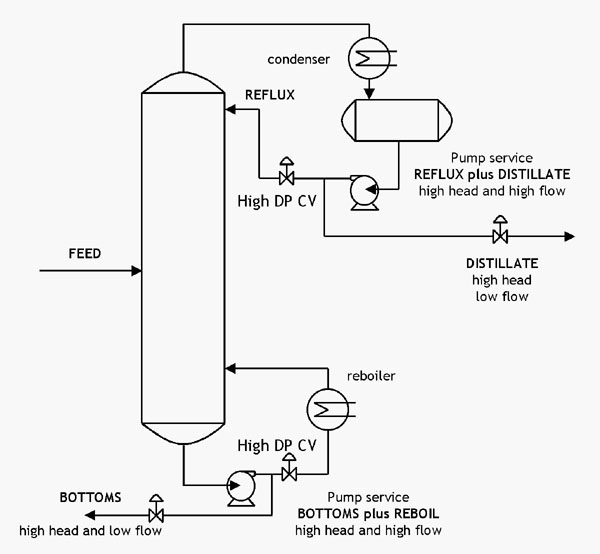

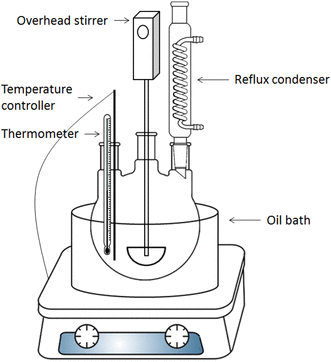

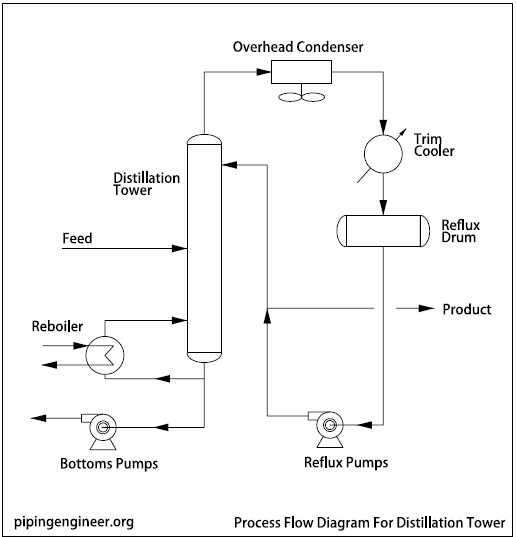

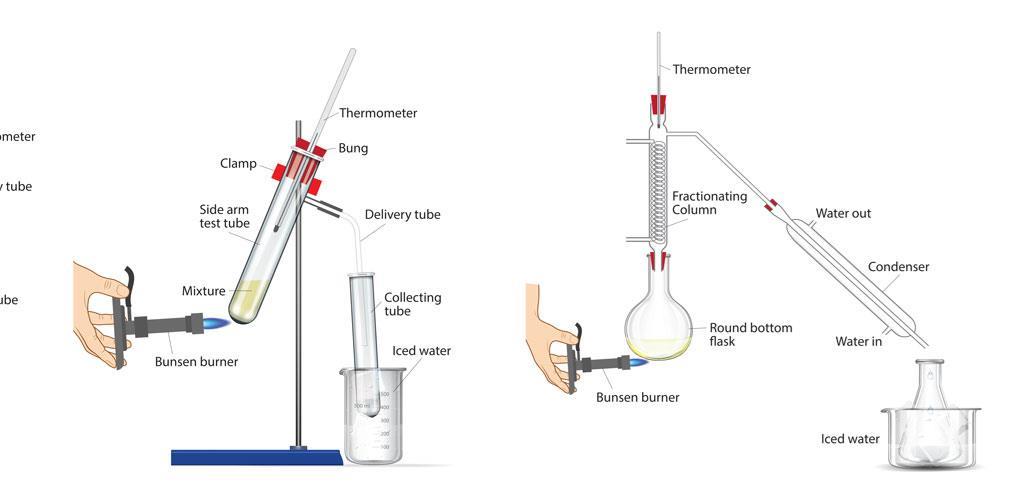

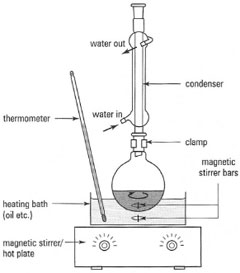

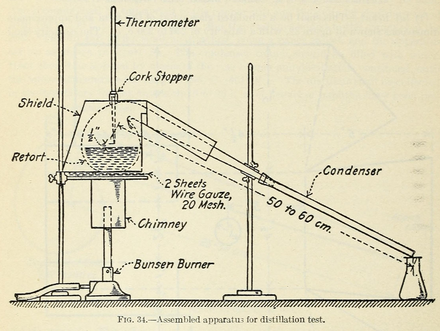

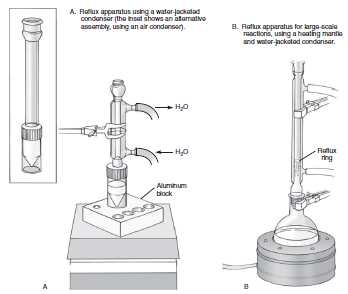

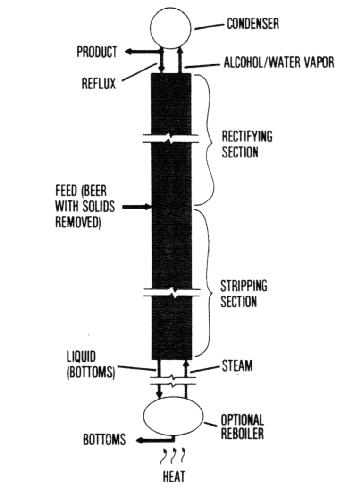

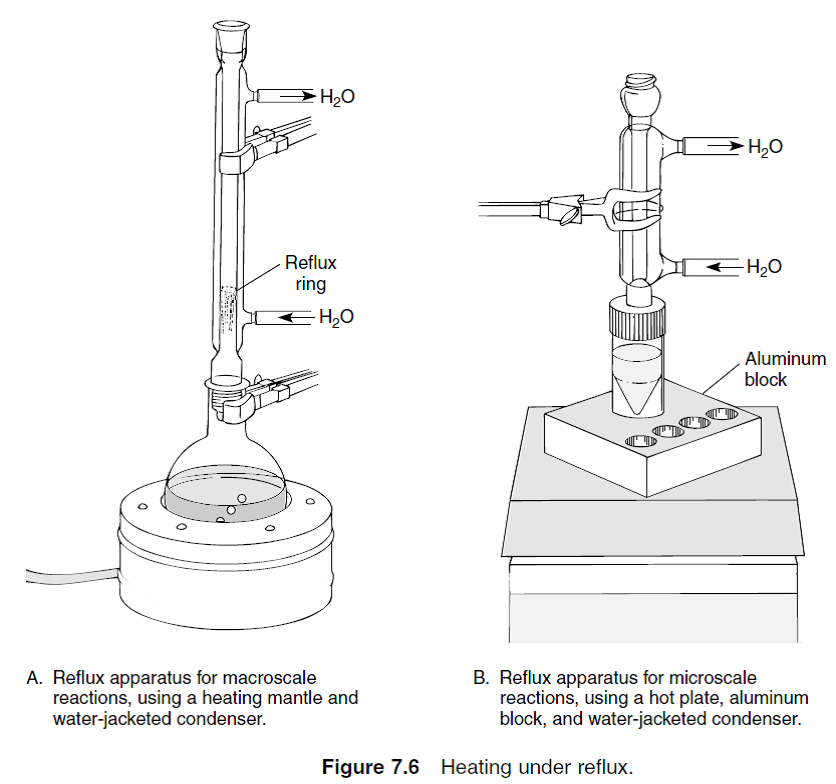

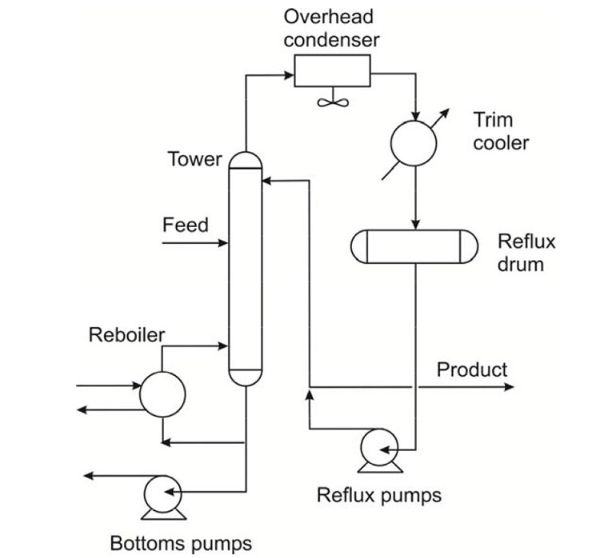

The diagram shows a typical reflux apparatus In a pot still, if the tube leading from the boiler to the condenser, the lyne arm, is angled upward, more liquid will have a chance to condense and flow back into the boiler leading to increased reflux Typical results can increase production as high as 50% over the basic worm type condenser. Reflux in industrial distillation See also Continuous distillation and Theoretical plate The use of reflux is widely practiced in industries that utilize largescale distillation columns such as petroleum refineries, petrochemical and chemical plants, and natural gas processing plants As shown in the schematic diagram of a typical industrial distillation column (Figure 1), reflux is the. Assumption Reflux return temperature is constant (overhead condenser duty varies to compensate for this) 537 Step 6) Determine inputs into ODE model Once all of the equations have been put into the model, all remaining unknown variables must be placed in a section so that the user can specify these input values when running the model.

