Aluminium Casting Process Flow Chart

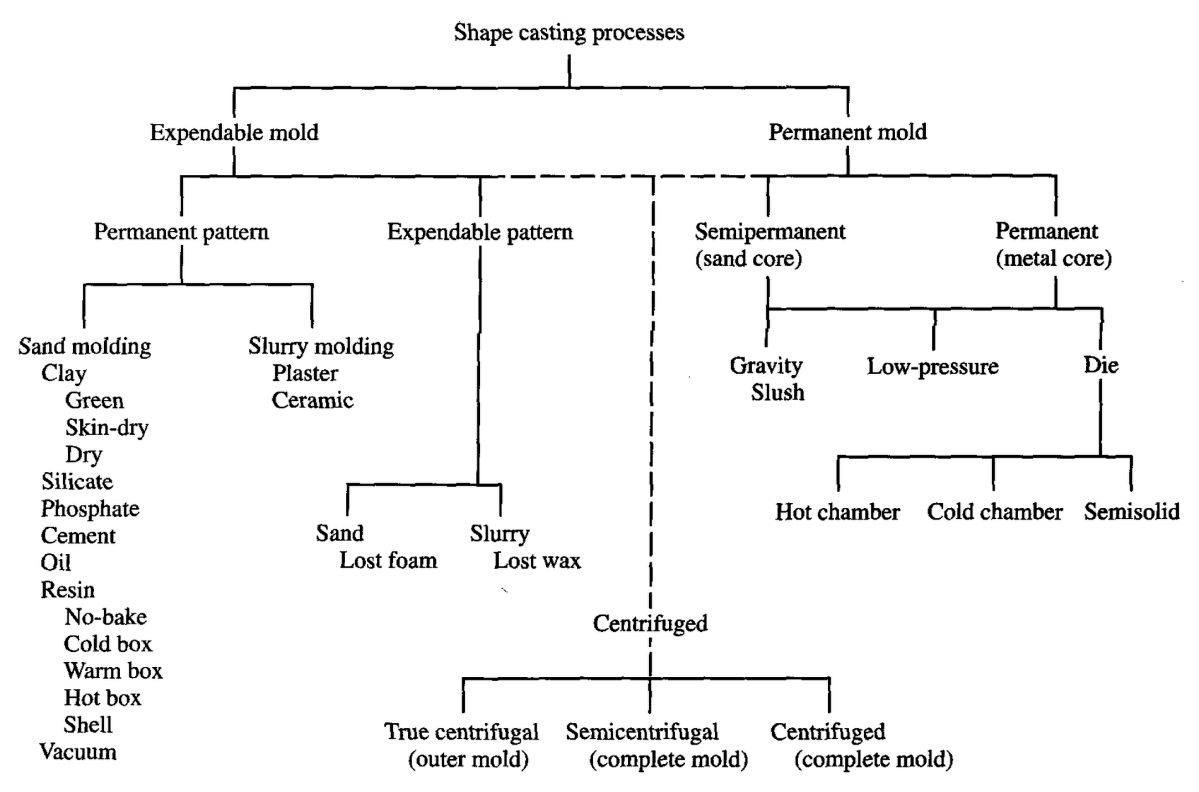

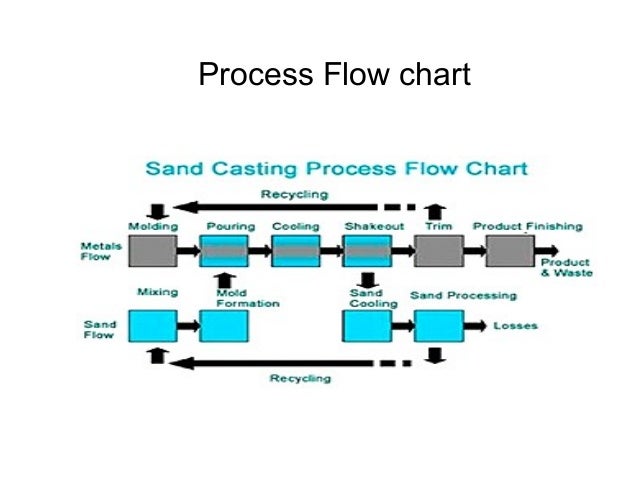

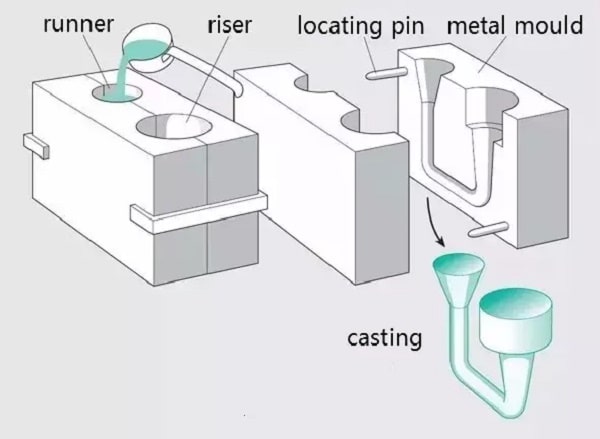

Metal casting is the process in which molten metal is poured into a mold and allowed to solidify into an object The object that solidifies is called a casting Sand casting is defined as pouring of molten metal into a sand mold and allowing it to solidify in the mold Sand casting is the most widely used metal casting process in manufacturing.

