Hazop Analyse

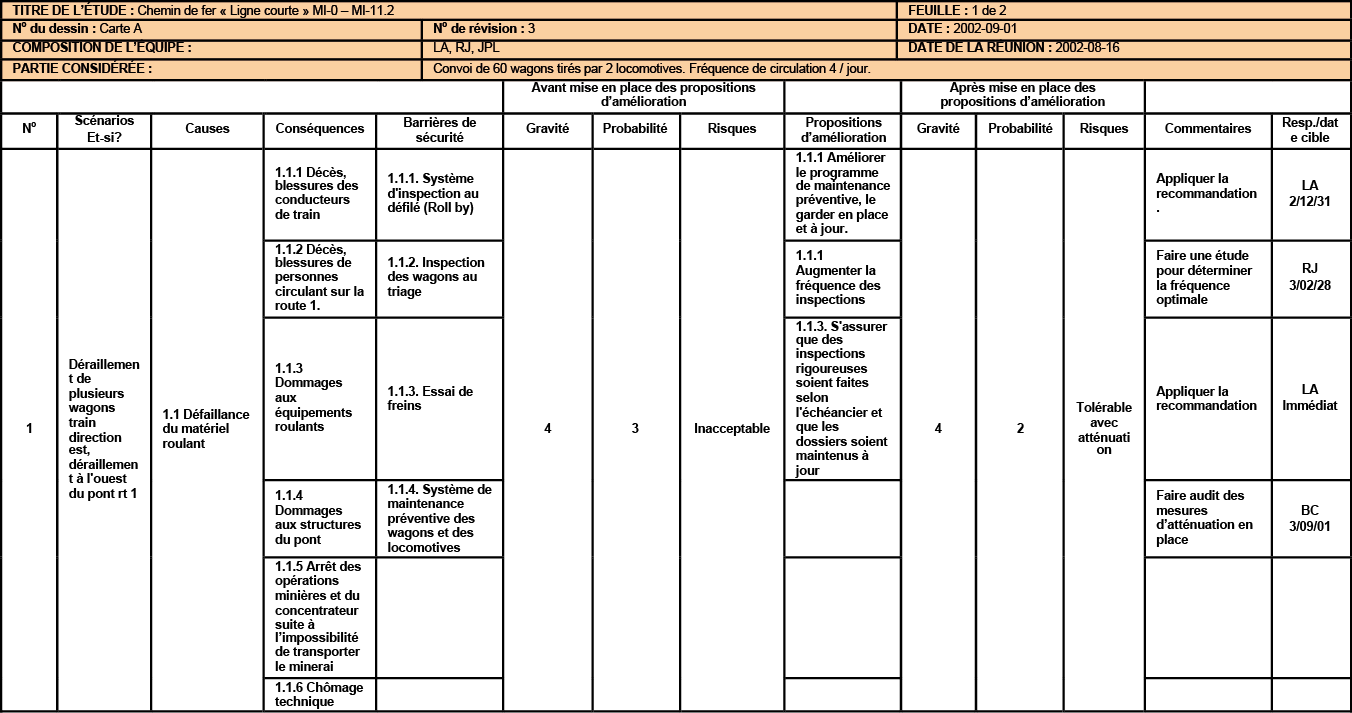

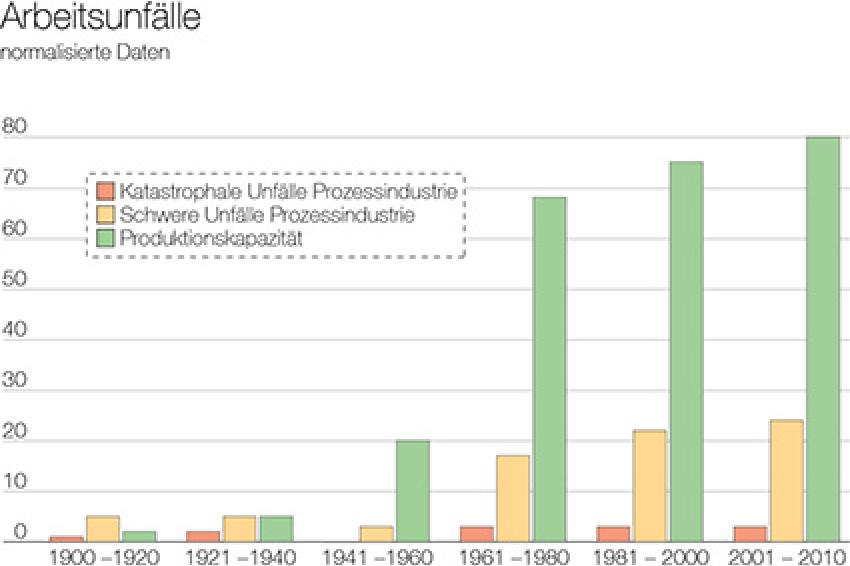

Carrying out HAZOPs using some form of prior information — prebuilt templates or the HAZOP from a similar project, for example Again, what the HAZOP is meant to do is analyze the possible specific risk scenarios (especially the nonobvious ones) of the process or project being studied at the time of the HAZOP (Figure 3).

Hazop analyse. Define HAZOP and PHA and their role to avoid major accidents in the process. To carry out a HAZOP. University of Nairobi Quantitative Risk Assessment & HAZOP and Risk Analysis Q1)The elimination of hazards is the first order of safety The control of physical condition is basic and frequently difficult in a plant and it requires the best of scientific, engineering and management information for its accomplishment.