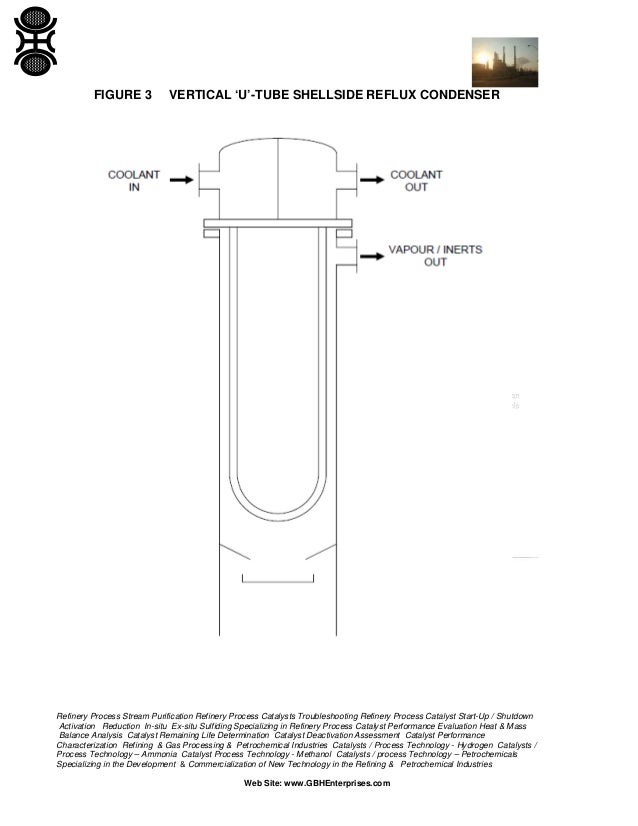

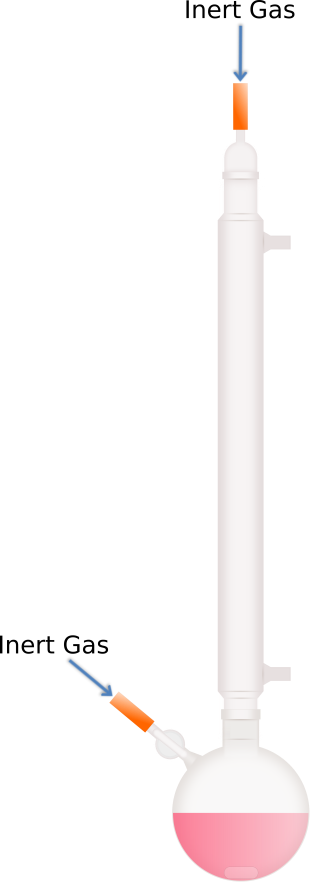

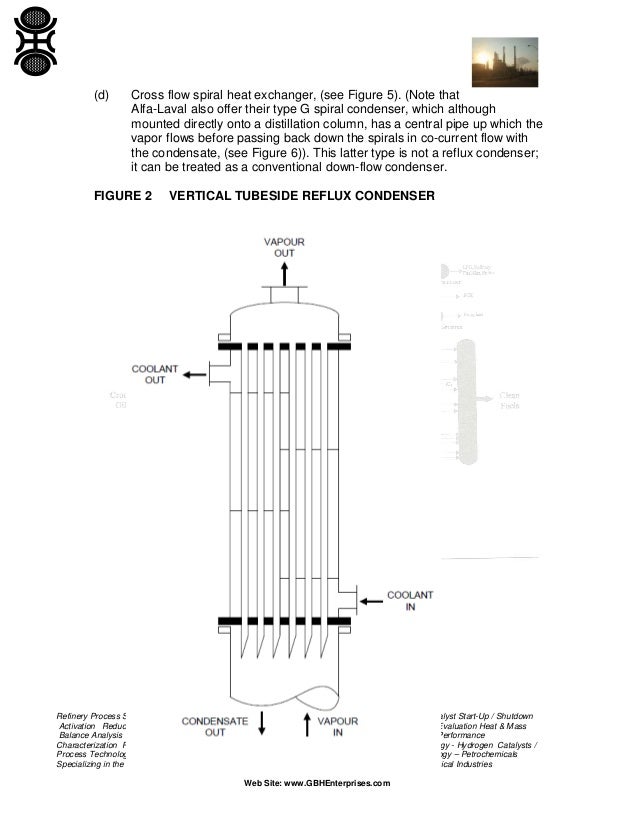

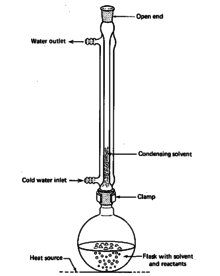

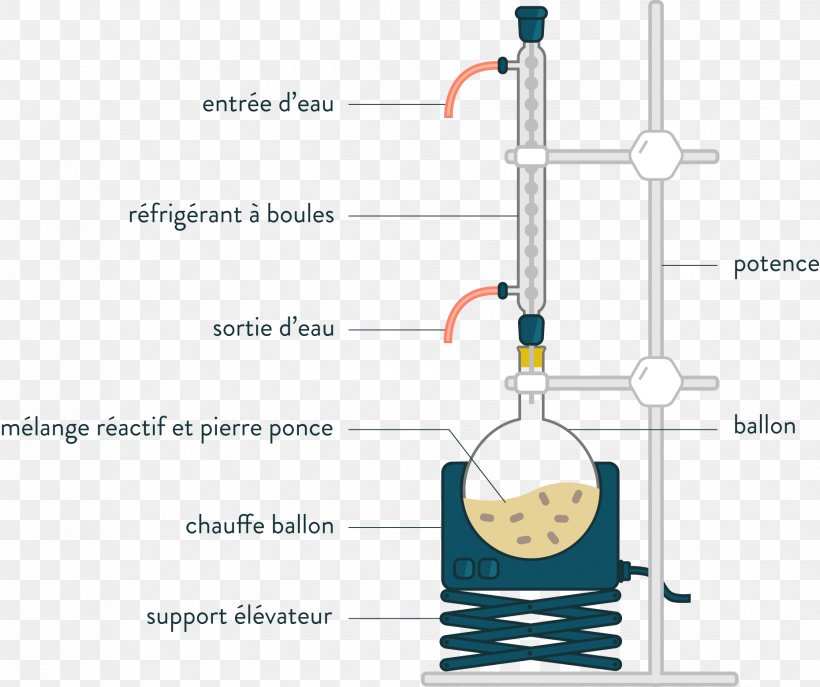

The "reflux apparatus" shown allows such heating;. A reflux condenser, also called a vent condenser or knockback condenser, is a vertical tubeside condenser in which the vapor flows upward, as indicated in Figure 117These units are typically used when relatively small amounts of light components are to be separated from a vapor mixture The heavier components condense and flow downward along the tube walls, while the light components remain. The condenser is connected to a receiving flask Conclusion Refluxing and distillation are chemical techniques used in many laboratories The main difference between reflux and distillation is that reflux method is used to complete a certain chemical reaction whereas distillation is used to separate components in a mixture Reference 1.

These plates will collect distillate from the condenser and allow it to exit the reflux still via the needle valve Using the template we printed off earlier trace out the slot on the column Use a hack saw or Dremel with a cutting wheel to cut the slot in the column If you use a grinder make sure the slot isn’t cut to wide. Process Flow Diagram Q High Temperature (Ambient) Q Low Temperature (Sub Ambient) Condenser Suction Drum Compressor Heat Exchanger JT Valve AccumulatorLNG out Rough “rule of thumb” 35 MW of shaft power per Mt/a for “efficient” liquefaction processes Where the magic happens GAS in Large amount of Energy Input Driver (not shown. Which is the better reflux condenser?.