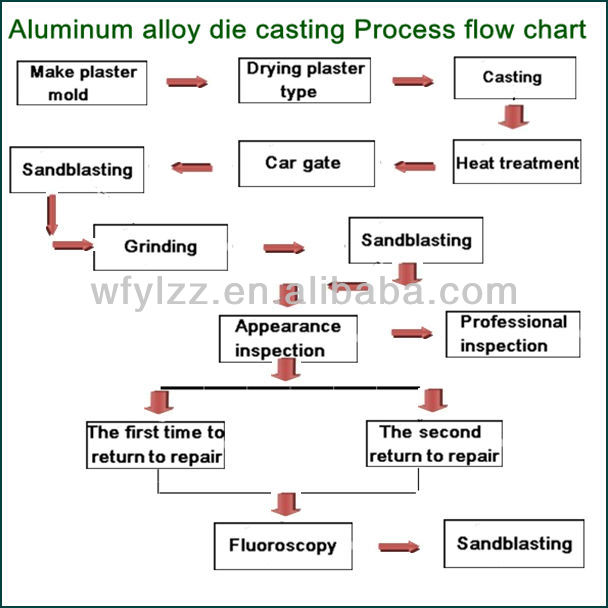

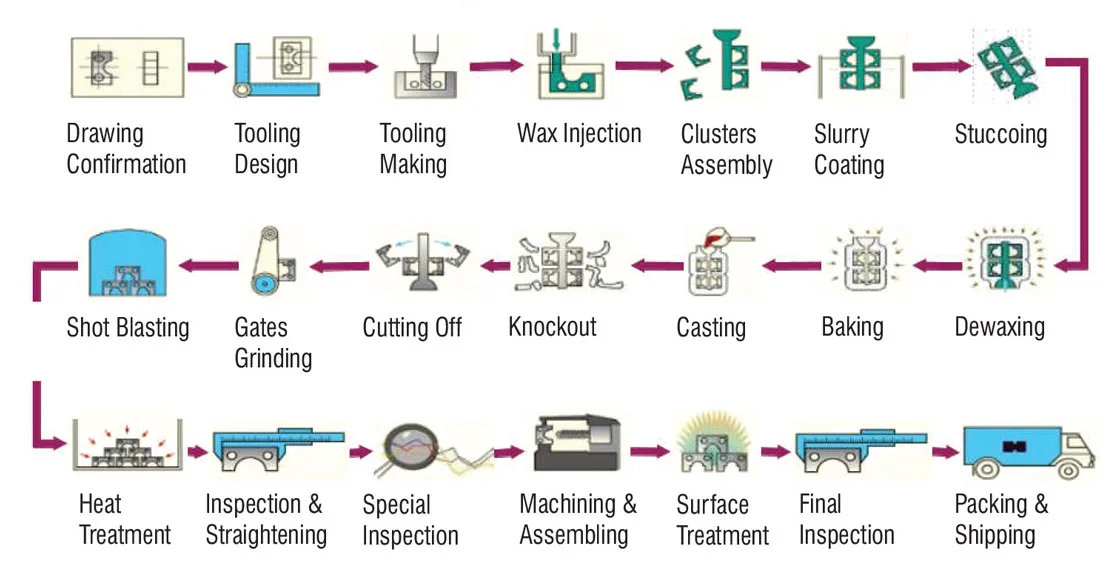

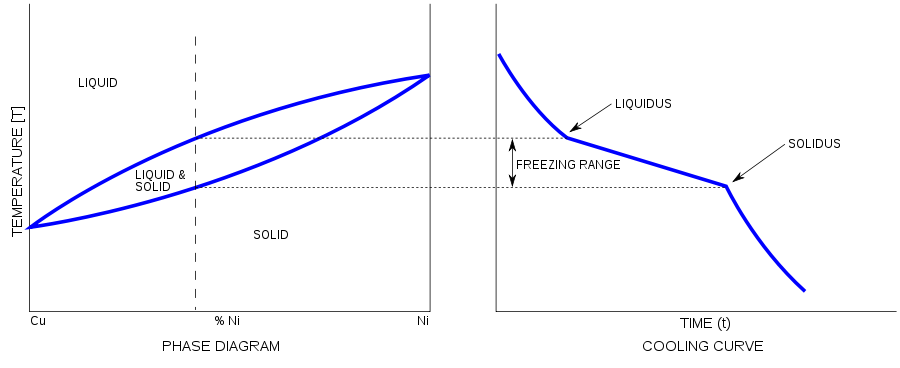

Aluminium casting process flow chart. A metal mold is used to produce wax replicas Wax replicas are placed in an investment material Wax is melted out and molten metal i poured into cavity The mold is broken and the casting is removed Ounces up to lbs ± 004" to ½" ±005" to 3" then add ±003"/inch RMS None 060" Under 1000 $4000 to $ Samples 6 to 10 weeks. The process of Aluminium Sand Casting is used for initial prototyping, smaller quantity production castings and larger Aluminium Castings too big to produce by other processes Alpac Alloys sand casting process equipment is capable of making complex castings from a few grams to 250 kg in weight. 4421 Ingot casting It is assumed that the casthouse of a smelter only transforms liquid metal from the electrolytic process and runaround scrapfrom the sawing of ingots into different forms of primary aluminium cast products All casthouses are requested to report additional solid metal inputs, ie remelt ngots, scrap i • •.