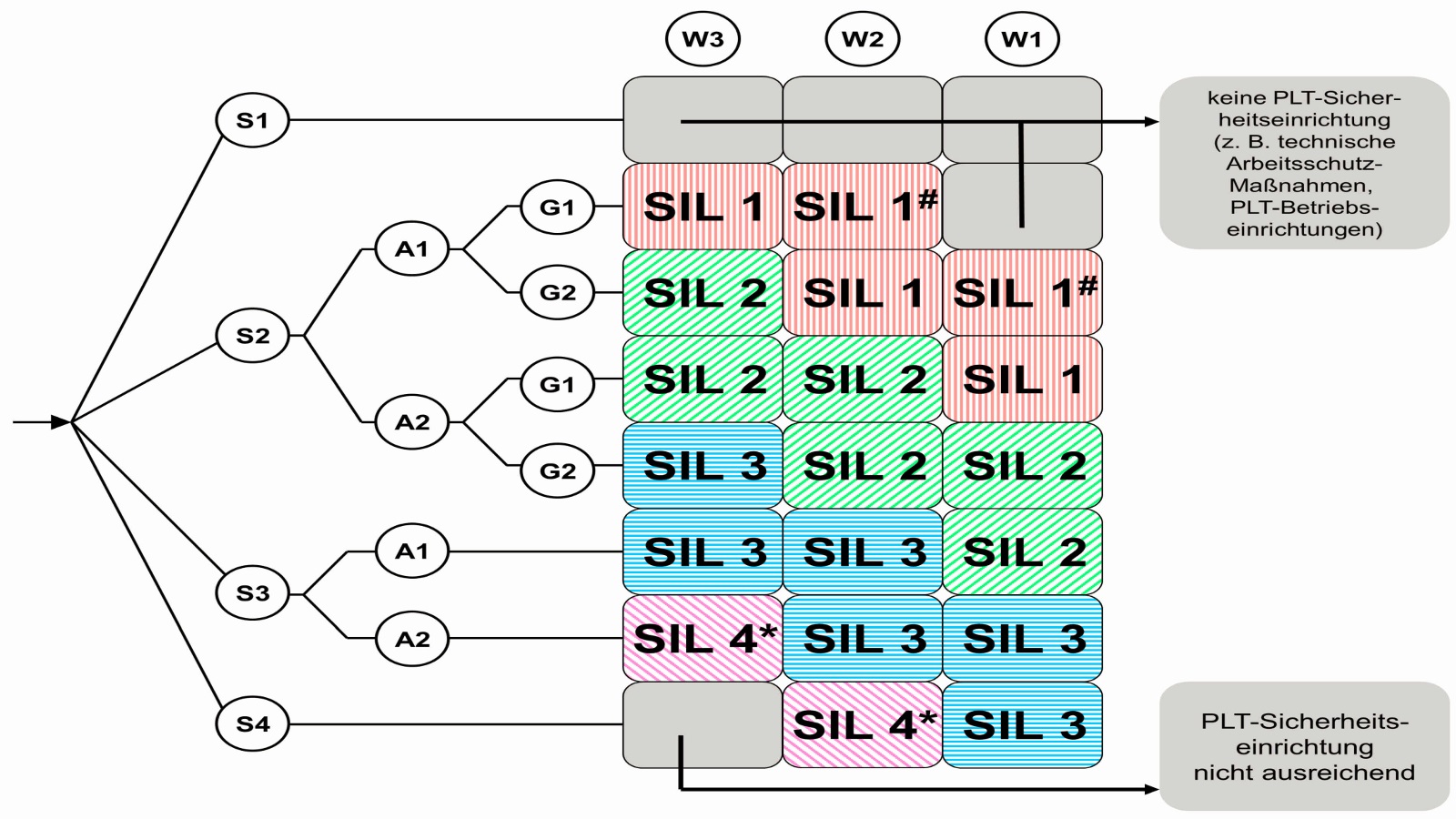

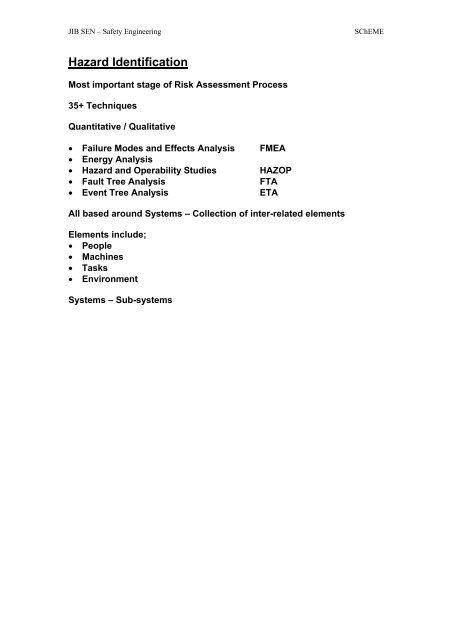

HAZOP is one technique out of a clutch of risk assessment techniques that engineers and other technical professionals use, such as FMEA (Failure Modes and Effects Analysis), LOPA (Layer of Protection Analysis), HAZID (Hazard Identification), WhatIf analysis and of course checklists. University of Nairobi Quantitative Risk Assessment & HAZOP and Risk Analysis Q1)The elimination of hazards is the first order of safety The control of physical condition is basic and frequently difficult in a plant and it requires the best of scientific, engineering and management information for its accomplishment. Introduction to HAZOP Analysis Process Template HAZOP is a structured and systematic examination of complex, planned, or existing processes or operations used to identify and evaluate problems that may represent risks to personnel equipment.

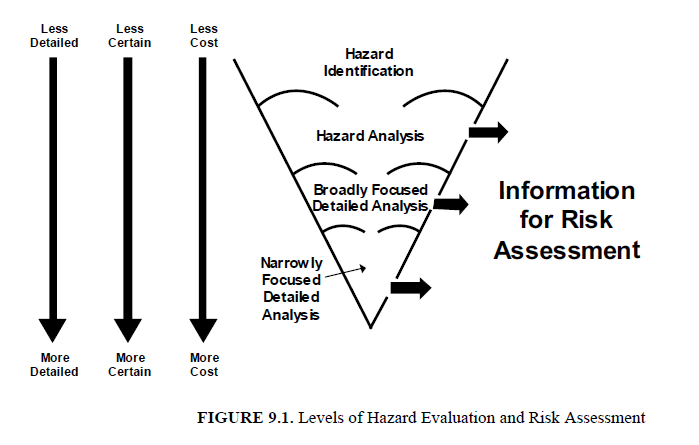

In our case, we are concentrating primarily on radiological hazards. Hazard and Operability (HAZOP) Study The HAZOP method is used to identify hazard scenarios with impacts on people and the environment as well as operability scenarios where the concern is the capacity of the process to function Originally, it was developed for fluid processes but it has also. Process Hazard Analysis (PHA) is a thorough, orderly, and systematic approach for identifying, evaluating, and controlling the hazards of processes The process hazard analysis methodology selected must be appropriate to the complexity of the process and must identify, evaluate, and control the hazards involved in the process.