The rising vapor comes from boiling LOX around the condenser/reboiler As the vapor climbs through the trays or packing, oxygen molecules condense and fall back to the sump The vapor at the top of the LP column is lowpurity nitrogen partially recondensed by the lean reflux sent from the top of the HP column. Browse Condensers in the NDS Technologies, Inc catalog including Allihn Condensers,Condenser, Cold Finger,Condenser, Dewar Type,Condenser, Friedrich, with TakeOff. (Source of diagram Wikipedia) Reflux involves heating the chemical reaction for a specific amount of time, while continually cooling the vapour produced back into liquid form, using a condenser The vapours produced above the reaction continually undergo condensation, returning to the flask as a condensate.

Diagram below shows the basic setup of Refluxing (Source of diagram Wikipedia) Reflux involves heating the chemical reaction for a specific amount of time, while continually cooling the vapour produced back into liquid form, using a condenser. The condenser is a total condenser, so it is not considered an equilibrium stage Set the external reflux ratio , as well as the methanol mole fractions in the distillate and bottoms streams, with sliders The number of stages is determined by stepping off stages starting at ;. When the Condenser is fully assembled it should look like the image to the right Building The Reflux Column of the Still The reflux column is the part of the Still that is responsible for producing high proof alcohol It does this by producing multiple distillations within the column To build the Reflux column we need to assemble a few.

In this step we will cut the pipes connecting the column and condenser, along with the reflux pipes Start by cutting a 70mm section of 15mm piping This will connect the condenser and column of the still Next, cut two 150mm sections of 15mm pipe These will act as reflux points, and provide water to the condenser Cut a 70mm section of 28mm pipe. The "reflux apparatus" shown allows such heating;. However, reducing the reflux and boilup ratios also reduces the cooling and heating requirements for the condenser and reboiler respectively since r = L/D and s = V/B To understand why, note that if F, x F , x D , and x B are fixed (which they are), then B and D are fixed by total mass balance for the distillation column.

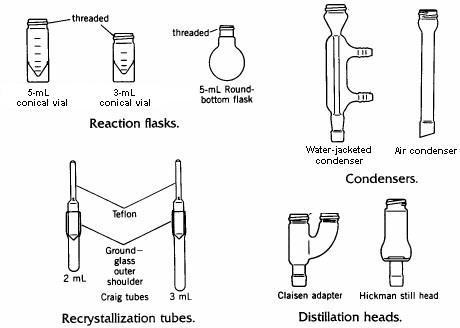

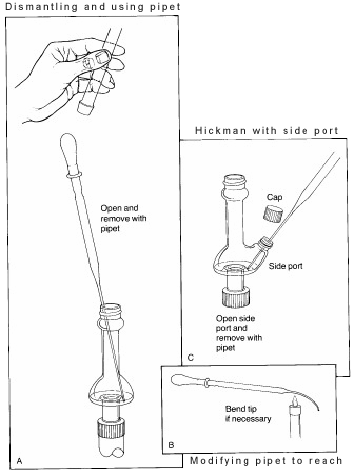

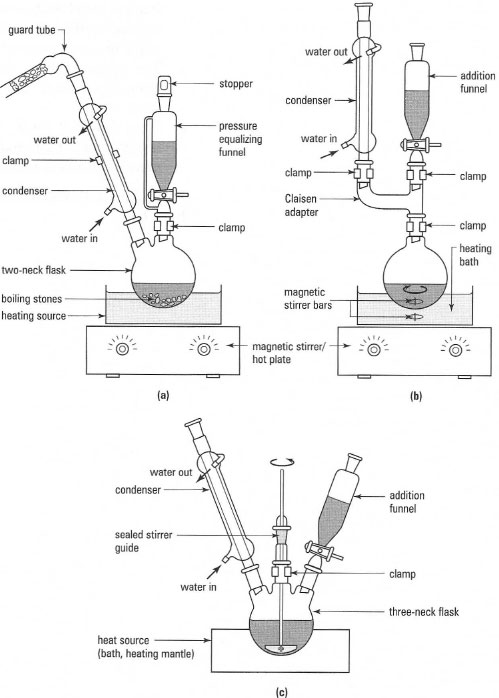

Internal Valved Reflux While fundamentally the same as the external valved reflux still, the internal valved reflux still is a variation in which the forcing of reflux is brought inside the main column The result is a better, sleeker appearance, but this does not substantially alter the performance or basic operation of the column. Exploded diagram of the connection between the conical vial and the reflux condenser 6 Watch the video below for a stepbystep description of how to setup a microscale reflux Performing a Reflux Reaction. A coolant source, usually water, for the condenser The procedure for setting up a simple reflux apparatus (Fig 161) is given in Box 161.