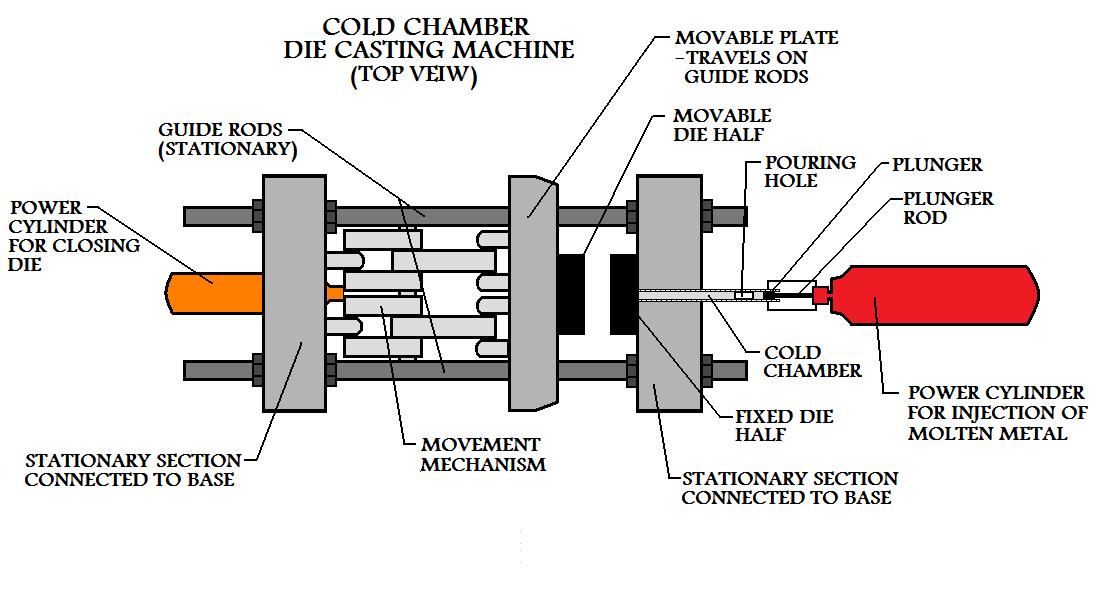

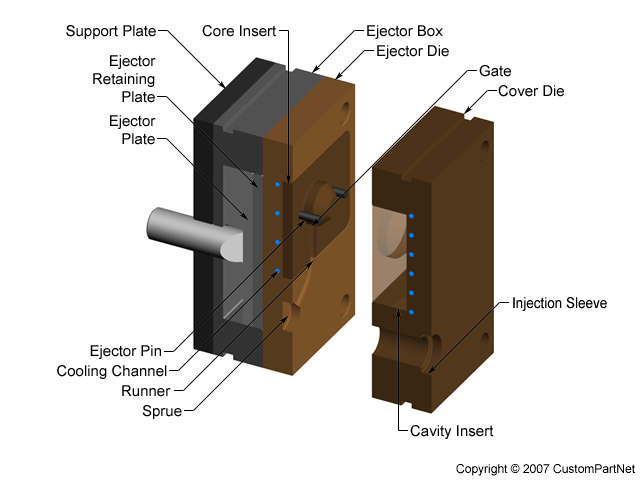

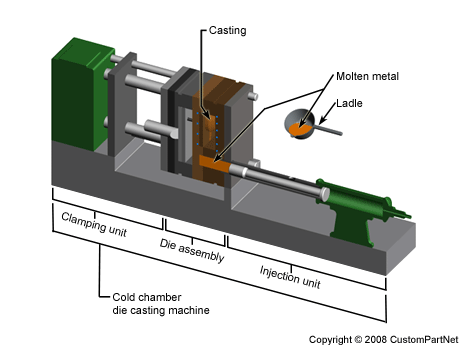

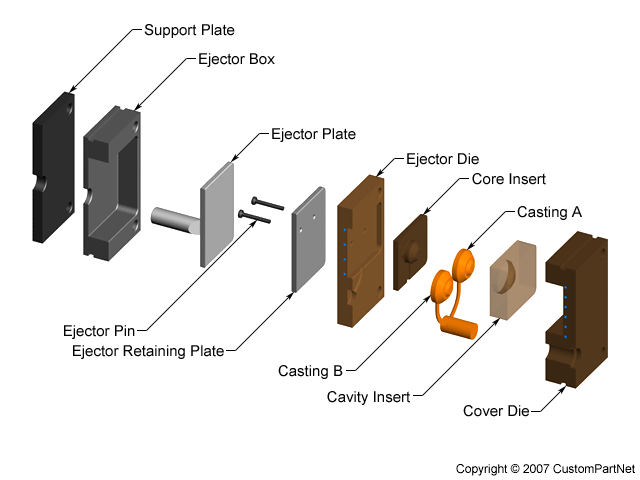

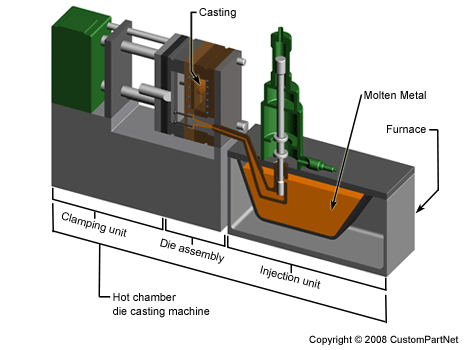

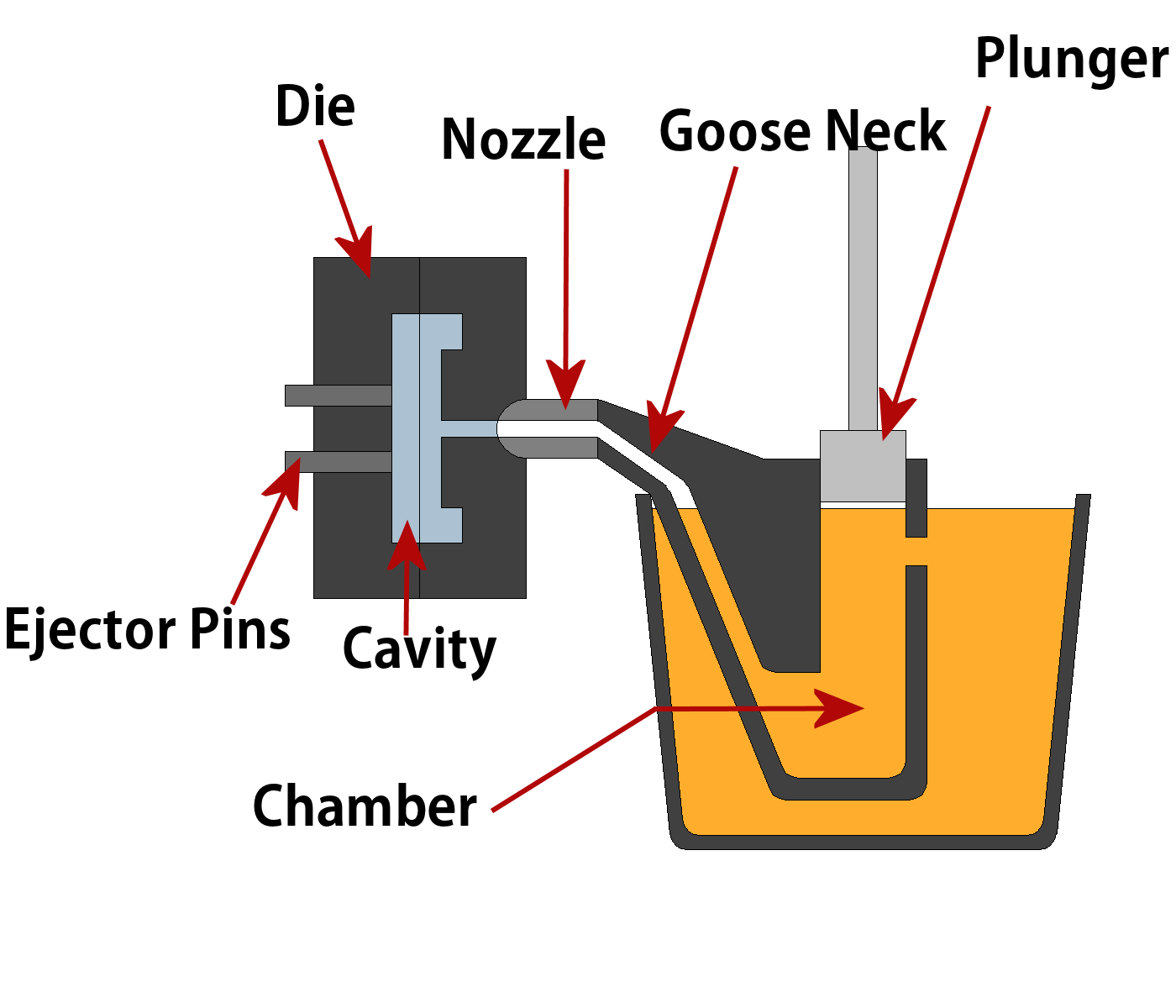

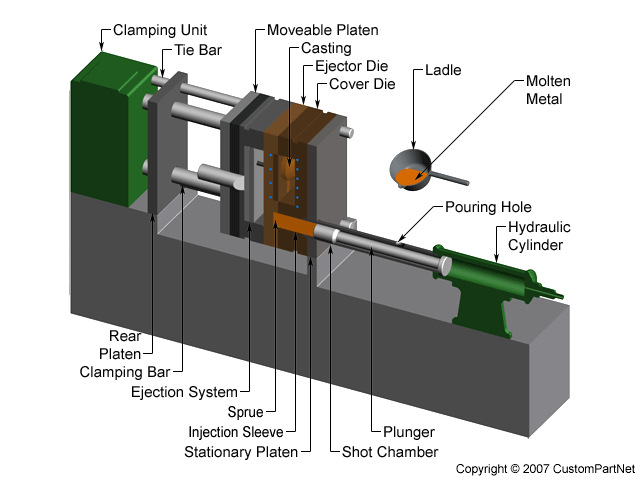

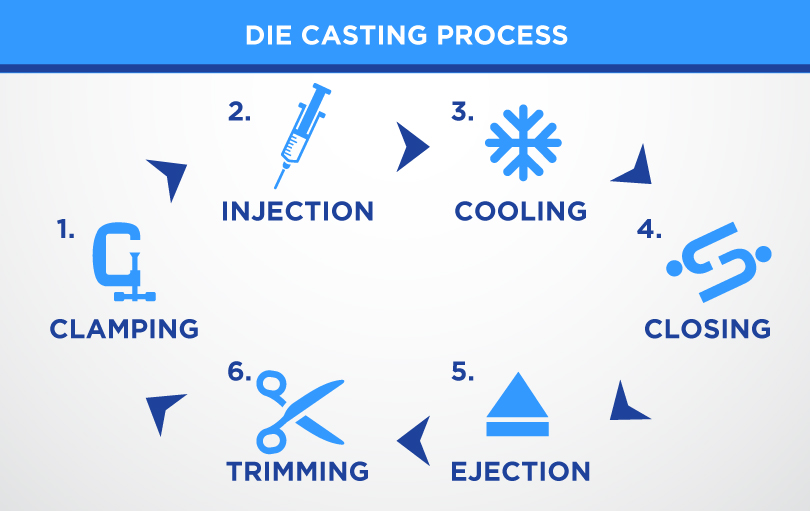

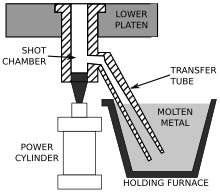

The die casting process involves the use of a furnace, metal, die casting machine, and die The metal, typically a nonferrous alloy such as aluminum or zinc, is melted in the furnace and then injected into the dies in the die casting machine. The traditional green sand casting process, combined with highspeed moulding lines, is a very flexible process with high productivity for the manufacture of aluminium castings Automatic patternchange stations enable complete sets to be changed within the cycle time. Casting This process uses molten aluminum and mold One from relies on gravity for the molten metal to fill the mold Another form uses suction to force the melted to fill the mold The metal cools and is removed from the mold The desired shape is made from the one piece of metal Computers monitor the process to check for pockets during the.

The aluminum die casting process is based on rapid production that allows a high volume of die casting parts to be produced very quickly and more costeffectively than alternative casting processes Aluminum die casting has become the favored option for buyers worldwide Characteristics and Advantages of Aluminum Die Castings include. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold Metal casting is arguably the earliest and most influential industrial process in history It’s used to make many of the metal objects used in our daily lives automotive parts, train wheels. Aluminum Casting 101 The process of casting aluminum Casting is the original and most widely used method of forming aluminum into products Technical advances have been made, but the principle remains the same Molten aluminum is poured into a mold to duplicate a desired pattern The three most important methods are die casting, permanent mold.