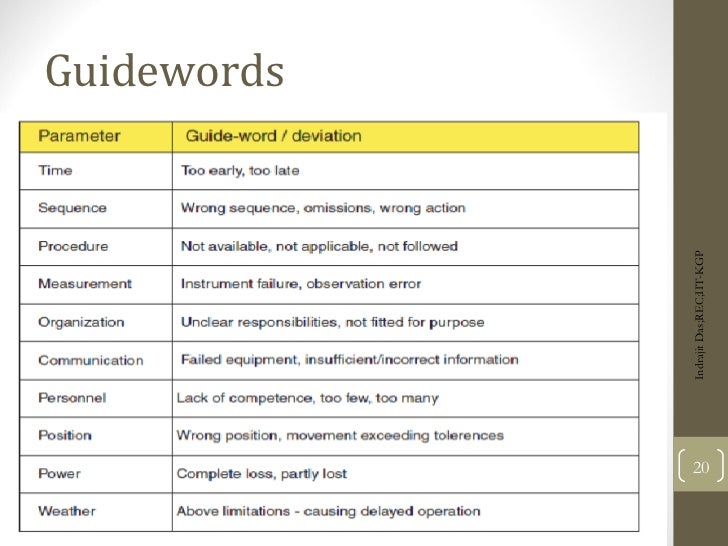

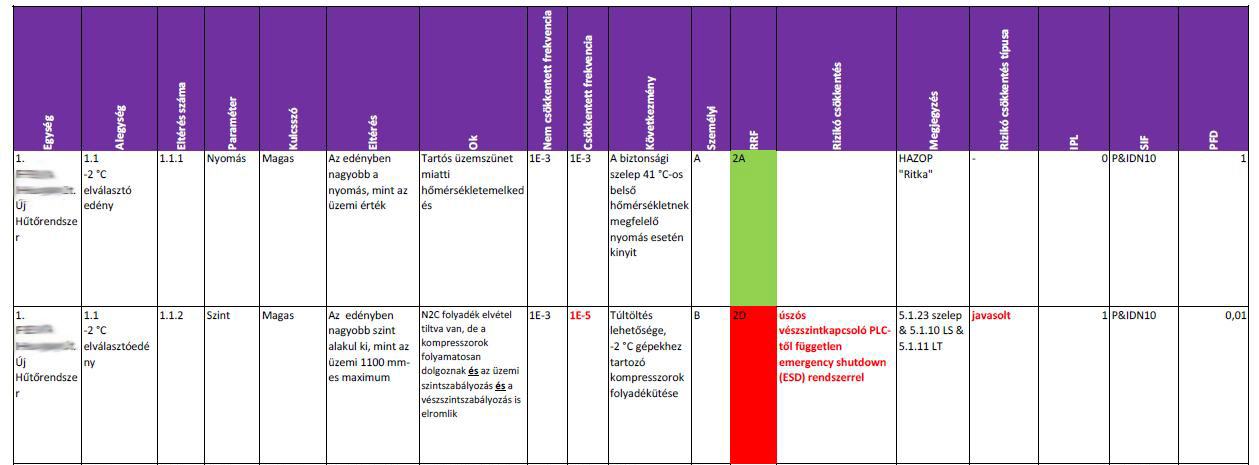

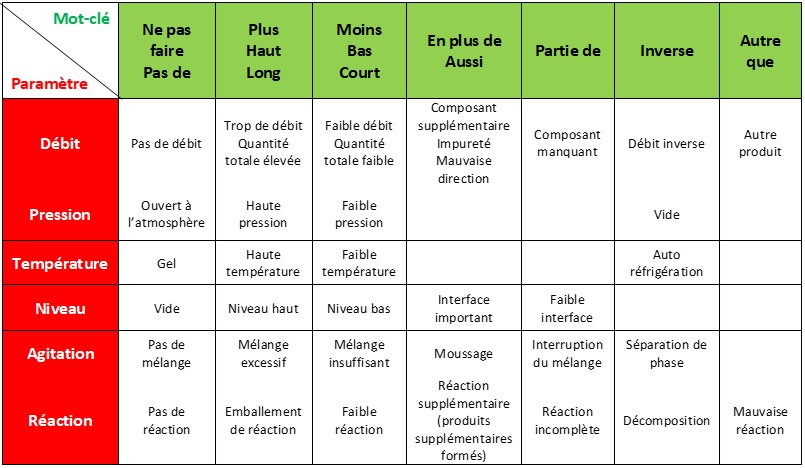

The hazard and operability (HAZOP) study is the most commonly used process hazard analysis (PHA) method in the world today It is one of the techniques commonly accepted by regulators The HAZOP method identifies deviations from design intent by applying guide words, such as No, More and Less, to aspects of the design intent (such as flow. HAZOP Analysis is nowadays the defacto Risk Assessment Technique that is used in Process Industries, such as Oil & Gas, Petroleum Refining, Chemical manufacturing, Mining, Pharmaceutical making, Water treatment, Pulp and Paper, Fibers and of course Chemical manufacturing. LOPA (Layer of Protection Analysis) Studies A Layer of Protection Analysis (LOPA) Study is used in conjunction with other PHA techniques, especially HAZOP, to determine if there are sufficient layers of protection against an identified highrisk incident or scenario.

HAZOP Analysis (HAZard and OPerability) Stoppages and constellations of a system or part of a system, which is predictable may not have a negative effect over the entire life cycle – that is a principle of safety relevant systems. Upon completing this HAZOP and Process Hazard Analysis (PHA) Leader Certification Training Course successfully, participants will be able to Gain an indepth understanding of what a HAZOP and PHA system does;. A Both HazID and HAZOP are risk analysis tools used in the workplace HAZOP, which stands for hazard and operability study, is used to identify abnormalities in the working environment and pinpoint the root causes of the abnormalities.

HAZOP Analysis is a popular hazard identification and risk assessment technique The HAZOP Study method was first used in the multinational chemical company known as Imperial Chemical Industries (ICI for short) Today the original company is no more but the hazard analysis technique that they pioneered has become almost the defacto risk. Upon completing this HAZOP and Process Hazard Analysis (PHA) Leader Certification Training Course successfully, participants will be able to Gain an indepth understanding of what a HAZOP and PHA system does;. HAZOP (Hazard and Operability Analysis) studies are well structured and systematic techniques to examine risk management This technique is used to identify potential hazards in any plant/system and find problems related to operability that may cause deviations from the actual design.