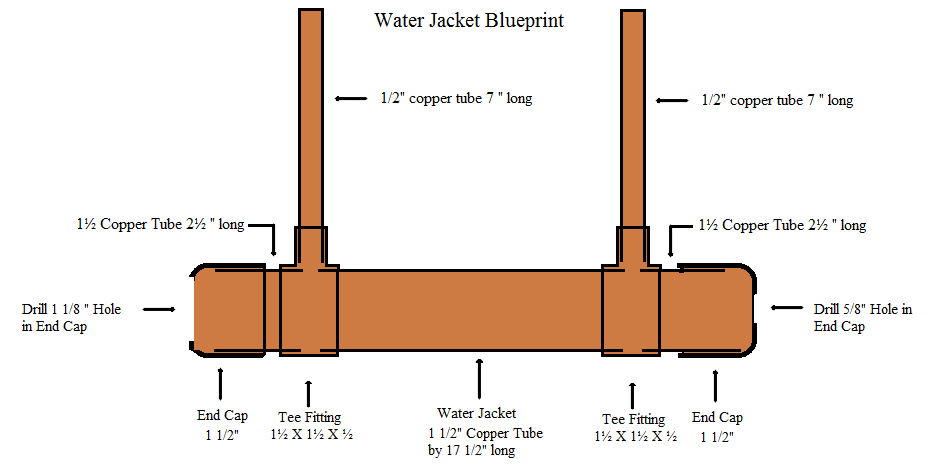

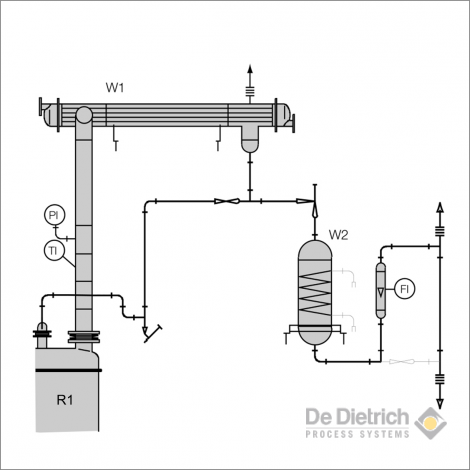

Shows the process flow diagram for a distillation tower containing sieve trays Feed Reboiler Condenser Overhead Reflux product Bottom liquid product Liquid Vapor Figure 441 Process flow of a distillation tower containing sieve trays The feed is normally introduced into the distillation at a location between the top and the bottom trays. The flow of water through the jacket condenses the alcohol vapor in the innertube This is a very efficient condenser It is used in both pot stilland reflux stilldesigns Liebig condenser This diagram shows 1/2" copper tubing going through 3/4"copper tubing with 2 3/4"x3/4"x1/2"tees and 2 3/4"x1/2 reducers. Overview of Reflux A reflux setup (Figure 158) allows for liquid to boil and condense, with the condensed liquid returning to the original flask A reflux setup is analogous to a distillation, with the main difference being the vertical placement of the condenser The liquid remains at the boiling point of the solvent (or solution) during active reflux.

Reflux is a technique involving the condensation of vapors and the return of this condensate to the system from which it originated vapours produced from the mixture are condensed by the condenser, The diagram shows a typical reflux apparatus. Allihn vs friedrich from the little bit of info i've read it seems like the friedrich is the way to go i have a 0mm allihn that serves me well for a myriad of refluxing tasks but i am in need of a 400mm reflux condenser so i'm thinking of getting a friedrich. Reflux System in the Amine Plant Reflux is a process where a fluid is removed from a vessel, condensed and returned to the vessel to enhance the process The reflux system consists of reflux condenser, accumulator and pump Overhead vapor from the stripper mainly consisting of water vapor and acid gases passed through the reflux condenser which condenses most of the water vapor and small.

Rev 01/07) CG10 Reflux Condensation Temperature Profiles (02) Q64 Heat Transfer Method for Condensation of Immiscible Mixtures (02). The goal here is to allow plans and diagrams to remain readily accessable and not get burried by pages and pages of chatter Hopefully Samohon will load this thing with some really nice information Heres a Double wound Reflux condenser with Coldfinger DoubleReflux(Small)jpg. Learn Log Mean Temperature Difference for Condenser and Evaporator l GATE Mechanical l Heat Transfer Visit our Website for more GATE Material, Guidance.

Reflux is a technique involving the condensation of vapors and the return of this condensate to the system from which it originated It is used in industrial 1 and laboratory 2 distillationsIt is also used in chemistry to supply energy to reactions over a long period of time Reflux in industrial distillation The term reflux 1 3 4 is very widely used in industries that utilize. Condenser, Reflux, 415mm, 24/40 Joint, Removable Hose Connections, 250mm Jacket Length Reflux condenser similar to CG1213 but with detachable hose connections Connections are made of polypropylene and provide a safe and easy way of connecting and disconnecting flexible tubing to the condenser. The partial reboiler is an equilibrium stage The number of.

Condenser Figure 449 Distillation column operation at total reflux The minimum number of equilibrium trays can also be approximated by Fenske equation, Nm = ( ) 1 log 1 log D B D B ave x x x x α − − (4422) In this equation αave = ( α1αB) 1/2 where α 1 is the relative volatility of the overhead vapor and. The vapor flows upward through the elbow, and the reflux runs back down it past a sampling point There are two ways to construct the sampling point, and both are shown in the diagram In one, a tube is set into the bottom of the delivery/return elbow, and all the reflux from the condenser flows over the opening of the sampling tube. The reflux condenser must be designed such that vapor velocity is less than the flooding velocity This is a limiting velocity above which drainage of condensate is irregular Divide the temperature/enthalpy diagram into a number of zones such that the curves of both the condensing stream and the coolant can be regarded as being reasonably.

DIAGRAM OF SHELLANDTUBE CONDENSER In the first series of tests the full effective condensing surface of 251 sq ft was utilized For the second series the level of the liquid ammonia in the lower part of the shell was maintained at a height of 621 ft by means of a drain pipe as shown in Fig 1, thus blocking off. It allows the reaction to be carried out at the boiling point of the solvent and yet it prevents loss of solvent or reagent due to evaporation A condenser is attached to the boiling flask and is clamped in an upright postion, the "reflux position", and cooling. CG9 Reflux Condenser Design State of the Art (1998;.

BUILDING A HOME DISTILLATION APPARATUS 7 C1hapter Introduction Government Regulations S o you’re interested in building a still In the US (and many other countries) I guess you know that doing that is just not the politically correct thing to do. Complete apparatus includes Airflux aluminum heat sink, removable glass condenser, and boiling flask Use with flasks up to 250 mL size and heating mantles with 60 W max output Condensers can be mounted in tandem* for flasks sizes up to 1 L and 300 W heating mantles with a controller for steady reflux rate. The basic components for a reflux apparatus are a reaction flask;.