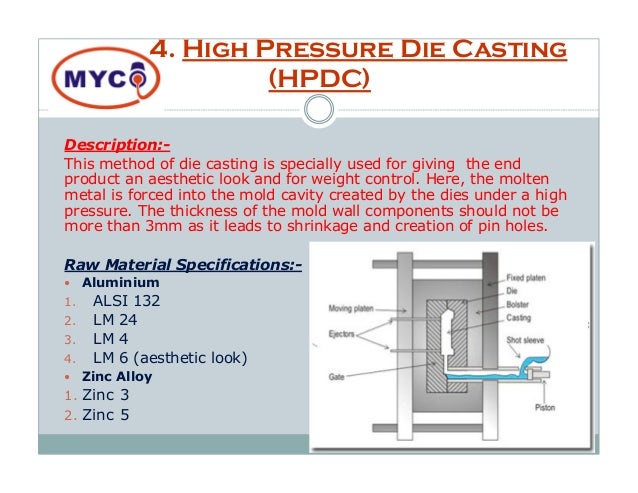

Pressure Die Casting • Pressure die casting is a quick, reliable and costeffective manufacturing process for production of high volume, metal components that are netshaped have tight tolerances • The pressure die casting process consists of injecting under high pressure a molten metal alloy into a steel mold (or tool). • Many new casting processes have been developed which can take into consideration the aspects of dimensional accuracy and surface finish Some of these processes are die casting process, investment casting process, vacuumsealed moulding process, and shell moulding process • Metal casting is a labour intensive process. Flowchart of Aluminum Casting Process By Vietnam Cast Iron CoLtd By Dinh Tien Vu / Metal Casting 1 Control the raw material The material used for the aluminum casting is from 40% Aluminum Ingot 50% Aluminum scrap 10% others 2 Manufacturing process Step 1 Make the pattern.