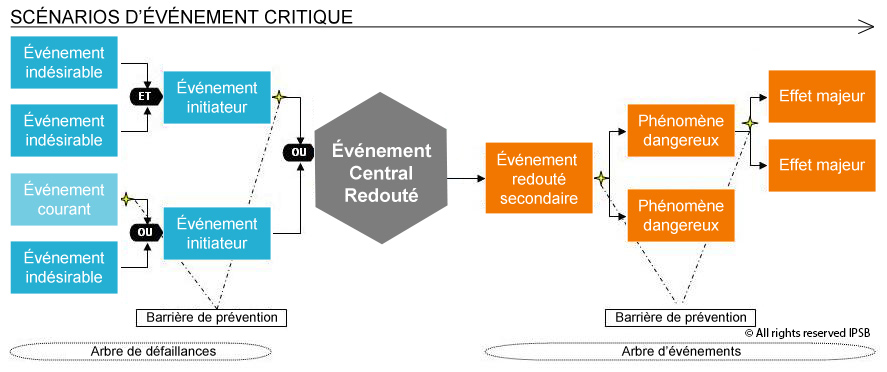

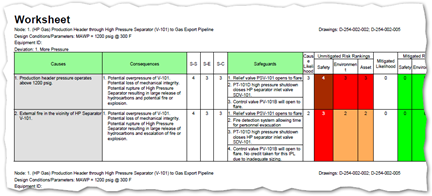

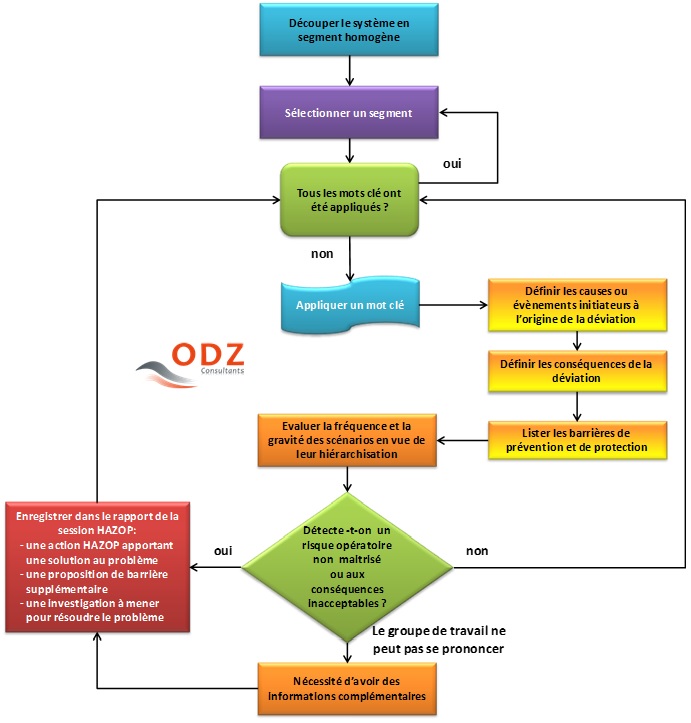

HAZOP (Hazard and Operability Analysis) studies are well structured and systematic techniques to examine risk management This technique is used to identify potential hazards in any plant/system and find problems related to operability that may cause deviations from the actual design. Carrying out HAZOPs using some form of prior information — prebuilt templates or the HAZOP from a similar project, for example Again, what the HAZOP is meant to do is analyze the possible specific risk scenarios (especially the nonobvious ones) of the process or project being studied at the time of the HAZOP (Figure 3). Create a Hazards Analysis (of the type HAZOP) to record the details of the Hazards and Operability (HAZOP) analysis This will analyze the known causes of a hazard Form Hazards Analysis Team Persona Analyst Form a multidisciplinary team that will perform the Hazards Analysis Assign the Facilitator role to one of the team members, and the.

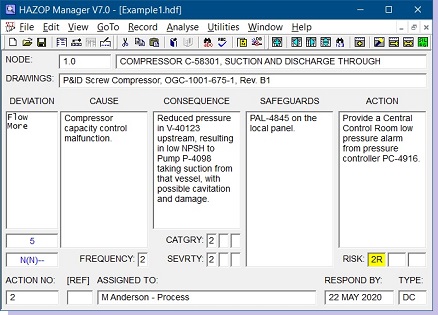

Our HAZOP software is a user friend and easily customized program that is in fact a framework for the preparation of HAZOP reviews and studies It is a comprehensible data storage and analysis software that facilitates HAZOP studies and the identification and evaluation of workplace hazards and risks and the damage they may pose to equipment. The HAZOP analysis would reveal the following potential process modifications Installation of a cooling water flow meter and low flow alarm to provide an immediate indication of cooling loss Installation of a high temperature alarm to alert the operator in the event of cooling function loss. 173 (1–3) 1932 5 Wan g F, Gao J, Wang H A new intelligent assistant s ystem for HAZOP analysis of complex process.

HAZOP’s meticulous approach is commonly used with chemical production and piping systems, where miles of pipes and numerous containers can cause logistical headaches HAZOP and Hazard Analysis Systems The task of analyzing hazards in a workplace or system can be daunting. Question Prepare A Hazop Analysis Study For SL1 Accident This question hasn't been answered yet Ask an expert Prepare a Hazop analysis study for SL1 Accident. Hazard and Operability (HAZOP) is the most appropriate Process Hazard Analysis (PHA) technique to study the complex process to identify potential hazards in the designed process and probable operability problems by analyzing the causes of the deviation of the process and associated risk and review the safeguards to prevent accidents during its.

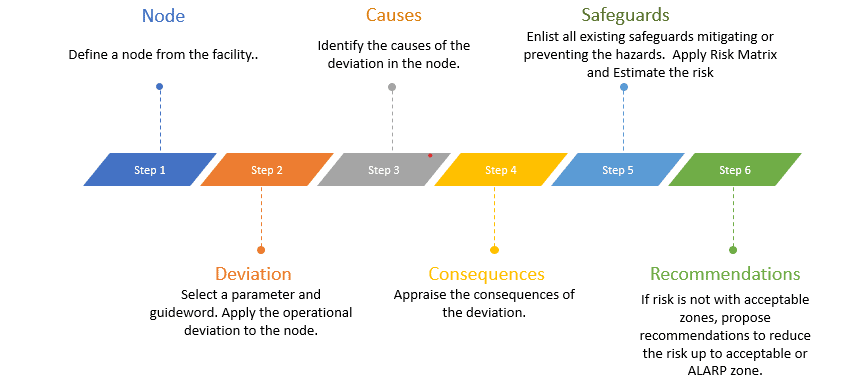

Hazard and Operability (HAZOP) is the most appropriate Process Hazard Analysis (PHA) technique to study the complex process to identify potential hazards in the designed process and probable operability problems by analyzing the causes of the deviation of the process and associated risk and review the safeguards to prevent accidents during its. Understand why there is a need for a HAZOP and PHA system;. The HAZOP process is a rigorous analysis tool that systematically analyzes each part of a system or activity To apply the HAZOP guide words effectively and to address the potential accidents that can result from the guide word deviations, the analysis team must have access to detailed design and operational information.

Understand why there is a need for a HAZOP and PHA system;. Question Prepare A Hazop Analysis Study For SL1 Accident This question hasn't been answered yet Ask an expert Prepare a Hazop analysis study for SL1 Accident. Despite its benefits, HazOp analysis typically requires significant effort, as it is time consuming and involves key figures from different departments and functions An assessment of new units or a review of existing ones may require several weeks of analysis and impact the site’s work organization.

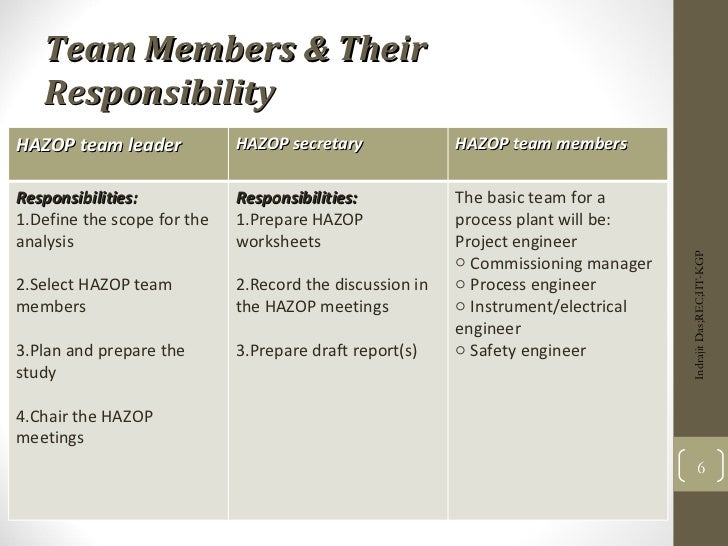

Question Prepare A Hazop Analysis Study For SL1 Accident This question hasn't been answered yet Ask an expert Prepare a Hazop analysis study for SL1 Accident. Hazard and Operability Study (Process Safety) HAZOP is essentially a qualitative procedure in which a small team consisting, eg, of a process engineer, a control instrument expert, a risk analyst, and an operator, guided by an experienced chairman, examines a proposed design by generating questions about it in a systematic manner. HAZOP (Hazard and Operability Analysis) studies are well structured and systematic techniques to examine risk management This technique is used to identify potential hazards in any plant/system and find problems related to operability that may cause deviations from the actual design.