It allows the reaction to be carried out at the boiling point of the solvent and yet it prevents loss of solvent or reagent due to evaporation A condenser is attached to the boiling flask and is clamped in an upright postion, the "reflux position", and cooling. Reflux Splitter Used to set the desired reflux ratio by switching the condensate flow from the reflux position to the distillate position a predetermined amount of time each The default (power OFF) position for the reflux splitter is for total reflux The timer to change the time allocated to each position is located on the rear of the apparatus. This flow management (FM) design of reflux still has been designed to create high percentage pure neutral spirit The FM technology used in this design makes this process robust and easy to use No need to worry about water pressures and fine tuning of water flow speeds The FM design gives you direct control of the reflux ratio and therefore the purity of your end product It’s never been.

A reflux condenser, also called a vent condenser or knockback condenser, is a vertical tubeside condenser in which the vapor flows upward, as indicated in Figure 117These units are typically used when relatively small amounts of light components are to be separated from a vapor mixture The heavier components condense and flow downward along the tube walls, while the light components remain. The condenser is mainly used in the distillation process A distillation is the separation of two liquids by heating The liquid with the lower boiling point will vaporize first It is converted back into a liquid inside the condenser If the condenser deposits the liquid back in the reaction flask, it is called a reflux condenser. In chemistry, a condenser is laboratory apparatus used to condense vapors — that is, turn them into liquids — by cooling them down Condensers are routinely used in laboratory operations such as distillation, reflux, and extractionIn distillation, a mixture is heated until the more volatile components boil off, the vapors are condensed, and collected in a separate container.

• Clamp the reflux condenser to the iron stand in the upright position 3) Setting up the tubes • Connect one end of one rubber tubing with the water tap and the other end with the bottom interface of the reflux condenser • Connect one end of the other rubber tubing with the top interface of the reflux condenser. Exploded diagram of the connection between the conical vial and the reflux condenser 6 Watch the video below for a stepbystep description of how to setup a microscale reflux Performing a Reflux Reaction. 0 INTRODUCTION/PURPOSE Most condensers are designed such that the vapor and condensate flow in a cocurrent fashion There is a class of condenser, known variously as ’Reflux condenser’, ’Dephlegmator’ or ’Knockback condenser’ in which the condensate flows in a countercurrent fashion to the vapor.

The partial reboiler is an equilibrium stage The number of. Which is the better reflux condenser?. Reflux is a technique involving the condensation of vapors and the return of this condensate to the system from which it originated It is used in industrial 1 and laboratory 2 distillationsIt is also used in chemistry to supply energy to reactions over a long period of time Reflux in industrial distillation The term reflux 1 3 4 is very widely used in industries that utilize.

The goal here is to allow plans and diagrams to remain readily accessable and not get burried by pages and pages of chatter Hopefully Samohon will load this thing with some really nice information Heres a Double wound Reflux condenser with Coldfinger DoubleReflux(Small)jpg. This refluxing of liquid inside of the column can be controlled by the flow rate of water going through your reflux condenser A higher flow rate will result in the more cooling of the reflux condenser, therefore creating more reflux inside the column, resulting in a higher purity of ethanol Our RS are able to distill up to 95% ethanol purity. Minimum reflux ratio The pole N has coordinates H^ Qc/D Qc/D is the heat removed in the condenser per unit mass of product, as liquid at its boiling point and is represented as shown in Figure 1128 The number of plates in the rectifying section is determined, for a given feed xf and product xd, by the height of this pole N.

Video of a 2 inch cooling management still in operation Flow rate is 1 gallon per hour on a spirit run at 180 proof This column will fit directly onto a be. A major limiting factor in the design and operation of reflux condensers occurs when vapor velocity at the condenser’s inlet inhibits condensate downflow from the condenser Flooding, a complex twophase flow phenomenon, can occur at different places within a tube, depending upon vapor and condensate liquid rates. Reflux to wash resins & other heavy materials that may contaminate the products Condenser Typically 05 to psig Balancing act •Low pressures reduce compression on overhead system •High pressures decrease vaporization but increase flash zone temperatures & furnace duty;.

The condenser is connected to a receiving flask Conclusion Refluxing and distillation are chemical techniques used in many laboratories The main difference between reflux and distillation is that reflux method is used to complete a certain chemical reaction whereas distillation is used to separate components in a mixture Reference 1. Diagram of the cooling system The technique entails connecting the reflux condenser in parallel with another condenser that is immersed in an icebath (Fig 1) The reflux condenser inlet and outlet are each connected to a Tconnector and are linked together by a section of tubing about a meter in length This tubing is connected to a second. Internal Reflux Still Building the Condenser This section deals with the construction of the Internal Reflux still condenser assembly If you plan to build the Valved Reflux model, please click here In the context of a still, the condenser is a device that cools down whatever hot vapors that flow through it to the point.

Allihn vs friedrich from the little bit of info i've read it seems like the friedrich is the way to go i have a 0mm allihn that serves me well for a myriad of refluxing tasks but i am in need of a 400mm reflux condenser so i'm thinking of getting a friedrich.