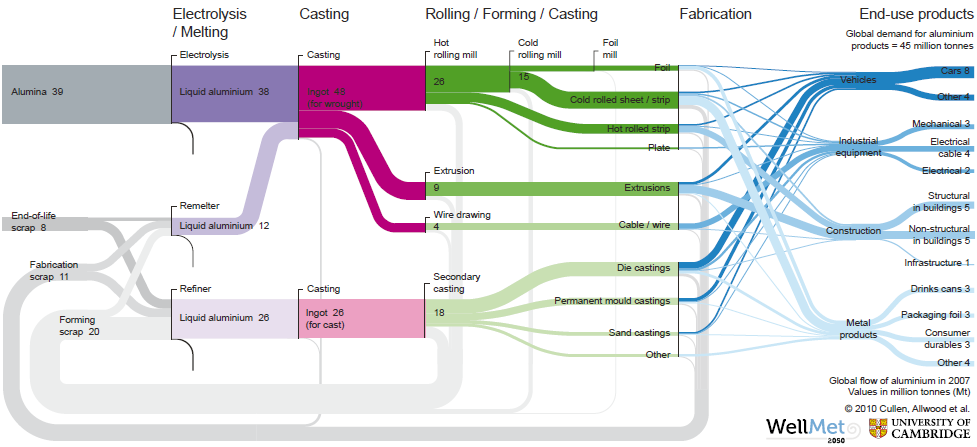

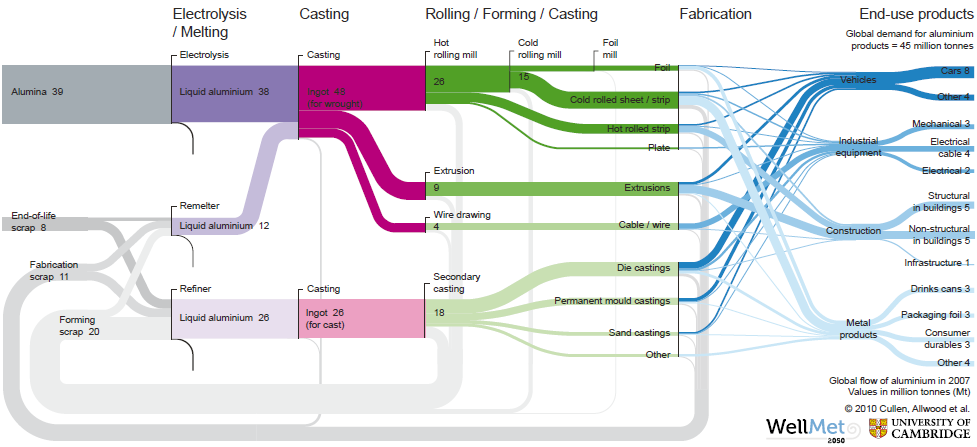

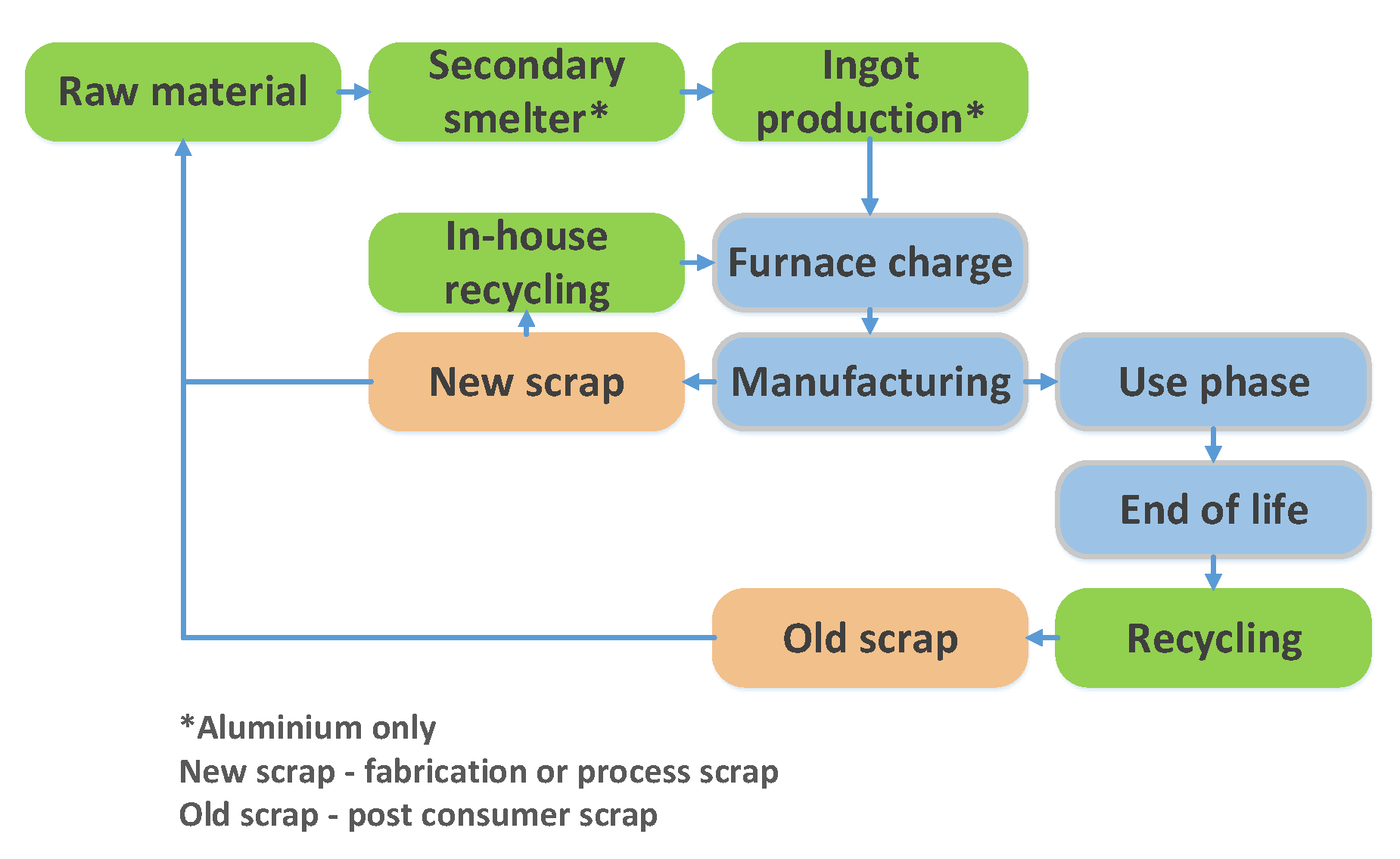

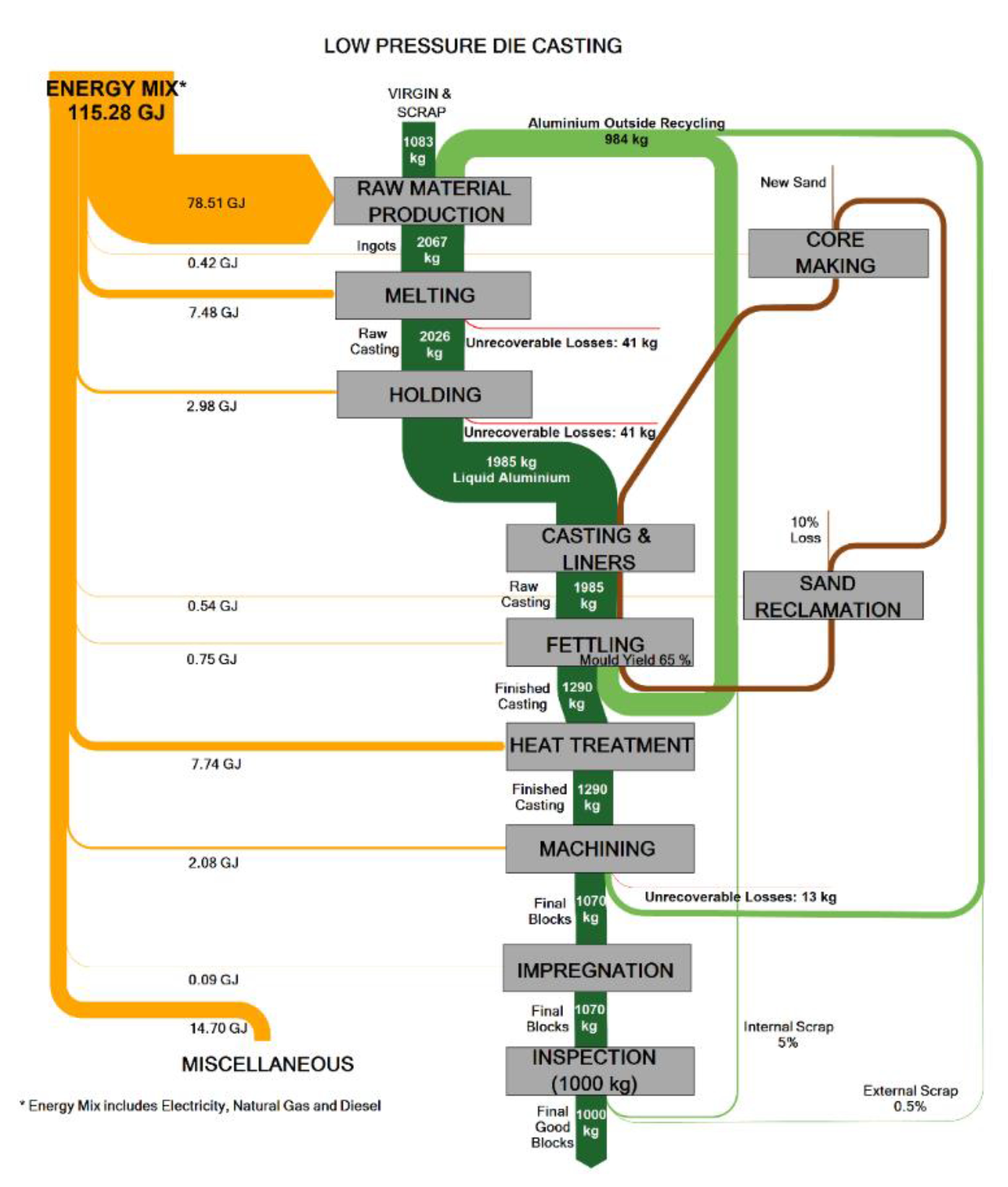

ALUMINIUM ALLOYS The process where the aluminium is shaped to its required form This process is used for making the vast majority of aluminium products from spectacle frames, telephone bodies, aeroplane fuselages or spaceship bodies The malleability of aluminium means it can be easily rolled into thin sheets. • Many new casting processes have been developed which can take into consideration the aspects of dimensional accuracy and surface finish Some of these processes are die casting process, investment casting process, vacuumsealed moulding process, and shell moulding process • Metal casting is a labour intensive process. Typical life cycle of an aluminium product A “cradle to grave” cycle of an aluminium product system can be modelled using different process steps as outlined in the flowchart below It should be noted that “grave” relates here to the end of life of the product, not of the material aluminium since it is being recycled.

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidifyThe solidified part is also known as a casting, which is ejected or broken out of the mold to complete the processCasting materials are usually metals or various time setting materials that cure after mixing two or more. Okordercom is a professional aluminum extrusion process flow chart supplier & manufacturer, offers integrated onestop services including realtime quoting and online cargo tracking We are funded by CNBM Group, a Fortune 500 enterprise and the largest aluminum extrusion process flow chart firm in China. A mold is formed into the geometric shape of a desired part Molten metal is then poured into the mold, the mold holds this material in shape as it solidifies A metal casting is created Although this seems rather simple, the manufacturing process of metal casting is both a science and an art Let's begin our study of metal casting with the mold.

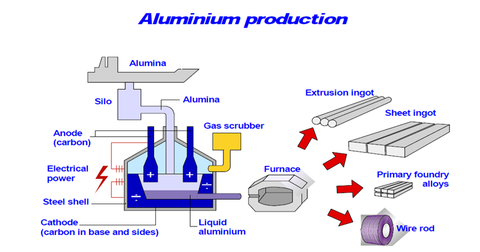

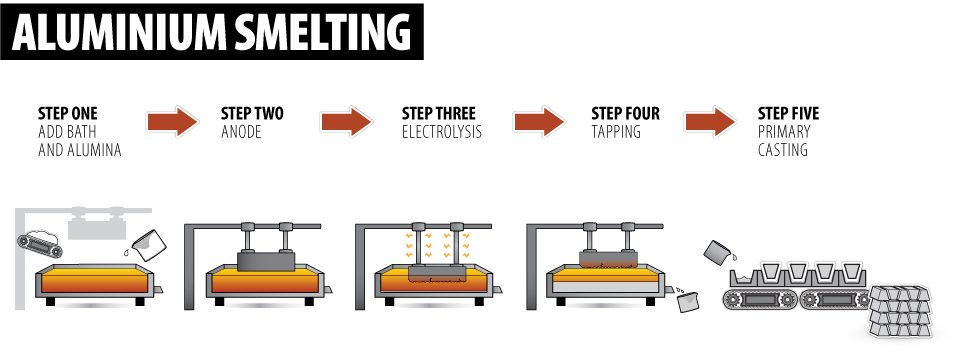

Die casting is a method of metal casting where molten metal is forced into a mold cavity by the use of very high pressure There are many different types of die casting, characterized by which nonferrous metals that are used in the process Among the most common are zinc, aluminum, copper, magnesium, lead, or tinbased alloys. Aluminium smelters use an electrolytic process to extract aluminium metal from alumina Aluminium can be formed into a variety of products by extruding, rolling or casting Australian operators provide products to key sectors of the market, including the construction, automotive and packaging sectors. Aluminium castings The Process One of the oldest methods of producing a shape in metal is that of casting Casting involves the melting of the metal in a furnace or ladle and pouring this molten metal into a hollow mould, usually made in sand, or in another suitable material A sand mould is used once and a metal.

Pressure Die Casting • Pressure die casting is a quick, reliable and costeffective manufacturing process for production of high volume, metal components that are netshaped have tight tolerances • The pressure die casting process consists of injecting under high pressure a molten metal alloy into a steel mold (or tool). AbouttheAuthors JG (Gil) Kaufman has a background of almost fifty years in the aluminum and materials information industries and remains an active consultant in both areas In 1997, he retired as vice president, technology, for the Aluminum Association, Inc, headquartered in Washington, DC, and. Aluminum Alloy Wheel 21 Flow Chart 22 Process 25 days per month, should be able to produce 10,000pcs of aluminum alloy wheels per Aluminum Alloy Ingot A3562 AlSr »More detailed.