Hazard and Operability Study (Process Safety) HAZOP is essentially a qualitative procedure in which a small team consisting, eg, of a process engineer, a control instrument expert, a risk analyst, and an operator, guided by an experienced chairman, examines a proposed design by generating questions about it in a systematic manner. Operability (HAZOP) analysis A literature review J Hazard Mater 10;. Hazop analysis complete report 1 A Report on HAZOP Analysis 2 CONTENTS 1 Introduction 2 HAZOP Preparation Selection of HAZOP study team members Information required for HAZOP study Other responsibilities 3 HAZOP Terminology System Design Intent HAZOP Guide words Safeguards & Recommendations HAZOP Study Record & Risk Assessment 4.

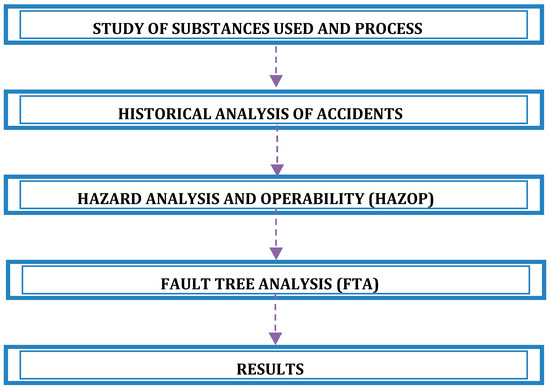

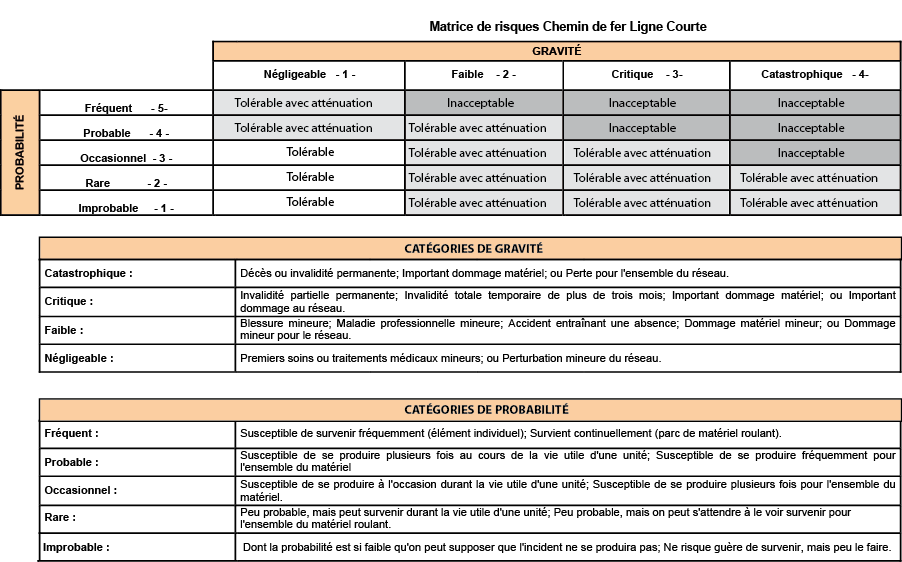

The hazard and operability (HAZOP) study is the most commonly used process hazard analysis (PHA) method in the world today It is one of the techniques commonly accepted by regulators The HAZOP method identifies deviations from design intent by applying guide words, such as No, More and Less, to aspects of the design intent (such as flow. HAZOP analysis shows that loading and unloading areas are the most sensitive areas of the plant and where the most significant danger is a fuel spill FTA analysis indicates that the most likely. HAZOP is a systematic ,reasonably comprehensive and flexible It is suitable mainly for team use where by it is possible to incorporate the general experience available It gives good identification of cause and excellent identification of critical deviations.

HAZOP study Ensuring a HAZOP meeting covers the required scope of HAZOP study is an important task Too often, HAZOP studies fail to completely cover the whole intended scope of potential hazards, or sometimes they exceed defined battery limits A clear scope definition is the key for a HAZOP. Executive Summary HAZOP is an acronym created by combining the words for HAZard and OPerability (Study)It is one of the most popular, nonquantitative Risk Assessment methods in use today across a wide range of industrial operations, but not limited to, Oil & Gas, Refining, Chemicals, Petrochemicals, Glass, Pulp and Paper, Pharmaceuticals, Food and Beverage, Power Generation and any kind of. University of Nairobi Quantitative Risk Assessment & HAZOP and Risk Analysis January 16, 21 / in Nursing Essays Writers / by Nursing Writing Help Q1)The elimination of hazards is the first order of safety The control of physical condition is basic and frequently difficult in a plant and it requires the best of scientific, engineering and.

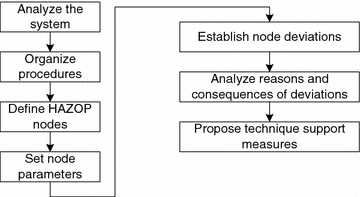

The HAZOP analysis technique (HAZard OPerability study) is generally considered to have originated in the Heavy Organic Chemicals Division of ICI, which was then a major British and international chemical companyThis is a kind of process hazard analysis ICI was formed in 1926 by the merger of the United Kingdoms four largest chemical companies. Analyze chemical process systems, but has later been extended to other types of systems and also to complex operations and to software systems 2 When to perform HAZOP The HAZOP study should preferably be carried out as early in the design phase as possible to have influence on the design On the other hand;. EHAZOP Methodology Overview The study will be performed on single line diagrams (SLDs) available at the time of EHAZOP review The study will also refer to equipment specifications, layouts and other documentation listed in the later section Methodology Words to generate a set of Deviation from design intent.

A Both HazID and HAZOP are risk analysis tools used in the workplace HAZOP, which stands for hazard and operability study, is used to identify abnormalities in the working environment and pinpoint the root causes of the abnormalities. HAZOP Tutorial Section I Introduction A Hazard and Operability Study, commonly referred to as a HAZOP study, is a structured analysis of process design to identify process safety incidents that a facility is vulnerable to. The HAZOP technique was initially developed in the 1960s to analyze major chemical process systems but has since been extended to other areas, including mining operations and other types of process systems and other complex systems such as nuclear power plant operation and software development.

The HAZOP approach is commonly used with chemical production and piping systems, where miles of pipes and numerous containers can result in logistical headaches It is best suited for assessing hazards in facilities, equipment, and processes and can assess systems from multiple perspectives. A HAZOP analysis is based on the theory that risk events are caused by deviations in the design or operational intent of a given system It can apply to a wide variety of systems and processes including pharmaceutical quality, industrial equipment handling, environmental health impacts and more. HAZOP (Hazard and Operability Analysis) studies are well structured and systematic techniques to examine risk management This technique is used to identify potential hazards in any plant/system and find problems related to operability that may cause deviations from the actual design.