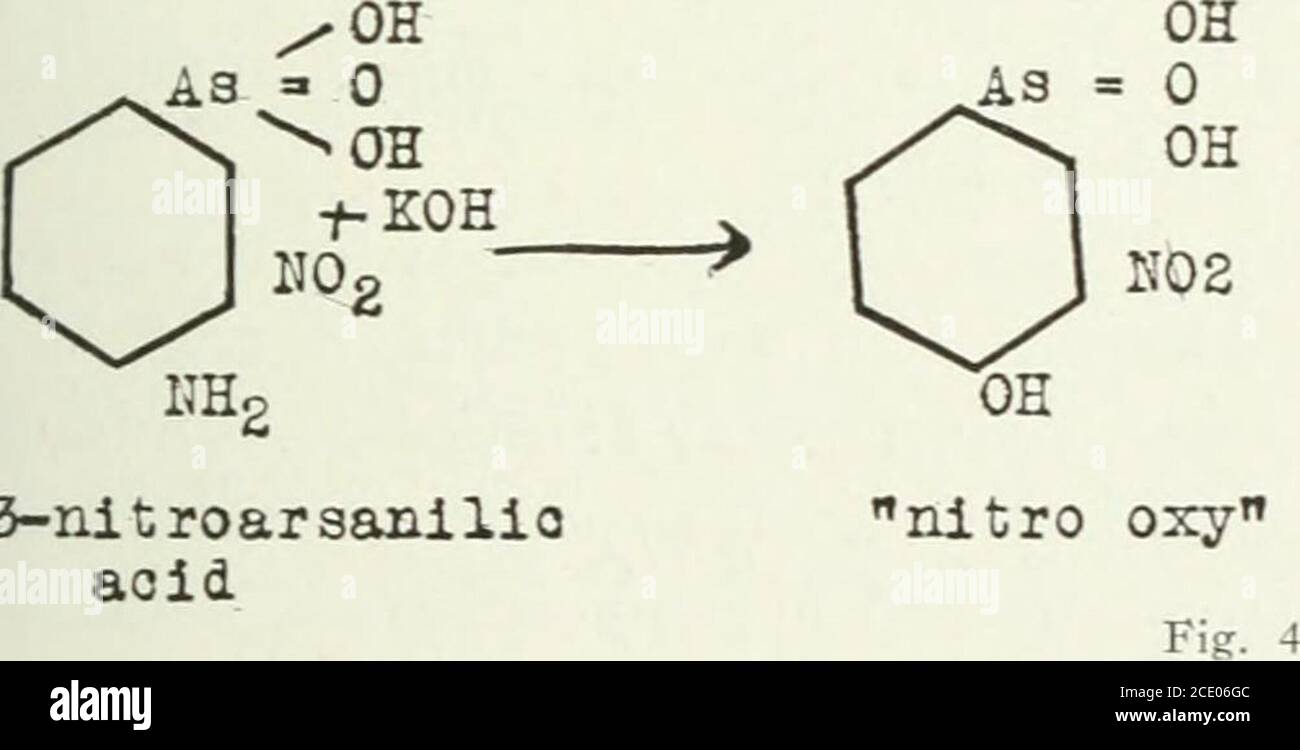

Reflux How To Make Methamphetamine

Dom S Cooking Tip In Site

Practical Distillation Cpd Rsc Education

Reflux Condenser Diagram のギャラリー

Organic Chemistry What Is Reflux A Level H2 Chemistry Tuition By 10 Year Series Author

Difference Between Reflux And Distillation Definition Technique Types Of Distillation Differences

Refluxing Condensation Systems Dephlegmators

Reflux Reaction Cum Distillation Unit Manufacturer

Split Flow Pumps Process Diagrams

Microscale Techniques Complete Manual

Figure 4 Transesterification Of Propylene Glycol Methyl Ether By Reactive Simulated Moving Bed Chromatography Using Homogeneous Catalyst Springerlink

Distillation Overhead Selection Criteria How To Size A Condenser

Arrangement Of Distillation Tower And Related Equipments The Piping Engineering World

Reflux Problems In Distillation

Optimize Batch Distillation

Organic Chemistry Laboratory Techniques For Standard And Micro Scale Experiments Setting Up A Reflux Reaction Top Hat

Choosing The Right Condenser Chemistry Stack Exchange

Sciencemadness Discussion Board Using Reflux Condenser In A Distillation Column Powered By Xmb 1 9 11

Downward Open Jacketed Glass Reactor Chemical Glass Reactor

Reflux Condenser High Resolution Stock Photography And Images Alamy

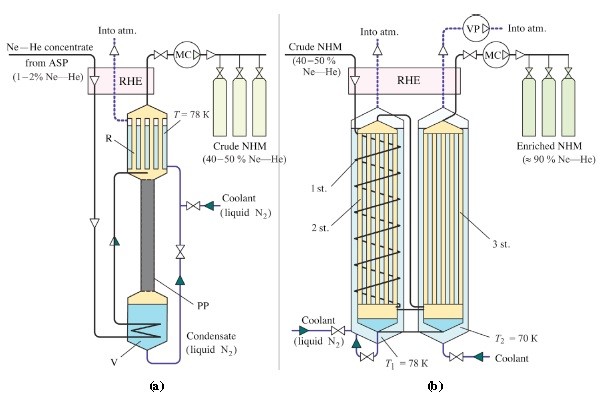

Analysis Of Losses In High Purity Neon Production Technology Part 2 Processing Of A Ne He Mixture To Obtain Pure Products Springerlink

Schematic Of Reflux Setup Download Scientific Diagram

Preparation Of 1 Bromobutane

1

9 6 Multistage Binary Batch Distillation Batch Distillation Informit

Heating Under Reflux

Installation Drawing Of Reflux Condenser Pipe Page 1 Line 17qq Com

Reactive Distillation Modeling Simulation And Optimization Intechopen

Q Tbn And9gcrxwo5j Pfb6qw1kffkpysjkec6 Uj7rlvynrses8eou1pjtoznzavpkscin7ivwo2 Srevytx0yjxyxfnlbl Iuclgd1 Lod4nlplmx Usqp Cau Ec

The Reflux Condenser Of A Distillation Unit

Http Chemistry Caltech Edu Courses Ch5 Step6 Pdf

Http Www Chem Ucalgary Ca Courses 351 Laboratory Reflux Pdf

Http Sites Psu Edu Mfl5156 Wp Content Uploads Sites 16 08 Mengying Li Instruction Set New Pdf