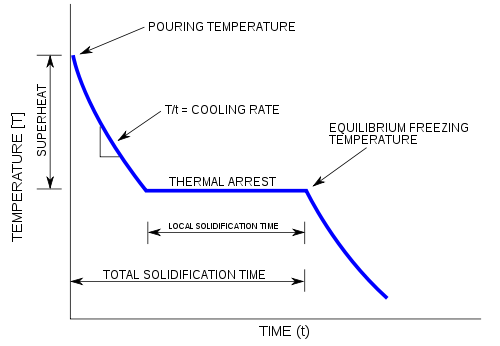

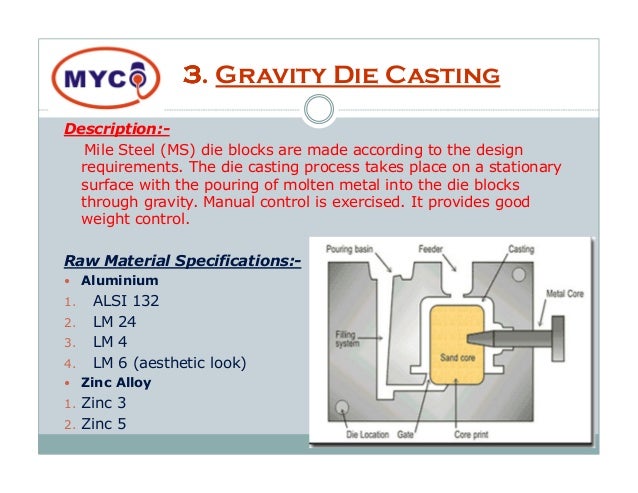

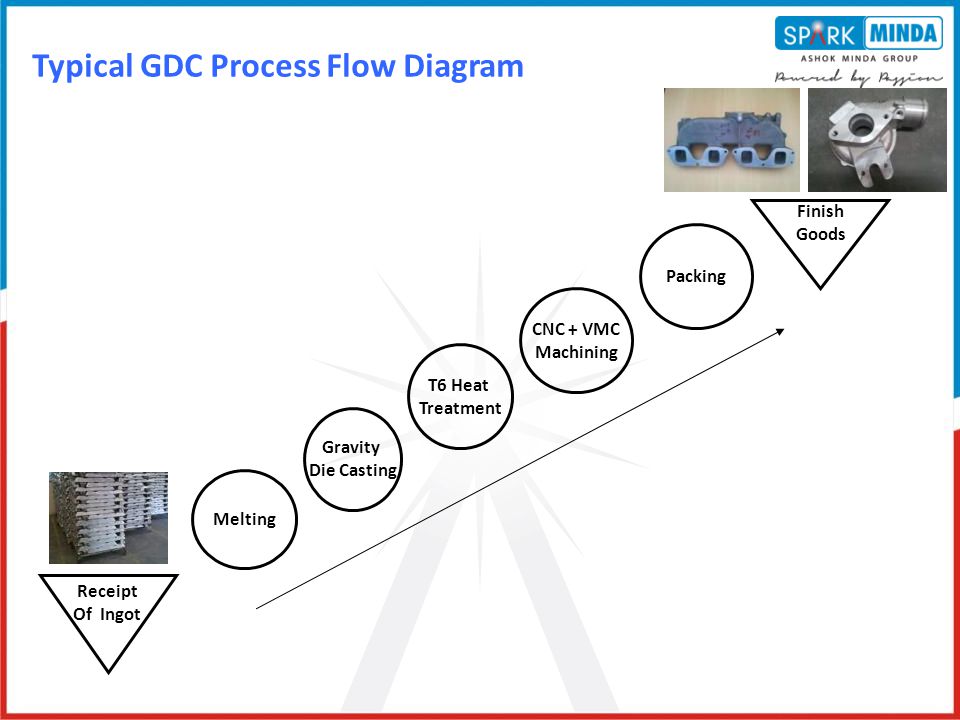

Casting Process • Pattern • Mold • Molten Metal / Pouring • Cooling / Shakeout • Cleaning / HT • QC • Machining – Added value Pattern Making 1 Casting Design –PL, draft, shrink, mach stock, tolerances, machine locators 2 Rigging risers, gating system, chills, vents 3 Solidification / Mold Filling Analysis. Wwwpyrotekcom © 16 Pyrotek, all rights reserved This video explores primary aluminium, smelting and casting processes. Casting process contains complex interactions with various parameters and operations related to molding, melting, degassing, metal composition, hardening, cooling and machining In Gravity die casting process the metals enters the mold under gravity Gravity die casting method is used for manufacturing of aluminium alloy oil tank.

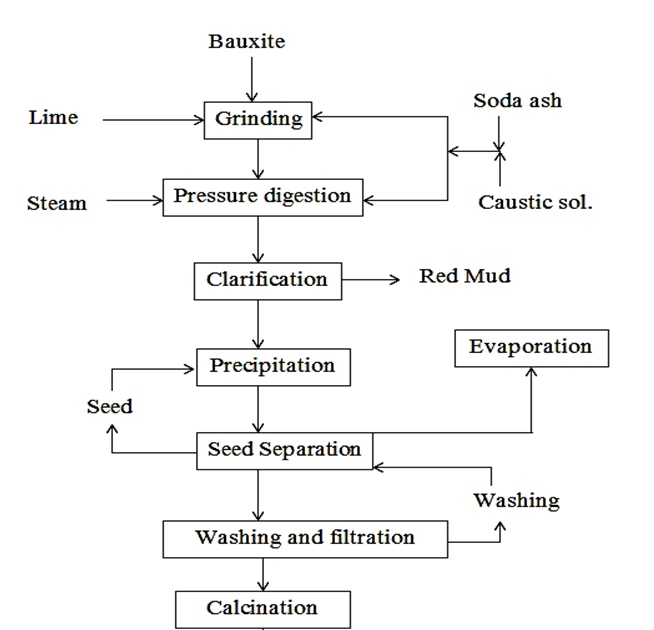

Wwwpyrotekcom © 16 Pyrotek, all rights reserved This video explores primary aluminium, smelting and casting processes. Aluminium production process ore and recycling aluminium from process scrap and used aluminium products Primary powder The second stage is the smelting process where aluminium oxide is dissolved in a Schema Schematic Flowchart tic Flowchart Melting »More detailed. Aluminium alloy sic powder aluminum alloy Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Expired Fee Related Application number EP Other languages German (de.

AbouttheAuthors JG (Gil) Kaufman has a background of almost fifty years in the aluminum and materials information industries and remains an active consultant in both areas In 1997, he retired as vice president, technology, for the Aluminum Association, Inc, headquartered in Washington, DC, and. What is Metal Casting?. Process Flow chart 5 Aluminium sand casting Process A mold is created by placing the mixture of sand, clay and water on a pattern The sand mold has two or more parts, the upper part is known as the cope while the bottom one is called the drag Additional parts known as cheeks can also be used.

Aluminum Alloy Wheel 21 Flow Chart 22 Process 25 days per month, should be able to produce 10,000pcs of aluminum alloy wheels per Aluminum Alloy Ingot A3562 AlSr »More detailed. The traditional green sand casting process, combined with highspeed moulding lines, is a very flexible process with high productivity for the manufacture of aluminium castings Automatic patternchange stations enable complete sets to be changed within the cycle time. The beneficial characteristics of a cast component are directly attributable to the inherent versatility of the casting process 21 SAND CASTING Sand casting is also known as sand molded casting, is a metal casting process characterized by using sand as a mold material It is relatively cheap and sufficiently refractory even for steel foundry use.

ALUMINIUM ALLOYS The process where the aluminium is shaped to its required form This process is used for making the vast majority of aluminium products from spectacle frames, telephone bodies, aeroplane fuselages or spaceship bodies The malleability of aluminium means it can be easily rolled into thin sheets. Aluminum, or aluminium (Al), is a silvery white metal with a melting point of 660 °C (1,2 °F) and a density of 27 grams per cubic cm The most abundant metallic element, it constitutes 81 percent of Earth’s crust In nature it occurs chemically combined with oxygen and other elements In the pure state it is soft and ductile, but it can be alloyed with many other elements to increase. Gravity Die Casting Gravity die casting is a process where the liquid metal is poured into metallic moulds without application of any external pressure, Figure 1 (a) and (b) Figure 1 (a) illustrative case, (b) industrial case "cylinder head" Figures 2 (a) and (b) shows the results of the flow front during filling, and Figure 3 shows the.