HAZard and OPerability Study (HAZOP) is a systematic risk assessment method that analyzes a process or operation to identify and evaluate problems that may represent. Define HAZOP and PHA and their role to avoid major accidents in the process. HAZOP analysis shows that loading and unloading areas are the most sensitive areas of the plant and where the most significant danger is a fuel spill FTA analysis indicates that the most likely.

Wwwicarusormcom/academyThis is a HAZOP Training video to introduce the concept of Hazard and Operability Study The first in a series of IcarusORM Proces. Usually the analysis is carried out on final P&ID’s, that is, prior to “Issue for Construction” Frequently the section of line undergoing a HAZOP Study may go through several other items of equipment which must be considered but providing there is no chemical change it is acceptable and normal to HAZOP in this way. HAZOP Tutorial Section I Introduction A Hazard and Operability Study, commonly referred to as a HAZOP study, is a structured analysis of process design to identify process safety incidents that a facility is vulnerable to.

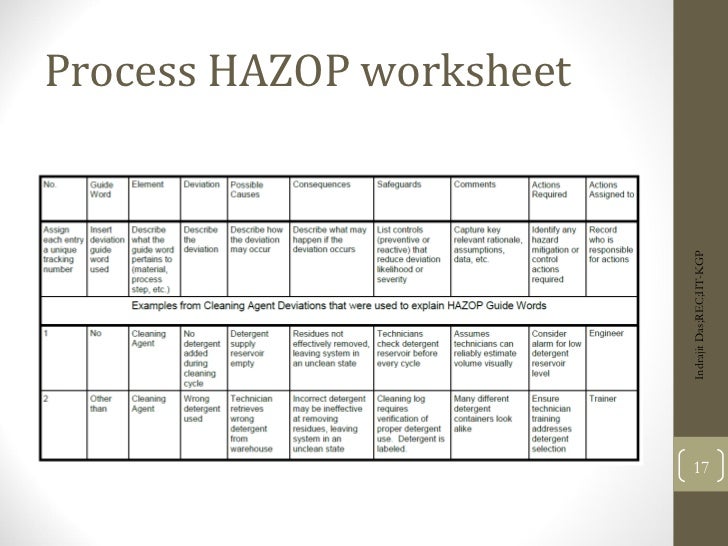

The HAZOP method was initially developed in the 1960s to analyze chemical process systems Later, it has been extended to other types of systems such as nuclear power plant operation and software development 1 What is HAZOP?. HAZOP is a systematic ,reasonably comprehensive and flexible It is suitable mainly for team use where by it is possible to incorporate the general experience available It gives good identification of cause and excellent identification of critical deviations. HAZOP Analysis Table 4 HAZOP Analysis for Reboiler Deviatio n Causes Consequence s Safeguards Actions Classificatio n Pressure High Steam utility malfunction Poor separation Pressure gauge Lower reboiler duty 4D Level High Excessive feed or low bottom flow rate Accumulatio n in reboiler unit and poor separation Flowmeter before and after.

HAZOP is an invaluable tool when it comes to hazard analysis In fact, there are several advantages that it holds unique to itself The first one is its helpfulness when facing hazards that are difficult to measure, such as ones rooted in human behaviors and ones that are difficult to detect.

Hazard Operability Hazop Ifluids Engineering

Hazop Group 19 Pdf Hpld Coursework 2 Hazard And Operability Study Hazop Safety Assessment On Formaldehyde Production Plant By Group No 19 Group Course Hero

Www Onepetro Org Download Conference Paper Spe 1122 Ms Id Conference Paper 2fspe 1122 Ms

Hazop Analyse のギャラリー

Hazop Analysis

Http Www Uobabylon Edu Iq Eprints Publication 7 6247 Pdf

Http Folk Ntnu No Skoge Prost Proceedings Npc07 Dtu Dtu08 Pdf

Hazop Studies Advantages And Disadvantages Of Its Use Opus Kinetic

Hazop Worksheet Printable Worksheets And Activities For Teachers Parents Tutors And Homeschool Families

Hazards And Operability Study Hazop

Www Environmental Expert Com Files 1272 Articles 79 Psep3 Pdf

Hazop Study Template Prevention Safety

Hazan Hazop Occupational Safety And Health Hazards

Http Pembeyond Eu Deliverables D6 5 hazop report Pdf

Hazop Analysis On The In Parallel Flow Heat Exchangers And The Feeding Download Scientific Diagram

Hazop Manager V7 0 Software For Hazop Studies And Other Pha Reviews

Hazard And Operability Hazop Studies Dekra

Www Icheme Org Media 9649 Xxi Paper 021 Pdf

Hazop Hazard And Operability Study Iqasystem

Introduction To Hazard Identification And Risk Analysis Aiche

Hazop Images Stock Photos Vectors Shutterstock

Analyse De Risques Methode Hazop Dekra Process Safety

Pha Hazid And Hazop Studies Functional Safety Engineering Services Fses

Hazop Toelichting Extra Hulp Studeersnel

Gratis Hazop Moc Ook Wel Veiligheids Analyse Genoemd Excelsheet Gratis Werkveilig Veilig Werk Werk Veilig Website Voor De Veiligheidskundige En Bhv Vgwm Hse Arbo Medewerkers Ruim 250 Sheets Teksten Apps En Ppp En 550