Refluxing Under An Inert Atmosphere The Schlenk Line Survival Guide

Iiiiiiiuuii H Trim Coolers Plan Above Overhead L Reflux Drum Condenser Reflux Pumps Di Tower Ea Bottoms Reboiler Pumps Pipe Rack Course Hero

Chemical Engineering Processing Basic Theory Distillation

Continuous Distillation With Reflux Rectification Food Tech Notes

Distillation Column Basic Distillation Equipment And Operation

Performance Indices To Design A Multicomponent Batch Distillation Column Using A Shortcut Method

Distillation Wikipedia

A Schematic Diagram Of Reflux Extraction B Reflux Equipment Download Scientific Diagram

How To Make A Copper Reflux Still 11 Steps With Pictures Instructables

Distillation And Reflux Chemicaltan97

Schematic Diagram Of Serpentine Condenser Page 7 Line 17qq Com

Reflux Condenser High Resolution Stock Photography And Images Alamy

Practical Dynamic Simulation Of Continuous Distillation Operation

Answered Nitrogen Product Atmospheric Pressure Bartleby

Chemistry Online Utsc

Shows The Schematic Diagram Of Refluxing Method For Synthesis Of Bi 2 Download Scientific Diagram

Liebig Condenser Function Uses Study Com

Basic Equipment And Operation Of Distillation Columns

Reflux Condenser An Overview Sciencedirect Topics

Practical Distillation Cpd Rsc Education

Http Sites Psu Edu Mfl5156 Wp Content Uploads Sites 16 08 Mengying Li Instruction Set New Pdf

Q Tbn And9gcsdjspbktiqfzqitrvxs9uxnrlfcgbmmjkskxcjkpi7cnax Lmyimfeo4pm2uducmftzmguusm6pkc8ppy6zynvyg7ecfsglh Dijz3xbdw Usqp Cau Ec

Reflux Laboratory Techniques

Reflux Distillation Encyclopedia Article Citizendium

Reflux Condenser An Overview Sciencedirect Topics

Condenser Laboratory Wikiwand

Reflux Condenser Condensation Alcohol Distillation

Reflux Assemblies Consists Of R B Flask And Liebig Condenser

Distillation Reflux Principle

Schematic Diagram Of The Pyrolysis Reactor With A Reflux Condenser Download Scientific Diagram

Enthalpy Composition Diagram Reflux Ratio Buffalo Brewing Blog

Common Types Of Condensers A Horizontal In Shell Condenser Tema E Type Shell B Horizontal In Shell Condenser Tema J Type Shell C A Vent Condenser Mounted On Top Of A Reflux Drum D An Internal

Shell And Tubes Heat Exchangers With Reflux Condenser Pilotta Srl

How To Make A Reflux Still Complete Plans To Build A Homemade Still Learn To Moonshine

Solved Criticize The Following Techniques A A Reflux Is Chegg Com

Rmp Lecture Notes

Schematic Diagram Of The Pyrolysis Reactor With A Reflux Condenser Download Scientific Diagram

Tdck Weebly Com Uploads 7 7 0 5 Experimental Procedures Organic Pdf

Ae 117

Reflux Distillation Encyclopedia Article Citizendium

Schema Of Apparatus For Water Soluble Qds Preparation In Reflux Condenser Download Scientific Diagram

Sciencemadness Discussion Board Solvent Stills Powered By Xmb 1 9 11

Reflux Wikipedia

Figure 3 1 From Optimization Of Biodiesel Production Via Reflux Condenser Methyl Acetate Reaction From Cerbera Odollam Sea Mango Sandip Singh Dhillon Semantic Scholar

Q Tbn And9gctrmwialrtphiyxty7vlsy6upinifzsf4hzqqcvyq41n Zl84lj7wzzuua3enwujj0tst Gh3itffz4g7paxuab 8itavpprjhrmrhcnhv Usqp Cau Ec

A Step By Step Guide To Successfully Model Any Distillation Column Simulate Live

Distillation Column

Organic Chemistry Laboratory Techniques For Standard And Micro Scale Experiments Setting Up A Reflux Reaction Top Hat

Reflux Condenser An Overview Sciencedirect Topics

Column Processdesign

Distillation Equipment For Reactors De Dietrich Process Systems

Distillation Column Basic Distillation Equipment And Operation

Qualifications Pearson Com Content Dam Pdf A level Chemistry 15 Teaching And Learning Materials As And A Level Chemistry Core Practical 5 Oxidation Of Ethanol Student Teacher Technician Worksheets Pdf

Ae 117

Refluxing Condensation Systems Dephlegmators

Lycaeum Leda Diagram Of Reaction Vessel With Reflux Condenser

Www Cheric Org Files Education Cyberlecture E11 E11 1101 Pdf

Reflux Laboratory Techniques

Reflux Condenser Diagram Schematic And Image 01

Reflux

Solved Criticize The Following Techniques A A Reflux Is Chegg Com

Http Faculty Cooper Edu avis Examplework Che142student1project Pdf

Solved The Mccabe Thiele Diagram For Binary Distillation Chegg Com

Reflux Setups Sciencemadness Wiki

China Laboratory Glass Reactor 5l With Reflux Condenser China Jacketed Glass Reactors Borosilicate Glass Reactor

Reflux Condenser Chemistry Chemical Synthesis Round Bottom Flask Png 1860x1560px Reflux Azeotrope Chemical Species Chemical Synthesis

Refluxing Under An Inert Atmosphere The Schlenk Line Survival Guide

Solved Part 2 P Id Diagrams Q2 Draw A Process And Instr Chegg Com

Chemistry Online Utsc

Distillation Tutorial Ii

Esters And Esterification Chemistry Tutorial

Reflux Wikipedia