The process of Aluminium Sand Casting is used for initial prototyping, smaller quantity production castings and larger Aluminium Castings too big to produce by other processes Alpac Alloys sand casting process equipment is capable of making complex castings from a few grams to 250 kg in weight. MANUFACTURING PROCESS OF ENGINE BLOCK THE END INTRODUCTION We need to discuss CONCLUSION Manufacturing is the process of converting raw materials into products that is useful and ease our life Type of materials play an important role for the product in the end of the process. A metal mold is used to produce wax replicas Wax replicas are placed in an investment material Wax is melted out and molten metal i poured into cavity The mold is broken and the casting is removed Ounces up to lbs ± 004" to ½" ±005" to 3" then add ±003"/inch RMS None 060" Under 1000 $4000 to $ Samples 6 to 10 weeks.

Learn about the various steps in investment casting process through flow chart and other. Aluminium Gravity Die casting is a gravity permanent mold casting process, which means gravity Die Casting, commonly known as die casting, which is made of metal materials and is made of gravity A process for casting a molten metal into a mold to obtain a casting products Since a metal type mold can be poured hundreds to thousands of times,Therefore, metal casting is also called permanent. Download this Free Vector about Metalworking process isometric flowchart poster, and discover more than 11 Million Professional Graphic Resources on Freepik.

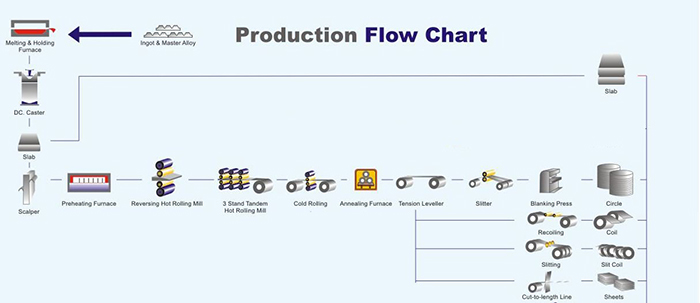

Metal casting is a modern process with ancient roots In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold Metal casting is arguably the earliest and most influential industrial process in history. Aluminium casting processes are classified as Ingot casting or Mould casting During the first process, primary or secondary aluminium is cast into rolling ingot (slab), extrusion ingot (billet) and wire bar ingot which are subsequently transformed in semi and finished products The second process is used in the foundries for producing cast. Aluminum cans provide longterm food quality preservation benefits Aluminum cans deliver 100 percent protection against oxygen, light, moisture and other contaminants The first generation of aluminum cans weighed approximately 3 ounces per unit Today’scans weigh less than half an ounce Aluminum cans bring packaging benefits as well.

To porous aluminum oxide The process derives its name from the fact that the aluminum part to be coated becomes the anode in an electrolytic cell This differentiates it from electroplating, in which the part is made the cathode Whereas anodizing is typically associated with aluminum, similar processes are used for other base metals,. The investmentcasting process, also called the lostwaxprocess, was first used during the period BC The pattern is made of wax or a plastic such as polystyrene The sequences involved in investment casting are shown in Figure 1118 The pattern is made by injecting molten wax or plastic into a metal die in the shape of the object. The Virtual Aluminum Castings methodology flowchart FIGURE 2 The key processingstructureproperty linkages and knowledge domains for cast aluminum alloys This could require a change in the geometry or the casting process resulting in costly and timeconsuming iterative rework of the casting tooling In contrast, use of a nominal fatigue.

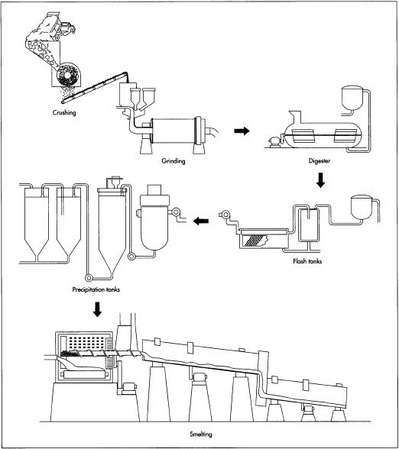

Aluminium manufacturing process flow chart How aluminium is produced The Manufacturing Process Aluminum manufacture is accomplished in two phases the Bayer process of refining the bauxite ore to obtain aluminum oxide, and the HallHeroult process of smelting the aluminum oxide to release pure aluminum. The process of Aluminium Sand Casting is used for initial prototyping, smaller quantity production castings and larger Aluminium Castings too big to produce by other processes Alpac Alloys sand casting process equipment is capable of making complex castings from a few grams to 250 kg in weight. The die casting manufacturing process is complex, so it’s imperative your reporting system be continuous and provide realtime feedback to help you control defects The way the metal flows inside the casting, which may be influenced by the casting’s geometry, may cause this layering effect If geometry were the problem, changing the.

Aluminum Alloy Wheel 21 Flow Chart 22 Process 25 days per month, should be able to produce 10,000pcs of aluminum alloy wheels per Aluminum Alloy Ingot A3562 AlSr »More detailed. Learn about the various steps in investment casting process through flow chart and other casting process comparison chart with investment castings Mold life of 15,000 cycles or more depending upon pouring temperature of metal and upon casting specs Both metal and sand cores are used. There are a number of stages in the manufacture of aluminium wheel rims metal the metal, lowpressure casting, quality control, topping, heat treatment, machining and painting The latest trend in this sector is selfpreparing alloy The process begins by smelting primary aluminium ingots with a low iron content in smelting towers.

Aluminum Casting 101 The process of casting aluminum Casting is the original and most widely used method of forming aluminum into products Technical advances have been made, but the principle remains the same Molten aluminum is poured into a mold to duplicate a desired pattern The three most important methods are die casting, permanent mold. Casting process contains complex interactions with various parameters and operations related to molding, melting, degassing, metal composition, hardening, cooling and machining In Gravity die casting process the metals enters the mold under gravity Gravity die casting method is used for manufacturing of aluminium alloy oil tank. Basically, die casting, is often the first process for shaping a piece of metal Some further processing is often required (eg drilling holes with CNC machining, surface treatment with electroplating) It is extremely common, and you will see if often if you purchase metal products from China or elsewhere Die Casting Videos.

Global Steel And Aluminium Flows Sankey Diagrams

Improvements In Energy Consumption And Environmental Impact By Novel Single Shot Melting Process For Casting Sciencedirect

Aluminum Production Mcr Safety

Aluminium Casting Process Flow Chart のギャラリー

Gravity Die Casting Openlearn Open University

Flow Chart Of Conventional Sand Casting Process Download Scientific Diagram

Injection Moulding Wikipedia

The High Pressure Die Casting Process Total Materia Article

Cold Chamber Die Casting

Aluminum Die Casting Impeller Used For Boeing Aircraft Parts Buy Boeing Aircraft Parts Impeller Aircraft Part Product On Alibaba Com

Global Steel And Aluminium Flows Sankey Diagrams

Process Comparisons Hazelett Corporation

Improvements In Energy Consumption And Environmental Impact By Novel Single Shot Melting Process For Casting Sciencedirect

Fracture Toughness Of Metal Castings Intechopen

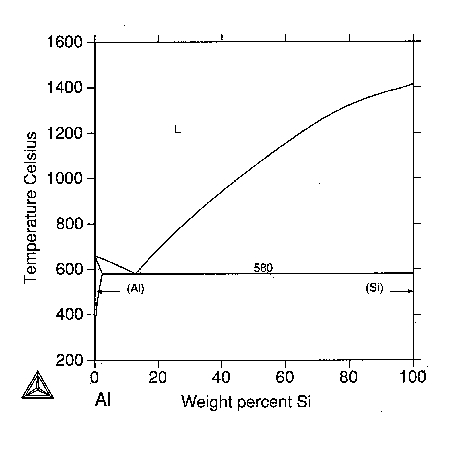

Aluminium Silicon Casting Alloys

Organizational Operation Flowchart Sheng Chang Metal Industry Co Ltd Die Casting Zinc Alloy Die Casting Aluminum Alloy Die Casting Computer Products Electronic Products Monitors Sheng Chang Metal Industry Co Ltd