Ipsb Les Risques Industriels

Top Pdf Hazop Study 1library

Hazard Operability Review Hazop Bornemann Consultancy

Blog Nihar

Wat Is Hazop Dd Engineering Multidisciplinaire Ingenieurs

Q Tbn And9gcrir0vceouluky4fec6dyz5lttsntw6crwgwrjqtqswvq Iq2vj Usqp Cau

Http Www Ipcbee Com Vol66 006 Ieea14 A013 Pdf

Case Study Training Certification Online Course In Hazard And Operability

Heaterams Fired Heater Software Hazop Analysis Tool Youtube

Research On Hazop Based Safety Methods Of Equipment Usage Springerlink

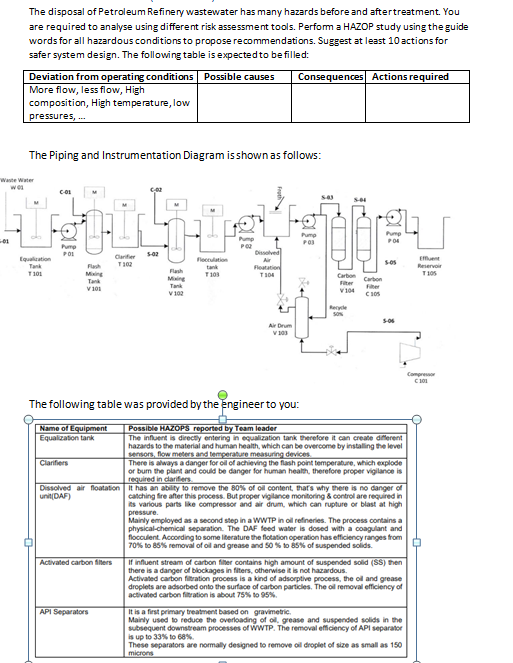

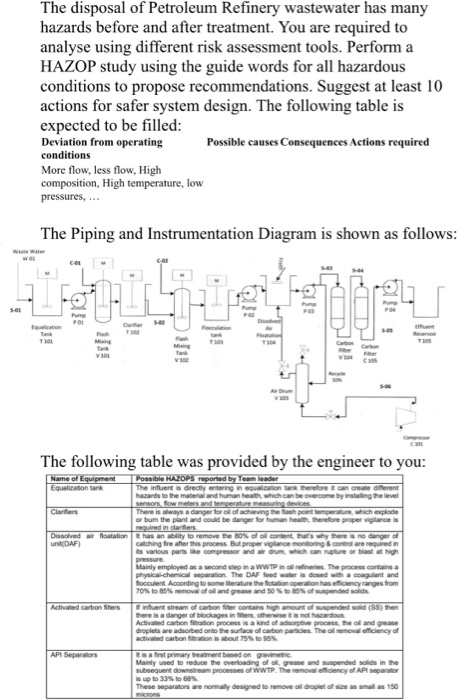

The Disposal Of Petroleum Refinery Wastewater Has Chegg Com

Hazop Hazard And Operability Study Iqasystem

Introduction To Hazop Study What Is Piping All About Piping Engineering

Procesveiligheid Hazop En Risico Evaluatie Visie Op Veiligheid

Pdf Hazop Study Carol Johnston Academia Edu

Http Www Ipedr Com Vol11 16 R Pdf

Hazard And Operability Analysis Hazop Youtube

Pha Data Quality Mining The Hidden Risks

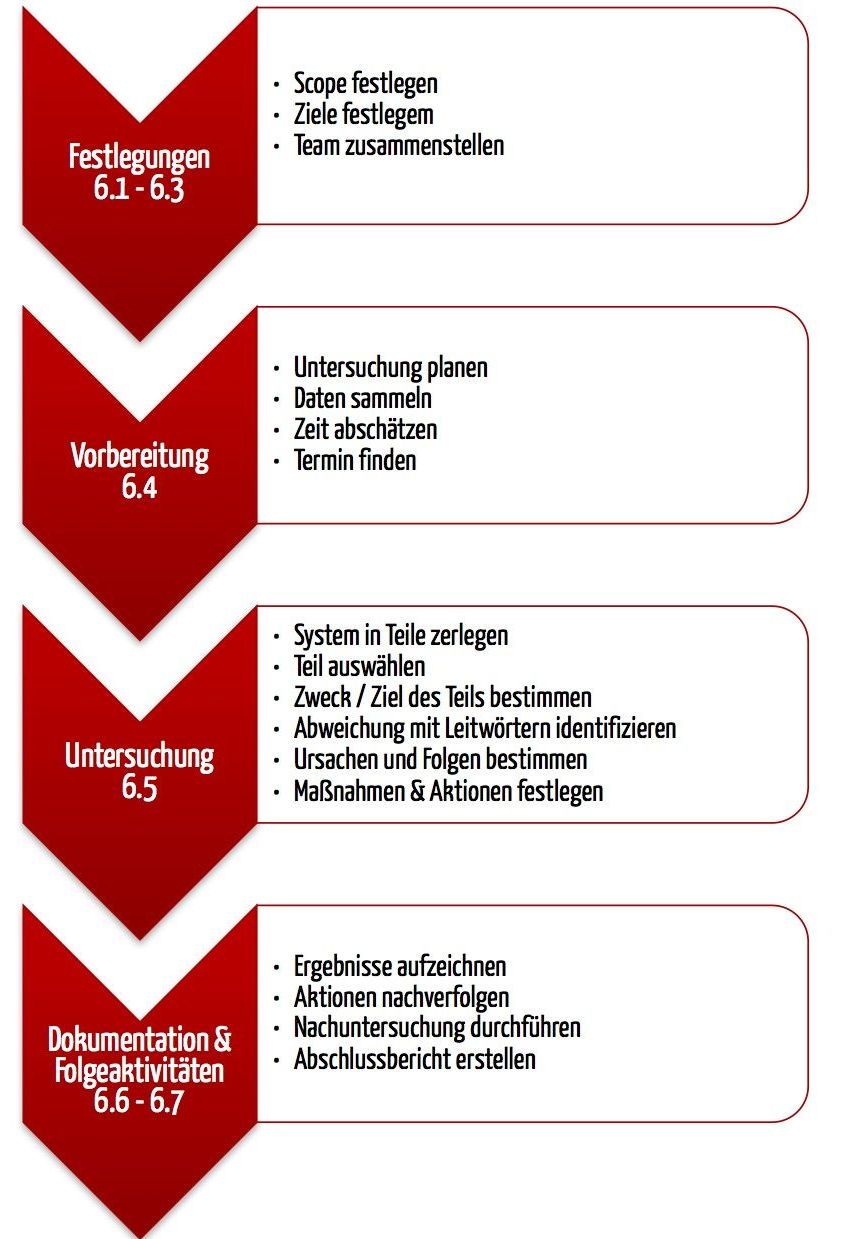

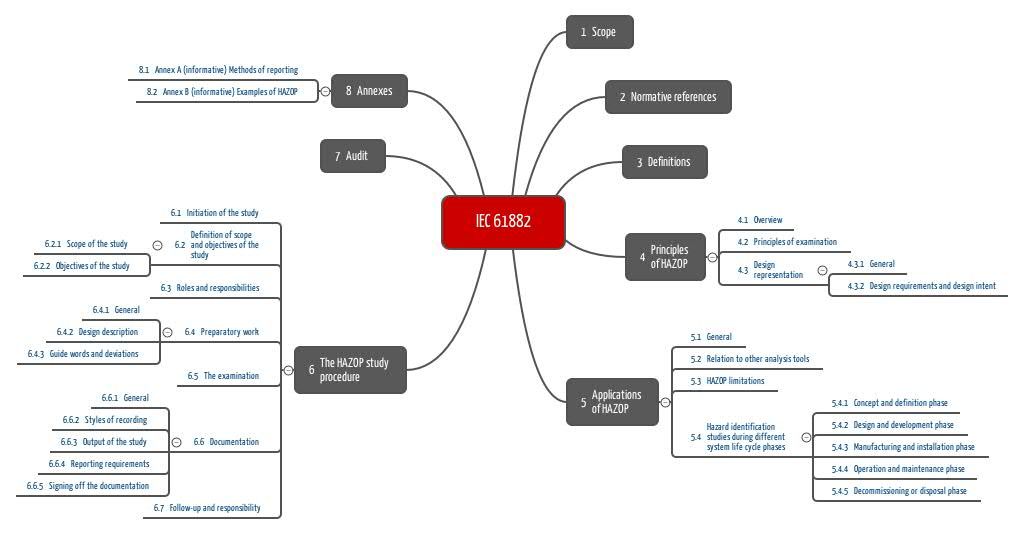

Hazop Analyse Iec 618 In 4 Schritten Zum Ergebnis

Fillable Online Risktec Co Hazop Study Training Course Risktec Solutions Risktec Co Fax Email Print Pdffiller