Mapl

Material And Energy Flow Chart Of A Crimson Sand Casting Process Download Scientific Diagram

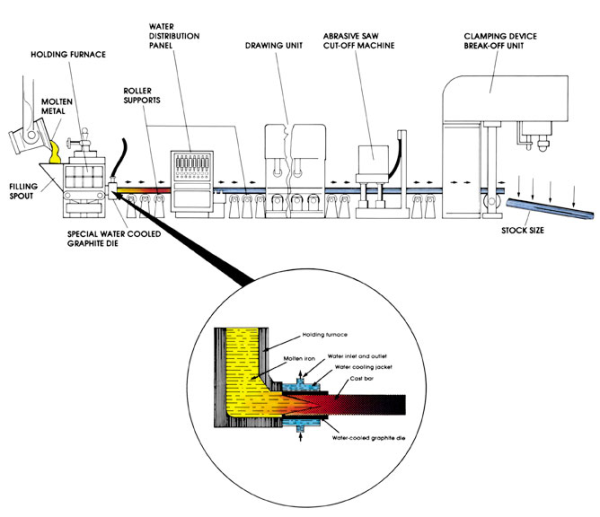

Advantages Of The Continuous Casting Process Benefits Of Cast Iron Production Description Of Continuous Casting Versa Bar

Metal Shrinkage An Overview Sciencedirect Topics

Squeeze Casting Process Part One Total Materia Article

Q Tbn And9gcrf Wenbvhvsv6dwjlln A3ypw5gxdcaero7zb5bymhcu3x2el8 Usqp Cau

Lecture Series On Die Casting Process

1

Casting Metalworking Wikipedia

Www European Aluminium Eu Media 1526 m Manufacturing 1 Casting Methods Pdf

Must Know Understanding Aluminum S Value Chain

Squeeze Casting And Squeeze Forming Openlearn Open University

Anodising Openlearn Open University

China Aluminium Die Casting Wiper Motor Housing Factory And Manufacturers Junhua

China Die Cast Aluminium Bollard Lights Archiproducts China Led Lamp Light Frame

Die Casting Process Defects Design

Recycling Aluminium The Australian Aluminium Council

Generic Pq2 Diagram Cylinder Engine Volume

Http Www Foundryinfo India Org Images Pdf 2a2 Pdf

Die Casting Design Guide Materials Advantages And Disadvantages Engineeringclicks

Casting Process Advantages And Limitations Sand Casting It Cast Aluminum Molding

Manufacturing Process

Core Ac Uk Download Pdf Pdf

Die Casting Process Defects Design

Hot Chamber Die Casting Process Hot Chamber Casting Dynacast

Manufacturing Process

Manufacturing Process

Cold Chamber Die Casting Process Machines

Lejpt Template

Www European Aluminium Eu Media 1526 m Manufacturing 1 Casting Methods Pdf

Aluminium Casting Techniques Sand Casting And Die Casting Processes

Aluminium Casting Techniques Sand Casting And Die Casting Processes

Aluminum Die Casting An Overview Sciencedirect Topics

Minimum Porosity Formation In Pressure Die Casting By uchi Method

Aluminum Casting Process And Casting Terminology

Die Casting Process Defects Design

Production Process Flow Chart Of Aluminum Profile

Dfm Improvements Commonly Made To Die Cast Parts Sofeast

Aluminium Sand Casting Process

Die Casting Process Defects Design

Production Process

Flow Chart For Die Casting Machine Selection Download Scientific Diagram

Www Researchgate Net File Postfileloader Html Id 56adbbbd509c8b458f Assetkey As 3a

Figure 2 A Review On Direct Hot Extrusion Technique In Recycling Of Aluminium Chips Springerlink

Investment Casting Process Steps And Flow Chart American Casting Company

Gravity Die Casting Openlearn Open University

Gravity Die Casting Openlearn Open University

Zenith Aluminum Company Profile Production Process Guangdong Zenith Aluminium Co Ltd

Die Casting Units Pune Chakan Greater Noida Product Range Ppt Video Online Download

Die Casting Process Hot And Cold Chamber

Aluminium Casting Techniques Sand Casting And Die Casting Processes

How To Aluminum Sand Casting Process Manufacturing

Custom Investment Aluminum Bronze Carbon Steel Casting For Mature Casting Tube Buy Stainless Steel Investment Casting Steel Lost Wax Casting Water Glass Castings Product On Alibaba Com

Http Www Ijaiem Org Volume7issue5 Ijaiem 18 05 22 13 Pdf

The Technical Process Of Cold Chamber Die Casting Machines Download Scientific Diagram

Permanent Mold Casting An Overview Sciencedirect Topics

China Aluminum Sand Casting Manufacturers Oeform

Flow Chart Of Conventional Sand Casting Process Download Scientific Diagram

Energies Free Full Text Life Cycle And Energy Assessment Of Automotive Component Manufacturing The Dilemma Between Aluminum And Cast Iron Html

How Aluminum Is Made Material Manufacture Making Used Processing Aluminium Composition Product

Die Casting Process Defects Design

Www Osti Gov Servlets Purl 2409

Casting Metalworking Wikipedia

Www European Aluminium Eu Media 1526 m Manufacturing 1 Casting Methods Pdf

Tooling And Samples Manufacturing Flow Ningbo Eastcasting Co Ltd

Http Www Eumerci Eu Wp Content Uploads 18 01 Other Metals Pdf

Flow Chart Of The Main Steps In Modeling Foundry Processes 1 Download Scientific Diagram

European Aluminium Eu Media 1329 Environmental Profile Report For The European Aluminium Industry Pdf

Die Casting Services Guide Die Casting Sourcing

Aluminium Casting Techniques Sand Casting And Die Casting Processes

How An Aluminum Smelter Is Made The Aluminum Smelting Process

Aluminium Smelting The Australian Aluminium Council

Depicting Aluminium Dc Casting By Means Of Dimensionless Numbers Intechopen

Q Tbn And9gcshmsmoarlcw3vq5xnlohrvb2ss8qtms L Nvakyjydarhdpw5y Usqp Cau

Aluminium Casting Techniques Sand Casting And Die Casting Processes

10 Different Types Of Casting Process Machinemfg

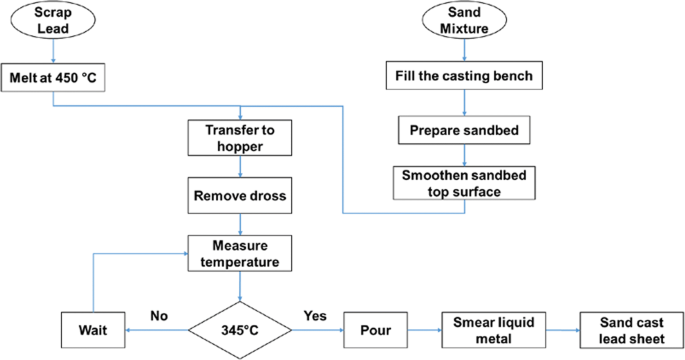

Sand Casting Of Sheet Lead Numerical Simulation Of Metal Flow And Solidification Springerlink

Die Casting Metal Die Casting Process

The Effect Of Casting Speed And The Fraction Of Al5 Ti1 B Inoculant On The Microstructure And Mechanical Properties Of The 5052 Aluminum Alloy Produced By The Direct Chill Process

Die Casting Wikipedia

Figure 1 From Optimization Of Molding Sand Composition For Casting Al Alloy Semantic Scholar

Energies Free Full Text Life Cycle And Energy Assessment Of Automotive Component Manufacturing The Dilemma Between Aluminum And Cast Iron Html

Vedanta Vedanta Limited Orissa India Smelter Captive Power Plant Cpp Mining Corporate Social Responsibility Csr Kalahandi Niyamgiri Jharsuguda Aluminium Company

Flow Chart Of Secondary Al Refining Operations For The Production Of Download Scientific Diagram

Process Flow Sheets Aluminum Production Process Bayer Hall Heroult

Die Casting Wikipedia

2 Flow Diagram Of Aluminium Production Download Scientific Diagram

Die Casting Metal Die Casting Process