Hazop Analyse Iec 618 In 4 Schritten Zum Ergebnis

Hazop Analysis

1

Ijerph Free Full Text Risk Analysis Of A Fuel Storage Terminal Using Hazop And Fta Html

Hazop Study Chennai India

Www3 Opic Gov Environment Eia Vistaaleph Esia Chapter 10 Chapter 10 Annex Pdf

Hazop 2 0 Ist Ein Bewahrtes Sicherheitsverfahren Zur Vorbeugung Von Chemieunfallen Chemanager

Www Ripublication Com Ijaer18 Ijaerv13n10 56 Pdf

What Is Hazop Analysis Or Assessment

Module 2 Industrial Safety Pages 101 150 Flip Pdf Download Fliphtml5

Pha Software Hazop Free Download

System Safety

Iamgold Hss Report Initiative In Which It Supports

Hazop Method Deviation Analysis Apppm

Plant Safety Available And Safe Production Systems Tuv Austria Tuv Osterreich

Http Oa Upm Es 1 Inve Mem 12 Pdf

Green Hazop Analysis Incorporating Green Engineering Into Design Assessment And Implementation Of Chemical Processes Green Chemistry Rsc Publishing Doi 10 1039 Ba

Generisk Hu Fehlerbaum Hazop Ereignisbaum Analyse

Hazop Method Deviation Analysis Apppm

Introduction To Hazop Study What Is Piping All About Piping Engineering

Hazard And Operability Hazop Studies Dekra

System Safety

Analyse De Risques Identification Et Estimation Demarches D Analyse De Risques Methodes Qualitatives D Analyse De Risques Hazard And Operability

Applying Hazop Analysis In Assessing Remote Handling Compatibility Of Iter Port Plugs Sciencedirect

Hazop Hazard And Operability Analyse Des Risques Odz Consultants

Http Environmentclearance Nic In Writereaddata Online Riskassessment vb8xsilwfinalhpclrayagadaqra Pdf

Http Webarchiv Ethz Ch Lsa Education Vorl Gtr Slides 10 02 Basismethoden Der Risikoanalytik Pdf

Hazard And Operability Analysis Hazop Process Download Scientific Diagram

Hazop Studies Meeting Facilitation Learning Courses Study

Www Mdpi Com 1660 4601 14 7 705 Pdf

Www Icheme Org Media Xiii Paper 22 Pdf

The Disposal Of Petroleum Refinery Wastewater Has Chegg Com

Www Ntnu Edu Documents Chapt09 Hazop Pdf 9ed Dc7f 41f8 9f04 9e13a4ce33

Results Matter Three Case Studies Comparing And Contrasting Pffm And Hazop Pha Reviews Sciencedirect

Www3 Opic Gov Environment Eia Vistaaleph Esia Chapter 10 Chapter 10 Risk Management Plan Pdf

Example Of Hazop Analysis Assuming The Booster Pumps As Hazop Node Download Table

Towards Automation Of Hazop With A New Tool Expertop Semantic Scholar

Hazop Analysis

Www Vttresearch Com Sites Default Files Pdf Tiedotteet 08 T2437 Pdf

Pha Data Quality Mining The Hidden Risks

2

Safety And Risk Assessment Lilleaker Consulting As

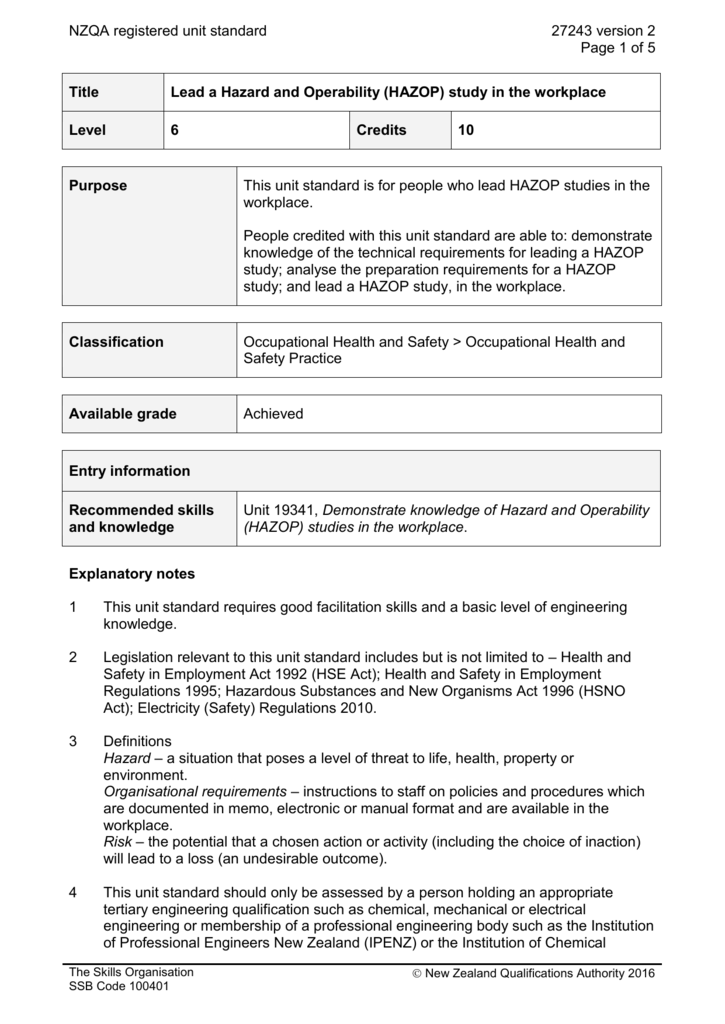

Lead A Hazard And Operability Hazop Study In The

Green Hazop Analysis Incorporating Green Engineering Into Design Assessment And Implementation Of Chemical Processes Green Chemistry Rsc Publishing

How To Do Hazid In Excel Cge Risk

Analyse Av Systemsikkerhet Ppt Video Online Laste Ned

Establishing A Methodology For Safety Analysis Of Fuel Cell Heating

Q Tbn And9gct Hqpo Dmhefgzzdh R5 Cfzdrfd9psjbu1u Q1qah Cyegcjt Usqp Cau

Pqri Org Wp Content Uploads 15 08 Pdf Hazop Training Guide Pdf

What If Analysis Cholarisk

What Is Hazop Graphic Products

Identification And Assessment Risks In Maintenance Operations Emerald Insight

Q Tbn And9gcqkezxd4h0nepogdfuhdrwyuht4kszmm9l87vtzbcrzkmbnqf Usqp Cau

Hazop Hazard And Operability Analyse Des Risques Odz Consultants

Hazop Krdgroup21

What Is Hazop Analysis Or Assessment

Psc Completes Hazop By Difference For Net4gas Czech Republic Pipe System Consult

Hazop Fmea Etc Health And Safety For Beginners

Hazop Group 19 Pdf Hpld Coursework 2 Hazard And Operability Study Hazop Safety Assessment On Formaldehyde Production Plant By Group No 19 Group Course Hero

Hazards And Operability Study Hazop